- DL manuals

- Vacon

- Media Converter

- NX series

- Applications Manual

Vacon NX series Applications Manual

Summary of NX series

Page 1

Vacon nx ac drives all in one application manual ®.

Page 3: Preface

Preface document id: dpd00903c date: 29.09.2014 software code: • basic application = asfiff01 • standard application = asfiff02 • local/remote control application = asfiff03 • multi-step speed control application = asfiff04 • pid control application = asfiff05 • multi-purpose control application - n...

Page 4

Note! You can download the english and french product manuals with applicable safety, warning and caution information from www.Vacon.Com/downloads. Remarque vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'en- semble des informations de sécurité, avertisseme...

Page 5

Vacon · 5 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com.

Page 6

Vacon · 6 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 7: Table of Contents

Table of contents preface about this manual 3 1 basic application 11 1.1 introduction 11 1.1.1 motor protection functions in the basic application 11 1.2 control i/o 12 1.3 control signal logic in basic application 13 1.4 basic application - parameter lists 14 1.4.1 monitoring values (control keypad...

Page 8

3.3 control signal logic in local/remote application 45 3.4 local/remote control application - parameter lists 45 3.4.1 monitoring values (control keypad: menu m1) 45 3.4.2 basic parameters (control keypad: menu m2 -> g2.1) 47 3.4.3 input signals (control keypad: menu m2 -> g2.2) 49 3.4.4 output sig...

Page 9

5.3 control signal logic in pid control application 98 5.4 pid control application - parameter lists 98 5.4.1 monitoring values (control keypad: menu m1) 98 5.4.2 basic parameters (control keypad: menu m2 -> g2.1) 101 5.4.3 input signals 104 5.4.4 output signals (control keypad: menu m2 -> g2.3 111 ...

Page 10

7.3 control signal logic in pump and fan control application 200 7.4 pump and fan control application - parameter lists 200 7.4.1 monitoring values (control keypad: menu m1) 200 7.4.2 basic parameters (control keypad: menu m2 -> g2.1) 203 7.4.3 input signals 206 7.4.4 output signals 214 7.4.5 drive ...

Page 11: Basic Application

1 basic application 1.1 introduction the basic application is a simple and easy-to-use application. It is the default setting on delivery from the factory. Otherwise select the basic application in menu m6 on page s6.2. See the product's user manual. Digital input din3 is programmable. The parameter...

Page 12

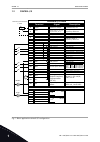

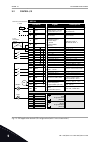

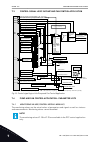

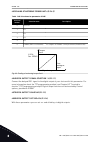

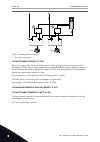

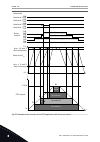

1.2 control i/o 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 opta 2 22 23 11 17 24 25 26 din4 din5 voltage for potentiometer, etc. Ground for reference and controls ground for reference and controls ground for reference and controls analogue input 2 frequency reference voltage for switches (see #...

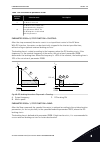

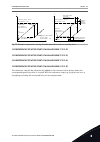

Page 13

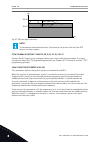

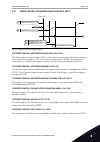

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 2: jumper ...

Page 14

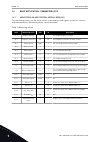

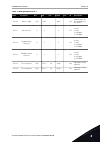

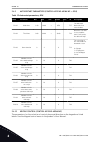

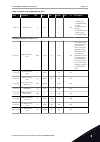

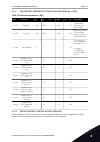

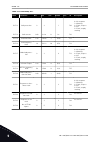

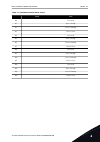

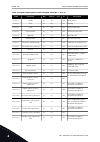

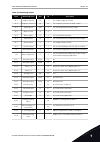

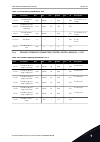

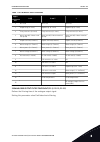

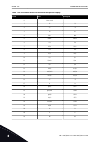

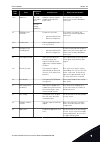

1.4 basic application - parameter lists 1.4.1 monitoring values (control keypad: menu m1) the monitoring values are the actual values of parameters and signals as well as statuses and measurements. Monitoring values cannot be edited. Table 1: monitoring values index monitoring value unit id descript...

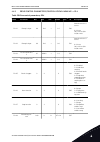

Page 15

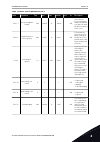

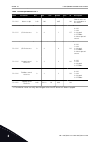

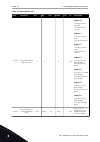

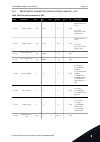

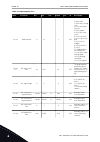

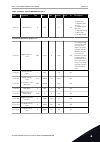

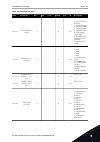

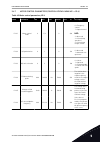

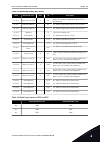

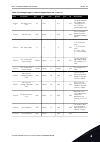

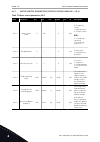

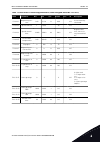

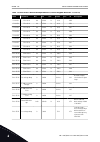

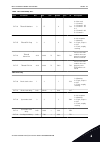

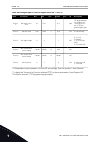

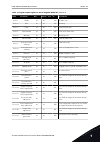

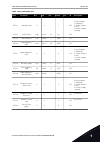

1.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 2: basic parameters g2.1 index parameter min max unit default cust id description p2.1 min frequency 0.00 p2.2 hz 0.00 101 p2.2 max frequency p2.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitability for m...

Page 16

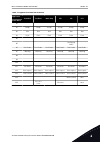

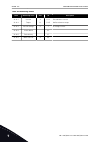

Table 2: basic parameters g2.1 index parameter min max unit default cust id description p2.10 motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.11 start function 0 2 0 505 0 = ramp 1 = flying start 2 = conditional fly- ing start p2.12 stop function 0 3 0 506 0 = co...

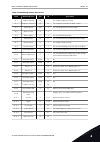

Page 17

Table 2: basic parameters g2.1 index parameter min max unit default cust id description p2.17 din3 function 0 7 1 301 0 = not used 1 = ext. Fault, clos- ing cont. 2 = ext. Fault, opening cont. 3 = run enable, cc 4 = run enable, oc 5 = force cp. To io 6 = force cp. To keypad 7 = force cp. To fieldbus...

Page 18

1.4.4 system menu (control keypad: menu m6) for parameters and functions related to the general use of the ac drive, such as application and language selection, customised parameter sets or information about the hardware and software, see the product's user manual. 1.4.5 expander boards (control key...

Page 19: Standard Application

2 standard application 2.1 introduction select the standard application in menu m6 on page s6.2. The standard application is typically used in pump and fan applications and conveyors for which the basic application is too limited but where no special features are needed. • the standard application h...

Page 20

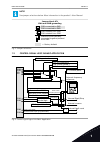

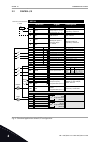

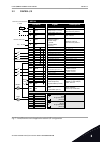

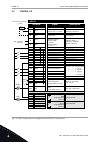

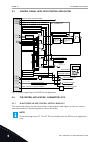

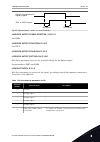

2.2 control i/o 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 din4 din5 ma ready run ao1- do1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal description +10 v ref ai1+ ai1- ai2+ ai2- +24v reference output i/o groun...

Page 21

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 5: jumper ...

Page 22

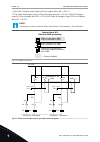

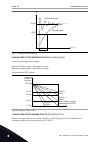

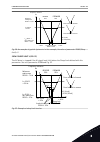

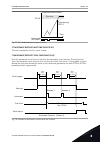

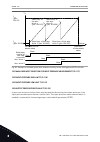

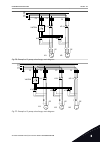

2.3 control signal logic in standard application din4 din5 ai1 ai2 din1 din2 din6 din3 ≥ 1 3.2 keypad reference 3.1 control place start forward start reverse start/stop reverse internal start/stop internal reverse internal fault reset fault reset input external fault input (programmable) reset butto...

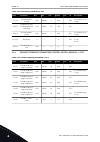

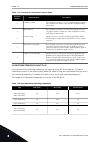

Page 23

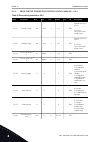

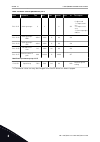

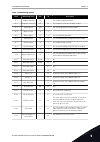

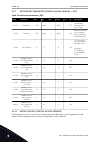

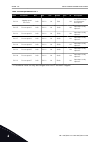

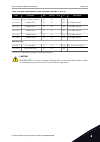

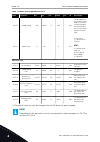

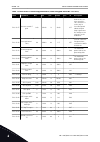

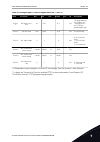

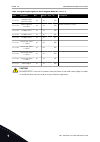

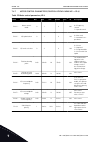

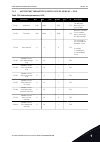

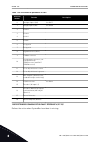

Table 4: monitoring values index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 motor torque ...

