- DL manuals

- Taylor

- Freezer

- 337

- Service Manual

Taylor 337 Service Manual

Summary of 337

Page 1

Model 337 soft serve freezer service manual 044869-s 8/21/00

Page 3: Table Of Contents

Model 337 table of contents table of contents section 1: introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refrigerant 2 . . . ....

Page 4

Table of contents model 337 table of contents -- page 2 section 4: parts 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Warranty explanation 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337 exploded vie...

Page 5: Section 1: Introduction

1 model 337 introduction section 1: introduction s safety s refrigeration s specifications s installation instructions.

Page 6: Safety

2 introduction model 337 070321 safety _________________________________ we at taylor are committed to manufacturing safe operating and serviceable equipment. The many built-in safety features that are part of all taylor equipment are aimed at protecting operators and trained service technicians ali...

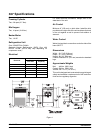

Page 7: 337 Specifications

3 model 337 introduction 337 specifications freezing cylinder two, 2.8 quart (2.7 liter). Mix hopper two, 14 quart (13.2 liter). Beater motor two, 1.0 hp. Refrigeration unit one, 9,500 btu/hr. R404a. Separate hopper refrigeration (shr), one, 400 btu/hr. R134a. (btu’s may vary depending on compressor...

Page 8: Running Specifications

4 introduction model 337 080918 running specifications the following are the pressure and temperature settings recommended by taylor and apply to all models covered in this manual. Pwm (pulse width module) valve pressure setting: hp62 = 20 to 22 psi (138 to152 kpa) normal product temperature should ...

Page 9: Installation Instructions

5 model 337 introduction installation instructions air cooled units air cooled units require a minimum 6” (152 mm) on both sides. Install the skirt provided on the right side of the unit and place the back of the unit against a wall to prevent recirculation of warm air. Failure to allow for adequate...

Page 10

6 introduction model 337 050920 electrical connections caution: this equipment must be properly grounded! Failure to do so can result in severe personal injury from electrical shock! Each freezer requires one dedicated power supply. Check the data label on the freezer for fuse, circuit ampacity and ...

Page 11

7 model 337 controls and systems section 2: controls and systems s operating and service screen displays s pulse width modulation s refrigeration system s pwm split flow chart s universal and interface boards s control overview.

Page 12: Operating Screen Displays

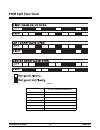

8 controls and systems model 337 operating screen displays the power switch off screen indicates that the power switch is in the off position. Power switch off =--=--=--=--=--=--=--=--=--= the normal operating screen will display the current mode of operation and the level of mix in each mix hopper....

Page 13

9 model 337 controls and systems possible fault descriptions no fault found -- no fault is found. Btr ovld or hpco -- the beater motor has gone off on overload or the compressor has reached its high pressure cut--out point. Comp on too long -- the compressor has been running more than 11 minutes. Be...

Page 14

10 controls and systems model 337 service menu _________________________________ the service menu option allows a trained service technician to access and modify critical operating parameters for the machine. Service menu a b c d e f g h i j exit to op. Menu sel the service menu options are listed i...

Page 15

11 model 337 controls and systems the set standby temperature screen displays the current temperatures of both freezing cylinders. Set standby temp standby temp: 30.0 present : 30.0 + + + -- -- -- sel pressing the menu/sel key accepts the setting and returns to the service menu. Set hopper temperatu...

Page 16

12 controls and systems model 337 pwm duty cycle (option i) the pwm (pulse width modulation) duty cycle setting controls the length of time the refrigerant will flow through each barrel (freezing cylinder). Pwm duty cycle duty cycle: 80% + + + -- -- -- sel the pwm duty cycle can be adjusted to a set...

Page 17: Pulse Width Modulation

13 model 337 controls and systems 070321 pulse width modulation the central feature of the model 337 is the precise control of the refrigerant flow. The flow of the refrigerant is distributed between the freezing cylinders on the basis of cylinder cooling load. This precise control is achieved by us...

Page 18

14 controls and systems model 337 pwm valve split during draw case present draw from refrigeration system operating because of last draw from left pwm right pwm case l c r l c r left pwm pwm 1 nd nd nd 0 0 0 0 0 2 nd nd d 0 0 0 l h 3 nd nd d 0 0 1 l h 4 nd nd d 0 1 0 l h 5 nd nd d 1 0 0 l h 6 nd d n...

