- DL manuals

- Taylor

- Freezer

- 161

- Operator's Manual

Taylor 161 Operator's Manual

Summary of 161

Page 1

Operator's manual model 161 soft serve freezer original operating instructions 055155-m 8/14/08 (original publication) (updated 7/8/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2008 carr...

Page 3: Table Of Contents

Table of contents model 161 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site p...

Page 4

Model 161 table of contents table of contents - page 2 section 7 important: operator checklist 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting bacterial ...

Page 5: Section 1

1 model 161 to the installer 131122 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should be...

Page 6

2 model 161 to the installer 130319 water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut- off valve. On the underside rear of the base pan, two 3/8” i.P.S. Water connections for inlet and outlet have been provided for easy hook- up. 1/2” inside ...

Page 7

3 model 161 to the installer 120529 electrical hook- up installation (60 cycle, 1 ph, supplied with cord and plug) this freezer is supplied with a 3- wire cord and grounding type plug for connection to a single phase, 60 cycle, branch circuit supply. This unit must be plugged into a properly grounde...

Page 8: Section 2

4 model 161 to the operator 131122 section 2 to the operator the model 161 soft serve freezer has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, it ...

Page 9: Section 3

5 model 161 safety 130319 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built- in safety features to protect both you and the service ...

Page 10

6 model 161 safety 130319 s do not allow untrained personnel to operate this machine. S do not put objects or fingers in door spout. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove the freezer door or beater assembly unless the cont...

Page 11: Section 4

7 model 161 operator parts identification section 4 operator parts identification model 161 figure 1 item description part no. 1 pan-drip *161* 055206 2 panel -side left 058491 3 gasket-hopper cover 037042 4 cover a.-hopper x37963-ser 4a knob-mix cover 025429 5 tube-feed 030797 6 panel-rear 058492 i...

Page 12

8 model 161 operator parts identification 140409 beater door assembly figure 2 item description part no. 1 valve-draw 024763-sp 2 o-ring-7/8 od x .103w 014402 3 seal-draw valve *small h-ring* 030930 4 door a.-3spt 1.5qt valox x56906ser1 5 pin a.-pivot *168-short* x38539 6 o-ring-5/16 od x .070w 0162...

Page 13

9 model 161 operator parts identification 110727 accessories figure 3 item description part no. 1 pail-6·qt. 023348 2 brush-rear brg 1” d x 2” lg 013071 3 brush-double·ended 013072 4 brush-draw·valve·1” od x 2” x 17” 013073 item description part no. 5 brush-mix·pump·body-3”x7” white 023316 6 lubrica...

Page 14: Section 5

10 model 161 important: to the operator section 5 important: to the operator figure 4 item description 1 power switch 2 mix refrigeration key 3 standby key 4 wash key 5 auto key 6 indicator light “mix low” 7 reset button symbol definitions to better communicate in the international arena, the words ...

Page 15

11 model 161 important: to the operator 130703 power switch when placed in the on position, the power switch allows softecht control panel operation. Mix ref key when the mix ref key is pressed, the light comes on indicating the mix hopper refrigeration system is operating. Mix ref is controlled by ...

Page 16

12 model 161 important: to the operator 130703 wash key when the wash key is pressed, the light comes on. This indicates beater motor operation. The standby or auto mode must be cancelled first to activate the wash mode. Auto key when the auto key is pressed, the light comes on. This indicates that ...

Page 17

13 model 161 important: to the operator 130703 2. Standby operation: during long “no sale” periods, the feed tube is inverted. The end of the feed tube without the mix delivery hole is placed in the mix inlet hole to prevent mix from entering the freezing cylinder. Feed tube position during standby ...

Page 18: Section 6

14 model 161 operating procedures 120529 section 6 operating procedures the model 161 is a soft serve counter model with a three spout door. Two individual flavors are available from the end spouts, and an equal combination of both is dispensed through the center spout to create a twist effect. It h...

