- DL manuals

- Taylor

- Freezer

- PH61

- Operator's Manual

Taylor PH61 Operator's Manual

Summary of PH61

Page 1

Operator's manual model ph61 heat treatment peristaltic pump shake freezer original operating instructions 048119ts 2006 (original publication) (updated 8/7/15).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Ph61 peristaltic pump table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the operator 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3 s...

Page 4

Table of contents ph61 peristaltic pump table of contents - page 2 regular maintenance checks: 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Winter storage 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 ph61 peristaltic pump to the installer 131212 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipme...

Page 6

2 ph61 peristaltic pump to the installer air cooled units do not obstruct the unit's air intake and discharge openings: air cooled units require a minimum of 6” (152 mm) of clearance around all sides of the unit. Failure to allow adequate clearance can reduce the refrigeration capacity of the unit a...

Page 7

3 ph61 peristaltic pump to the installer 131212 s supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) installed with the proper cord anchorage ...

Page 8: Section 2

4 ph61 peristaltic pump to the operator 131212 section 2 to the operator the unit you have purchased has been carefully engineered and manufactured to give you dependable operation. When properly operated and cared for, it will produce a consistent quality product. Like all mechanical products, this...

Page 9

5 ph61 peristaltic pump to the operator 131212 compressor warranty disclaimer the refrigeration compressor(s) on this unit are warranted for the term stated in the limited warranty section in this manual. However, due to the montreal protocol and the u.S. Clean air act amendments of 1990, many new r...

Page 10: Section 3

6 ph61 peristaltic pump safety 131212 section 3 safety we, at taylor company, are concerned about the safety of the operator at all times when they are coming in contact with the unit and its parts. Taylor makes every effort to design and manufacture built-in safety features to protect both operator...

Page 11

7 ph61 peristaltic pump safety an equipotential grounding lug is provided with this unit. Some countries require the grounding lug be properly attached to the rear of the frame by the authorized installer. The installation location is marked by the equipotential bonding symbol (5021 of iec 60417-1) ...

Page 12: Section 4

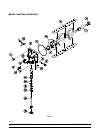

8 ph61 peristaltic pump operator parts identification 140612 section 4 operator parts identification model ph61 figure 1.

Page 13

9 ph61 peristaltic pump operator parts identification 140612 model ph61 parts identification list item description part no. 1 kit a.-cover-hopper x65369 2 agitator x44797 3 pump a.-mix simplified shake x57028-14 4 pan-drip-ht 048204 5 panel-rear 048203 6 guide a.-drip pan-mix pump x48228 7 panel-sid...

Page 14

10 ph61 peristaltic pump operator parts identification 141021 beater and door assembly figure 2.

Page 15

11 ph61 peristaltic pump operator parts identification 141021 beater & door assembly item description part no. 1 shaft-beater*7qt fluted 050985 2 blade-scraper-fcb 16l 041103 3 seal-drive shaft 032560 4 bearing-door-front 1.390 055605 5 o-ring-6 in odx5 3/4 idx 1/8 033493 6 door-1spt 4flv ht tts x55...

Page 16

12 ph61 peristaltic pump operator parts identification 140612 x57028-xx pump a. - mix simplified figure 3 item description part no. 1-7 pump a.-mix simplified shake x57028-14 1 cylinder-pump hopper shake 057944 2 pin-retaining x55450 3 piston-pump-simplified 053526 4 o-ring-pkg *50 to bag* 020051 5 ...

Page 17

13 ph61 peristaltic pump operator parts identification 141021 accessories figure 4 item description part no. 1 tool-seal install- remove 035460 2 lubricant-taylor hi-perf 048232 3 pail-10 qt. 013163 4 bottle-wash-plastic 044818 5 tool-shaft-drive-pump 047919 6 tool-mix pump shaft removal 057167 7 to...

Page 18

14 ph61 peristaltic pump operator parts identification syrup valve figure 5 item description part no. 1-6 valve-syrup 053874 1 cap-syrup valve 053874-001 2 spring-syrup valve 053874-003 3 plunger-syrup valve w/seals 053874-009 3a o-ring-syrup valve plunger l 053874-007 3b plunger-syrup 053874-002 3c...

Page 19

15 ph61 peristaltic pump operator parts identification brush a.-package-ht x44127 figure 6 item description part no. 1 brush-rear brg 1"d x 2"lg x 14 013071 2 brush-double end 013072 3 brush-draw valve 1"od x 2"x17" 013073 4 brush-draw valve 1-1/2"od x 3" 014753 item description part no. 5 brush-1/2...

