- DL manuals

- Taylor

- Freezer

- C300 NP

- Operating Instructions Manual

Taylor C300 NP Operating Instructions Manual

Summary of C300 NP

Page 1

Model c300 np non-pressurized slush freezer original operating instructions 055072np 9/22/06 (original publication) (updated 5/6/11).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Model c300 np table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air cooled units 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wate...

Page 4

Table of contents model c300 np table of contents - page 2 section 7 important: operator checklist 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting bacter...

Page 5: Section 1

1 model c300 np to the installer 071010 section 1 to the installer the model c300np is designed for indoor use only. Do not install the machine in an area where a water jet could be used. Failure to follow this instruction may result in serious electrical shock. Air cooled units air cooled units req...

Page 6

2 model c300 np to the installer 110506 electrical connections each unit requires one power supply for each data label on the unit. Check the data label(s) on the freezer for branch circuit overcurrent protection or fuse, circuit ampacity, and other electrical specifications. Refer to the wiring dia...

Page 7: Section 2

3 model c300 np to the operator 110506 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The model c300np, when properly operated and cared for, will produce a consistent quality product. Like all mechanical prod...

Page 8: Section 3

4 model c300 np safety 110506 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both the operator and ...

Page 9

5 model c300 np safety caution: this unit is pressurized when in operation. The control switch must be in the off position until the unit is completely assembled. No part should ever be removed from the machine while it is in operation. No parts should be removed until the control switch has been tu...

Page 10: Section 4

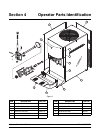

6 model c300 np operator parts identification section 4 operator parts identification 2 3 4 8 7 6 9 1 5 9 10 11 figure 3 item description part no. 1 panel-side-left 054676 2 panel-rear 054672 3 panel-side-right 054671 4 display-lighted 054683-27 5 panel-front-upper 054669 6 panel-front-shell 054668 ...

Page 11

7 model c300 np operator parts identification 081110 beater door assembly 2 1a 3 4 12 12 5 6 7 8 1b 1c 1d 1e 1i 11 1g 1f 1h 1j 9 10 5 figure 4 item description part no. 1 door a.-slush-slfclose- ice buster (complete) x57323 (1a-1j) 1a cap a.-spring retainer x30591 1b spring-comp.970x.082x3.87 030344...

Page 12

8 model c300 np operator parts identification accessories kay-5 sanitizer/cleaner ® caution keep out of reach of children for institutional use only 1 oz (28.4 g) 2a 1 2b 2c 2d 5 4 3 048260 048260 r figure 5 item description part no. 1 pail-mix 10 qt 013163 2a brush-mix pump body-3”x7” 023316 2b bru...

Page 13: Section 5

9 model c300 np important: to the operator section 5 important: to the operator 4 3 5 1 2 6 prime auto alarm silencer alarm silencer off beater prime auto menu off beater select figure 6 item description 1 product light - left side 2 control switch 3 keypad - left side 4 liquid crystal display 5 key...

Page 14

10 model c300 np important: to the operator control switch the control switch is located at the top left corner of the control channel. When placed in the on position, allows slushtech operation. Liquid crystal display the liquid crystal display (lcd) is located on the front control panel. The lcd i...

Page 15

11 model c300 np important: to the operator operator menu timeout if the display is left in the operator menu or any of the operator menu selections, except for current conditions, the display will return to the system mode screen 60 seconds after the last keypress. The current conditions screen wil...

Page 16

12 model c300 np important: to the operator 6. Syrup press low - when the syrup out indicator displays a lack of syrup, the unit will enter a hold mode. At this time, no refrigeration or product flow from the flow control will be allowed. Only the beater will operate. When the syrup is satisfied, th...

Page 17

13 model c300 np important: to the operator screen c is set clock. Use the auto (- ->) and off ( element to be set (hours, minutes, month, day, or year). Use the prime (+++) and beater (- - -) keys to increment or decrement the value. Press the menu (sel) key to advance to the daylight saving time s...

Page 18

14 model c300 np important: to the operator the fourth feature will display the power saver mode, off, rest, or standby status. If the power saver mode is off, the following screen will be displayed. Power saver mode off sel if a power saver mode is programmed, one of the following screens will appe...

