- DL manuals

- Vacon

- Media Converter

- 20

- Complete User's Manual

Vacon 20 Complete User's Manual

Summary of 20

Page 1

Vacon ® 20 ac drives complete user manual phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 3

1 1.Safety 1 1.1warnings 1 1.2safety instructions 3 1.3earthing and earth fault protection 3 1.4before running the motor 5 2.Receipt of delivery 7 2.1type designation code 7 2.2storage 7 2.3maintenance 8 2.3.1capacitor recharge 8 2.4warranty 9 2.5manufacturer’s declaration of conformity 10 3.Install...

Page 4

1 7.4navigation on the vacon 20 control panel 58 7.4.1main menu 58 7.4.2reference menu 59 7.4.3monitoring menu 60 7.4.4parameter menu 65 7.4.5system menu 67 8.Standard application parameters 69 8.1quick setup parameters (virtual menu, shows when par. 17.2 = 1) 70 8.2motor settings (control panel: me...

Page 5

1 9.15application setting (control panel: menu par->p17) 134 9.16system parameter 136 9.17modbus rtu 138 9.17.1termination resistor 138 9.17.2modbus address area 138 9.17.3modbus process data 139 10.Technical data 143 10.1vacon 20 technical data 143 10.2power ratings 145 10.2.1vacon 20 – mains volta...

Page 6

1 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 7

Safety vacon • 1 1 1. Safety only a competent electrician is allowed to carry out the electrical installation! This manual contains clearly marked cautions and warnings which are intended for your personal safety and to avoid any unintentional damage to the product or con- nected appliances. Please ...

Page 8

2 • vacon safety 1 after disconnecting the frequency converter from the mains, wait until the fan stops and the indicators on the display go out. Wait 5 more minutes before doing any work on vacon 20 connections. The motor can start automatically after a fault situation, if the autoreset function ha...

Page 9

Safety vacon • 3 1 1.2 safety instructions the vacon 20 frequency converter has been designed for fixed installations only. Do not perform any measurements when the frequency con- verter is connected to the mains. Do not perform any voltage withstand tests on any part of vacon 20. The product safety...

Page 10

4 • vacon safety 1 mi4 mi5 • the earth fault protection inside the frequency converter protects only the converter itself against earth faults. • if fault current protective switches are used they must be tested with the drive with earth fault currents that are possible to arise in fault situations....

Page 11

Safety vacon • 5 1 1.4 before running the motor checklist: before starting the motor, check that the motor is mounted properly and ensure that the machine connected to the motor allows the motor to be started. Set the maximum motor speed (frequency) according to the motor and the machine connected t...

Page 12

6 • vacon safety 1 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 13

Receipt of delivery vacon • 7 2 2. Receipt of delivery after unpacking the product, check that no signs of transport damages are to be found on the product and that the delivery is complete (compare the type designation of the product to the code below). Should the drive have been damaged during the...

Page 14

8 • vacon receipt of delivery 2 2.3 maintenance in normal operating conditions, vacon 20 frequency converters are maintenance- free. However, regular maintenance is recommended to ensure a trouble-free oper- ating and a long lifetime of the drive. We recommended to follow the table below for mainten...

Page 15

Receipt of delivery vacon • 9 2 2.4 warranty only manufacturing defects are covered by the warranty. The manufacturer as- sumes no responsibility for damages caused during or resulting from transport, re- ceipt of the delivery, installation, commissioning or use. The manufacturer shall in no event a...

Page 16

10 • vacon receipt of delivery 2 2.5 manufacturer’s declaration of conformity eu declaration of conformity we manufacturer's name: vacon oyj manufacturer's address: p.O.Box 25 runsorintie 7 fin-65381 vaasa finland hereby declare that the product product name: vacon 20 frequency converter model desig...

Page 17

Installation vacon • 11 3 3. Installation 3.1 mechanical installation there are two possible ways to mount vacon 20 in the wall. For mi1-mi3, either screw or din-rail mounting; for mi4-mi5, screw or flange mounting. Figure 3.1: screw mounting, mi1 - mi3 figure 3.2: screw mounting, mi4 - mi5 note! Se...

Page 18

12 • vacon installation 3 figure 3.3: din-rail mounting, mi1 - mi3 figure 3.4: flange mounting, mi4 - mi5 1 2 loc rem back reset ok phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 19

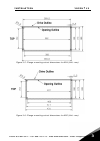

Installation vacon • 13 3 figure 3.5: flange mounting cutout dimensions for mi4 (unit: mm) figure 3.6: flange mounting cutout dimensions for mi5 (unit: mm) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 20

14 • vacon installation 3 figure 3.7: flange mounting depth dimensions for mi4 and mi5 (unit: mm) mi5 mi4 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 21

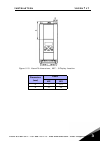

Installation vacon • 15 3 3.1.1 vacon 20 dimensions figure 3.8: vacon 20 dimensions, mi1 - mi3 figure 3.9: vacon 20 dimensions, mi4 - mi5 w2 w3 w (w1) h (h1) h2 h3 d2 d (d1) w2 w3 h (h1) w (w1) d (d1) h3 h2 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 22

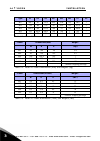

16 • vacon installation 3 type h1 h2 h3 w1 w2 w3 d1 d2 mi1 160.1 147 137.3 65.5 37.8 4.5 98.5 7 mi2 195 183 170 90 62.5 5.5 101.5 7 mi3 254.3 244 229.3 100 75 5.5 108.5 7 mi4 370 350.5 336.5 165 140 7 165 - mi5 414 398 383 165 140 7 202 - table 3.1: vacon 20 dimensions in millimetres frame dimension...