Page 19

15 model 161 operating procedures 120501 step 3 place the large o- rings into the grooves on the back of the machine door and lubricate. Figure 13 step 4 slide the front bearings over the baffle rods so the flanged edge is against the door. Place the white plastic guide bearings on the end of the ba...

Page 20

16 model 161 operating procedures step 9 slide the two o- rings into the grooves on the remaining draw valves and lubricate. Figure 17 step 10 lubricate the inside of the freezer door spouts from the bottom. Insert the draw valves into the freezer door from the bottom until the slot in the draw valv...

Page 21

17 model 161 operating procedures step 13 snap the design caps over the bottom of the freezer door spouts. Figure 21 step 14 lay the feed tubes in the bottom of the mix hoppers. Step 15 install the front drip tray and splash shield under the freezer door. Figure 22 step 16 install the drip pans. Fig...

Page 22

18 model 161 operating procedures step 3 while the solution is flowing into the freezing cylinder, brush clean the mix hopper, the mix inlet hole, and the feed tube. Figure 25 figure 26 step 4 place the power switch in the on position. Figure 27 step 5 press the wash key. This will cause the sanitiz...

Page 23

19 model 161 operating procedures 140717 priming prime the machine as close as possible to the time of first product draw. Step 1 with a pail beneath the door spouts, open the draw valves. Fill the mix hopper with fresh mix and allow it to flow into the freezing cylinder. This will force out any rem...

Page 24

20 model 161 operating procedures rinsing step 1 pour one gallon (3.8 liters) of cool, clean water into the mix hopper. With the brushes provided, scrub the mix hopper, and the mix inlet hole. Step 2 with a pail beneath the door spouts, press the wash key and open the draw valves. Step 3 drain all t...

Page 25

21 model 161 operating procedures step 3 from the freezer door, remove design caps, pivot pins, draw handles, and draw valves. Remove all o- rings. Note: to remove o- rings, use a single service towel to grasp the o- ring. Apply pressure in an upward direction until the o- ring pops out of its groov...

Page 26: Section 7

22 model 161 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit has a “sta...

Page 27

23 model 161 important: operator checklist j 5. If your machine is air cooled, check the condenser for an accumulation of dirt and lint. A dirty condenser will reduce the efficiency and capacity of the machine. Condensers should be cleaned monthly with a soft brush. Never use screwdrivers or other m...

Page 28: Section 8

24 model 161 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. The power switch is in the off position. A. Place the power switch in the auto position. 18 b. The mix level is inadequate in the mix hopper. B. Fill the mix h...

Page 29

25 model 161 troubleshooting guide problem probable cause remedy page ref. 4. The product is too soft. A. The control is set too warm. A. Contact service technician. - - - b. The air tube is not installed. B. Install the air tube in the mix inlet hole at the bottom of the mix hopper. 19 c. Out- draw...

Page 30

26 model 161 troubleshooting guide problem probable cause remedy page ref. 9. The unit goes out on overload excessively. A. There are too many appliances plugged into the circuit. A. A separate 20a circuit is needed for the freezer to operate properly. - - - b. An extension cord has been placed betw...

Page 31: Section 9

27 model 161 parts replacement schedule 120501 section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Beater drive shaft cup seal x 2 freezer door o- ring x 2 freezer door front bearing x 2 freezer door guide bearing x 2 draw valve o- ring x 4 center draw v...

Page 32

28 model 161 limited warranty on equipment 131122 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment a...

Page 33

29 model 161 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return ...

Page 34: Section 11

30 model 161 limited warranty on parts 131122 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement com...

Page 35

31 model 161 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clean...

Page 36

32 model 161 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owner...

Page 37: Section 12

Section 12 parts list 33 + available separately model 161 parts list 140409 016127f 000 descri pti o n part number qty. W arr. Class comments actuator- sw itch- plasti c 035609 2 103 draw sw itch arm a .- sw it ch *162/ 168* x30736 2 103 draw sw itch bead- rubber 010613- 17 1 000 beari ng- front 023...

