- DL manuals

- Taylor

- Freezer

- Taylormate 150

- Operating Instructions Manual

Taylor Taylormate 150 Operating Instructions Manual

Summary of Taylormate 150

Page 1

Models 150, 152, 162, & 168 taylormate soft serve freezers operating instructions 028749-m 6/98.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on data plate: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: amps minimum wire ampacity: amps part numb...

Page 3: Table Of Contents

Table of contents models 150, 152, 162, 168 table of contents ______________________________________________________________________________ section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air cooled units 1 . . . . . . . . . . . ....

Page 4

Models 150, 152, 162, 168 table of contents section 7 important: operator checklist 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting bacterial count 22 . ...

Page 5: Section 1

1 models 150, 152, 162, 168 to the installer 031030 section 1 to the installer air cooled units the models 150 and 152 require a minimum of 6” (152 mm) of clearance around both sides. Install the skirt provided on the right side of the unit and place the back of the unit against a wall to prevent re...

Page 6: Section 2

2 models 150, 152, 162, 168 to the operator 050818 section 2 to the operator the freezer you have purchased has been careeru3n4s50818.

Page 7: Section 3

3 models 150, 152, 162, 168 safety 031030 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and...

Page 8: Section 4

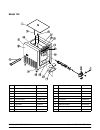

4 models 150, 152, 162, 168 operator parts identification section 4 operator parts identification model 150

Page 9

5 models 150, 152, 162, 168 operator parts identification model 152 item description part no. 1 hopper cover assembly x48690 2 feed tube 025061 3 float a.-mix level x39690 4 back panel 025868-ss 5 left side panel 028591-ss 6 drip pan 027503 7 leg-plastic 024755 8 mix low light 039708 9 right side pa...

Page 10

6 models 150, 152, 162, 168 operator parts identification model 162.

Page 11

7 models 150, 152, 162, 168 operator parts identification model 168.

Page 12

8 models 150, 152, 162, 168 operator parts identification models 150 & 152 door assembly.

Page 13

9 models 150, 152, 162, 168 operator parts identification models 162 & 168 door assembly.

Page 14: Section 5

10 models 150, 152, 162, 168 important: to the operator section 5 important: to the operator figure 1 item description 1 push button switch 2 power switch 3 temperature control 4 mix refrigeration switch 5 indicator lights -- “mix low” symbol definitions to better communicate in the international ar...

Page 15

11 models 150, 152, 162, 168 important: to the operator push-button switch if an overload condition occurs, the freezer will automatically stop operating. To properly reset the freezer, place the toggle switch in the “off” position. Wait two or three minutes; then press the push-button switch. Place...

Page 16

12 models 150, 152, 162, 168 important: to the operator mix refrigeration switch the mix refrigeration switch is located under the control channel and is used for several purposes: 1. For the unit to operate in the “auto” mode, the mix refrigeration switch must be “on”. 2. For the separate hopper re...

Page 17: Section 6

13 models 150, 152, 162, 168 operating procedures section 6 operating procedures the model 150 has been selected to illustrate the pictured step-by-step operating procedures. All models in this manual are similar. They each have a 1.5 quart (1.4 liter) capacity freezing cylinder. The mix flows by gr...

Page 18

14 models 150, 152, 162, 168 operating procedures 060421 assembly note: when lubricating parts, use an approved food grade lubricant (example: taylor lube). Step 1 install the beater assembly. Slide the small, thick o-ring into the groove on the drive shaft of the beater assembly. Apply an even coat...

Page 19

15 models 150, 152, 162, 168 operating procedures step 4 install the freezer door. With both hands, hold the sides of the freezer door and insert the baffle rod(s) into the center of the beater assembly(ies). The white guide bearing(s) must fit securely in the hole(s) of the drive shaft(s). Finger-t...

Page 20

16 models 150, 152, 162, 168 operating procedures step 6 install the draw valve handle. Insert the valve lifter arm through the slotted opening in the draw valve and align the other end with the cross holes of the freezer door. Hint: the valve lifter arm may be aligned with the left or right cross h...

Page 21

17 models 150, 152, 162, 168 operating procedures note: models 162/168 have three draw handles. Slide the tip of the draw handle into the slot of the draw valve, starting from the right. Slide the short pivot pin through the far right draw handle. Slide the long pivot pin through the far left and mi...

Page 22

18 models 150, 152, 162, 168 operating procedures.

Page 23

19 models 150, 152, 162, 168 operating procedures 031030 priming prime the machine as close as possible to the time of first product draw. Step 1 with a pail beneath the door spout, raise the draw valve. Fill the mix hopper with fresh mix. (maximum hopper capacity is 8 quarts [7.6 liters].) allow th...

Page 24

20 models 150, 152, 162, 168 operating procedures step 6 slide the rear drip pan into the hole in the side panel. Figure 33 closing procedure to disassemble the models 150/152/162/168, the following items will be needed: s two cleaning pails s sanitized stainless steel rerun can with lid s necessary...