Page 23

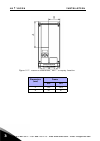

Installation vacon • 17 3 figure 3.10: vacon20 dimensions, mi2 - 3 display location dimensions (mm) frame mi2 mi3 a 17 22.3 b 44 102 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 24

18 • vacon installation 3 figure 3.11: vacon20 dimensions, mi4 - 5 display location dimensions (mm) frame mi2 mi3 a 205 248.5 b 87 87 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 25

Installation vacon • 19 3 3.1.2 cooling enough free space shall be left above and below the frequency converter to ensure sufficient air circulation and cooling. You will find the required dimensions for free space in the table below. If several units are mounted above each other the required free s...

Page 26

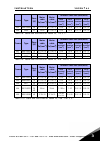

20 • vacon installation 3 3.1.3 power losses if the operator wants to raise the switching frequency of the drive for some reason (typically e.G. In order to reduce the motor noise), this inevitably affects the power losses and cooling requirements, for different motor shaft power, operator can se- l...

Page 27

Installation vacon • 21 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 28

22 • vacon installation 3 mi1 - mi5 3p 230 v power loss phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 29

Installation vacon • 23 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 30

24 • vacon installation 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 31

Installation vacon • 25 3 mi1 - mi3 1p 230 v power loss phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 32

26 • vacon installation 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 33

Installation vacon • 27 3 3.1.4 emc levels en61800-3 defines the division of frequency converters into four classes according to the level of electromagnetic disturbances emitted, the requirements of a power system network and the installation environment (see below). The emc class of each product i...

Page 34

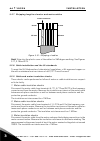

28 • vacon installation 3 3.1.5 changing the emc protection class from c2 or c3 to c4 the emc protection class of mi1-3 frequency converters can be changed from class c2 or c3 to class c4 by removing the emc-capacitor disconnecting screw , see fig- ure below. Mi4 & 5 can also be changed by removing ...

Page 35

Installation vacon • 29 3 figure 3.15: emc protection class, mi5 figure 3.16: jumpers • remove the main cover and locate the two jumpers. • disconnect the rfi-filters from ground by lifting the jumpers up from their default positions. See figure 3.11 phone: 800.894.0412 - fax: 888.723.4773 - web: ww...

Page 36

30 • vacon installation 3 3.2 cabling and connections 3.2.1 power cabling note! Tightening torque for power cables is 0.5 - 0.6 nm (4-5 in.Lbs). Figure 3.17: vacon 20 power connections, mi1 figure 3.18: vacon 20 power connections, mi2 - mi3 1~ (230v) 3~ (230v, 400v) motor out mains motor strip the p...

Page 37

Installation vacon • 31 3 figure 3.19: vacon 20 power connections, mi4 figure 3.20: vacon 20 power connections, mi5 mains motor motor out brake resistor 3~ (380, 480v) mains motor motor out brake resistor 3~ (380, 480v) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrw...

Page 38

32 • vacon installation 3 3.2.2 control cabling figure 3.21: mount the pe-plate and api cable support, mi1 - mi3 attach this plate before installing the power cables attach the support after installing the power cables phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwt...

Page 39

Installation vacon • 33 3 figure 3.22: mount the pe-plate and api cable support, mi4 - mi5 attach the support after installing attach this plate before installing the power cables phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 40

34 • vacon installation 3 figure 3.23: open the lid, mi1 - mi3 figure 3.24: open the lid, mi4 - mi5 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 41

Installation vacon • 35 3 figure 3.25: install the control cables. Mi1 - mi3. See chapter 6.2 figure 3.26: install the control cables. Mi4 - mi5. See chapter 6.2 strip the plastic cable coating for 360 ° earthing control cable tightening torque: 0.4 nm phone: 800.894.0412 - fax: 888.723.4773 - web: ...

Page 42

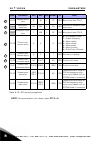

36 • vacon installation 3 3.2.3 allowed option boards in vacon20 see below for the allowed option boards in the slot: note! Opt-b1 and opt-b4 only support external power supply. Option board assembly structure: 6/27 ( ( ( ( % % % % % %+ %) 1 2 3 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clr...

Page 43

Installation vacon • 37 3 4 5 6 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 44

38 • vacon installation 3 3.2.4 screw of cables figure 3.27: mi1 screws figure 3.28: mi2 screws m4*8 screws 12pcs m4*8 screws 10pcs phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 45

Installation vacon • 39 3 figure 3.29: mi3 screws figure 3.30: mi4 - mi5 screw m4*8 screws 10pcs m4*10 screws 4pcs m4*17 screws 6pcs m4*9 screws 14pcs phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 46

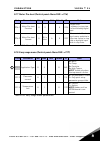

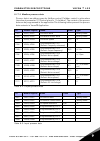

40 • vacon installation 3 3.2.5 cable and fuse specifications use cables with heat resistance of at least +70 °c. The cables and the fuses must be dimensioned according to the tables below. Installation of cables according to ul regulations is presented in chapter 3.2.8. The fuses function also as c...

Page 47

Installation vacon • 41 3 frame type fuse [a] mains cable cu [mm 2 ] motor cable cu [mm 2 ] terminal cable size (min/max) main terminal [mm 2 ] earth terminal [mm 2 ] control terminal [mm 2 ] relay terminal [mm 2 ] mi2 0001-0004 20 2*2.5+2.5 3*1.5+1.5 1.5-4 1.5-4 0.5-1.5 0.5-1.5 mi3 0005 32 2*6+6 3*...

Page 48

42 • vacon installation 3 note! To fulfil standard en61800-5-1, the protective co nductor should be at least 10 mm 2 cu or 16 mm 2 al . Another possibility is to use an additional protective con- ductor of at least the same size as the original one. Frame type fuse [a] mains cable cu [mm 2 ] motor c...

Page 49

Installation vacon • 43 3 3.2.6 general cabling rules 1 before starting the installation, check that none of the components of the fre- quency converter is live. 2 place the motor cables sufficiently far from other cables: • avoid placing the motor cables in long parallel lines with other cables. • ...