Page 20: Section 5

16 ph61 peristaltic pump important: to the operator section 5 important: to the operator item description 1 power switch 2 indicator lights 3 flavor selector keypad 4 liquid crystal display 5 keypads symbol definitions to better communicate in the international arena, the words on many of our operat...

Page 21

17 ph61 peristaltic pump important: to the operator power switch the power switch is located under the control panel on the left hand side of the unit. When placed in the on position, the power switch allows softech panel operation. Liquid crystal display the liquid crystal display (lcd) is located ...

Page 22

18 ph61 peristaltic pump important: to the operator operating screen descriptions when the machine is powered the system will initialize. The screen will display “initializing”. There will be four types of data the system will check: language, system data, config data, and lockout data. During the i...

Page 23

19 ph61 peristaltic pump important: to the operator the mix temperature must be raised above 151_f (66.1_c) within 90 minutes or the unit will be locked in standby, and the cycle failure display will appear. In the example, the hopper temperature is 140_f (60_c). The phase shows that the machine is ...

Page 24

20 ph61 peristaltic pump important: to the operator soft lock: if a heat treatment cycle has not been initiated within the last 24 hours, all four led's on the front of the machine will light and a message will appear on the lcd. Line 3 of the lcd will indicate the reason the message appears. Follow...

Page 25

21 ph61 peristaltic pump important: to the operator operator menu the operator menu is used to enter the operator function displays. To access the operator menu, simply press the menu key. The cursor will flash over the letter “a” indicating that this is screen “a”. To select a different screen, use...

Page 26

22 ph61 peristaltic pump important: to the operator 141021 if an invalid date is entered, a second screen will appear. When the sel key is pressed, the previous lcd screen will appear to allow for correction of the entry. The controller will not advance to the daylight saving time screen until a val...

Page 27

23 ph61 peristaltic pump important: to the operator screen “e” is auto heat time. This screen is used to set the time of day in which the unit will automatically enter the heat treatment cycle. Pressing the arrow keys moves the cursor, pressing the plus or minus keys changes the selected digits, and...

Page 28

24 ph61 peristaltic pump important: to the operator screen “h” is the lockout history. This screen displays a history of the last 40 hard locks, soft locks, and brush clean dates. Page numbers are indicated in the upper right hand corner. Page 1 contains the most recent failure. Press the plus key t...

Page 29: Section 6

25 ph61 peristaltic pump operating procedures section 6 operating procedures equipment set up evaluate the condition of lights and screen messages (hard lock or soft lock, etc.) before performing opening procedures. If all four led's on the front of the unit are lit, the unit is locked. (see figure ...

Page 30

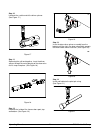

26 ph61 peristaltic pump operating procedures note: to ensure that the mix does not leak out of the back of the freezing cylinder, the middle section of the boot seal should be convex or extend out from the seal. If the middle section of the boot seal is concave or extending into the middle of the s...

Page 31

27 ph61 peristaltic pump operating procedures step 6 place the freezer door o-ring into the groove on the back of the freezer door. Do not lubricate the o-ring. Lubricate the outside diameter of the front bearing. Slide the front bearing into the door hub. (see figure 13.) figure 13 step 7 install t...

Page 32

28 ph61 peristaltic pump operating procedures step 10 lubricate the smaller end of the driven spinner. (see figure 17.) figure 17 step 11 squeezing the split end together, insert the driven spinner through the metal opening of the draw valve until it snaps into place. (see figure 18.) figure 18 step...

Page 33

29 ph61 peristaltic pump operating procedures step 15 with the stopping tab of the draw handle facing down, slide the fork of the draw handle into the slot of the draw valve. Secure the draw handle with the pivot pin. (see figure 22.) figure 22 step 16 lubricate the shaft of the spinner blade up to ...

Page 34

30 ph61 peristaltic pump operating procedures step 19 snap the restrictor cap over the end of the door spout. (see figure 26.) figure 26 step 20 insert the syrup valve retainers and push them down. Install the syrup valve pin retainer. (see figure 27.) figure 27 step 21 slide the long drip pan into ...

Page 35

31 ph61 peristaltic pump operating procedures step 3 apply a thin layer of lubricant to the inside of the pump cylinder at the retaining pin hole end. (see figure 30.) figure 30 step 4 insert the piston into the retaining pin hole end of the pump cylinder. (see figure 31.) figure 31 step 5 assemble ...