Page 24

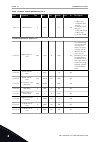

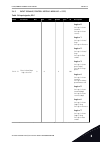

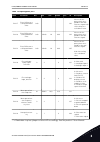

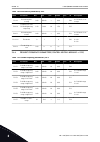

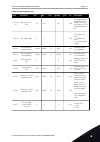

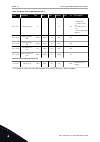

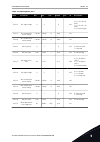

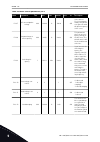

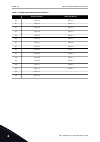

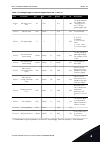

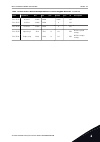

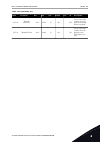

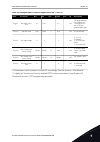

2.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 5: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabili...

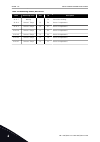

Page 25

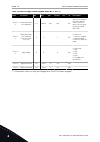

Table 5: basic parameters g2.1 index parameter min max unit default cust id description p2.1.10 motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.11 i/o reference 0 3 0 117 0 = ai1 1 = ai2 2 = keypad 3 = fieldbus p2.1.12 keypad control reference 0 3 2 121 0 = ai1...

Page 26

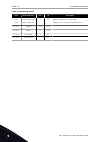

2.4.3 input signals (control keypad: menu m2 -> g2.2) table 6: input signals, g2.2 index parameter min max unit default cust id description p2.2.1 start/stop logic 0 6 0 300 logic = 0 ctrl sgn 1 = start forward ctrl sgn 2 = start reverse logic = 1 ctrl sgn 1 = start/ stop ctrl sgn 2 = reverse logic ...

Page 27

Table 6: input signals, g2.2 index parameter min max unit default cust id description p2.2.2 din3 function 0 8 1 301 0 = not used 1 = ext. Fault, closing cont. 2 = ext. Fault, open- ing cont. 3 = run enable 4 = acc./dec. Time select. 5 = force cp. To io 6 = force cp. To key- pad 7 = force cp. To fie...

Page 28

*** = use ttf method to program these parameters. Vacon · 28 standard application 2 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 29

2.4.4 output signals (control keypad: menu m2 -> g2.3 table 7: output signals, g2.3 index parameter min max unit default cust id description p2.3.1 analogue output 1 signal selection 0 a.1 464 ttf programming method used. See 8.9 "terminal to function" (ttf) pro- gramming principle. P2.3.2 analogue ...

Page 30

Table 7: output signals, g2.3 index parameter min max unit default cust id description p2.3.7 digital output 1 function 0 16 1 312 0 = not used 1 = ready 2 = run 3 = fault 4 = fault inverted 5 = fc overheat warning 6 = ext. Fault or warning 7 = ref. Fault or warning 8 = warning 9 = reversed 10 = pre...

Page 31

Table 7: output signals, g2.3 index parameter min max unit default cust id description p2.3.15 analogue output 2 inversion 0 1 0 474 0 = not inverted 1 = inverted p2.3.16 analogue output 2 minimum 0 1 0 475 0 = 0 ma (0 v) 1 = 4 ma (2 v) p.2.3.17 analogue output 2 scaling 10 1000 % 1.00 476 * = use t...

Page 32

2.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 8: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 smooth ratio for s- curves. 0 = linear 100 = full acc/dec inc/dec tmes p2.4.2 ramp 2 shape 0.0 10.0 ...

Page 33

Table 8: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.9 dc braking time at stop 0.00 600.00 s 0.00 508 0 = dc brake is off at stop p2.4.10 frequency to start dc braking during ramp stop 0.10 10.00 hz 1.50 515 p2.4.11 dc braking time at start 0.00 600.0...

Page 34

2.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 10: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 * motor control mode 0 1/3 0 600 0 = frequency control 1 = speed control nxp: 2 = open loop tor- que control 3 = closed loop speed...

Page 35

Table 10: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.7 * u/f curve midpoint voltage 0.00 100.00 % 100.00 605 if the value of p2.6.3 is program- mable, this param- eter gives the mid- dle point frequency of the curve. P2.6.8 * output voltage at zero f...

Page 36

Table 10: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.13 identification 0 1/2 0 631 0 = no action 1 = identification w/o run 2 = identification with run 3 = encoder id run 4 = no action 5 = id run failed closed loop parameter group 2.6.14 p2.6.14.1 ma...

Page 37

Table 10: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.14.11 start-up torque 0 3 0 621 0 = not used 1 = torque mem- ory 2 = torque refer- ence 3 = start-up torque fwd/rev p2.6.14.12 start-up torque fwd -300.0 300.0 % 0.0 633 p2.6.14.13 start-up torque ...

Page 38

2.4.8 protections (control keypad: menu m2 -> g2.7 table 11: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 0 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4.7...

Page 39

Table 11: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 0 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 2 x i h a i h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711 ...

Page 40

2.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 12: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial ...

Page 41

Table 13: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 1 3 1 125 1 = i/0 terminal 2 = keypad 3 = fieldbus p3.2 keypad reference p2.1 p2.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 you can adjust the frequency refer- ence on the keypad...

Page 42

3 local/remote control application 3.1 introduction select the local/remote control application in menu m6 on page s6.2. With the local/remote control application it is possible to have two different control places. For each control place the frequency reference can be selected from either the contr...

Page 43

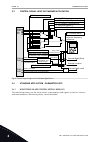

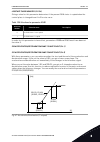

3.2 control i/o reference potentiometer, 1-10kΩ 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 ma remote reference remote control ground 0(4) - 20 ma run ready ao1- do1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal...

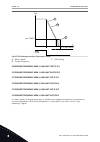

Page 44

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 8: jumper ...

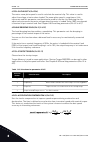

Page 45

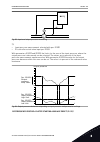

3.3 control signal logic in local/remote application din3 ≥ 1 din6 din2 din3 ai1 ai2 din1 din2 din3 din4 din5 a b a b a b internal reverse internal fault reset fault reset input (programmable) 3.3 keypad direction internal start/stop reference from fieldbus start/stop from fieldbus direction from fi...

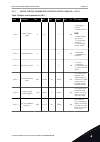

Page 46

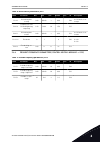

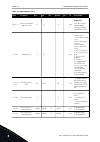

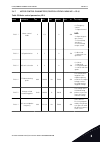

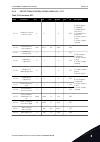

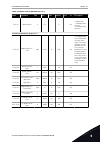

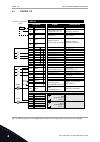

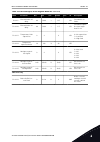

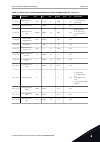

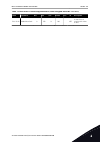

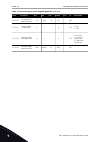

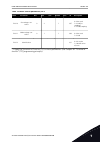

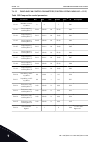

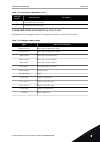

Table 14: monitoring values index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 motor torque...

Page 47

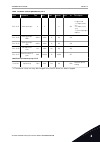

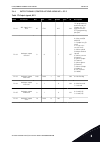

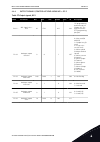

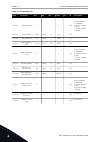

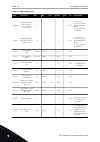

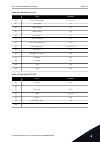

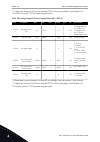

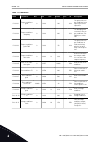

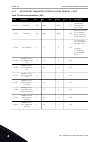

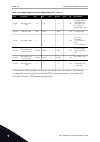

3.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 15: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabil...

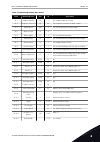

Page 48

Table 15: basic parameters g2.1 index parameter min max unit default cust id description p2.1.10 * motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.11 * i/o a reference 0 4 1 117 0 = ai1 1 = ai2 2 = keypad 3 = fieldbus 4 = motor potenti- ometer p2.1.12 * i/o b r...