Page 50

44 • vacon installation 3 3.2.7 stripping lengths of motor and mains cables figure 3.31: stripping of cables note! Strip also the plastic cover of the cables for 360 degree earthing. See figures 3.17, 3.18 and 3.25. 3.2.8 cable installation and the ul standards to meet the ul (underwriters laborator...

Page 51

Commissioning vacon • 45 4 4. Commissioning before commissioning, read the warnings and instructions listed in chapter 1! 4.1 commissioning steps of vacon 20 1 read carefully the safety instructions in chapter 1 and follow them. 2 after the installation, make sure that: • both the frequency converte...

Page 52

46 • vacon commissioning 4 7 perform test run without motor . Perform either test a or test b: a) control from the i / o terminals: • turn the start/stop switch to on position. • change the frequency reference (potentiometer). • check the monitoring menu and make sure that the value of output fre- q...

Page 53

Fault tracing vacon • 47 5 5. Fault tracing when a fatal fault is detected by the frequency converter control electronics, the drive will stop and the symbol ft and the fault code blinked on the display are in the following format, e.G.: the active fault can be reset by pressing back / reset button ...

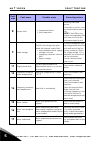

Page 54

48 • vacon fault tracing 5 8 system fault • component failure • faulty operation reset the fault and restart. If the fault re-occurs, con- tact the distributor near to you. Note! If fault f8 occurs, find out the subcode of the fault from the fault his- tory menu under id xxx! 9 under voltage the dc-...

Page 55

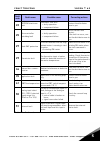

Fault tracing vacon • 49 5 22 eeprom checksum fault parameter save fault • faulty operation • component failure contact the distributor near to you. 25 microcontroller watchdog fault • faulty operation • component failure reset the fault and restart. If the fault re-occur, con- tact the distributor ...

Page 56: 111

50 • vacon fault tracing 5 52 door panel fault control place is keypad, but door panel has been disconnected. Check the connection between optional board and api. If connection is correct, contact the near- est vacon distributor. 53 fieldbus fault the data connection between the fieldbus master and ...

Page 57

Vacon 20 api vacon • 51 6 6. Vacon 20 application interface 6.1 introduction there is only one version of control board available for the vacon 20 drive: this section provides you with a description of the i / o-signals for vacon 20 and in- structions for using the vacon 20 general purpose applicati...

Page 58

52 • vacon vacon 20 api 6 • protections and supervisions (all fully programmable; off, alarm, fault): • analog input low fault • external fault • undervoltage fault • earth fault • motor thermal, stall and underload protection • fieldbus communication • output phase fault • thermistor fault • 8 pres...

Page 59

Vacon 20 api vacon • 53 6 6.2 control i / o terminal signal factory preset description 1 +10 vref ref. Voltage out maximum load 10 ma 2 ai1 analog signal in 1 freq. Reference p) 0 - 10 v, ri >= 200 k 3 gnd i / o signal ground 6 24 vout 24 v output for di's %, max. Load 50 ma 7 di_c digital input com...

Page 60

54 • vacon vacon 20 api 6 figure 6.1: microswitchs vacon 20 i / o terminals: 22 ro 13 relay out 1 active = run p) max. Switching load: 250 vac / 2 a or 250 vdc / 0.4 a 23 ro 14 24 ro 22 relay out 2 active = fault p) max. Switching load: 250 vac / 2 a or 250 vdc / 0.4 a 25 ro 21 26 ro 24 terminal sig...

Page 61

Control panel vacon • 55 7 7. Control panel 7.1 general the panel is an irremovable part of the drive consisting of corresponding control board; the overlay with display status on the cover and the button are in clarifica- tions in the user language. The user panel consists of an alphanumeric lcd di...

Page 62

56 • vacon control panel 7 figure 7.1: vacon 20 control panel 7.3 keypad the keypad section of the control panel consists of 9 buttons (see figure 7.1). The buttons and their functions are described as table 7.1. The drive stops by pressing the keypad stop button, regardless of the selected con- tro...

Page 63: Back

Control panel vacon • 57 7 note! The status of all the 9 buttons are available for application program! Symbol button name function description start motor start from the panel stop motor stop from the panel ok used for confirmation.Enter edit mode for parameter. Alternate in display between the par...

Page 64

58 • vacon control panel 7 7.4 navigation on the vacon 20 control panel this chapter provides you with information on navigating the menus on vacon 20 and editing the values of the parameters. 7.4.1 main menu the menu structure of vacon 20 control software consists of a main menu and sev- eral subme...

Page 65

Control panel vacon • 59 7 7.4.2 reference menu figure 7.3: reference menu display move to the reference menu with the up / down button (see figure 7.2). The refer- ence value can be changed with up / down button as shown in figure 7.3. If the value has big change, first press left and right buttons...

Page 66

60 • vacon control panel 7 7.4.3 monitoring menu figure 7.4: monitoring menu display monitoring values are actual values of measured signals as well as status of some control settings. It is visible in vacon 20 display, but it can not be edited. The moni- toring values are listed in table 7.2. Press...

Page 67

Control panel vacon • 61 7 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 68

62 • vacon control panel 7 code monitoring signal unit id description v1.1 output frequency hz 1 output frequency to motor v1.2 frequency reference hz 25 frequency reference to motor con- trol v1.3 motor speed rpm 2 calculated motor speed v1.4 motor current a 3 measured motor current v1.5 motor torq...

Page 69

Control panel vacon • 63 7 v2.14 die1, die2, die3 33 this monitor value shows status of the digital inputs 1-3 from option board, hidden until an option board is connected v2.15 die4, die5, die6 34 this monitor value shows status of the digital inputs 4-6 from option board, hidden until an option bo...

