- DL manuals

- U-Line

- Refrigerator

- CLRCO2075

- Service And Parts Manual Supplement

U-Line CLRCO2075 Service And Parts Manual Supplement

Service and Parts Manual

Supplement

For Model

CLRCO2075

U-Line Corporation

U-Line Corporation

8900 North 55th Street

PO Box 245040

Milwaukee, WI 53223

Milwaukee, WI 53224-9540

www.U-LineService.com

Phone (414) 354-0300 • FAX (414) 354-7905

Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696

R

Summary of CLRCO2075

Page 1

Service and parts manual supplement for model clrco2075 u-line corporation u-line corporation 8900 north 55th street po box 245040 milwaukee, wi 53223 milwaukee, wi 53224-9540 www.U-lineservice.Com phone (414) 354-0300 • fax (414) 354-7905 service & parts tech lines phone (800) 779-2547 • fax (414) ...

Page 2: Introduction

Introduction 2 design ■ features ■ performance introduction three generations of pride and quality manufacturing and design improvements are built into all u-line products. The result: u-line leads the market with innovative technology and superior craftsmanship. This manual contains specific instru...

Page 3: Introduction

Introduction 3 design ■ features ■ performance serial number format the serial number is divided into four segments. A typical serial number is 035497-03-0004. The first two digits of the first segment, 03, represents the year the unit was made. The next four digits of the first segment, 5497, repre...

Page 4: Introduction

Introduction 4 design ■ features ■ performance notes.

Page 5: Introduction

Introduction 5 design ■ features ■ performance table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 serial number format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6: General Information

General information 6 design ■ features ■ performance limited warranty u-line corporation warrants each u-line product to be free from defects in materials and workmanship for a period of one year from the date of purchase; and warrants the sealed system (consisting of the com- pressor, the condense...

Page 7: General Information

General information 7 design ■ features ■ performance warranty claims procedure when submitting claims for warranty payment, please follow these guidelines. You can use any form you would normally use to bill your customer (your own computer generated form, narda, usa, etc.). The model and serial nu...

Page 8: General Information

8 design ■ features ■ performance safety precautions do not attempt to service or repair the unit until you have read the entire procedure. Safety items through- out this manual are labeled with warning or caution. General information warning means that failure to follow this safety statement may re...

Page 9: Servicing

9 design ■ features ■ performance servicing electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. These pins should never measure any resistance to ground. This would indicate a shor...

Page 10: Servicing

10 design ■ features ■ performance leveling and installation requirements it is extremely important that the unit is level. If it is not level, the ice mold will not fill evenly. This can cause a reduction in ice rate, uneven sized cubes or water spilling into the storage area which will cause the i...

Page 11: Servicing

11 design ■ features ■ performance gravity drain installation these guidelines must be followed when installing drain lines to prevent water from flowing back into the ice maker storage bin and potentially flowing onto the floor causing water damage: • drain lines and fittings must have a 5/8" insid...

Page 12: Servicing

12 design ■ features ■ performance connecting a drain pump if a gravity drain connection is not available, u-line strongly recommends the use of the u-line p60 drain pump. If your clrco2075 is not equipped with a factory installed pump, a p60 drain pump is available through your dealer, or direct fr...

Page 13: Servicing

13 design ■ features ■ performance servicing self-cleaning cycle instructions to maintain operational efficiency, clean unit every six months (depending on water conditions more or less frequent cleaning may be necessary). If the ice maker requires more frequent cleaning, consult a quali- fied plumb...

Page 14: Servicing

14 design ■ features ■ performance interior storage bin cleaning 1. Disconnect power from the ice maker. 2. Remove any ice from the storage bin. 3. Wipe down the storage bin with a solution of non-abrasive mild soap or detergent and warm water. Rinse with clean water. Sanitize the bin with a solutio...

Page 15: Servicing

15 design ■ features ■ performance 6. When the initial three-minute fill cycle is complete, the unit will enter ice making and refrigeration mode (1) if the bin is empty or below the sensor. However, after the first slab of cubes is harvested, the controller will follow the logic defined in #5 above...

