- DL manuals

- Taylor

- Freezer

- 161

- Service Manual

Taylor 161 Service Manual

Summary of 161

Page 1

Model 161 soft serve freezer service manual 055155-s 10/18/07.

Page 3: Table Of Contents

Model 161 table of contents table of contents section 1: introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ref...

Page 4

Table of contents model 161 table of contents - page 2 x58494-27 control a.-161 gen ii 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X55480-27 control a.-channel 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X59447-27 box a.-cap & rel...

Page 5: Section 1: Introduction

1 model 161 introduction section 1: introduction s safety s refrigerant s specifications s installation instructions s running specifications.

Page 6: Safety

2 introduction model 161 safety ______________________________ we at taylor are committed to manufacturing safe operating and serviceable equipment. The many built-in safety features that are part of all taylor equipment are aimed at protecting operators and trained service technicians alike. This m...

Page 7: Model 161 Specifications

3 model 161 introduction 071018 model 161 specifications freezing cylinder two, 1.5 quart (1.4 liter) volume. Mix hopper two, 8 quart (7.6 liter) capacity. Beater motor two, 0.5 hp. Refrigeration unit one, 8,000 btu/hr compressor. R404a. Separate hopper refrigeration (shr), one 300 btu/hr. R134a. (a...

Page 8

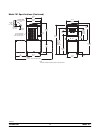

4 introduction model 161 071018 model 161 specifications (continued) 18 (458) 20-7/8 (531) 24-1/16 (611) 28-1/8 (715) 24-3/16 (614) 50-7/8 (1292) 43-11/16 (1110) top of draw handle 7-3/4 (197) 31-13/16 (808) 3-5/8 (92) 60-9/16 (1539) (both doors open) 17-5/8 (448) 19.625 (499) top of draw handle 15-...

Page 9: Installation Instructions

5 model 161 introduction installation instructions air cooled units air cooled units require a minimum of 6” (152 mm) of clearance around all sides of the freezer . Failure to allow for adequate clearance can reduce the refrigeration capacity of the freezer and possibly cause damage to the compresso...

Page 10: Running Specifications

6 introduction model 161 running specifications pressures/temperatures the following are the taylor recommended settings for various components within these models. The model 161 uses r404a. Expansion valve - low side (suction) soft serve air cooled - 21 psi. (145 kpa) for a normal product of 16_ to...

Page 11: Section 2: Controls

7 model 161 controls section 2: controls s generation ii control logic board s service tips for generation ii boards s control overview.

Page 12

8 controls model 161 generation ii control logic board the generation ii logic board’s primary function is to interpret modes of operation. The board monitors mix levels and temperatures by sending commands to the control’s power board. Commands are sent via a ribbon cable, enabling the proper relay...

Page 13

9 model 161 controls viscosity function in soft serve freezers the logic board monitors amp draw on the beater motor, which is directly related to the viscosity of the product in the freezing cylinder. When the amp draw reaches its set point, the unit cycles off. Therefore, the viscosity of the prod...

Page 14

10 controls model 161 setting the mix hopper temperature 1. To set the mix hopper temperature, fill the hopper at least half full with approximately 40_f (4.4_c) mix. 2. Install a suction pressure gauge at the epr valve (evaporator pressure regulator) and verify the correct operating pressure. Adjus...

Page 15

11 model 161 controls thermistor curve when checking a thermistor probe, first determine the present temperature at the probe and find it on this chart along with the approximate correct ohmmeter reading. The ohmmeter reading may vary from the correct one. Determine whether the difference is accepta...

Page 16

12 controls model 161 070809 f._ c._ k ohm 56 13.3 16.998 57 13.8 16.557 58 14.4 16.128 59 15.0 15.710 60 15.5 15.315 61 16.1 14.929 62 16.6 14.554 63 17.2 14.187 64 17.7 13.830 65 18.3 13.482 66 18.8 13.143 67 19.4 12.812 68 20.0 12.490 69 20.5 12.185 70 21.1 11.888 71 21.6 11.598 72 22.2 11.315 73...

Page 17

13 model 161 controls service tips for generation ii boards initial service tips 1. Check all connections. 2. Check the cable to verify that it is secure. 3. Verify that all pins are securely fastened in their sockets. 4. Verify that all cables correctly face away from the boards. If the cable is at...

Page 18

14 controls model 161 4. The pump relay closes and opens again. The mix light extinguishes. 5. The “btr” (beater motor) relay closes and opens again. The standby light extinguishes. 6. The “com” (compressor) relay closes and opens again. The wash light extinguishes. 7. All lights are off and a tone ...