Page 70

64 • vacon control panel 7 v3.2 application status word 89 bit codes status of application: b3 = ramp 2 active b5 = remote ctrl place 1 active b6 = remote ctrl place 2 active b7 = fieldbus control active b8 = local control active b9 = pc control active b10 = preset frequencies active v3.3 din status...

Page 71

Control panel vacon • 65 7 7.4.4 parameter menu in parameter menu only the quick setup parameter list is shown as default. By giving the value 0 to the parameter 17.2, it is possible to open other advanced parameter groups. The parameter lists and descriptions can be found in chapters 8 and 9. The f...

Page 72

66 • vacon control panel 7 in edit mode, left and right buttons are used to select the digit which has to be changed, and up increases / down decreases parameter value. In edit mode, the value of px.X is displayed blinkingly in the panel. After about 10 s, px.X is displayed in the panel again if you...

Page 73

Control panel vacon • 67 7 7.4.5 system menu sys menu including fault submenu, field bus submenu and system parameter sub- menu, and the display and operation of the system parameter submenu is similar to par menu or mon menu.In system parameter submenu, there are some editable parameter (p) and som...

Page 74

68 • vacon control panel 7 note! Fault history can be reset by long pressing the back / reset button for 5 second time,when the api is in fault history sub- menu level (f6.X), it will also clear all active faults. See chapter 5 for fault descriptions. Phone: 800.894.0412 - fax: 888.723.4773 - web: w...

Page 75

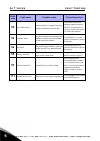

Parameters vacon • 69 8 8. Standard application parameters on the next pages you can find the lists of parameters within the respective param- eter groups. The parameter descriptions are given in chapter 9 . Explanations: code: location indication on the keypad; shows the operator the present monito...

Page 76

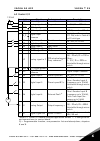

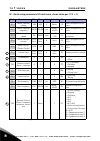

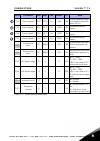

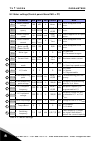

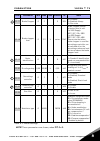

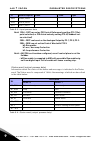

70 • vacon parameters 8 8.1 quick setup parameters (virtual menu, shows when par. 17.2 = 1) code parameter min max unit default id note motor nominal voltage 180 690 v varies 110 check rating plate on the motor. Motor nominal frequency 30,00 320,00 hz 50,00 / 60,00 111 check rating plate on the moto...

Page 77

Parameters vacon • 71 8 p3.4 preset speed 0 p3.1 p3.2 hz 5,00 180 preset speed 0 is used as frequency reference when p3.3 = 1 p3.5 preset speed 1 p3.1 p3.2 hz 10,00 105 activated by digital inputs p3.6 preset speed 2 p3.1 p3.2 hz 15,00 106 activated by digital inputs p3.7 preset speed 3 p3.1 p3.2 hz...

Page 78

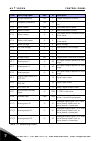

72 • vacon parameters 8 8.2 motor settings (control panel: menu par -> p1) code parameter min max unit default id note motor nominal voltage 180 690 v varies 110 check rating plate on the motor motor nominal fre- quency 30,00 320,00 hz 50,00 / 60,00 111 check rating plate on the motor motor nominal ...

Page 79

Parameters vacon • 73 note! These parameters are shown, when p17.2 = 0. 8 brake chopper 0 2 0 504 0 = disabled 1 = enabled: always 2 = run state brake chopper level 0 911 v varies 1267 brake chopper control activation level in volt. For 240v supply: 240*1.35*1.18 = 382v for 400v supply: 400*1.35*1.1...

Page 80

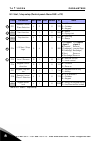

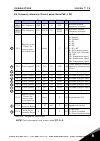

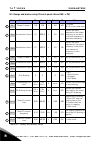

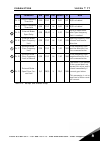

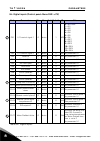

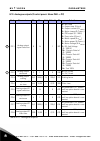

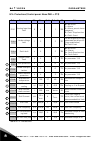

74 • vacon parameters 8 8.3 table 8.3: start / stop setup code parameter min max unit default id note i i i i i p2.1 remote control place selection 0 2 0 172 0 = i / o terminals 1 = fieldbus 2 = keypad p2.2 start function 0 1 0 505 0 = ramp 1 = flying start p2.3 stop function 0 1 0 506 0 = coasting ...

Page 81

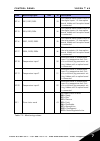

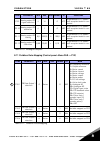

Parameters vacon • 75 8 8.4 frequency references (control panel: menu par -> p3) note! These parameters are shown, when p17.2 = 0. Code parameter min max unit default id note min frequency 0,00 p3.2 hz 0,00 101 minimum allowed frequency reference max frequency p3.1 320,00 hz 50,00 / 60,00 102 maximu...

Page 82

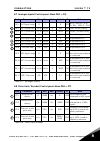

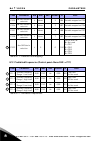

76 • vacon parameters 8 8.5 ramps and brakes setup (control panel: menu par -> p4) code parameter min max unit default id note ramp s-shape 1 0,0 10,0 s 0,0 500 0 = linear >0 = s-curve ramp time acceleration time 1 0,1 3000,0 s 3,0 103 defines the time required for the output frequency to increase f...

Page 83

Parameters vacon • 77 8 p4.13 accel2 frequency threshold 0.00 p3.2 hz 0,00 527 0,00 = disabled p4.14 decel2 frequency threshold 0,00 p3.2 hz 0,00 528 0,00 = disabled p4.15 external brake: open delay 0,00 320,00 s 0,20 1544 delay to open brake after open frequency limit is reached p4.16 external brak...