Page 49

3.4.3 input signals (control keypad: menu m2 -> g2.2) table 16: input signals, g2.2 index parameter min max unit default cust id description p2.2.1 *** place a start/stop logic selection 0 8 0 300 logic = 0 ctrl sgn 1 = start forward ctrl sgn 2 = start reverse logic = 1 ctrl sgn 1 = start/ stop ctrl...

Page 50

Table 16: input signals, g2.2 index parameter min max unit default cust id description p2.2.1 *** place a start/stop logic selection 0 8 0 300 logic = 8 ctrl sgn 1 = start forward (edge) ctrl sgn 2 = motor potentiometer up p2.2.2 din3 function 0 13 1 301 0 = not used 1 = ext. Fault, closing cont. 2 ...

Page 51

Table 16: input signals, g2.2 index parameter min max unit default cust id description p2.2.7 ai1 signal inver- sion 0 1 0 323 analogue input 1 ref- erence inversion yes/no. P2.2.8 ai1 signal filter time 0.00 10.00 s 0.10 324 analogue input 1 ref- erence filter time, constant. P2.2.9 **** ai2 signal...

Page 52

Table 16: input signals, g2.2 index parameter min max unit default cust id description p2.2.15 *** place b start/stop logic selection 0 6 0 363 logic = 0 ctrl sgn 1 = start forward ctrl sgn 2 = start reverse logic = 1 ctrl sgn 1 = start/ stop ctrl sgn 2 = reverse logic = 2 ctrl sgn 1 = start/ stop c...

Page 53

Table 16: input signals, g2.2 index parameter min max unit default cust id description p2.2.17 place a reference scaling maximum value 0.00 304 selects the fre- quency that corre- sponds to the max. Reference signal 0.00 = no scaling >0 = scaled max. Value. P2.2.18 place b reference scaling minimum ...

Page 54

*** = parameter value can only be changed after the ac drive has been stopped. **** = use ttf method to program these parameters. Vacon · 54 local/remote control application 3 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 55

3.4.4 output signals (control keypad: menu m2 -> g2.3 table 17: output signals, g2.3 index parameter min max unit default cust id description p2.3.1 ao1 signal selec- tion 0.1 e.10 a11 464 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.2 analo...

Page 56

Table 17: output signals, g2.3 index parameter min max unit default cust id description p2.3.7 digital output 1 function 0 22 1 312 0 = not used 1 = ready 2 = run 3 = fault 4 = fault inverted 5 = fc overheat warning 6 = ext. Fault or warning 7 = ref. Fault or warning 8 = warning 9 = reversed 10 = jo...

Page 57

Table 17: output signals, g2.3 index parameter min max unit default cust id description p2.3.12 output frequency limit 2 supervision 0 2 0 346 0 = no limit 1 = low limit supervision 2 = high limit supervision p2.3.13 output frequency limit 2; supervi- sion value 0.00 320.00 hz 0.00 347 p2.3.14 torqu...

Page 58

Table 17: output signals, g2.3 index parameter min max unit default cust id description p2.3.24 analogue output 2 filter time 0.00 10.00 s 1.00 473 0 = no filtering p2.3.25 analogue output 2 inversion 0 1 0 474 0 = not inverted 1 = inverted p2.3.26 analogue output 2 minimum 0 1 0 475 0 = 0 ma (0 v) ...

Page 59

3.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 18: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 smooth ratio for s- curves. 0 = linear 100 = full acc/dec inc/dec tmes p2.4.2 ramp 2 shape 0.0 10.0...

Page 60

Table 18: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.9 dc braking time at stop 0.00 600.00 s 0.00 508 0 = dc brake is off at stop p2.4.10 frequency to start dc braking during ramp stop 0.10 10.00 hz 1.50 515 p2.4.11 dc braking time at start 0.00 600....

Page 61

3.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 20: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 * motor control mode 0 1/3 0 600 0 = frequency control 1 = speed control nxp: 2 = open loop tor- que control 3 = closed loop speed...

Page 62

Table 20: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.7 * u/f curve midpoint voltage 0.00 100.00 % 100.00 605 if the value of p2.6.3 is program- mable, this param- eter gives the mid- dle point frequency of the curve. P2.6.8 * output voltage at zero f...

Page 63

Table 20: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.13 identification 0 1/2 0 631 0 = no action 1 = identification w/o run 2 = identification with run 3 = encoder id run 4 = no action 5 = id run failed closed loop parameter group 2.6.14 p2.6.14.1 ma...

Page 64

Table 20: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.14.11 start-up torque 0 3 0 621 0 = not used 1 = torque mem- ory 2 = torque refer- ence 3 = start-up torque fwd/rev p2.6.14.12 start-up torque fwd -300.0 300.0 % 0.0 633 p2.6.14.13 start-up torque ...

Page 65

3.4.8 protections (control keypad: menu m2 -> g2.7 table 21: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 0 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4.7...

Page 66

Table 21: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 0 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 2 x i h a i h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711 ...

Page 67

3.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 22: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial ...

Page 68

Table 23: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 1 3 1 125 1 = i/0 terminal 2 = keypad 3 = fieldbus p3.2 keypad reference p2.1 p2.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 you can adjust the frequency refer- ence on the keypad...

Page 69

4 multi-step speed control application 4.1 introduction select the multi-step speed control application in menu m6 on page s6.2. The multi-step speed control application can be used in applications where fixed speeds are needed. In total, 15 + 2 different speeds can be programmed: one basic speed, 1...

Page 70

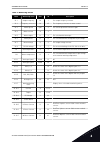

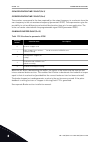

4.2 control i/o 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 ma basic reference (optional) run ready ao1- do1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal description +10v ref ai1+ ai1- ai2+ ai2- +24v reference ...

Page 71

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 11: jumper...

Page 72

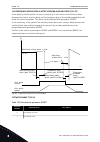

4.3 control signal logic in multi-step speed control application din4 din5 ai1 ai2 din1 din2 din3 din6 din3 din3 3.2 keypad reference 2.1.11 i/o reference 2.1.12 keypad ctrl reference 2.1.13 fieldbus ctrl reference 2.1.15 preset speed 1 ...2.1.29 preset speed 15 3.1 control place internal frequency ...

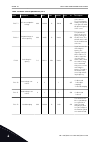

Page 73

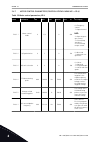

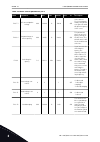

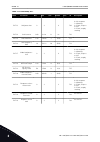

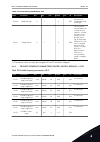

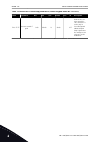

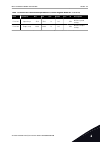

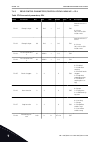

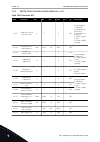

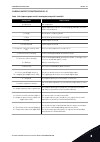

Table 24: monitoring values index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 motor torque...

Page 74

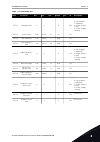

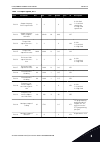

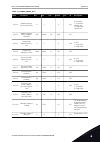

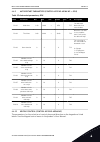

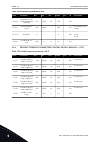

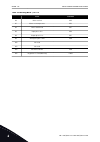

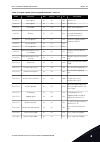

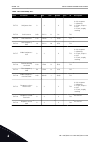

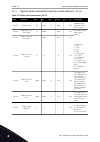

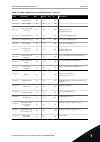

4.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 25: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabil...

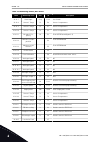

Page 75

Table 25: basic parameters g2.1 index parameter min max unit default cust id description p2.1.10 * motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.11 * i/o reference 0 3 1 117 0 = ai1 1 = ai2 2 = keypad 3 = fieldbus p2.1.12 * keypad control reference 0 3 2 121 ...

Page 76

Table 25: basic parameters g2.1 index parameter min max unit default cust id description p2.1.25 preset speed 11 0.00 p2.1.2 hz 32.50 136 speeds preset by operator. P2.1.26 preset speed 12 0.00 p2.1.2 hz 35.00 137 speeds preset by operator. P2.1.27 preset speed 13 0.00 p2.1.2 hz 40.00 138 speeds pre...

Page 77

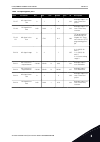

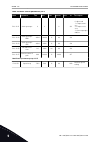

4.4.3 input signals (control keypad: menu m2 -> g2.2) table 26: input signals, g2.2 index parameter min max unit default cust id description p2.2.1 *** start/stop logic 0 6 0 300 logic = 0 ctrl sgn 1 = start forward ctrl sgn 2 = start reverse logic = 1 ctrl sgn 1 = start/ stop ctrl sgn 2 = reverse l...

Page 78

Table 26: input signals, g2.2 index parameter min max unit default cust id description p2.2.2 din3 function 0 13 1 301 0 = not used 1 = ext. Fault, closing cont. 2 = ext. Fault, open- ing cont. 3 = run enable 4 = acc./dec. Time select. 5 = force cp. To io 6 = force cp. To key- pad 7 = force cp. To f...

