- DL manuals

- Taylor

- Freezer

- 161

- Operating Instructions Manual

Taylor 161 Operating Instructions Manual

Summary of 161

Page 1

Model 161 soft serve freezer operating instructions 055155--m 10/02/01.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e october, ...

Page 3: Table Of Contents

Table of contents model 161 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air cooled units 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electric...

Page 4

Model 161 table of contents notes:.

Page 5: Section 1

1 model 161 to the installer 040211 section 1 to the installer this machine is designed for indoor use only. Do not install the machine in an area where a water jet could be used. Failure to follow this instruction may result in serious electrical shock. Air cooled units the model 161 requires 6” (1...

Page 6: Section 2

2 model 161 to the operator 050818 section 2 to the operator the model 161 soft serve freezer has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, it ...

Page 7: Section 3

3 model 161 safety 040211 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service tec...

Page 8: Section 4

4 model 161 operator parts identification section 4 operator parts identification model 161 item description part no. 1 panel-rear *161* 055129 2 panel-side-right *161* 055130 3 leg-4” 3/8-16 stud 036397 4 cap-rubber 037268 5 shield-splash 022765 6 tray-drip 16-7/8l x 5-1/8 020157 7 panel-lower fron...

Page 9

5 model 161 operator parts identification beater door assembly item description part no. 1 draw valve 024763 2 o--ring 7/8 od x .103 w 014402 3 seal--valve 030930 4 door a.--3 spout x30753--ser 5 pivot pin a.--short x38539 6 o--ring 5/16 od x .070 w 016272 7 draw valve handle 030564 8 hand screw (st...

Page 10

6 model 161 operator parts identification accessories item description part no. 1 pail-6·qt. 023348 2 brush-rear brg 1” d x 2” lg 013071 3 brush-double·ended 013072 4 brush-draw·valve·1” od x 2” x 17” 013073 item description part no. 5 brush-mix·pump·body-3”x7” white 023316 6 lubricant-taylor·4·oz. ...

Page 11: Section 5

7 model 161 important: to the operator section 5 important: to the operator item description 1 power switch 2 mix refrigeration key 3 standby key 4 wash key 5 auto key 6 indicator light “mix low” 7 reset button symbol definitions to better communicate in the international arena, the words on many of...

Page 12

8 model 161 important: to the operator softecht control machines note: if your machine is not equipped with softecht controls, please use the instructions on page 10. Power switch when placed in the on position, the power switch allows softecht control panel operation. Mix ref when the mix ref key i...

Page 13

9 model 161 important: to the operator if the beater motor is turning properly, press the wash key to cancel the cycle. Press the auto key on both sides of the unit to resume normal operation. If the freezer shuts down again, contact a service technician. Air tube the air tube serves two purposes. O...

Page 14

10 model 161 important: to the operator non--softecht control machines note: if your machine is equipped with the softecht controls, please use the instructions on page 7. Push-button switch if an overload condition occurs, the freezer will automatically stop operating. To properly reset the freezer...

Page 15: Section 6

11 model 161 operating procedures 040211 section 6 operating procedures the model 161 is a soft serve counter model with a three spout door. Two individual flavors are available from the end spouts, and an equal combination of both is dispensed through the center spout to create a twist effect. It h...

Page 16

12 model 161 operating procedures step 3 place the large o-rings into the grooves on the back of the machine door and lubricate. Figure 6 step 4 slide the front bearings over the baffle rods so the flanged edge is against the door. Place the white plastic guide bearings on the end of the baffle rods...

Page 17

13 model 161 operating procedures step 8 lubricate the inside of the freezer door spouts from the bottom. Insert the draw valves into the freezer door from the bottom until the slot in the draw valves comes into view. Figure 11 step 9 slide the o-ring onto each pivot pin and lubricate. Figure 12 ste...

Page 18

14 model 161 operating procedures sanitizing step 1 prepare one gallon (3.8 liters) of an approved 100 ppm sanitizing solution (example: kay-5r). Use warm water and follow the manufactur- er’s specifications. Step 2 pour the sanitizing solution into the hopper and allow it to flow into the freezing ...