Page 84

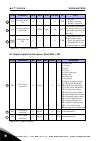

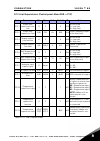

78 • vacon parameters 8 8.6 digital inputs (control panel: menu par -> p5) code parameter min max unit default id note p5.1 i / o control signal 1 0 varies 1 403 0 = not used 1 = di1 2 = di2 3 = di3 4 = di4 5 = di5 6 = di6 7 = die1 8 = die2 9 = die3 10 = die4 11 = die5 12 = die6 p5.2 i / o control s...

Page 85

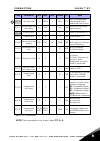

Parameters vacon • 79 8 8.7 analogue inputs (control panel: menu par -> p6) 8.8 pulse train / encoder (control panel: menu par -> p7) code parameter min max unit default id note p6.1 ai1 signal range 0 1 0 379 0 = 0 - 100% (0 - 10 v) 1 = 20% - 100% (2 - 10 v) p6.2 ai1 custom min -100,00 100,00 % 0,0...

Page 86

80 • vacon parameters 8 8.9 digital outputs (control panel: menu par -> p8) p7.5 encoder direc- tion 0 2 0 1233 0 = disable 1 = enable / normal 2 = enable / inverted p7.6 encoder pulses / revolution 1 65535 ppr 256 629 pulse count of encoder per round. Used for scal- ing encoder rpm monitor value on...

Page 87

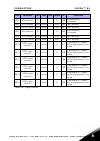

Parameters vacon • 81 8 p8.4 ro2 inversion 0 1 0 1588 0 = no inversion 1 = inverted p8.5 ro2 on delay 0,00 320,00 s 0,00 460 0,00 = no delay p8.6 ro2 off delay 0,00 320,00 s 0,00 461 0,00 = no delay p8.7 ro1 inversion 0 1 0 1587 0 = no inversion 1 = inverted p8.8 ro1 on delay 0,00 320,00 s 0,00 458 ...

Page 88

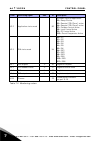

82 • vacon parameters 8 8.10 analogue outputs (control panel: menu par -> p9) code parameter min max unit default id selections p9.1 analog output signal selection 0 14 1 307 0 = not used 1 = output freq. (0-f max ) 2 = output current (0-i nmotor ) 3 = motor torque (0-t nmotor ) 4 = pid output (0 - ...

Page 89

Parameters vacon • 83 8 8.11 fieldbus data-mapping (control panel: menu par -> p10) p9.9 analog output e2 signal selection 0 14 0 479 as parameter p9.1, hidden until an option board is con- nected p9.10 analog output e2 minimum 0 1 0 482 as parameter p9.2, hidden until an option board is con- nected...

Page 90

84 • vacon parameters 8 8.12 prohibited frequencies (control panel: menu par -> p11) p10.5 fb data output 5 selection 0 varies 5 856 variable mapped on pd5 p10.6 fb data output 6 selection 0 varies 3 857 variable mapped on pd6 p10.7 fb data output 7 selection 0 varies 6 858 variable mapped on pd7 p1...

Page 91

Parameters vacon • 85 8 8.13 limit supervisions (control panel: menu par -> p12) code parameter min max unit default id note p12.1 output freq. Supervision func- tion 0 2 0 315 0 = not used 1 = low limit 2 = high limit p12.2 output freq. Supervision limit 0,00 p3.2 hz 0,00 316 output frequency super...

Page 92

86 • vacon parameters 8 8.14 protections (control panel: menu par -> p13) code parameter min max unit default id note p13.1 analog input low fault 0 4 1 700 0 = no action 1 = alarm 2 = alarm, preset alarm frequency 3 = fault: stop function 4 = fault: coast under voltage fault 1 2 2 727 1 = no respon...

Page 93

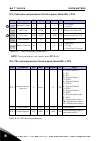

Parameters vacon • 87 8 note! These parameters are shown, when p17.2 = 0. Ul:time limit 1,0 300,0 s 20,0 716 this is the maximum time allowed for an underload state to exist p13.17 analog input low fault delay 0,0 10,0 s 0,5 1430 delay time for analog input low fault external fault 0 3 2 701 same as...

Page 94

88 • vacon parameters 8 8.15 fault autoreset parameters (control panel: menu par -> p14) note! These parameters are shown, when p17.2 = 0 . 8.16 pid control parameters (control panel: menu par -> p15) code parameter min max unit default id note automatic reset 0 1 0 731 0 = disabled 1 = enable wait ...

Page 95

Parameters vacon • 89 8 p15.4 feedback source selection 0 varies 1 334 0 = ai1 1 = ai2 2 = processdatain1 (0 -100%) 3 = processdatain2 (0 -100%) 4 = processdatain3 (0 -100%) 5 = processdatain4 (0 -100%) 6 = ai2-ai1 7 = pulse train / encoder 8 = aie1 9 = temperature input 1 10 = temperature input 2 1...

Page 96

90 • vacon parameters 8 note! These parameters are shown, when p17.2 = 0. P15.15 setpoint boost time 0 60 s 10 1072 boost time after p15.12 p15.16 sleep maxi- mum loss 0,0 50,0 % 5,0 1509 referred to feedback value after boost p15.17 sleep loss check time i i i i i i i 1 300 s 30 1510 after boost ti...

Page 97

Parameters vacon • 91 8 8.17 motor pre-heat (control panel: menu par -> p16) 8.18 easy usage menu (control panel: menu par -> p17) code parameter min max unit default id note p16.1 motor pre-heat function 0 2 0 1225 0 = not used 1 = always in stop state 2 = controlled by digital input p16.2 motor pr...