Page 79

Table 26: input signals, g2.2 index parameter min max unit default cust id description p2.2.9 **** ai2 signal selec- tion 0.1 e.10 a.2 388 ttf programming method used. See chapter 8.9 "termi- nal to function" (ttf) programming princi- ple. P2.2.10 ai2 signal range 0 2 1 325 0 = 0-10v (0-20 ma**) 1 =...

Page 80

Table 26: input signals, g2.2 index parameter min max unit default cust id description p2.2.18 free analogue input, function 0 4 0 362 0 = no function 1 = reduces current limit (p2.1.5) 2 = reduces dc braking current, p2.4.8 3 = reduces accel. And decel. Tmes 4 = reduces torque supervision limit p2....

Page 81

4.4.4 output signals (control keypad: menu m2 -> g2.3 table 27: output signals, g2.3 index parameter min max unit default cust id description p2.3.1 * ao1 signal selec- tion 0.1 e.10 a11 464 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.2 ana...

Page 82

Table 27: output signals, g2.3 index parameter min max unit default cust id description p2.3.7 digital output 1 function 0 22 1 312 0 = not used 1 = ready 2 = run 3 = fault 4 = fault inverted 5 = fc overheat warning 6 = ext. Fault or warning 7 = ref. Fault or warning 8 = warning 9 = reversed 10 = jo...

Page 83

Table 27: output signals, g2.3 index parameter min max unit default cust id description p2.3.12 output frequency limit 2 supervision 0 2 0 346 0 = no limit 1 = low limit supervision 2 = high limit supervision p2.3.13 output frequency limit 2; supervi- sion value 0.00 320.00 hz 0.00 347 p2.3.14 torqu...

Page 84

Table 27: output signals, g2.3 index parameter min max unit default cust id description p2.3.24 * analogue output 2 filter time 0.00 10.00 s 1.00 473 0 = no filtering p2.3.25 * analogue output 2 inversion 0 1 0 474 0 = not inverted 1 = inverted p2.3.26 * analogue output 2 minimum 0 1 0 475 0 = 0 ma ...

Page 85

4.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 28: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 smooth ratio for s- curves. 0 = linear 100 = full acc/dec inc/dec tmes p2.4.2 ramp 2 shape 0.0 10.0...

Page 86

Table 28: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.9 dc braking time at stop 0.00 600.00 s 0.00 508 0 = dc brake is off at stop p2.4.10 frequency to start dc braking during ramp stop 0.10 10.00 hz 1.50 515 p2.4.11 dc braking time at start 0.00 600....

Page 87

4.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 30: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 * motor control mode 0 1/3 0 600 0 = frequency control 1 = speed control nxp: 2 = open loop tor- que control 3 = closed loop speed...

Page 88

Table 30: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.7 * u/f curve midpoint voltage 0.00 100.00 % 100.00 605 if the value of p2.6.3 is program- mable, this param- eter gives the mid- dle point frequency of the curve. P2.6.8 * output voltage at zero f...

Page 89

Table 30: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.13 identification 0 1/2 0 631 0 = no action 1 = identification w/o run 2 = identification with run 3 = encoder id run 4 = no action 5 = id run failed closed loop parameter group 2.6.14 p2.6.14.1 ma...

Page 90

Table 30: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.14.11 start-up torque 0 3 0 621 0 = not used 1 = torque mem- ory 2 = torque refer- ence 3 = start-up torque fwd/rev p2.6.14.12 start-up torque fwd -300.0 300.0 % 0.0 633 p2.6.14.13 start-up torque ...

Page 91

4.4.8 protections (control keypad: menu m2 -> g2.7) table 31: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 0 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4....

Page 92

Table 31: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 0 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 2 x i h a 1 h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711 ...

Page 93

4.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 32: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial ...

Page 94

Table 33: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 1 3 1 125 1 = i/0 terminal 2 = keypad 3 = fieldbus p3.2 keypad reference p2.1.1 p2.1.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 you can adjust the frequency refer- ence on the ke...

Page 95: Pid Control Application

5 pid control application 5.1 introduction select the pid control application in menu m6 on page s6.2 in the pid control application, there are two i/o terminal control places; place a is the pid controller and source b is the direct frequency reference. The control place a or b is selected with dig...

Page 96

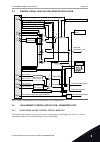

5.2 control i/o - + 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 2-wire transmitter reference potentiometer, 1-10kΩ ma run ready ao1- do1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal description +10v ref ai1+ ai...

Page 97

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 14: jumper...

Page 98

5.3 control signal logic in pid control application din2 din5 din3 din2 din3 din5 din6 din2 din3 ai1 ai2 0 1 2 3 4 0 1 2 3 4 5 +a a b 0 1 2 3 4 5 0 1 2 3 4 5 k 0 1 2 3 4 5 f pid + din1 din4 a b a b a/b internal reverse internal fault reset fault reset input (programmable) 3.3 keypad direction intern...

Page 99

Table 34: monitoring values index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 motor torque...

Page 100

Table 34: monitoring values index monitoring value unit id description v1.24 pt-100 temperature ºc 42 highest temperature of used inputs g1.25 monitoring items displays three selectable monitoring values v1.26.1 current a 1113 v1.26.2 torque % 1125 v1.26.3 dc voltage v 44 v1.26.4 status word 43 vaco...

Page 101

5.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 35: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabil...

Page 102

Table 35: basic parameters g2.1 index parameter min max unit default cust id description p2.1.10 * motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.11 * pid controller ref- erence signal (place a) 0 4 1 332 0 = ai1 1 = ai2 2 = pid ref from keypad control page, p...

Page 103

Table 35: basic parameters g2.1 index parameter min max unit default cust id description p1.1.16 sleep delay 0 3600 s 30 1017 the minimum quantity of time during which the frequency has to stay below the sleep level before the drive stops. P1.1.17 wake up level 0.00 100.00 % 25.00 1018 gives the lev...

Page 104

5.4.3 input signals table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.1 ** din2 function 0 13 1 319 0 = not used 1 = external fault cc 2 = external fault oc 3 = run enable 4 = acc/dec time selection 5 = cp: i/o termi- nal (id125) 6 = cp: keypad (id125) 7 = c...

Page 105

Table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.4 ** pid sum point ref- erence 0 7 0 376 0 = direct pid out- put value 1 = ai1+pid output 2 = ai2+pid output 3 = ai3+pid output 4 = ai4+pid output 5 = pid keypad +pid output 6 = fieldbus+pid output (process- ...

Page 106

Table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.9 ** actual value 1 selection 0 10 2 334 0 = not used 1 = ai1 signal (c- board) 2 = ai2 signal (c- board) 3 = ai3 4 = ai4 5 = fieldbus proc- essdatain2 6 = motor torque 7 = motor speed 8 = motor current 9 = m...

Page 107

Table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.16 ai1 signal range 0 2 0 320 0 = 0—10 v (0—20 ma*) 1 = 2—10 v (4 – 20 ma*) 2 = custom range* p2.2.17 ai1 custom mini- mum setting –160.00 160.00 % 0.00 321 p2.2.18 ai1 custom maxi- mum setting –160.00 160.00...

Page 108

Table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.28 motor potentiom- eter frequency reference mem- ory reset 0 2 1 367 0 = no reset 1 = reset if stop- ped or powered down 2 = reset if pow- ered down p2.2.29 motor potentiom- eter pid reference memory reset 0...

Page 109

Table 36: input signals, g2.2 index parameter min max unit default cust id description p2.2.39 ai3 signal range 0 1 1 143 0 = signal range 0 —10 v 1 = signal range 2 —10 v p2.2.40 ai3 inversion 0 1 0 151 0 = not inverted 1 = inverted p2.2.41 ai3 filter time 0.00 10.00 s 0.10 142 0 = no filtering p2....

Page 110

** = parameter value can only be changed after the fc has been stopped. *** = use ttf method to program these parameters. Vacon · 110 pid control application 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 111

5.4.4 output signals (control keypad: menu m2 -> g2.3 table 37: output signals, g2.3 index parameter min max unit default cust id description p2.3.1 * ao1 signal selec- tion 0.1 e.10 a.1 464 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.2 ana...

Page 112

Table 37: output signals, g2.3 index parameter min max unit default cust id description p2.3.6 analogue output scale 10 1000 % 100 311 p2.3.7 digital output 1 function 0 23 1 312 0 = not used 1 = ready 2 = run 3 = fault 4 = fault inverted 5 = fc overheat warning 6 = ext. Fault or warning 7 = ref. Fa...

Page 113

Table 37: output signals, g2.3 index parameter min max unit default cust id description p2.3.11 output frequency limit 1; supervised value 0.00 320.00 hz 0.00 316 p2.3.12 output frequency limit 2 supervision 0 2 0 346 0 = no limit 1 = low limit supervision 2 = high limit supervision p2.3.13 output f...