Page 19

15 model c300 np important: to the operator press the auto (- ->) key to move to the next screen. The next screen will indicate when the fault was satisfied. Fault history 2 10/25/06 14:06:19 restored from fault page 2 + + + - - - sel press the menu (sel) key to return to the operator menu. Screen h...

Page 20

16 model c300 np important: to the operator co 2 out indicator auto mode auto ok syrup ok co2-out water-ok on the lcd, if the word “out” appears next to the word “co2” it indicates a lack of co2 being supplied to the freezer. The product light will also illuminate and a warning tone will sound. This...

Page 21: Section 6

17 model c300 np operating procedures section 6 operating procedures the model c300np contains two 7 quart (6.6 liter) freezing cylinders. The syrup flow control combines the two ingredients of water and syrup, and sends this combination to the freezing cylinder. As product is drawn, new product wil...

Page 22

18 model c300 np operating procedures step 3 check the scraper blade for any nicks or signs of wear. If any nicks are present, replace the blade. If the blade is in good condition, place the clip over the blade. Place the rear scraper blade and clip over the single holding pin on the beater (knife e...

Page 23

19 model c300 np operating procedures step 8 insert the draw valve into the door. 11320 figure 13 step 9 rotate the draw valve so the groove on the top of the draw valve is perpendicular to the door face. 90 11261 figure 14 step 10 insert the ice buster through the door spout and into the slot locat...

Page 24

20 model c300 np operating procedures step 13 place the large rubber gasket into the groove on the back side of the freezer door. 11324 figure 18 step 14 slide the white, plastic front bearing onto the bearing hub, making certain that the flanged end of the bearing is resting against the freezer doo...

Page 25

21 model c300 np operating procedures sanitizing note: if a unit is sanitized, and will not be used for an extended period of time, clean water should be used to flush all sanitizer from the lines. Remove the water from all the lines and components prior to storage of the unit. Upon return to servic...

Page 26

22 model c300 np operating procedures press the menu (sel) key. Move the cursor under the word “sanitize” by pressing the off ( rinse / sanitize rinse sanitize exit - - - - - sel step 7 pressing the menu (sel) key will give you the option for sanitizing the left freezing cylinder. Move the cursor un...

Page 27

23 model c300 np operating procedures priming/brixing step 1 connect the syrup line to the bag-in-box (bib) syrup. Step 2 remove the drip tray, splash shield and the lower front panel to gain access to the syrup sampling valves. Step 3 open the prime plug. Step 4 place the sampling valve in the off ...

Page 28

24 model c300 np operating procedures step 7 pour the product from the syrup sampling valve into a cup. Close the syrup sampling valve by turning the handle to the center position. Figure 31 step 8 stir the finished product. Pour a small amount of product over the refractometer. The brix reading sho...

Page 29

25 model c300 np operating procedures step 11 place a pail beneath the door spout. Open the draw valve and drain the freezing cylinder to remove any incorrectly brixed product. Close the draw valve. Step 12 hold a large cup under the prime plug port on the door, until the liquid level (not foam) rea...

Page 30

26 model c300 np operating procedures step 2 when all the product has been drained from the freezing cylinder, close the draw valve and press the off ( figure 37 repeat steps 1 and 2 for the other freezing cylinder. Rinsing step 1 to place the left cylinder in the rinse mode, press the menu (sel) ke...

Page 31

27 model c300 np operating procedures step 3 to place the left freezing cylinder in the sanitize mode, press the menu (sel) key. Move the cursor by pressing the auto (- ->) key until the third line indicates rinse / sanitize. Press the menu (sel) key. Move the cursor under the word “sanitize”. Rinse...

Page 32

28 model c300 np operating procedures 080926 brush cleaning step 1 prepare a sink or a pail with an approved cleaning solution. Use warm water and follow the manufacturer's specifications (example: kay-5 r ). Important: follow the label directions. Too strong of a solution can cause parts damage, wh...

Page 33: Section 7

29 model c300 np important: operator checklist 080926 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following chec...

Page 34

30 model c300 np important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from the ma...