Page 98

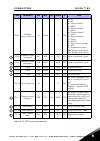

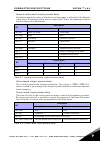

92 • vacon parameters 8 8.19 system parameters code parameter min max default id note software information (menu par -> v1) v1.1 api sw id 2314 v1.2 api sw version 835 v1.3 power sw id 2315 v1.4 power sw version 834 v1.5 application id 837 v1.6 application revision 838 v1.7 system load 839 when no f...

Page 99

Parameters vacon • 93 8 p2.7 communication time out 0 255 10 814 0 = not used 1 = 1 sec 2 = 2 secs, etc p2.8 reset communication status 0 1 0 815 when canopen e6 board has been installed, the comm. Parameters are as follows v2.1 canopen communication status 14004 0 = initialising 4 = stopped 5 = ope...

Page 100

94 • vacon parameters 8 when profidbus e3/e5 board has been installed, the comm. Parameters are as follows v2.1 communication status 14022 v2.2 fieldbus protocol status 14023 v2.3 active protocol 14024 v2.4 active buad rate 14025 v2.5 telegram type 14027 p2.6 operate mode 1 3 1 14021 1 = profidrive ...

Page 101

Parameters vacon • 95 8 other information v3.1 mwh counter 827 million watt hour v3.2 power on days 828 v3.3 power on hours 829 v3.4 run counter: days 840 v3.5 run counter: hours 841 v3.6 fault counter 842 v3.7 panel parameter set status monitor hidden when connect with pc. Restore factory defaults ...

Page 102

96 • vacon parameters 8 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 103

Parameter descriptions vacon • 97 9 9. Parameter descriptions on the next pages you can find the descriptions of certain parameters. The descrip- tions have been arranged according to parameter group and number. 9.1 motor settings (control panel: menu par -> p1) 1.7 c urrent limit this parameter det...

Page 104

98 • vacon parameter descriptions 9 1 = square: the voltage of the motor changes following a squared curve form with the frequency in the area from 0 hz to the field weakening point where the field weakening point voltage is also supplied to the motor. The motor runs under magnetised below the field...

Page 105

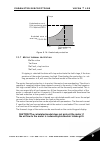

U n p a r. 1.11 u [v ] f[h z] p a r. 1.13 p a r. 1.14 default: nom inal voltage of the m otor field weakening point default: nom inal frequency of the m otor p a r. 1.12 p a r. 1.10 parameter descriptions vacon • 99 9 figure 9.2: programmable u / f curve 1.10 f ield weakening point the field weakeni...

Page 106

100 • vacon parameter descriptions 9 1.15 t orque boost when this parameter has been activated, the voltage to the motor changes au- tomatically with high load torque which makes the motor produce sufficient torque to start and run at low frequencies. The voltage increase depends on the motor type a...

Page 107

Parameter descriptions vacon • 101 9 when standstill identification is selected, the drive will perform an id-run when it is started from selected control place. Drive has to be started within 20 seconds, otherwise identification is aborted. The drive does not rotate the motor during standstill iden...

Page 108

102 • vacon parameter descriptions 9 9.2 start / stop setup (control panel: menu par -> p2) 2.1 r emote control place selection with this parameter, the user can select the active control place, frequency converter can be selected with p3.3/p3.12. The selections are: 0 = i / o termina 1 = fieldbus 2...

Page 109

Parameter descriptions vacon • 103 9 after the stop command, the speed of the motor is decelerated ac- cording to the set deceleration parameters. If the regenerated energy is high it may be necessary to use an exter- nal braking resistor for to be able to decelerate the motor in accepta- ble time. ...

Page 110

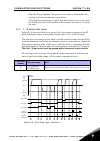

104 • vacon parameter descriptions 9 explanations 1 control signal (cs) 1 actives causing the output frequency to rise. The motor runs forward. 8 run enable signal is set to false, which drops the frequency to 0.The run enable signal is configured with par. 5.7. 2 if start forward signal [cs1] and s...

Page 111

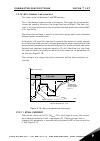

1 2 3 4 5 6 7 8 9 t output frequerty 0 hz set frequerty set frequerty rev fwd run enable ctrl signal 1 ctrl signal 2 keypad stop button parameter descriptions vacon • 105 9 figure 9.4: start/stop logic, selection 1 selection number selection name note 1 cs1:forward(edge) cs2:inverted stop explanatio...

Page 112

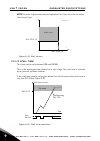

1 2 3 4 5 6 7 8 9 10 11 t output frequerty 0 hz set frequerty set frequerty rev fwd run enable ctrl signal 1 ctrl signal 2 keypad stop button 106 • vacon parameter descriptions 9 figure 9.5: start/stop logic, selection 2 selection number selection name note 2 cs1:forward(edge) cs2:backward(edge) sha...

Page 113

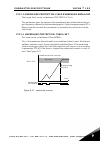

Parameter descriptions vacon • 107 9 1 2 3 4 5 6 7 8 9 10 11 12 t output frequerty 0 hz set frequerty set frequerty rev fwd run enable ctrl signal 1 ctrl signal 2 keypad start button keypad stop button figure 9.6: start/stop logic, selection 3 selection number selection name note 3 cs1:start cs2:rev...

Page 114

1 2 3 4 5 6 7 8 9 10 11 t output frequerty 0 hz set frequerty set frequerty rev fwd run enable ctrl signal 1 ctrl signal 2 keypad stop button 108 • vacon parameter descriptions 9 figure 9.7: start/stop logic, selection 4 selection number selection name note 4 cs1:start(edge) cs2:reverse shall be use...

Page 115

Parameter descriptions vacon • 109 9 2.5 l ocal / remote this parameter defines whether the control place of the drive is remote (i / o or fieldbus) or local. 0 = remote control 1 = local control the priority order of selecting control place is 1. Pc control from vacon live operation window 2. Loc /...