Page 19

15 model 161 operating procedures step 5 press the wash key. This will cause the sanitizing solution in the freezing cylinder to be agitated. Allow it to agitate for five minutes. Figure 20 note: non--softecht machines: place the power switch in the wash position. This will cause the sanitizing solu...

Page 20

16 model 161 operating procedures step 3 press the auto key. When the unit cycles off, the product will be ready to serve. Figure 24 note: non--softecht machines: place the power switch in the auto position. When the unit cycles off, the product will be ready to serve. Figure 25 step 4 momentarily r...

Page 21

17 model 161 operating procedures draining product from the freezing cylinder step 1 press the auto key to cancel operation. Press the mix ref key to cancel hopper refrigeration. These operations should be cancelled as far ahead of cleaning time as possible. This will allow frozen product to soften ...

Page 22

18 model 161 operating procedures disassembly make sure the power switch is in the “off” position. Failure to follow this instruction may result in severe personal injury to fingers or hands from hazardous moving parts. Step 1 remove the handscrews and the freezer door. Remove the beater assemblies ...

Page 23: Section 7

19 model 161 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check points s...

Page 24

20 model 161 important: operator checklist j 6. If your machine is equipped with an auxiliary refrigeration system, check the auxiliary condenser for accumulation of dirt and lint. A dirty condenser will reduce the refrigeration capacity of the mix hopper. Condensers must be cleaned monthly with a s...

Page 25: Section 8

21 model 161 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. The power switch is in the off position. A. Place the power switch in the auto position. 14 b. The mix level is inadequate in the mix hopper. B. Fill the mix h...

Page 26

22 model 161 troubleshooting guide problem probable cause remedy page ref. 4. The product is too soft. A. The control is set too warm. A. Contact service technician. 10 b. The air tube is not installed. B. Install the air tube in the mix inlet hole at the bottom of the mix hopper. 15 c. Out-drawing ...

Page 27

23 model 161 troubleshooting guide problem probable cause remedy page ref. 9. The unit goes out on overload excessively. A. There are too many appliances plugged into the circuit. A. A separate 20a circuit is needed for the freezer to operate properly. - - - b. An extension cord has been placed betw...

Page 28: Section 9

24 model 161 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Beater drive shaft o-ring x 2 freezer door o-ring x 2 freezer door front bearing x 2 freezer door guide bearing x 2 draw valve o-ring x 4 center draw valve seal x...

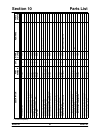

Page 29: Section 10

Section 10 parts list 25 + available separately model 161 parts list de s cri p t io n part num be r qty . W arr. Cl as s re m arks part s up da t e bear in g -fr o n t 023262 2 000 bear in g -g u id e 014496 2 000 bear in g -r ear sh el l *1 5 0 -5 2 -6 8 * 023648 2 000 + c o l l a r -r ear bear in...

Page 30

+ available separately 26 parts list model 161 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r + g asket -h o pper c o ver -8 q t 037042 1 000 kn o b -m ix c o ver 025429 1 103 c o r d -p o w e r -250v -15a -95” l -s o 042936 -2 7 1 103 de ca l -de c -t a y l or 1 6 1...

Page 31

27 + available separately model 161 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r to o l -o -r in g r em o val -f r eezer 048260 -w h t 1 000 l abel -c au tio n -g r d -per m -en g /sp 032164 1 000 l abel -d o o r -m o v e par t 032749 1 000 l abel -s w -...

Page 32

+ available separately 28 parts list model 161 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r r e s is t o r a .- *161* c o n t . B o x * x 55449 1 103 beater m o to r c o n tac t o r san itizer kay -5 1 2 5 pac kets 041082 1 000 s h e l l a .- in s u la t e d *161* ...

Page 33

29 + available separately model 161 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r 50hz bl o c k -ter m in al -7 po l e g r een 024156 1 103 220 -240v 50h z 1 p h d ia g r a m -w ir in g *161* 055376 -40s 1 000 ” c o m p r esso r r s8 0 c 1 e -c az -2 2 4 ...

Page 34

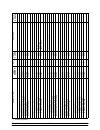

Model 161 055376--27s rev. 8/01.

Page 35

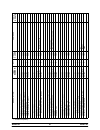

Model 161 055376--40s rev. 8/01.