Page 19: Refrigeration System

15 model 337 controls and systems refrigeration system the criteria used to cycle off the refrigeration in the model 337 are different from those used in other taylor equipment. System cycle off depends on both product viscosity and product temperature. For system cycle off to occur, the following c...

Page 20: Pwm Split Flow Chart

16 controls and systems model 337 pwm split flow chart figure 4 pwm settings corresponding suction pressure at 70 _ f (21 _ c) ambient temperature 90% 24 -- 15 80% 22 --13 70% 20 --11 60% 18 -- 8 50% 16 -- 6 40% 14 -- 4 30% 12 -- 2.

Page 21

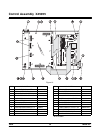

17 model 337 controls and systems universal & interface boards external connections j2 p4 left mix out probe p2 right mix out probe p3 left mix low probe p1 right mix low probe j4 p6 compressor contactor coil p5 beater motor contactor coil p4 left pwm valve p3 right pwm valve p1 hopper refrigeration...

Page 22: Control Overview

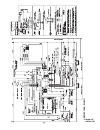

18 controls and systems model 337 control overview figure 5.

Page 23: Section 3: Troubleshooting

19 model 337 troubleshooting section 3: troubleshooting s general troubleshooting s electrical troubleshooting s control faults.

Page 24

20 troubleshooting model 337 general troubleshooting guide problem probable cause remedy 1. The lcd is blank. The unit is unplugged. Plug the main power cord into the wall receptacle. The fuse is blown or the circuit breaker is in the off position. Replace the fuse or place the breaker in the on pos...

Page 25

21 model 337 troubleshooting problem probable cause remedy 7. The liquid line is frosted. The dryer or the tubing is restricted. Replace or remove the restrictions. 8. No product is being dispensed. The control switch is in the off position. Place the unit in the auto position. There is a freeze--up...

Page 26

22 troubleshooting model 337 problem probable cause remedy 12. An excessive amount of mix leaked through the rear of the unit into the drip pan there is a worn or missing drive shaft boot seal. Replace the boot seal. Into the drip pan. Inadequate lubrication of the drive shaft boot seal. Lubricate t...

Page 27: Electrical Troubleshooting

23 model 337 troubleshooting electrical troubleshooting the following are the paths of power to be followed: wash mode to operate the beater motor: l1 power source -- power switch -- high pressure cut--out switch -- reset button -- interface board -- coil of the beater motor contactor. Auto mode to ...

Page 28: Control Faults

24 troubleshooting model 337 control faults when a specific fault occurs (during the auto or standby modes), the unit will operate in the mode indicated: fault mode btr ovld or hpco off comp on too long on beater over current off fuse/mtr/comp/pwm hopper therm bad off left brl therm bad off right br...

Page 29: Section 4: Parts

25 model 337 parts section 4: parts s warranty explanation s exploded views s parts list s wiring diagrams.

Page 30: Warranty Explanation

26 parts model 337 070321 warranty explanation class 103 parts: the warranty for new equipment parts is one year from the original date of unit installation, with a replacement parts warranty of three months. Class 212 parts: the warranty for new equipment parts is two years from the original date o...

Page 31

27 model 337 parts notes:.

Page 32: 337 Exploded View

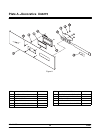

28 parts model 337 337 exploded view figure 6.

Page 33

29 model 337 parts 337 exploded view parts identification item description part no. 1 shell a.-insulated x53251 1a bearing-rear shell 031324 1b washer-bearing lock 012864 1c nut-brass bearing 028991 1d guide-drip seal 028992 2 coupling-drive 3/4 hex 012721 3 gear a.*reducer-dual 042934 4 pulley-2ak7...

Page 34: 337 Panels

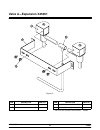

30 parts model 337 337 panels figure 7.

Page 35

31 model 337 parts 337 panel identification parts identification item description part no. 1 louver-side 017471 2 bushing-panel 013289 3 trim-rear corner l. 044280 4 cover-hopper-14 qt-gray 041682-gry 5 panel a.-front x44247 6 panel-rear 044287 7 panel a.-side x48596 8 trim-rear corner r. 044281 9 s...

Page 36: Beater Door Assembly

32 parts model 337 beater door assembly figure 8 item description part no. 1 seal--drive shaft 032560 2 shaft--beater 033235 3 beater a.--2.8 qt. Helicore x35466 4 blade--scraper--plastic 035480 5 bearing--front 050216 6 gasket--door ht 4” dbl 048926 7 o--ring 3/8” od x 0.70 w 016137 8 plug--prime 0...