Page 116

110 • vacon parameter descriptions 9 9.3 frequency references (control panel: menu par -> p3) 3.3 r emote control place frequency reference selection it defines the selected frequency reference source when the drive is remote control. A second reference source is programmable in par. 3.12. 1 = prese...

Page 117

Parameter descriptions vacon • 111 9 3.13 m otor potentiometer ramp 3.14 m otor potentiometer reset p3.13 is the speed variation ramp when motor potentiometer reference is in- creased or decreased. P3.14 tells under which circumstances the potentiometers reference should be reset and start over from...

Page 118

112 • vacon parameter descriptions 9 9.4 ramps & brakes setup (control panel: menu par -> p4) 4.1 r amp s- shape the start and end of the acceleration and deceleration ramp can be smoothed with this parameter. Setting value 0 gives a linear ramp shape which causes acceleration and deceleration to ac...

Page 119

Parameter descriptions vacon • 113 9 4.7 f lux braking instead of dc braking, flux braking is a useful form of braking with motors of max. 15 kw. When braking is needed, the frequency is reduced and the flux in the motor is increased, which in turn increases the motor's capability to brake. Unlike d...

Page 120

Fn fn t t t = 1 x par. 4.10 t = 0,1 x par. 4.10 0,1 x fn run stop run stop output frequency motor speed output frequency motor speed dc-braking on dc-braking on fout fout 114 • vacon parameter descriptions 9 figure 9.10: dc-braking time when stop mode = coasting par. 2.3 = 1 (stop function = ramp): ...

Page 121

Parameter descriptions vacon • 115 9 4.11 s top dc current frequency it is the output frequency at which the dc-braking is applied. 4.12 s tart dc current time dc-brake is activated when the start command is given. This parameter de fines the time for how long dc current is fed to motor before accel...

Page 122

116 • vacon parameter descriptions 9 2. When the opening frequency limit has been reached the open delay (p4.15) must also elapse. Note! The output frequency is held at the open frequency limit until this. 3. When the two previous conditions are reached. The brake will open if the output current is ...

Page 123

Parameter descriptions vacon • 117 9 9.5 digital inputs (control panel: menu par -> p5) these parameters are programmed using the ftt-method (function to ter- minal), where you have a fixed input or output that you define a certain func- tion for. You can also define more than one function to a digi...

Page 124

118 • vacon parameter descriptions 9 9.6 analogue inputs (control panel: menu par -> p6) 6.4 ai1 filter time 6.8 ai2 filter time this parameter, given a value greater than 0, activates the function that filters out disturbances from the incoming analogue signal. Long filtering time makes the regulat...

Page 125

Parameter descriptions vacon • 119 otherwise f51 occur. 9 9.7 pulse train / encoder (control panel: menu par -> p7) 7.1 m in pulse frequency 7.2 m ax pulse frequency minimum and maximum pulse frequency correspond to a signal value of 0% and 100% respectively. Frequencies over max pulse frequency are...

Page 126

120 • vacon parameter descriptions 9 9.8 digital outputs (control panel: menu par -> p8) 8.1 ro1 signal selection 8.2 ro2 signal selcetion 8.3 do1 signal selcetion table 9.2: output signals via ro1, ro2 and do1 setting signal content 0 = not used output is not in operation. 1 = ready the frequency c...

Page 127

Parameter descriptions vacon • 121 9 9.9 analogue outputs (control panel: menu par -> p9) 9.1 a nalog output signal selection 0 = not used 1 = output frequency (0 - f max ) 2 = output current (0 - i nmotor ) 3 = motor torque (0 - t nmotor ) 4 = pid output (0 - 100%) 5 = frequency reference (0 - f ma...

Page 128

122 • vacon parameter descriptions 9 9.10 fieldbus data-mapping (control panel: menu par -> p10) 10.1 fb data out 1 selection parameter couples read only variables to output process data 1. 0 = frequency reference 1 = output reference 2 = motor speed 3 = motor current 4 = motor voltage 5 = motor tor...

Page 129

Parameter descriptions vacon • 123 9 9.11 prohibited frequencies (control panel: menu par -> p11) 11.1 p rohibit frequency range 1: l ow limit 11.2 p rohibit frequency range 1: h igh limit 11.3 p rohibit frequency range 2: l ow limit 11.4 p rohibit frequency range 2: h igh limit two skip frequency r...

Page 130

124 • vacon parameter descriptions 9 9.12 protections (control panel:menu par->p13) 13.5 s tall protection 0 = no action 1 = alarm 2 = fault, stop function 3 = fault, coast the motor stall protection protects the motor from short time overload situa- tions such as one caused by a stalled shaft. The ...

Page 131

U nderload curve at zero freq. P13.15= 10% f 5 h z u nderload cu rv e at field w eaken ing point , p1.11 u nd e rlo ad a re a to rq ue feild weakening point, p13.14(default)=50% parameter descriptions vacon • 125 9 figure 9.16: underload protection 13.7 m otor thermal protection 0 = no action 1 = al...

Page 132

126 • vacon parameter descriptions 9 note: if you use long motor cables (max. 100m) together with small drives ( the actual motor current due to capacitive currents in the motor cable. Con- sider this when setting up the motor thermal protection functions. 13.8 m tp :a mbient temperature when the mo...

Page 133

Parameter descriptions vacon • 127 9 13.10 m tp : thermal time constant this time can be set between 1 and 200 minutes. This is the thermal time constant of the motor. The bigger the frame and/or slower the speed of the motor, the longer the time constants. The time con- stant is the time within whi...

Page 134

128 • vacon parameter descriptions 9 note ! In order to guarantee desired operation, this limit must be set below the current limit. F i par. P3.9.12 par. P3.9.14 100k34.Fh11 stall area figure 9.19: stall current p13.12 stall time this time can be set between 0.00 and 300.00s. This is the maximum ti...

Page 135

Parameter descriptions vacon • 129 9 p13.14 underload protection: field weakening area load the torque limit can be set between 10.0-150.0 % x t nmotor . This parameter gives the value for the minimum torque allowed when the out- put frequency is above the field weakening point. If you change parame...