Page 25

21 models 150, 152, 162, 168 operating procedures when the solution stops flowing from the door spout, lower the draw valve and place the power switch in the “off” position. Repeat steps 1 through 5 for the other side of the freezer on models 162/168. Disassembly step 1 be sure the power switch is i...

Page 26: Section 7

22 models 150, 152, 162, 168 important: operator checklist 080107 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly....

Page 27

23 models 150, 152, 162, 168 important: operator checklist 051215 j 5. If your machine is air cooled, check the condenser for an accumulation of dirt and lint. A dirty condenser will reduce the efficiency and capacity of the machine. Condensers should be cleaned monthly with a soft brush. Never use ...

Page 28: Section 8

24 models 150, 152, 162, 168 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. The power switch is in the “off” position. A. Place the power switch in the “auto” position. 19 b. The mix level is inadequate in the mix hoppe...

Page 29

25 models 150, 152, 162, 168 troubleshooting guide problem probable cause remedy page ref. 4. The product is too soft. A. The temperature control or the t.Q.C. Is set too warm. A. Adjust the temperature control. If t.Q.C., contact service technician. 11 b. The air tube is not installed. B. Install t...

Page 30

26 models 150, 152, 162, 168 troubleshooting guide problem probable cause remedy page ref. 9. The unit goes out on overload excessively. A. There are too many appliances plugged into the circuit. A. A separate 20 amp. Circuit is needed for the freezer to operate properly. - - - b. An extension cord ...

Page 31: Section 9

27 models 150, 152, 162, 168 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. 150/152 162/168 beater drive shaft o-ring x 1 2 freezer door o-ring x 1 2 freezer door front bearing x 1 2 freezer door guide bearing x 1 2 draw v...

Page 32: Section 10

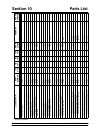

Section 10 parts list + available separately 28 parts list models 150, 152, 162, 168 de s cri p t io n part num be r 150 qty . 152 qty . 162 qty . 168 qty . W arr. Cl as s re m arks part s up da t e bear in g --f r o n t 023262 1 1 2 2 000 bear in g --g u id e 014496 1 1 2 2 000 bear in g --r ear sh...

Page 33

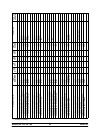

29 + available separately models 150, 152, 162, 168 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r + r el a y --st ar t --c o m pr esso r 047609 1 103 115- 60- 1 + c a p a c it o r --r u n -- 15u f /370v 027087 1 103 230- ...

Page 34

+ available separately 30 parts list models 150, 152, 162, 168 de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r d e c a l- -d e c --t a y lo r 162/ 168 047666 1 1 000 de ca l- -m ix re f. S ta ndb y o f f --on 022177 1 1 1 000 de ca l-...

Page 35

31 + available separately models 150, 152, 162, 168 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r g u a r d --s w it c h *150 --2* 025496 1 1 103 g u ar d --p o w er & d an fo ss switc h 035548 1 1 103 g u id ea .-- d r i...

Page 36

+ available separately 32 parts list models 150, 152, 162, 168 de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r o --r in g --13/ 16 o d x .139w 021278 2 2 000 o --r in g --2 --3/ 4 o d x .139w 019998 2 2 000 o --r in g --5 /1 6 o d x ....

Page 37

33 + available separately models 150, 152, 162, 168 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r p a n e l- -i n s e r t *150* 025533 --s s 1 103 p a n e l- -t o p b a c k *168* 030790 --s s 1 103 p a n e l- -l o w e r s...

Page 38

+ available separately 34 parts list models 150, 152, 162, 168 de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r + s t u d --n o s e c o n e --5 /1 6- -18x 5/ 16 --18 013496 2 2 2 2 103 s h ie ld --s p la s h 11 --1/ 4 x 4- -13/ 16 0250...

Page 39

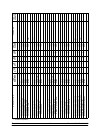

35 + available separately models 150, 152, 162, 168 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r nut --p u s h on --1 /2 d ia .S ha f t 039735 2 2 000 s c r e w --4 --4 0x 1 r hh ds t e e l- -z p 028890 2 2 000 + s p r i...

Page 40

+ available separately 36 parts list models 150, 152, 162, 168 de s cri p t io n part s up da t e re m arks w arr. Cl as s 168 qty . 162 qty . 152 qty . 150 qty . Part num be r v a lv e --e p r 1/ 4s 022665 1 1 1 103 sh r v a lv e --exp --au to --1 /4 s x 1/4 fpt 047232 1 1 2 2 103 + b o o t --exp a...

Page 41

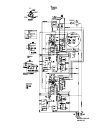

Model 150 050416-12.

Page 42

Model 150 050416-27.

Page 43

Model 150 050416-40

Page 44

Model 152 047514.

Page 45

Models 162/168 050205-12.

Page 46

Models 162/168 050205-27.

Page 47

Models 162/168 050205-40s.