Page 19

15 model 161 controls 11. The capability of this terminal to read the thermistor probe can be checked by the following method: a. Remove the thermistor probe wire from the “mix 1” terminal. B. Connect the “mix 1” terminal directly to ground (simulating a warm probe). The mix light will illuminate. C...

Page 20: Control Overview

16 controls model 161 control overview com o.L. L1 l2 btr pump fan mix bea ter gnd cable 2.4 5 8 11.2 taylor co. 36641-1 ametek/dixon 000-49560 dip switch up = off 1 - comp 5 2 - comp 10 3 - btr 5 4 - btr 10 5 - fan 2 6 - stby dis 7 - interval 8 - interval 4.5 com 13 mix diff. Shunt s.S. Viscosity s...

Page 21: Refrigeration Schematic

17 model 161 controls refrigeration schematic compressor pressure switch condenser mix tank hpr thermistor probe axv dryer epr valve heat exchanger capillary tube access valve 20-22 psi (134a) access valve 1-5 psi access valve 13-14 psi (r12) 29-31 psi (hp62) access valve 13-14 psi (r12) 29-31 psi (...

Page 22: Valve Functions

18 controls model 161 valve functions comp label description function basic operating logic input / output epr inlet pressure upstream regulator limits the minimum refrigerant pressure in the hopper (currently set to 60 psig). Limiting the minimum refrigerant pressure in the hopper prevents freezing...

Page 23: Section 3: Troubleshooting

19 model 161 troubleshooting section 3: troubleshooting s general troubleshooting guide s electrical troubleshooting.

Page 24

20 troubleshooting model 161 general troubleshooting guide problem probable cause remedy 1. No product is being dispensed. Low on mix. The mix out light is on. Add mix to the mix hopper the power switch is in the off position. Place the power switch to the on position and press the auto key. Beater ...

Page 25

21 model 161 troubleshooting problem probable cause remedy 4. The mix in the hopper is too warm. The hopper cover is not in position. Clean the hopper cover and place it in position. The hopper temperature is out of adjustment. Adjust the temperature control. 5. The mix in the hopper is too cold. Th...

Page 26

22 troubleshooting model 161 problem probable cause remedy 12.The unit will not run when in the auto mode the unit is unplugged. Plug into wall receptacle. The auto mode. The beater motor is out on reset. Allow the beater motor to cool. Place the power switch to the off position. Press the reset but...

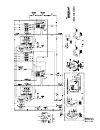

Page 27: Electrical Troubleshooting

23 model 161 troubleshooting electrical troubleshooting the following information provides a sequential list of electrical components that l-1 power travels through to initiate various operations. Auto mode of operation: l-1 power travels through the power switch, beater overload switch, the compres...

Page 28

24 troubleshooting model 161 notes:.

Page 29: Section 4: Parts

25 model 161 parts section 4: parts s warranty explanation s exploded views s complete parts list s wiring diagrams.

Page 30: Warranty Explanation

26 parts model 161 warranty explanation class 103 parts: the warranty for new equipment parts is one year from the original date of unit installation, with a replacement parts warranty of three months. Class 212 parts: the warranty for new equipment parts is two years from the original date of unit ...

Page 31

27 model 161 parts notes:.

Page 32: Model 161 Exploded View

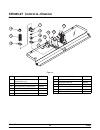

28 parts model 161 model 161 exploded view 4 5 2 7a 45 7 8 6 6a 9 10 11 12b 13 14 15 16 17 18 19 20a 20 21a 23 22 21b 21c 21d 21e 21f 24 25 26 27 28 29 30 31 32 33 34 24 38 35 36 34 37c 37b 37a 37 39 40 24 41 43 42 44 46 47 48 49 50 55 56 51 53 59 60 54 54a 12a 58 57 57a 64 62 63 61a 61 63 3 1 12 6b...

Page 33

29 model 161 parts model 161 exploded view item description part no. 1 motor-1/2 hp remote caps 055097-27g 2 nut-5/16-18 whiz flange 017327 3 screw-5/16-18x5/8 serr. 017326 4 pulley-ak20x5/8 041162 5 valve-exp-auto-1/4s x1/4 046365 6 line a.-liquid *solenoid x55592-27 6a valve-solenoid 7/64 orf 0434...

Page 34

30 parts model 161 model 161 exploded view (continued) item description part no. 57a valve-access-1/4mfl x 3/8 053565 58 stud-nose cone- 5/16-18x5/16 013496 59 washer-5/16 uss flat cr3 000651 60 nut-5/16-18 whiz flange 017327 item description part no. 61 line a.-access low x64407 61a valve-access-1/...