Page 35: Section 8

31 model c300 np troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Product is too stiff. A. Too much water to syrup ratio. Improper brix adjustment. A. Adjust the brix accordingly. 23 b. Consistency control needs adjustment. B. Contact a service technic...

Page 36

32 model c300 np troubleshooting guide problem probable cause remedy page ref. 6. Unable to remove the drive shaft from the rear shell bearing. A. Rounded corners of hex end of drive shaft, drive coupling, or both. A. Replace the drive shaft, or call a service technician to replace the direct drive ...

Page 37: Section 9

33 model c300 np parts replacement schedule section 9 parts replacement schedule part description every 4 months every 8 months annually scraper blade x drive shaft seal x drive shaft o-ring x freezer door gasket x draw valve o-ring x front bearing x prime plug o-ring x black bristle brush, 1” x 2” ...

Page 38: Section 10

Section 10 parts list 34 parts list model c300 np 080207 de s cri p t io n p art num be r qty . W arr. Cl as s re m arks p art s up dat e accumulator- c opper 2” di a 13” lg 053377 1 103 accum ul at o r -co pper 2 "di a 1 3 "l g 053377 1 103 a r m- b a f f l e *345/ 46/ 49/ 355/ 390 047729 2 103 a r...

Page 39

35 model c300 np parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r c abl e-r ibbo n -5 0 c - 3 "l -d il /d il 040040- 055 1 103 j 10u c t o j 9i f ca rd-che ck out s l u s h t e ch-5 y r 039976- w 5 1 000 c l ip -r e t a in e r *355* s y r u p li n e 053197 ...

Page 40

36 parts list model c300 np 081110 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r + l en s-d ispl ay 038221 1 103 +stan d o ff- l e n s 038225 4 000 d o o r a.-par tial -sl u sh -sl f c l o x 57324- s e r 2 103 + b us t e r-i c e 047735 2 103 + c ap a.-spr in g r et...

Page 41

37 model c300 np parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r h a r n ess-wir e -c 300- l0 v o lt 055503 1 103 h o l d er -fu se-in l in e -type h l r 045606 1 103 h o o d *c 300* 054677 1 103 k it a .- t u n e u p *c 300* n p x 56829 2 000 bear in g -f...

Page 42

38 parts list model c300 np de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r h o se-bever ag e-.3 7 5 id x.6 3 5 r 30333 6' 000 re gul a t o r-w a t e r-3 0 p s i f ix e d 064388 1 103 tee-3 /8 bar bx1 /4 m f l x 3 /8 bar b 038582 1 103 li n e -o u t le t -f c /s mp v...

Page 43

39 model c300 np parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r c h ip-so ftwar e u vc 2 c h ip-sel x 40873 1 103 c h ip-so ftwar e u vc 2 d ispl ay x 40872 1 103 c h ip-so ftwar e u vc 2 u 1 0 en g l ish x 40875 1 103 c h ip-so ftwar e u vc 2 u 1 1 x 408...

Page 44

40 parts list model c300 np de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r +w a s h e r -f r e e z e r s t u d *348- 350 036265 4 000 s h ie ld -s p l a s h *c 300* 057939 1 103 s /n k 3013295 & u p s h r o u d a .- c o n d e n s e r *c 300* x 54662 1 103 str a in e...

Page 45

41 model c300 np parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r val ve-exp-au to -1 /4 s x 1 /4 f pt 046365 2 103 + b o o t -expan sio n val ve 050900 2 000 v a l v e -s o le n o id 208/ 240 v - 028824- 27 1 103 val ve-so l 1 /8 o r f 1 /4 in x3 /8 o u t ...

Page 46

42 parts list model c300 np de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r 50hz (380- 415v 50h z 3 n ) coi l -s ol e n oi d-f l ow cont rol 062013- 40 2 b l o c k -t e r m in a l 4p l1, l2, l3, n 039424 1 103 bl o c k-ter m in al -7 po l e g r een 024156 1 103 c o m...

Page 47

C300np 056828-27 5/11.

Page 48

C300np 056828-33 5/11.

Page 49

C300np 056828-58 5/11.