Page 16: Servicing

16 design ■ features ■ performance sequence of operation mode 1: ice making and refrigeration ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator re...

Page 17: Servicing

17 design ■ features ■ performance servicing mode 2: ice making and no refrigeration ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator refrigerati...

Page 18: Servicing

18 design ■ features ■ performance servicing mode 3: refrigeration and no ice making ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator refrigerati...

Page 19: Servicing

19 design ■ features ■ performance servicing mode 4: ice harvest (no refrigeration possible) ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator ref...

Page 20: Servicing

20 design ■ features ■ performance mode 5: all satisfied ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator refrigeration h2o in - water supply cir...

Page 21: Servicing

21 design ■ features ■ performance mode 6: water fill - no refrigeration required ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator refrigeration ...

Page 22: Servicing

Design ■ features ■ performance mode 7: cleaning (no refrigerator possible) ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve dryer discharge tube suction tube accumulator refrigeration h2o in...

Page 23: Servicing

23 design ■ features ■ performance servicing mode 8: water fill with refrigeration required (note: normal start-up with a warm refrigerator) ice maker evaporator comp - compressor condenser bypass valve (upper) valve (lower) refrigeration refrigerator evaporator capillary tube hot gas bypass valve d...

Page 24: Servicing

24 design ■ features ■ performance thermistors condenser thermistor the condenser thermistor senses the refrigeration system “high side” temperature. This is used in conjunc- tion with the control board to determine the length of the freeze and harvest cycles. Thermistors generally fail due to moist...

Page 25: Servicing

25 design ■ features ■ performance controller the temperature controller is located below the clear ice maker. It consists of an led display, three led status indicator lights and three touchpad buttons. The led display shows the refrigerator temperature set point and is calibrated in degrees fahren...

Page 26: Servicing

26 design ■ features ■ performance led status meaning 1 solid refrigerator temperature displayed flashing not applicable 2 solid service menu – wait 10 seconds and it will exit automatically flashing open thermistor – refer to thermistors. 3 solid service menu – wait 10 seconds and it will exit auto...

Page 27: Servicing

Check lights on control board the lights on the control board indicate power to the labeled component. The exception is the “ref valve” (refrigeration valve). When this light is off, the refrigeration bypass valve is powered. 1. Pwr 5. Hot gas 2. Ref valve 6. H2o in – water inlet 3. Fan 7. Comp 4. H...

Page 28: Servicing

28 design ■ features ■ performance compressor comp to energize the compressor touch the previously disconnected pink lead back to the board. You should hear the compressor start up and the green comp light will illuminate. If it does not start check voltage at the compressor and at the output from t...

Page 29: Servicing

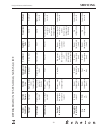

Refrigera tion system diagnosis guide system suction suction compressor condenser capillary evaporator w attage condition pressure line discharge tube normal normal slightly below v ery hot v ery hot w arm cold normal room temperature overcharge higher than v ery cold slightly warm hot to warm cool ...

Page 30: Servicing

30 design ■ features ■ performance ice thickness adjustment your u-line clear ice maker uses advanced technology to make ice that is crystal clear. This technology cascades a flow of water over a chilled ice mold that is mounted vertically so no water sits in it. Because of this ice making technolog...

Page 31: Servicing

31 design ■ features ■ performance 1. Disconnect power to the unit. Access cover 2. Remove the screws securing the front access panel. Ice thickness adjustment dial clrco031 0 1 2 -2 3 4 5 -5 -4 -3 -1 dial is factory set to “0” ice cube thickness adjustment dial clrco030 warmer colder set temp acces...

Page 32: Servicing

32 design ■ features ■ performance 3. Locate the ice cube thickness adjustment dial on the control board. Turn the dial clockwise (+ number) to thicken or counterclockwise (- number) to thin the ice bridge. Ice cube mold 4. Reinstall front access cover. 5. Reconnect power to ice maker. 6. Empty ice ...

