Samson 5825 Mounting And Operating Instructions - Attachment to Valve

2

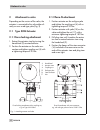

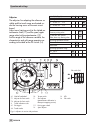

Attachment to valve

Depending on the version of the valve, the

actuator is connected to the valve either di-

rectly or over a rod-type yoke (Fig. 3).

2.1 Type 5824 Actuator

2.1.1 Force-locking attachment

1. Retract the actuator stem by turning the

handwheel (2) counterclockwise.

2. Position the actuator on the valve con-

nection and tighten coupling nut (4) with

a tightening torque of 20 Nm.

2.1.2 Form-fit attachment

1. Position actuator on the rod-type yoke

and tighten the coupling nut (4) with a

tightening torque of 20 Nm.

2. Position actuator with yoke (15) on the

valve and tighten the nut (17) with a

minimum tightening torque of 150 Nm.

3. Pull plug stem until it reaches the actua-

tor stem or extend actuator stem using

the handwheel (2).

4. Position the clamps of the stem connector

(16) included in the accessories on the

ends of the actuator stem and plug stem

and screw tight.

8

EB 5824 EN

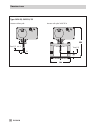

Attachment to valve

Force-locking attachment with a coupling nut,

e.g. on Type 3222 Valve

Form-fit attachment with stem connector,

e.g. with rod-type yoke on Series V2001 Valve

Fig. 3 · Attaching actuator and valve

2

Handwheel

3

Actuator stem

4

Coupling nut

15

Rod-type yoke

16

Stem connector

17

Nut