Page 36

32 ph61 peristaltic pump operating procedures step 7 insert the valve cap into the hole in the mix inlet adapter. (see figure 34.) figure 34 step 8 insert the mix inlet assembly into the pump cylinder. (see figure 35.) figure 35 note: the adapter must be positioned into the notch located at the end ...

Page 37

33 ph61 peristaltic pump operating procedures step 11 install one red o-ring on each end of the mix feed tube, and thoroughly lubricate. (see figure 38.) figure 38 step 12 lay the pump assembly, pump clip, feed tube, cotter pin and agitator in the bottom of the mix hopper for sanitizing. (see figure...

Page 38

34 ph61 peristaltic pump operating procedures sanitizing step 1 prepare a 2.5 gallon (9.5 liter) pail of a cleaning/sanitizing solution with an active chlorine concentrate of 100 - 200 ppm (parts per million), approved for use by your company. Use warm water and follow the cleaning/sanitizing soluti...

Page 39

35 ph61 peristaltic pump operating procedures step 14 press the wash and pump keys to stop the wash and pump modes. Close the draw valve. (see figure 44.) figure 44 note: be sure your hands are clean and sanitized before going on in these instructions. Step 15 place the agitator on the agitator driv...

Page 40

36 ph61 peristaltic pump operating procedures step 2 when mix stops bubbling down into the freezing cylinder, remove the cotter pin from the outlet fitting of the mix pump. Remove the mix feed tube. Insert the outlet end of the mix feed tube into the mix inlet hole in the mix hopper. Place the inlet...

Page 41

37 ph61 peristaltic pump operating procedures the unit must be in the auto or standby mode before the heat cycle may be started. (see figure 49.) mode: auto mix: ok hopper 40.0f brush clean on: mm/dd figure 49 step 1 prepare the 3-compartment sink for washing, rins- ing, and sanitizing. Fill the fir...

Page 42

38 ph61 peristaltic pump operating procedures step 10 with the syrup port brush, brush each syrup port hole 10 to 15 times. Dip the brush in the cleaning solution before brushing each port. (see figure 52.) figure 52 step 11 with sanitized hands, remove the syrup valve pin retainer and the syrup val...

Page 43

39 ph61 peristaltic pump operating procedures step 16 install the short drip pan in the rear panel. Step 17 use a clean, sanitized towel and wipe down the freezer door and area around the bottom of the freezer door. The heat cycle will start when the clock on the machine reaches the auto heat time s...

Page 44

40 ph61 peristaltic pump operating procedures step 5 return to the unit with a small amount of cleaning/sanitizing solution. With a pail below the door spout, dip the door spout brush into the solution and brush clean the syrup ports in the freezer door, door spout, bottom of the driven spinner and ...

Page 45

41 ph61 peristaltic pump operating procedures step 10 install the shake cup holder. Step 11 raise a syrup valve retainer. Install the syrup valve. Push the syrup valve retainer down to hold the valve in place. Repeat this procedure for each syrup valve. (see figure 61.) figure 61 step 12 when ready ...

Page 46

42 ph61 peristaltic pump operating procedures 141020 calibration procedure step 1 disconnect the syrup valve from the freezer door. Raise the syrup valve retainer and pull the valve straight out. (see figure 64.) figure 64 step 2 hold an empty cup under the syrup valve. (see figure 65.) figure 65 st...

Page 47

43 ph61 peristaltic pump operating procedures 141020 step 8 the pump will automatically stop. If the amount of syrup delivered is 1 fluid oz. (30 ml.), the syrup pump is properly calibrated. Step 9 if less than 1 fluid oz. (30 ml.) of syrup was delivered, turn the corresponding syrup adjustment knob...

Page 48

44 ph61 peristaltic pump operating procedures step 9 press the wash key to start the pump and to prime the syrup line. Step 10 when a steady stream of syrup is flowing from the syrup valve, and all the air has been removed from the syrup line, press the cal key again to stop the pump. Note: there is...

Page 49

45 ph61 peristaltic pump operating procedures 140718 step 5 when the flow of product stops, press the wash and pump keys, cancelling the wash and pump modes, and close the draw valve. Discard this product. (see figure 73.) figure 73 step 6 remove the locking clip, mix feed tube, pump clip and the as...

Page 50

46 ph61 peristaltic pump operating procedures cleaning and sanitizing step 1 prepare a 2.5 gallon (9.5 liter) pail of a cleaning/sanitizing solution with an active chlorine concentrate of 100 - 200 ppm (parts per million), approved for use by your company. Use warm water and follow the cleaning/sani...