Page 37

33 model 337 parts draw switch assembly x38547 figure 9 item description part no. 1 bracket a.-switch x38252 2 switch a.-draw-twin twist x39269 2a switch-lever-spdt-11a-125 039252 2b screw-4-40 x1/2”taptite pan 042604 2c bracket-draw switch-twin 039264 3 screw-8-32x3/8 hex hd 039267 4 arm-switch-dra...

Page 38: Control Assembly X45055

34 parts model 337 control assembly x45055 figure 10 item description part no. 1 connector-bx 3/8 str 014569 2 pcb a.-interface x44295-ser 3 insulator-pcb-interface 045394 4 block-terminal-plug 8p 040322-004 5 cable-ribbon-50c- 5”l-dil 040040-010 6 standoff-nylon-snap 053413 7 box a.-control x45373 ...

Page 39

35 model 337 parts plate a.--decorative x44275 figure 11 item description part no. 1 plate a.-dec x44276 2 screw-2-56x1/2 fhm-slot 038219 3 standoff-lens 038225 4 lens-display 038221 5 display-liquid crystal x38062-ser 6 switch-membrane-5 pos.-8 044520 item description part no. 7 plate-back up-memb....

Page 40: Control Assembly X48482--

36 parts model 337 control assembly x48482-- figure 12 item description part no. 1 relay-3 pole-20a-208/240 012725- 2 screw-8x1/4 sl hex hd typ b 009894 3 block-terminal 2p-l1,l2 039422 4 screw-8 x 1-1/4 rd hd typ b 039420 5 starter-1 phase-4.5 to 7 a 041950- 6 connector-bx 3/8 str 014569 7 trans.-c...

Page 41: Valve A.--Expansion X45051

37 model 337 parts valve a.--expansion x45051 figure 13 item description part no. 1* valve-exp-pulse-3/8 s-240 044335- 2 ** tee-3/8s x 3/8s x 1/4s-copper 016441 item description part no. 3 screw-8x1/4 sl hex hd typ b 009894 4 bracket-mtg-pulse valve 045879 *coil-pulse exp valve - 044335-27c **valve ...

Page 42: Parts List

Parts list + available separately 38 parts list model 337 j5075161/ up -- hp 62 ref ri g eran t de s cri p t io n part num be r qty . W arr. Cl as s re m arks part s up da t e bear in g -fr o n t 050216 2 000 bear in g -r ear sh el l *n ic k .Pl a te 031324 2 000 + g u id e -d r ip seal 028992 2 000...

Page 43

39 + available separately model 337 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r coup l ing -dri v e 3 /4 h e x x 1 -7 /8 012721 2 103 c o ver -h o pper 1 4 q t g r a y 041682 -g r y 2 103 d e c a l -c l ean in st. -h o pper 019029 1 000 de ca l -de c -t...

Page 44

+ available separately 40 parts list model 337 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r c a p -d e s ig n -1 .010” id -6 p o in t 014218 3 000 g asket -d o o r h t 4 ”- d o u bl e 048926 2 000 o -r in g .291i d x .080w 018550 6 000 o -r in g -. 643 o d x .077w ...

Page 45

41 + available separately model 337 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r pl ate a .- d e c -3 3 7 x 44276 1 103 p r o b ea .- m ix* s q u a r e * x 30922 2 103 p r o b ea .- m ixo u t x 41348 2 103 pr o b e a .- th er m isto r - h o pper x 45047 ...

Page 46

+ available separately 42 parts list model 337 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r br ac ket a. -spr in g r etu r n x 38257 1 103 br ac ket a. -s witc h *3 3 8 -3 9 -7 5 4 x 38252 1 103 e -ri ng 1 /4 032190 4 000 pin -pivo t -d r a w s witc h 038484 1 103 ...

Page 47

43 + available separately model 337 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r wa te r c oole d conde ns e r -w /c 049309 1 103 mo t o r -f a n -25w 230v o l t 015184 - 1 103 + f an -5 bl ad e 1 0 ” pu sh 013043 1 103 switc h -p r essu r e 3 5 0 psi -s...

Page 48

Model 337 044553--27g.

Page 49

Model 337 044553--33g.

Page 50

Model 337 044553--62g.