Page 38

+ available separately 34 parts list model 161 descri pti o n comments w arr. Class qty. Part number com pressor l63b562bbcb 048727- 27e 1 512 +capaci t or- s tart 161- 193uf/ 25 031790 1 103 +capaci t or- run 30uf/ 370v 038487 1 103 +relay- start- compressor 047067 1 103 +grommet- compressor m ount...

Page 39

35 + available separately model 161 parts list descri pti o n comments w arr. Class qty. Part number +o -r in g -5/ 16 o d x .070w 016272 1 000 +pi n a. -p iv o t *168- sho r t* x38539 1 103 +o -r in g -5/ 16 o d x .070w 016272 1 000 +valve- draw *150- 2* 024763 2 103 +o -r in g -7/ 8 o d x .103w 01...

Page 40

+ available separately 36 parts list model 161 descri pti o n comments w arr. Class qty. Part number ki t a .- tune up* 162- 168* x31167 1 000 beari ng- front 023262 2 000 beari ng- gui de 014496 2 000 cap- desi g n 1. 010" id -6 po in t 014218 3 000 seal- u -cup 080534 2 000 5/ 16/ 12 & u p - repla...

Page 41

37 + available separately model 161 parts list descri pti o n comments w arr. Class qty. Part number panel a. -s id e r ig ht *161* x58490 1 103 +screw -10- 32x3/ 8 s ltd t rus 024298 2 000 panel- si d e panel- l o w er- f ro nt *161* 058493 1 103 panel- r ear *161* ac 058492 1 103 panel- s id e- le...

Page 42

+ available separately 38 parts list model 161 descri pti o n comments w arr. Class qty. Part number in sulato r- sw it ch 1/ 64 arm ite 029099 1 000 nut- push o n- 1/ 2di a. Shaft 039735 2 000 screw -4- 40x5/ 8 s ltd r o und 027219 2 000 sw it ch- lever- spdt- 15a- 125- 25 027214 1 103 +actuator- s...

Page 43

39 + available separately model 161 parts list descri pti o n comments w arr. Class qty. Part number bracket- valve- w /c *c708* 058440 1 103 clamp- hose 3/ 4 id c onst t 067113 6 000 condenser- w c- spi ral 11- 1/ 2 o 049309 1 103 elbow -3/ 8mp x 1 /2 barb- br 018641 2 103 hose- rubber 1/ 2 id x 7/...

Page 44

+ available separately 40 parts list model 161 descri pti o n comments w arr. Class qty. Part number leg -4" 3/ 8- 16 stud 036397 4 103 panel- l o w er- f ro nt *161* 058493- sp2 2 103 +screw -8- 32x3/ 8 unsltd h ex 041951 4 000 panel- ski rt- a ir *161* 055508 1 103 tube- feed- .219 hole- ss- tm 03...

Page 45

41 + available separately model 161 parts list descri pti o n comments w arr. Class qty. Part number decal- in st- c ln hpr- chi nes 019029- ch 1 000 decal- troubleshoot- chi nes 038374- ch 1 000 di ag ram -w iri ng *161* 063820- 40s 1 000 d r y e r -f il t e r 1 /4 x 1 /4 s o 048878 1 000 form- q u...

Page 46

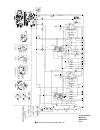

Model 161 069262-27s 07/14 taylor company 2014 carrier commercial refrigeration, inc. C c c c n0 nc t t c n0 nc t l1 l2 winding protector (internal) main winding start winding start relay start capacitor 14 12 13 10 11 compressor wiring (model w/hst) start relay start winding main winding winding pr...

Page 47

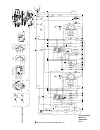

Model 161 069262-40s 07/14 taylor company 2014 carrier commercial refrigeration, inc. C ground frame securely l1 t1 l1 m t2 l2 main compressor (fig. 1) blk wht wht mix fan pump btr com o.L. L2 l1 gnd 1 cable left power board min max min max min max s.S. Viscosity shake temp. Mix standby mix standby ...