Page 51

47 ph61 peristaltic pump operating procedures the following screen is displayed if the machine is not in a brush clean state. (see figure 77.) if any of the requirements for a brush clean have not been met, the time displayed will remain at 5:00 minutes. Power switch off out time: 4:40 out 68.5 hopp...

Page 52

48 ph61 peristaltic pump operating procedures step 8 from the pump cylinder, remove the retaining pin, valve cap, piston, and the feed tube. Remove all o-rings and the check ring. Step 9 remove the pump drive shaft from the drive hub in the rear wall of the mix hopper. Step 10 remove the 2 small o-r...

Page 53

49 ph61 peristaltic pump operating procedures sanitizing the syrup lines the syrup lines must be sanitized weekly. Step 1 prepare a 2.5 gallon (9.5 liter) pail of a cleaning/sanitizing solution with an active chlorine concentrate of 100 - 200 ppm (parts per million), approved for use by your company...

Page 54

50 ph61 peristaltic pump operating procedures step 11 using the white end of the double-ended brush, scrub the inside of the syrup valve body and syrup line to remove any residual particles. Step 12 using a shake cup filled with cleaning/sanitizing solution, rinse the syrup valve body thoroughly. St...

Page 55

51 ph61 peristaltic pump operating procedures step 8 allow the cleaning/sanitizing solution to flow until all of the syrup is flushed from the line. Step 9 press the cal key on the control panel to stop the flow of cleaning solution. Step 10 once the line is free of syrup, remove the syrup feed tube...

Page 56

52 ph61 peristaltic pump operating procedures pump tube installation step 1 lubricate the o-rings on the syrup line fittings with taylor lube hp. (see figure 85.) figure 85 step 2 press the fittings into the new pump tube. Step 3 install the clips into their respective collars. Step 4 using your han...

Page 57: Section 7

53 ph61 peristaltic pump important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following ch...

Page 58

54 ph61 peristaltic pump important: operator checklist 081111 winter storage if the place of business is to be closed during the winter months, it is important to protect the unit by following certain precautions, particularly if the building is to be left unheated and subject to freezing conditions...

Page 59: Section 8

55 ph61 peristaltic pump troubleshooting guide section 8 troubleshooting guide problem probable cause corrective action all four led's are flashing. The unit is locked. See soft lock and hard lock information. Soft lock message appears on lcd. More than 24 hours since the last heat cycle. The unit m...

Page 60

56 ph61 peristaltic pump troubleshooting guide problem corrective action probable cause no product is being dispensed. (cont'd.) air/mix pump is incorrectly assembled or improperly lubricated. Follow assembly procedures carefully. The mix pump ball crank is broken. Call service technician. The pump ...

Page 61

57 ph61 peristaltic pump troubleshooting guide problem corrective action probable cause the mix in the hopper is too warm. Hopper cover is not in position. Clean the hopper cover and place in position. The agitator is not installed. Clean the agitator and install. The hopper temperature is out of ad...

Page 62

58 ph61 peristaltic pump troubleshooting guide problem corrective action probable cause the drive shaft is stuck in the drive coupling. Mix and lubricant collected in drive coupling. Brush clean the rear shell bearing area regularly. Rounded corners of drive shaft, drive coupling or both. Call servi...

Page 63

59 ph61 peristaltic pump troubleshooting guide problem corrective action probable cause machine will not run when in the auto mode. Machine is unplugged. Plug into wall receptacle. Beater motor is out on reset. Clear the tone. Allow the beater motor to cool. Place the power switch to off. Press the ...

Page 64

60 ph61 peristaltic pump troubleshooting guide problem corrective action probable cause syrup flows constantly, or not at all. Difficult to calibrate syrups. Syrup lines are clogged. Disassemble and clean the syrup valves. Flush syrup lines with warm water and sanitize weekly. The pump tube has coll...

Page 65: Section 9

61 ph61 peristaltic pump parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blade-shake x drive shaft seal x freezer door o-ring-shake x front bearing x draw valve o-ring x spinner shaft seal-shake x pivot pin o-ring x rest...

Page 66

62 ph61 peristaltic pump limited warranty on equipment 131212 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer...

Page 67

63 ph61 peristaltic pump limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use...

Page 68: Section 11

64 ph61 peristaltic pump limited warranty on parts 131212 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine rep...

Page 69

65 ph61 peristaltic pump limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal mainte...

Page 70

66 ph61 peristaltic pump limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The or...