Page 114

Table 37: output signals, g2.3 index parameter min max unit default cust id description p2.3.23 analogue output 2 function 0 14 4 472 as parameter 2.3.2 p2.3.24 analogue output 2 filter time 0.00 10.00 s 1.00 473 0 = no filtering p2.3.25 analogue output 2 inversion 0 1 0 474 0 = not inverted 1 = inv...

Page 115

5.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 38: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 0 = linear >0 = s-curve ramp time p2.4.2 ramp 2 shape 0.0 10.0 s 0.0 501 0 = linear >0 = s-curve ra...

Page 116

Table 38: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.10 frequency to start dc braking during ramp stop 0.10 10.00 hz 1.50 515 p2.4.11 dc braking time at start 0.00 600.00 s 0.00 516 0 = dc brake is off at start p2.4.12 * flux brake 0 1 0 520 0 = off ...

Page 117

5.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 40: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 motor control mode 0 1/3 0 600 0 = frequency control 1 = speed control nxp: 2 = not used 3 = closed loop speed ctrl 4 = closed loo...

Page 118

Table 40: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.7 u/f curve midpoint voltage 0.00 100.00 % 100.00 605 if the value of p2.6.3 is program- mable, this param- eter gives the mid- dle point frequency of the curve. P2.6.8 output voltage at zero frequ...

Page 119

Table 40: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.13 identification 0 1/2 0 631 0 = no action 1 = identification w/o run 2 = identification with run closed loop parameter group 2.6.14 p2.6.14.1 magnetizing cur- rent 0.00 2 x i h a 0.00 612 the mag...

Page 120

Table 40: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.14.11 start-up torque 0 3 0 621 0 = not used 1 = torque mem- ory 2 = torque refer- ence 3 = start-up torque fwd/rev p2.6.14.12 start-up torque fwd -300.0 300.00 % 0.0 633 p2.6.14.13 start-up torque...

Page 121

5.4.8 protections (control keypad: menu m2 -> g2.7 table 41: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 4 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4.7...

Page 122

Table 41: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 1 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 2 x i h a 1 h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711 ...

Page 123

Table 41: protections, g2.7 index parameter min max unit default cust id description p2.7.25 response to pt100 fault 0 3 0 740 0 = no response 1 = warning 2 = fault,stop acc. To 2.4.7 3 = fault,stop by coasting p2.7.26 pt100 warning limit -30.0 200.0 ºc 120.0 741 p2.7.27 pt100 fault limit -30.0 200....

Page 124

5.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 42: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial ...

Page 125

Table 43: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 1 3 1 125 1 = i/0 terminal 2 = keypad 3 = fieldbus p3.2 keypad reference p2.1.1 p2.1.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 you can adjust the frequency refer- ence on the ke...

Page 126

6 multi-purpose control application 6.1 introduction select the multi-purpose control application in menu m6 on page s6.2. The multi-purpose control application provides a wide range of parameters for controlling motors. It can be used for various kinds of different processes, where wide flexibility...

Page 127

The parameters of the multi-purpose control application are explained in chapter 8 parameter descriptions of this manual. The explanations are arranged according to the individual id number of the parameter. Multi-purpose control application vacon · 127 24-hour support +358 (0)201 212 575 · email: v...

Page 128

6.2 control i/o 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 ma run ready aoa1- doa1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal description +10 v ref ai1+ ai1- ai2+ ai2- +24v reference output i/o ground analog...

Page 129

Note! See jumper selections below. More information in the product's user manual. Jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together,isolated from gnd = factory default fig. 17: jumper...

Page 130

6.4 multi-purpose control application - parameter lists 6.4.1 monitoring values (control keypad: menu m1) the monitoring values are the actual values of parameters and signals as well as statuses and measurements. Monitoring values marked with asterisk (*) can be controlled from the fieldbus. Vacon ...

Page 131

Table 44: monitoring values, nxs drives index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 ...

Page 132

Table 44: monitoring values, nxs drives index monitoring value unit id description v1.21.7 warnig 74 last active warning. V1.21.8 sensor 1 temp ºc 50 sensor 1 temperature v1.21.9 sensor 2 temp ºc 51 sensor 2 temperature v1.21.10 sensor 3 temp ºc 52 sensor 3 temperature v1.21.25 sensor 4 temp ºc 69 s...

Page 133

Table 45: monitoring values, nxp drives index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 ...

Page 134

Table 45: monitoring values, nxp drives index monitoring value unit id description v1.21.7 shaft angle deg 1169 see id1090 v1.21.8 sensor 1 temp ºc 50 sensor 1 temperature v1.21.9 sensor 2 temp ºc 51 sensor 2 temperature v1.21.10 sensor 3 temp ºc 52 sensor 3 temperature v1.21.11 encoder 2 fre- quenc...

Page 135

Table 45: monitoring values, nxp drives index monitoring value unit id description v1.22.6 motor current to fb a 45 motor current (drive independent) given with one decimal point v1.22.7 din statusword 1 56 see table 47 digital input statuses: id56 and id57 v1.22.8 din statusword 2 57 see table 47 d...

Page 136

Table 47: digital input statuses: id56 and id57 din statusword 1 din statusword 2 b0 din: a.1 din: c.5 b1 din: a.2 din: c.6 b2 din: a.3 din: d.1 b3 din: a.4 din: d.2 b4 din: a.5 din: d.3 b5 din: a.6 din: d.4 b6 din: b.1 din: d.5 b7 din: b.2 din: d.6 b8 din: b.3 din: e.1 b9 din: b.4 din: e.2 b10 din:...

Page 137

Table 48: fault word 1, id1172 fault comment b0 overcurrent or igbt f1, f31, f41 b1 overvoltage f2 b2 undervoltage f9 b3 motor stalled f15 b4 earth fault f3 b5 motor underload f17 b6 drive overtemperature f14 b7 overtemperature f16, f56, f29 b8 input phase f10 b11 keypad or pc control f52 b12 fieldb...

Page 138

Table 50: warning word 1, id1174 fault comment b0 motor stalled w15 b1 motor overtemperature w16 b2 motor underload w17 b3 input phase loss w10 b4 output phase loss w11 b9 analogue input w50 b10 not used b13 not used b14 mechanical brake w58 b15 keypad or pc fault/warning fw52 vacon · 138 multi-purp...

Page 139

Table 51: systembus status word, id1601 false true b0 reserved b1 drive 1 ready b2 drive 1 running b3 drive 1 fault b4 reserved b5 drive 2 ready b6 drive 2 running b7 drive 2 fault b8 reserved b9 drive 3 ready b10 drive 3 running b11 drive 3 fault b12 reserved b13 drive 4 ready b14 drive 4 running b...

Page 140

Table 52: follower drive status word false true b0 flux not ready flux ready (>90 %) b1 not in ready state ready b2 not running running b3 no fault fault b4 charge switch state b5 b6 run disabled run enable b7 no warning warning b8 b9 b10 b11 no dc brake dc brake is active b12 no run request run req...

Page 141

Table 53: appliction status word content application standard loc/rem multi-step pid mp pfc status word b0 b1 ready ready ready ready ready ready b2 run run run run run run b3 fault fault fault fault fault fault b4 b5 no emstop (nxp) b6 run enable run enable run enable run enable run enable run enab...

Page 142

6.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 54: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabil...

Page 143

Table 54: basic parameters g2.1 index parameter min max unit default cust id description p2.1.9 * nominal current of the motor varies varies a 5.40 113 find the value in on the rating plate of the motor. P2.1.10 motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.1...

Page 144

Table 54: basic parameters g2.1 index parameter min max unit default cust id description p2.1.14 jogging speed refrerence 0.00 p2.1.2 hz 5.00 124 see id413 in chap- ter 8 parameter descriptions. P2.1.15 preset speed 1 0.00 p2.1.2 hz 10.00 105 speeds preset by operator. P2.1.16 preset speed 2 0.00 p2...

Page 145

6.4.3 input signals table 55: basic settings (control keypad: menu m2 -> g2.2.1) index parameter min max unit default cust id description start/p2.2.1.1 ** stop logic selec- tion 0 7 0 300 logic = 0 ctrl sgn 1 = start forward ctrl sgn 2 = start reverse logic = 1 ctrl sgn 1 = start/ stop ctrl sgn 2 =...

Page 146

Table 55: basic settings (control keypad: menu m2 -> g2.2.1) index parameter min max unit default cust id description p2.2.1.2 ** motor potentiom- eter ramp time 0.1 2000.0 hz/s 10.0 331 the rate of change in the motor potenti- ometer reference when it is increased or decreased with di5 or di6. P2.2...

Page 147

Table 56: analogue input 1 (control keypad: menu m2 -> g2.2.2) index parameter min max unit default cust id description p2.2.2.1 ** ai1 signal selec- tion 0.1 e.10 a.1 377 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.2.2 ai1 filter time 0.00 320.00 s ...

