Sussman ES Installation, Operation And Maintenance Manual

Sussman Boilers

:

ES, SSB & HU

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Dimensional Information and

Component Identification

. . . . . . . . . . . . . . . . . 2

Dimensional & Clearing Specifications

. . . . . . . . . 3

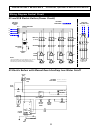

Wiring Diagrams

. . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Installation

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Operation Check

. . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Controls, Operation & Testing

. . . . . . . 10

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Blowdown

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Timing Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Optional Equipment

. . . . . . . . . . . . . . . . . . . . . . . 14

Auxiliary Low Water Cut Off

. . . . . . . . . . . . . . . . 14

Line Pressure Water Feed System

. . . . . . . . . . . . . 14

High Pressure Water Feed System

. . . . . . . . . . . . . 14

Condensate Return System

. . . . . . . . . . . . . . . . . . 14

Vacuum Breaker Systems

. . . . . . . . . . . . . . . . . . . 15

Automatic Blowdown System

. . . . . . . . . . . . . . . . 15

Blowdown Separators

. . . . . . . . . . . . . . . . . . . . . 15

Control Voltage Stepdown Transformer

. . . . . . . . 15

Multistage Load Progressive Sequencers

. . . . . . . . 15

Condensate Return Systems

. . . . . . . . . . . . . . . . 16

Blowdown Separator Tanks

. . . . . . . . . . . . . . . . . 17

Specification Charts

. . . . . . . . . . . . . . . . . . . . . . . 18

Sizing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gauge Glass Installation

. . . . . . . . . . . . . . . . . 20-21

Element Replacement

. . . . . . . . . . . . . . . . . . . . . . 22

Water Quality Information

for Carbon Steel Boilers

. . . . . . . . . . . . . . . . . . 23

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Products covered by this manual:

Max

Series

KW Range

Steam Rate*

BHP

Design Pres.

Work Pres.

______________________________________________________________________

ES, HU

12-180

36-542 lbs/hr 1.2-18.4

0-100 psig

85 psig

SSB

12-180

36-542 lbs/hr 1.2-18.4

0-100 psig

85 psig

*Steam Rate- Steam @ 212 F with 50 F feed water

SSB Boilers have Stainless Steel all wetted metal parts. SSB

boilers shall be operated using only deionized water, having

a maximum conductance of 1 microSiemen per cm

(1

µ

S/cm) [minimum specific resistivity of 1 megohm per cm

(1

ΜΩ

/cm)].

ES and HU boilers are of Carbon Steel construction.

See page 23 for Water Quality Information.

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101 • (718) 937-4500

1-800-238-3535 • Fax: (718) 937-4676 • email: seb@sussmancorp.com

www.sussmanboilers.com

Made in USA

PUR 101137

2

/07

states a hazard which may

cause serious injury or

death if precautions are not followed.

signals a situation where

minor injury or product dam-

age may occur if you do not follow instructions.

IMPORTANT NOTE:

This highlights information that is especial-

ly relevant to a problem-free installation.

IMPORTANT NOTE:

As you follow these instructions, you will notice warning and caution symbols. This blocked information is important for the safe and efficient

installation and operation of electric boilers. These are two types of potential hazards that may occur during this installation and operation:

!

CAUT

ION

!

WAR

NING

Model No. ______________________

Boiler Serial No. _________________

National Board No. ______________

Safety Valve Set Pressure________

PSIG

Power Circuit Voltage ____________

Control Circuit Voltage ___________

Amps _____ Phase _____ HZ ______

IMPORTANT:

This data file contains the National

Board Registration Certificate approving your boiler.

It must be kept near the boiler at all times.