Page 136

130 • vacon parameter descriptions 9 9.13 automatic reset (control panel: menu par -> p14) 14.1 a utomatic reset activate the automatic reset after fault with this parameter. Note: automatic reset is allowed for certain faults only. Fault: 1 . Under voltage 2 . Over voltage 3 . Over current 4 . Moto...

Page 137

Parameter descriptions vacon • 131 9 9.14 pid control parameters (control panel: menu par -> p15) 15.5 f eedback value minimum 15.6 f eedback value maximum this parameter sets the minimum and maximum scaling points for feedback value. 0 v 0 ma par. 15.5 custom min par. 6.2 /6.6 custom max par. 15.6 ...

Page 138

132 • vacon parameter descriptions 9 15.11 s leep min frequency 15.12 s leep delay 15.13 w ake - up error this function will put the drive into sleep mode if the frequency stays below the sleep limit for a longer time than that set with the sleep delay (p15.12). This means that the start command rem...

Page 139

Parameter descriptions vacon • 133 9 frequency reference is then forced at minimum frequency and the feedback value is sampled. If the variation on the feedback value stays then lower than p15.16 for the time in p15.17, the drive will enter sleep condition. If this sequence is not needed, then progr...

Page 140

134 • vacon parameter descriptions 9 9.15 application setting (control panel: menu par->p17) 17.1 d rive setup with this parameter you can easily set up your drive for four different applica- tions. Note! This parameter is only visible when the startup wizard is active. The startup wizard will start...

Page 141

Parameter descriptions vacon • 135 9 figure 9.26: drive setup 1 2 3 4 selections: parameters affected: p1.7 current limit (a) p1.8 motor control mode p1.15 torque boost p2.2 start function p2.3 stop function p3.1 min frequency p4.2 acc. Time (s) p4.3 dec time (s) startup wizard showns par 17.1 numbe...

Page 142

136 • vacon parameter descriptions 9 9.16 system parameter 4.3 p assword vacon20 api provides password function that is used when changing param- eter value. Inside par or sys menu the selected parameter symbol and its value are al- ternating in the display. The single ok button pressing causes ente...

Page 143

Parameter descriptions vacon • 137 9 repeat insertion of password; press ok button --> password is locked; in case of different values for the two passwords: display fault; press ok button --> repeat password a second time; to interrupt insertion of password --> press back / res. Disabling a passwor...

Page 144

138 • vacon parameter descriptions 9 9.17 modbus rtu vacon 20 has a built-in modbus rtu bus interface. The signal level of the interface is in accordance with the rs-485 standard. The built-in modbus connection of vacon 20 supports the following function codes: 9.17.1 termination resistor the rs-485...

Page 145

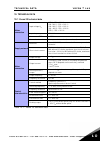

Parameter descriptions vacon • 139 9 9.17.3 modbus process data process data is an address area for fieldbus control. Fieldbus control is active when the value of parameter 2.1 (control place) is 1 (= fieldbus). The content of the process data can be programmed in the application.The following table...

Page 146

140 • vacon parameter descriptions 9 note! 2004 - 2007 can set as pid control reference by setting p15.1(set- point selection) or pid actual value by setting p15.4(feedback val- ue selection)! 2004 - 2007 can be set as the analogue output by p9.1, p9.5, p9.9. 2004 - 2008 can set as aux control word ...

Page 147

Parameter descriptions vacon • 141 9 general status word (output process data) information about the status of the device and messages is indicated in the general status word. The general status word is composed of 16 bits the meanings of which are described in the table below: actual speed (output ...

Page 148

142 • vacon parameter descriptions 9 speed reference (input process data) this is the reference 1 to the frequency converter. Used normally as speed refer- ence. The allowed scaling is 0...10000. The value is scaled in percentage of the fre- quency area between the set minimum and maximum frequencie...

Page 149

Technical data vacon • 143 10 10. Technical data 10.1 vacon 20 technical data mains connection input voltage u in 115 v, -15%...+10% 1~ 208…240 v, -15%...+10% 1~ 208…240 v, -15%...+10% 3~ 380 - 480 v, -15%...+10% 3~ 575 v, -15%...+10% 3~ input frequency 45…66 hz line current thd > 120% connection to...

Page 150

144 • vacon technical data 10 ambient conditions ambient operating temperature -10 °c (no frost)…+40 / 50 °c (depends on the unit size): rated loadability i n side by side installation for mi1-3 it is always 40 °c; for ip21/nema1 option in mi1-3 the maximum temparture is also 40 °c storage temperatu...

Page 151

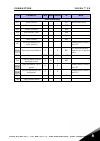

Technical data vacon • 145 10 10.2 power ratings 10.2.1 vacon 20 – mains voltage 208-240 v * the maximum ambient operating temperature of these drives is + 40 °c. Mains voltage 208-240 v, 50/60 hz, 1~ series freq. Converter type rated loadability motor shaft power nominal input current mechanical si...

Page 152

146 • vacon technical data 10 10.2.2 vacon 20 – mains voltage 115 v 10.2.3 vacon 20 – mains voltage 380-480 v mains voltage 115 v, 50/60 hz, 1~ series freq. Converter type rated loadability motor shaft power nominal input current mechanical size weight (kg) 100% contin. Current i n [a] 150% over- lo...

Page 153

Technical data vacon • 147 10 10.2.4 vacon 20 – mains voltage 575 v note 1: the input currents are calculated values with 100 kva line transformer supply. Note 2: the mechanical dimensions of the units are given in chapter 3.1.1. 10.3 brake resistors vacon 20 type minimum brak- ing resistance resist...

Page 154

148 • vacon technical data 10 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 155

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 156

Rev. E1 document id: subject to change without prior notice © 2013 vacon plc. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.