Page 35

31 model 161 parts model 161 panel identification 7 8 11 4 4a 5 6 2 1 12 13 9 10 r m a n u f a c t u r e d b y t h e t a y l o r c o m p a n y r o c k t o n , i l l i n o i s u . S . A . 3 figure 4 item description part no. 1 pan-drip *161* 055206 2 panel a.-side left *161* 058491 3 gasket-hopper co...

Page 36: Beater Door Assembly

32 parts model 161 beater door assembly 16 15 14 13 1 12 2 3 7 11 4 6 10 8 9 5 figure 5 item description part no. 1 draw valve 024763 2 o-ring 7/8 od x .103 w 014402 3 seal-valve 030930 4 door a.-3 sp 1.5 qt valox x56906ser1 5 pivot pin a.-short x38539 6 o-ring 5/16 od x .070 w 016272 7 draw valve h...

Page 37: Accessories

33 model 161 parts accessories figure 6 item description part no. 1 pail-6·qt. 023348 2 brush-rear brg 1” d x 2” lg 013071 3 brush-double·ended 013072 4 brush-draw·valve·1” od x 2” x 17” 013073 item description part no. 5 brush-mix·pump·body-3”x7” white 023316 6 lubricant-taylor·4·oz. 047518 7 kit·a...

Page 38

34 parts model 161 x58494-27 control a.-161 gen ii 1 2 3 1 2 13 12 4 5 14 5 10 9 10 9 7 8 15 15 5 11 6 figure 7 item description part no. 1 board-power-gen 1 & 2 x32326-ser 2 screw-6-32x5/8 unsltd 041363 3 contactor 230vac 1ph 50/60hz 055248-27 4 block-terminal 7p 20a 300v 022606 5 screw-8x1/4 sltd ...

Page 39

35 model 161 parts x55480-27 control a.-channel 1a 2 1b 1g 1e 1c 1f 1b 1a 4 3 1d 5 figure 8 item description part no. 1 switch a.-draw (includes: 1a-1f) x55234 1a bearing-switch 029244 1b nut-push on-1/2dia. Shaft 039735 1c screw-4-40 x 1 sltd round 028890 1d switch-lever-spdt-15a-125 027214 1e insu...

Page 40

36 parts model 161 x59447-27 box a.-cap & relay 8 4 1 9 9 6 4 7 1 2 8 4 3 4 5 figure 9 item description part no. 1 capacitor-start 72-88uf/330v 059757 2 capacitor-start 161-193uf/25 031790 3 relay-start-compressor 047067 4 screw-10x3/8 slotted hex 015582 5 bushing-snap 11/16 id x 7/8 010548 item des...

Page 41: Parts List

Parts list 37 + available separately model 161 parts list de s cri p t io n part num be r qty . W arr. Cl as s re m arks part s up da t e beari n g -front 023262 2 000 beari n g -gui d e 014496 2 000 beari n g -rear shell *150 -5 2 -68* 023648 2 000 +collar -rear beari n g *150 -2 -68* 025564 2 103 ...

Page 42

+ available separately 38 parts list model 161 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r +harness -w ir e -cap/ relay *161 055840 -2 7 1 103 k5103486 & p ri o r - 208 -230v 60hz 1 ph com p ressor p l35g 055187 -2 7 1 512 shr +capaci t or -s tart - 4 3 -52uf/ 250...

Page 43

39 + available separately model 161 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r seal -valve 030930 1 000 center draw valve door a. -3 spout -1 .5 qt x30753 -ser 1 103 k2024231 & p ri o r use x 56906 -ser ki t dryer -c ap. Tube .021 id x 9 ft 055522 1 00...

Page 44

+ available separately 40 parts list model 161 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r +capaci t or -s tart 72 -88uf/ 330v 059757 2 103 k5103487 & u p m o to r -1/ 2 h p 1 ph 60 hz 055097 -2 7 2 212 k4126923 & p ri o r - 208 -230v 60hz 1 ph +capaci t or -s tar...

Page 45

41 + available separately model 161 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r sani t iz er kay -5 125 packets 041082 1 000 shell a .- in sulated *161* x58457 512 k5103487 & u p +stud -no se co ne -5 /1 6 -18x5/ 16 -1 8 013496 2 103 shell a .- in sulat...

Page 46

+ available separately 42 parts list model 161 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r valve -s olenoi d 7 /64orf x 1 /4 s 043449 -2 7 2 103 li q u id li ne valve -t rev 3 /8 x3/ 8 220 *161* 055378 1 103 li q u id rei n j valve k5103486 & p ri o r vi deo -trai...

Page 47

Model 161 055376-27s rev. 11/06.

Page 48

Model 161 055376-40s rev. 11/06.