Page 148

Table 56: analogue input 1 (control keypad: menu m2 -> g2.2.2) index parameter min max unit default cust id description p2.2.2.11 ai1 joystick offset -100.00 100.00 % 0.00 165 press 'enter' for 1s to set offset, 'reset' to set 0.00. * = remember to place jumpers of block x2 accordingly. See the prod...

Page 149

Table 57: analogue input 2 (control keypad: menu m2 -> g2.2.3) index parameter min max unit default cust id description p2.2.3.1 ** ai2 signal selec- tion 0.1 e.10 a.2 388 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.3.2 ai2 filter time 0.00 320.00 s ...

Page 150

** = apply the terminal to function method (ttf) to these parameters (see chapter 8.9 "terminal to function" (ttf) programming principle) table 58: analogue input 3 (control keypad: menu m2 -> g2.2.4) index parameter min max unit default cust id description p2.2.4.1 ** ai3 signal selec- tion 0.1 e.1...

Page 151

Table 59: analogue input 4 (control keypad: menu m2 -> g2.2.5) index parameter min max unit default cust id description p2.2.5.1 ** ai4 signal selec- tion 0.1 e.10 0.1 152 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.5.2 ai4 filter time 0.00 320.00 s ...

Page 152

Table 60: free analogue input, signal selection (keypad: menu m2 -> g2.2.6) index parameter min max unit default cust id description p2.2.6.1 scaling of current limit 0 5 0 399 0 = not used 1= ai1 2 = ai2 3 = ai3 4 = ai4 5 = fb limit scal- ing see group g2.9 p2.2.6.2 scaling of dc- braking current 0...

Page 153

Table 61: digital inputs (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.2.7.1 * start signal 1 0.1 a.1 403 see p2.2.1.1. P2.2.7.2 * start signal 2 0.1 a.2 404 see p2.2.1.1. P2.2.7.3 * run enable 0.1 0.2 407 motor start enabled (cc) p2.2.7.4 * reverse 0.1 0.1 4...

Page 154

Table 61: digital inputs (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.2.7.21 * parameter set 1/set 2 selection 0.1 0.1 496 closed cont.=set 2 is used open cont.= set 1 is used p2.2.7.22 * motor control mode 1/2 0.1 0.1 164 closed cont.= mode 2 is used open c...

Page 155

6.4.4 output signals table 62: delayed digital output 1 (keypad: menu m2 -> g2.3.1) index parameter min max unit default cust id description p2.3.1.1 * digital output 1 signal selection 0.1 e.10 0.1 486 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle...

Page 156

Table 62: delayed digital output 1 (keypad: menu m2 -> g2.3.1) index parameter min max unit default cust id description p2.3.1.2 digital output 1 function 0 29 1 312 0 = not used 1 = ready 2 = run 3 = fault 4 = fault inverted 5 = fc overheat warning 6 = ext. Fault or warning 7 = ref. Fault or warnin...

Page 157

Table 62: delayed digital output 1 (keypad: menu m2 -> g2.3.1) index parameter min max unit default cust id description p2.3.1.3 digital output 1 on delay 0.00 320.00 s 0.00 487 0.00 = on delay not in use p2.3.1.4 digital output 1 off delay 0.00 320.00 s 0.00 488 0.00 = on delay not in use nxp drive...

Page 158

Table 64: digital ouput signals (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.3.3.1 * ready 0.1 a.1 432 ready to run p2.3.3.2 * run 0.1 b.1 433 running p2.3.3.3 * fault 0.1 b.2 434 drive in fault state p2.3.3.4 * inverted fault 0.1 0.1 435 drive not in fault ...

Page 159

Table 64: digital ouput signals (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.3.3.23 * motor regulator activation 0.1 0.1 454 p2.3.3.24 * fieldbus din 1 0.1 0.1 455 see fieldbus manual p2.3.3.25 * fieldbus din 2 0.1 0.1 456 see fieldbus manual p2.3.3.26 * fie...

Page 160

Table 65: limit settings (control keypad: menu m2 -> g2.3.4) index parameter min max unit default cust id description p2.3.4.1 output frequency limit 1 supervision 0 3 0 315 0 = no supervision 1 = low limit supervision 2 = high limit supervision 3 = brake-on con- trol p2.3.4.2 output frequency limit...

Page 161

Table 65: limit settings (control keypad: menu m2 -> g2.3.4) index parameter min max unit default cust id description p2.3.4.9 external brake-off delay 0.0 100.0 s 0.5 352 from brake-off limits. P2.3.4.10 external brake-on delay 0.0 100.0 s 1.5 353 from run request. Use time longer than p2.1.4. P2.3...

Page 162

Table 66: analogue output 1 (control keypad: menu m2 -> g2.3.5) index parameter min max unit default cust id description p2.3.5.1 * analogue output 1 signal selection 0.1 e.10 a.1 464 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.5.2 analogue...

Page 163

Table 66: analogue output 1 (control keypad: menu m2 -> g2.3.5) index parameter min max unit default cust id description p2.3.5.6 analogue output 1 scale 10 1000 % 100 311 p2.3.5.7 analogue output 1 offset -100.00 100.00 % 0.00 375 * = use ttf method to program these parameters. Table 67: analogue o...

Page 164

Table 68: analogue output 3 (control keypad: menu m2 -> g2.3.7) index parameter min max unit default cust id description p2.3.7.1 * analogue output 3 signal selection 0.1 e.10 0.1 478 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle . P2.3.7.2 analogu...

Page 165

6.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 69: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 0 = linear 100 = full acc/dec inc/dec times p2.4.2 ramp 2 shape 0.0 10.0 s 0.0 501 0 = linear 100 =...

Page 166

Table 69: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.7 stop function 0 3 0 506 0 = coasting 1 = ramp 2 = ramp+run enable coast 3 = coast+run enable ramp p2.4.8 dc braking cur- rent 0.00 i l a 0.7 x i h 507 defines the cur- rent injected into the moto...

Page 167

Table 69: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.20 modulator type 0 1 0 1516 parameter for changing the mod- ulator type. P2.4.21 ramp; skip s2 0 1 0 1900 this function is used to bypass the second corner s ramp (i.E. To avoid the unnecessary sp...

Page 168

6.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 71: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 motor control mode 0 2/4 0 600 0 = frequency control 1 = speed control 2 = torque control nxp: 3 = closed loop speed ctrl 4 = clos...

Page 169

Table 71: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.7 u/f curve midpoint voltage 0.00 100.00 % 100.00 605 if the value of p2.6.3 is program- mable, this param- eter gives the mid- dle point frequency of the curve. P2.6.8 output voltage at zero frequ...

Page 170

Table 71: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.15 load drooping 0.00 100.00 % 0.00 620 the drooping func- tion enables speed drop as a function of load. Drooping will be defined in percent of nominal speed at nominal load. P2.6.16 identificatio...

Page 171

Table 72: nxs drives: closed loop parameters (control keypad: menu m2 ->g2.6.23) index parameter min max unit default cust id description p2.6.17.1 magnetizing cur- rent 0.00 2 x i h a 0.00 612 if zero internally calculated. P2.6.17.2 speed control p 1 1000 30 613 p2.6.17.3 speed control i time -320...

Page 172

Table 72: nxs drives: closed loop parameters (control keypad: menu m2 ->g2.6.23) index parameter min max unit default cust id description p2.6.17.17 current control p gain 0.00 100.00 % 40.00 617 gain for the cur- rent controller. This controller is active only in closed loop and advanced open loop....

Page 173

Table 73: nxp drives: closed loop parameters (control keypad: menu m2 ->g2.6.23) index parameter min max unit default cust id description p2.6.23.1 magnetizing cur- rent 0.00 2 x i h a 0.00 612 if zero internally calculated. P2.6.23.2 speed control p 1 1000 30 613 p2.6.23.3 speed control i time -320...

Page 174

Table 73: nxp drives: closed loop parameters (control keypad: menu m2 ->g2.6.23) index parameter min max unit default cust id description p2.6.23.17 current control p gain 0.00 320.00 % 40.00 617 gain for the cur- rent controller. This controller is active only in closed loop and advanced open loop....

Page 175

Table 73: nxp drives: closed loop parameters (control keypad: menu m2 ->g2.6.23) index parameter min max unit default cust id description p2.6.23.34 modulation limit 0 150 % 100 655 if sinus filter is used set this value to 96%. Multi-purpose control application vacon · 175 24-hour support +358 (0)2...

Page 176

Table 74: nxp drives: pms motor control parameters (control keypad: menu m2 -> g2.6.24) index parameter min max unit default cust id description p2.6.24.1 motor type 0 1 0 650 0 = induction motor 1 = pms motor p2.6.24.2 pmsmshaft posi- tion 0 65535 0 649 low word of encoder (endat) angle correspond-...

Page 177

Table 75: nxs drives: identification parameters (control keypad: menu m2 -> g2.6.25) index parameter min max unit default cust id description p2.6.18.1 speed step -50.0 50.0 % 0.0 1252 ncdrive speed tuning. P2.6.18.2 torque step -100.0 300.0 % 0.0 1253 ncdrive torque tuning. Multi-purpose control ap...

