- DL manuals

- Sveba Dahlen AB

- Oven

- Classic DC-1

- Operating Maintenance Installation

Sveba Dahlen AB Classic DC-1 Operating Maintenance Installation - Baking - Personal Settings

Summary of Classic DC-1

Page 1

Classic deck oven type: dc-1 dc-2 dc-2e dc-3 dc-4 operating maintenance installation rev.3 860004-02.

Page 2

2 operating maintenance installation classic 3:3500-2 --> 860004-02 data plate. Positioning of data plate. Data plate for classic deck oven model designation serial number connected voltage to obtain assistance with installation or service of the oven the oven serial number and model desig-nation mu...

Page 3: Table of Contents

3 operating maintenance installation classic 3:3500-2 --> 860004-02 table of contents table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 description ....

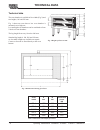

Page 4: Technical Data

4 operating maintenance installation classic 3:3500-2 --> 860004-02 the oven chamber is available in five widths (fig. 2) and two heights, 160 and 220 mm. Fig. 1 shows an oven where a low oven chamber is mounted over a high one. Low and high oven chambers can be combined to form 5 decks of oven cham...

Page 5: Description

5 operating maintenance installation classic 3:3500-2 --> 860004-02 description design principle the deckoven is ce-approved according to emc, lvd the deck oven is manufactured in detachable sections. The advantage of this is that the sections can be combined to suit special purposes or areas. This ...

Page 6: Instrument Panel

6 operating maintenance installation classic 3:3500-2 --> 860004-02 thermostat regulates the temperature in the oven to the temperature which is set on the thermostat. Steam indicator, red when the lamp goes off the steam gene- rator is ready for use. When the lamp lights the steam generator is heat...

Page 7: Instrument Panel

7 operating maintenance installation classic 3:3500-2 --> 860004-02 instrument panel functions of the buttons button function setting the time, reset to running time. Switching of daylight-saving time reset button programming button return to timer function / pulse programming setting the day settin...

Page 8: Baking

8 operating maintenance installation classic 3:3500-2 --> 860004-02 baking table 2 setting for common products. Where double temperatures are given (temp. 1/temp. 2) this refers to initial temperature and final baking temperature. Heat controls the classic deck oven is fitted with three groups of el...

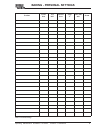

Page 9: Baking - Personal Settings

9 operating maintenance installation classic 3:3500-2 --> 860004-02 baking - personal settings table 3 personal settings product front heat top heat bottom heat temp. ºc bake time min. Steam.

Page 10: Care And Maintenance

10 operating maintenance installation classic 3:3500-2 --> 860004-02 care and maintenance brush out the oven chamber regularly from bread crumbs and soot. Wipe off the door glass inside and out with a moist cloth with a little detergent. You can do this when the door is warm, but not over 60°c. If t...

Page 11: Trouble Shooting

11 operating maintenance installation classic 3:3500-2 --> 860004-02 trouble shooting table 4 trouble shooting. Trouble shooting in the event of a problem you should first look through the trouble shooting list below to see if you can correct the fault yourself. If this does not help contact sveba-d...

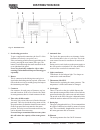

Page 12: Distribution Box

12 operating maintenance installation classic 3:3500-2 --> 860004-02 1 2 3 7 8 2 4 5 6 9 10 1 overheating protection to get a complete disconnection, the fuse f1 of the elements will also trip (see point 5 too). If the overheating protection has triggered this can be reset by pressing the reset butt...

Page 13: Unpacking

13 operating maintenance installation classic 3:3500-2 --> 860004-02 open the packing materials carefully so that the oven is not damaged. Inside the oven chamber there are several parts which must be used during assembly. Take these out and check with the enclosed packing list. They should include ...

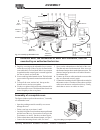

Page 14: Unpacking

14 operating maintenance installation classic 3:3500-2 --> 860004-02 fig. 14 lifting of the parts of the oven. Use the planks from the loading pallet when lifting off the oven section. Fig. 16 lifting of section in lifting hooks. Never lift or pull on the area of the oven which is marked! Fig. 15 li...

Page 15: Assembly

15 operating maintenance installation classic 3:3500-2 --> 860004-02 3 bss b10x32 bss b10x13 m6s 6x16 + m6m 6 3 bss b10x13 4 5 bss b10x13 2a 1a m6s 8x20 + m6m 8 7 6 6 bss b10x13 electrical work, the connection of water and ventilation, must be executed by an authorized technician. 1 begin by screwin...

Page 16: Assembly

16 operating maintenance installation classic 3:3500-2 --> 860004-02 fig. 21 hearth grid for more even bottom heat. Fig. 20 assembly of heat distribution plate. Assembly hearth grid. The hearth grid is another quality improving part which is enclosed with the oven. The grid equalizes the bottom heat...

Page 17: Installation

17 operating maintenance installation classic 3:3500-2 --> 860004-02 installation ventilation and suction ducts are fire classed, and must therefore be insulated and fire classed as per current regulations. The air which is led off via the ducts has a temperature of approx. 50-80°c if the installati...

Page 18: Installation

18 operating maintenance installation classic 3:3500-2 --> 860004-02 installation connection of water. If the oven is fitted with a built-in steam generator this must be connected to cold water. Connection is made to the solenoid valves (figs. 25, 26) on the rear of the oven. Water pressure should b...

Page 19: Installation

19 operating maintenance installation classic 3:3500-2 --> 860004-02 connection of external steam. Steam pipe union g 3/8 fig. 27 connection of external steam. Steam valve if there is a steam boiler in the bakery the oven can be connected to it. This connection is made to the steam valve on the back...

Page 20: Installation

20 operating maintenance installation classic 3:3500-2 --> 860004-02 installation first start of the oven. Before the oven is first used it must be burned out so that residual protective oil in the oven chamber disappears. During this procedure there will be a certain amount of smoke from the oven, ...

Page 21

Eu-declaration of conformity document sveba-dahlen ab company manufacturer address phone no. + 46 33-15 15 00 se-513 82 fristad place date fristad signature name title managing director bengt gabrielsson company sveba-dahlen ab +46 33-15 15 00 se-513 82 fristad (directive 98/37/ec, annex ii, a) addr...