Page 33: Servicing

33 design ■ features ■ performance servicing troubleshooting 1 not refrigerating (compressor and fan are operating) cause remedy a. Little or no frost pattern on evaporator a. Check for sealed system leak or restriction 2 not refrigerating (compressor not operating, fan operating) cause remedy a. Wi...

Page 34: Servicing

34 design ■ features ■ performance servicing 8 no ice production cause remedy a. No water supplied to unit a. Check that water is connected and turned on b. Stand pipe not inserted in water trough b. Insert stand pipe securely into water trough 9 low ice production cause remedy a. High ambient tempe...

Page 35: Servicing

35 design ■ features ■ performance servicing clr2075 wiring diagram clrco028 -1 -2 -3 -4 -5 5 4 3 2 1 0 white green red black red black white green this side to display 10 9 8 7 6 5 4 3 2 1 thermistors: ice/ref 1 and 2 cond to 3 and 4 ref to 5 and 6.

Page 36: Servicing

36 design ■ features ■ performance servicing parts listing how to order replacement parts 1. Locate the illustration(s) for the model you are servicing. 2. Refer to the area where the desired part would be installed, locate the part and note the item number assigned to it. 3. Locate the item number ...

Page 37: Clrco2075 Model

37 design ■ features ■ performance clrco2075 model notes.

Page 38: Clrco2075 Model Parts

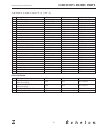

Model clrco2075 (1 of 3) clrco032 2 3 4 5 6 10 11 12 13 14 15 16 17 18 22 23 24 25 26 27 7 1 8 21 20 19 9 38 design ■ features ■ performance clrco2075 model parts.

Page 39: Clrco2075 Model Parts

39 design ■ features ■ performance model clrco2075 (1 of 3) clrco2075 model parts parts not shown item description white black stainless steel 1 door assembly 80-17019-02 80-17019-01 see parts not shown 2 door handle top 11926-4-kit 11926-4-blk see parts not shown 3 door handle bottom 11927-4-kit 11...

Page 40: Clrco2075 Model Parts

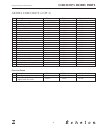

40 design ■ features ■ performance clrco2075 model parts model clrco2075 (2 of 3) clrco033 16 1 15 17 18 19 20 21 22 23 2 3 4 5 6 7 8 9 10 11 12 13 14.

Page 41: Clrco2075 Model Parts

Model clrco2075 (2 of 3) 41 design ■ features ■ performance clrco2075 model parts item description white black stainless steel 1 cover - front 12070-01 12070-01 12070-01 2 evaporator assembly 2276-clrco-s 2276-clrco-s 2276-clrco-s 3 water dispersion receptacle 11812 11812 11812 4 tube retainer 26009...

Page 42: Clrco2075 Model Parts

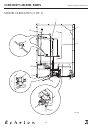

42 design ■ features ■ performance clrco2075 model parts model clrco2075 (3 of 3) clrco034 5 4 9 10 13 2 1 6 7 8 3 14 11 12.

Page 43: Clrco2075 Model Parts

43 design ■ features ■ performance clrco2075 model parts item description white black stainless steel 1 heat exchanger assembly 72006-s 72006-s 72006-s 2 back panel 11969-02 11969-02 11969-02 3 valve manifold assembly 80-37005-00-s 80-37005-00-s 80-37005-00-s 4 power cord 2894 2894 2894 5 water valv...

Page 44

44 design ■ features ■ performance notes.

Page 45

45 design ■ features ■ performance notes.

Page 46

46 design ■ features ■ performance notes.

Page 47

47 fax parts order form fax # 414-354-7905 account# ____________________________________ bill to: ______________________________________ ____________________________________________ ____________________________________________ date:________________________________________ phone#_____________________...

Page 48

P.O. Box 245040 milwaukee, wi 53224-9540 phone 414.354.0300 fax 414.354.7905 printed in u.S.A. – a ugust 2003 ulin 9332 p/n 30018.