Page 178

Table 76: nxp drives: identification parameters (control keypad: menu m2 -> g2.6.25) index parameter min max unit default cust id description p2.6.25.1 flux 10 % 0.0 250.0 % 10.0 1355 p2.6.25.2 flux 20 % 0.0 250.0 % 20.0 1356 p2.6.25.3 flux 30 % 0.0 250.0 % 30.0 1357 p2.6.25.4 flux 40 % 0.0 250.0 % ...

Page 179

Table 76: nxp drives: identification parameters (control keypad: menu m2 -> g2.6.25) index parameter min max unit default cust id description p2.6.25.22 iu offset -32000 32000 10000 668 p2.6.25.23 iv offset -32000 32000 0 669 p2.6.25.24 iw offset -32000 32000 0 670 p2.6.25.25 speed step -50.0 50.0 %...

Page 180

Table 77: stabilators index parameter min max unit default cust id description p2.6.26.1 torque stabilator gain 0 1000 100 1412 the gain of the tor- que stabilator in an open loop control operation. P2.6.26.2 torque stabilator damping 0 1000 900 1413 the damping time constant of the tor- que stabila...

Page 181

6.4.8 protections (control keypad: menu m2 -> g2.7 table 78: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 0 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4.7...

Page 182

Table 78: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 0 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 p2.1.2 a 1 h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711 p...

Page 183

Table 78: protections, g2.7 index parameter min max unit default cust id description p2.7.24 tboard1 numbers 0 5 0 739 0 = not used 1 = channel 1 2 = channel 1 & 2 3 = channel 1 & 2 & 3 4 = channel 2 & 3 5 = channel 3 p2.7.25 tboard flt. Resp 0 3 0 740 0 = no response 1 = warning 2 = fault, stop acc...

Page 184

Table 78: protections, g2.7 index parameter min max unit default cust id description p2.7.33 speed error mode 0 2 0 752 0 = no response 1 = warning 2 = fault, stop by coasting p2.7.34 speed error maxi- mum difference 0 100 % 5 753 p2.7.35 speed error fault delay 0.00 100.0 s 0.50 754 p2.7.36 safe di...

Page 185

Table 78: protections, g2.7 index parameter min max unit default cust id description p2.7.38 tboard2 warn.Lim -30.0 200.0 cº 120 745 set here the limit at which the tem- perature warning will be activated. P2.7.39 tboard2 flt.Lim -30.0 200.0 cº 130 746 set here the limit at which the tem- perature f...

Page 186

6.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 79: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial ...

Page 187

6.4.10 fieldbus parameters (control keypad: menu m2 ->g2.9) table 80: fieldbus parameters index parameter min max unit default cust id description p2.9.1 fieldbus min scale 0.00 320.00 hz 0.00 850 p2.9.2 fieldbus max scale 0.00 320.00 hz 0.00 851 p2.9.3 fieldbus process data out 1 selec- tion 0 1000...

Page 188

Table 80: fieldbus parameters index parameter min max unit default cust id description p2.9.10 fieldbus process data out 8 selec- tion 0 10000 37 859 make the selection of the process data out with the parameter id. Nxp drives only (in nxs, default values are not editable) p2.9.11 fieldbus process d...

Page 189

Table 80: fieldbus parameters index parameter min max unit default cust id description p2.9.17 fieldbus process data in 7 selection 0 10000 0 882 the raw value of process data in a 32-bit signed for- mat. Choose con- trolled data with parameter id. P2.9.18 fieldbus process data in 8 selection 0 1000...

Page 190

6.4.11 torque control parameters (control keypad: menu m2 -> g2.10) table 81: torque control parameters, g2.10 index parameter min max unit default cust id description p2.10.1 torque limit 0.0 300.0 % 300.0 609 combination of id1288 & id1287, lower is used. P2.10.2 torque limit con- trol p-gain 0 32...

Page 191

Table 81: torque control parameters, g2.10 index parameter min max unit default cust id description p2.10.8 minimum fre- quency for open loop torque con- trol 0.00 p2.1.2 hz 3.00 636 the output fre- quency limit below which the drive operates in the frequency control mode. P2.10.9 torque controller ...

Page 192

Table 81: torque control parameters, g2.10 index parameter min max unit default cust id description p2.10.14 window positive 0.00 50.00 hz 2.00 1304 p2.10.15 window negative off 0.00 p2.10.13 hz 0.00 1307 p2.10.16 window positive off 0.00 p2.10.14 hz 0.00 1306 p2.10.17 speed control out- put limit 0...

Page 193

6.4.12 nxp drives: master follower parameters (control keypad: menu m2 - > g2.11) table 82: master follower parameters, g2.5 index parameter min max unit default cust id description p2.11.1 master follower mode 0 2 0 1324 0 = single drive 1 = master drive 2 = follower drive p2.11.2 follower stop fun...

Page 194

Table 82: master follower parameters, g2.5 index parameter min max unit default cust id description p2.11.4 follower torque reference select 0 9 9 1083 0 = not used 1 = ai1 2 = ai2 3 = ai3 4 = ai4 5 = ai1 joystick 6 = ai2 joystick 7 = torque refer- ence from keypad, r3.5 8 = fb torque ref- erence 9 ...

Page 195

Table 83: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 0 3 1 125 0 = pc control 1 = i/0 terminal 2 = keypad 3 = fieldbus r3.2 keypad reference p2.1.1 p2.1.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 0 = forward 1 = reverse p3.4 stop b...

Page 196

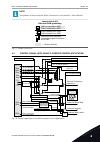

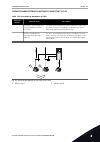

7 pump and fan control application 7.1 introduction select the pump and fan control application in menu m6 on page s6.2. The pump and fan control application can be used to control one variable speed drive and up to four auxiliary drives. The pid controller of the ac drive controls the speed of the ...

Page 197

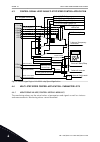

7.2 control i/o 1 6 2 3 4 5 18 19 20 12 7 13 8 9 10 14 15 16 21 22 23 11 17 24 25 26 fault + - ao1-(gnd) do1 +24 v gnd gnd din1 din2 din3 din4 din5 din6 r o1 r o1 r o1 cma cmb r o2 r o2 r o2 opta1 opta2 terminal signal description +10v ref ai1+ ai1- ai2+ ai2- +24v reference output i/o ground analogu...

Page 198

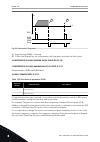

*) see table 92 digital output signals (control keypad: menu m2 -> g2.3.1). **) see table 94 analogue output 1 (control keypad: menu m2 -> g2.3.3), table 95 analogue output 2 (control keypad: menu m2 -> g2.3.4) and table 96 analogue output 3 (control keypad: menu m2 -> g2.3.7). Note! See jumper sele...

Page 199

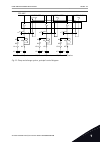

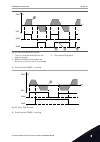

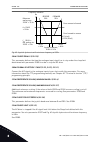

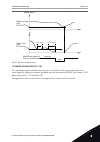

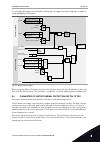

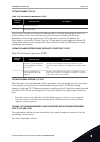

22 23 din2 a o mains a o mains 25 26 230 vac s1 k1 k1.1 k1.1 k2 k2 k1 vacon opt-b5 k1 k2 k2 k2.1 m1/vacon m2/vacon m3/vacon m2/mains m1/mains 24 vdc s2 k3 k3 k2.1 k1 k3 din3 k3 28 29 a o mains s3 k3 k3.1 k3.1 k2 k2 k3 k1 k1 din4 10 12 9 14 vacon opt-b5 vacon opt-a1 vacon opt-a1 vacon opt-a1 m3/mains...

Page 200

7.3 control signal logic in pump and fan control application ≥ 1 ≥ 1 din5 din# din6 din# din# ai1 ai2 0 1 2 3 0 1 2 3 4 5 a2 a1 b 0 1 2 3 4 0 1 2 3 4 k 0 1 2 3 4 f pid din1 din4 a b a b a/b din2 din3 6 5 6 7 5 6 5 6 5 6 ai3 ai4 4 a1 = pid reference (i/o a); a2 = pid reference 2 (i/o a); b = direct f...

Page 201

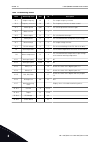

Table 84: monitoring values index monitoring value unit id description v1.1 output frequency hz 1 the output frequency to motor v1.2 frequency reference hz 25 the frequency reference to motor control v1.3 motor speed rpm 2 the actual speed of the motor in rpm v1.4 motor current a 3 v1.5 motor torque...

Page 202

Table 84: monitoring values index monitoring value unit id description v1.26.1 current a 1113 filtered motor current v1.26.2 torque % 1125 unfiltered motor torque v1.26.3 dc-link voltage v 7 dc voltage in volts v1.26.4 status word 43 v1.26.5 fault history 37 v1.26.6 motor current a 45 vacon · 202 pu...

Page 203

7.4.2 basic parameters (control keypad: menu m2 -> g2.1) table 85: basic parameters g2.1 index parameter min max unit default cust id description p2.1.1 min frequency 0.00 p2.1.2 hz 0.00 101 p2.1.2 max frequency p2.1.1 320.00 hz 50.00 102 if f max > than the motor synchro- nous speed, check suitabil...

Page 204

Table 85: basic parameters g2.1 index parameter min max unit default cust id description p2.1.10 * motor cos phi 0.30 1.00 0.85 120 find the value on the rating plate of the motor. P2.1.11 * pid controller ref- erence signal (place a) 0 6 4 332 0 = ai1 1 = ai2 2 = ai3 3 = ai4 4 = pid ref from keypad...

Page 205

Table 85: basic parameters g2.1 index parameter min max unit default cust id description p2.1.16 sleep delay 0 3600 s 30 1017 the minimum quantity of time during which the frequency has to stay below the sleep level before the drive stops. P2.1.17 wake up level 0.0 1000.0 % 25.0 1018 gives the level...

Page 206

7.4.3 input signals table 86: basic settings (control keypad: menu m2 -> g2.2.1) index parameter min max unit default cust id description p2.2.1.1 * i/o b frequency reference selec- tion 0 7 0 343 0 = ai1 1 = ai2 2 = ai3 3 = ai4 4 = keypad refer- ence 5 = fieldbus refer- ence (fb spee- dreference) 6...

Page 207

Table 86: basic settings (control keypad: menu m2 -> g2.2.1) index parameter min max unit default cust id description p2.2.1.8 * pid actual value selection 0 7 0 333 0 = actual value 1 1 = actual 1 + actual 2 2 = actual 1 - actual 2 3 = actual 1 * actual 2 4 = max (actual 1, actual 2) 5 = min (actua...

Page 208

Table 86: basic settings (control keypad: menu m2 -> g2.2.1) index parameter min max unit default cust id description p2.2.1.15 motor potentiom- eter ramp time 0.1 2000.0 hz/s 10.0 331 p2.2.1.16 motor potentiom- eter frequency reference mem- ory reset 0 2 1 367 0 = no reset 1 = reset if stop- ped or...

Page 209

Table 87: analogue input 1 (control keypad: menu m2 -> g2.2.2) index parameter min max unit default cust id description p2.2.2.1 ** ai1 signal selec- tion 0.1 e.10 a.1 377 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.2.2 ai1 filter time 0.00 10.00 s 0...

Page 210

Table 88: analogue input 2 (control keypad: menu m2 -> g2.2.3) index parameter min max unit default cust id description p2.2.3.1 ** ai2 signal selec- tion 0.1 e.10 a.2 388 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.3.2 ai2 filter time 0.00 10.00 s 0...

Page 211

Table 89: analogue input 3 (control keypad: menu m2 -> g2.2.4) index parameter min max unit default cust id description p2.2.4.1 ** ai3 signal selec- tion 0.1 e.10 0.1 141 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.4.2 ai3 filter time 0.00 10.00 s 0...

Page 212

Table 90: analogue input 4 (control keypad: menu m2 -> g2.2.5) index parameter min max unit default cust id description p2.2.5.1 ** ai4 signal selec- tion 0.1 e.10 0.1 152 ttf programming. See chapter 8.9 "terminal to func- tion" (ttf) pro- gramming principle. P2.2.5.2 ai4 filter time 0.00 10.00 s 0...

Page 213

Table 91: digital inputs (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.2.6.1 * start a signal 0.1 a.1 423 p2.2.6.2 * start b signal 0.1 a.4 424 p2.2.6.3 * control place a/b selection 0.1 a.6 425 control place a (oc) control place b (cc) p2.2.6.4 * external fa...

Page 214

Table 91: digital inputs (control keypad: menu m2 -> g2.2.4) index parameter min default cust id description p2.2.6.19 * autochange 2 interlock 0.1 a.3 427 activated if cc p2.2.6.20 * autochange 3 interlock 0.1 0.1 428 activated if cc p2.2.6.21 * autochange 4 interlock 0.1 0.1 429 activated if cc p2...

Page 215

Table 92: digital output signals (control keypad: menu m2 -> g2.3.1) index parameter min default cust id description p2.3.1.1 ready 0.1 0.1 432 ready to run p2.3.1.2 run 0.1 0.1 433 running p2.3.1.3 fault 0.1 a.1 434 drive in fault state p2.3.1.4 inverted fault 0.1 0.1 435 drive not in fault state p...

Page 216

Table 92: digital output signals (control keypad: menu m2 -> g2.3.1) index parameter min default cust id description p2.3.1.22 analogue input supervision limit 0.1 0.1 463 p2.3.1.23 motor regulator activation 0.1 0.1 454 a limit controller is active p2.3.1.24 fieldbus din 1 0.1 0.1 455 p2.3.1.25 fie...

Page 217

Table 93: limit settings (control keypad: menu m2 -> g2.3.2) index parameter min max unit default cust id description p2.3.2.1 output frequency limit 1 supervision 0 2 0 315 0 = no limit 1 = low limit supervision 2 = high limit supervision p2.3.2.2 output frequency limit 1; supervised value 0.00 320...

Page 218

Table 93: limit settings (control keypad: menu m2 -> g2.3.2) index parameter min max unit default cust id description p2.3.2.12 fc temperature supervised value -10 100 °c 40 355 p2.3.2.13 supervised ana- logue input 0 1 0 372 0 = ai1 1 = ai2 p2.3.2.14 analogue input limit supervision 0 2 0 373 0 = n...

Page 219

Table 94: analogue output 1 (control keypad: menu m2 -> g2.3.3) index parameter min max unit default cust id description p2.3.3.1 * analogue output 1 signal selection 0.1 e.10 a.1 464 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.3.2 analogue...

Page 220

Table 94: analogue output 1 (control keypad: menu m2 -> g2.3.3) index parameter min max unit default cust id description p2.3.3.7 analogue output offset -100.00 100.00 % 0.00 375 * = use ttf method to program these parameters. Table 95: analogue output 2 (control keypad: menu m2 -> g2.3.4) index par...

Page 221

Table 96: analogue output 3 (control keypad: menu m2 -> g2.3.7) index parameter min max unit default cust id description p2.3.5.1 * analogue output 3 signal selection 0.1 e.10 0.1 478 ttf programming method used. See chapter 8.9 "ter- minal to function" (ttf) programming principle. P2.3.5.2 analogue...

Page 222

7.4.5 drive control parameters (control keypad: menu m2 -> g2.4 table 97: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.1 ramp 1 shape 0.0 10.0 s 0.1 500 smooth ratio for s- curves. 0 = linear 100 = full acc/dec inc/dec tmes p2.4.2 ramp 2 shape 0.0 10.0...

Page 223

Table 97: drive control parameters, g2.4 index parameter min max unit default cust id description p2.4.9 dc braking time at stop 0.00 600.00 s 0.00 508 0 = dc brake is off at stop p2.4.10 frequency to start dc braking during ramp stop 0.10 10.00 hz 1.50 515 p2.4.11 dc braking time at start 0.00 600....

Page 224

7.4.7 motor control parameters (control keypad: menu m2 -> g2.6) table 99: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.1 * motor control mode 0 1 0 600 0 = frequency control 1 = speed control p2.6.2 * u/f optimisation 0 1 0 109 0 = not used 1 = automa...

Page 225

Table 99: motor control parameters, g2.6 index parameter min max unit default cust id description p2.6.10 overvoltage con- troller 0 2 1 607 0 = not used 1 = used (no ramping) 2 = used (ramping p2.6.11 undervoltage con- troller 0 1 1 608 0 = not used 1 = used p2.6.12 identification 631 0 = no action...

Page 226

7.4.8 protections (control keypad: menu m2 -> g2.7 table 100: protections, g2.7 index parameter min max unit default cust id description p2.7.1 response to 4 ma reference fault 0 5 4 700 0 = no response 1 = warning 2 = warning+pre- vious freq. 3 = wrng+preset- freq 2.7.2 4 = fault, stop acc. To 2.4....

Page 227

Table 100: protections, g2.7 index parameter min max unit default cust id description p2.7.13 stall protection 0 3 1 709 0 = no response 1 = warning 2 = fault, stop acc. To 2.4.7 3 = fault, stop by coasting p2.7.14 stall current 0.00 2 x i h a 1 h 710 p2.7.15 stall time limit 1.00 120.00 s 15.00 711...

Page 228

Table 100: protections, g2.7 index parameter min max unit default cust id description p2.7.25 response to pt100 fault 0 3 0 740 0 = no response 1 = warning 2 = fault,stop acc. To 2.4.7 3 = fault,stop by coasting p2.7.26 pt100 warning limit -30.0 200.0 ºc 120.0 741 p2.7.27 pt100 fault limit -30.0 200...

Page 229

7.4.9 autorestart parameters (control keypad: menu m2 -> g2.8) table 101: autorestart parameters, g2.8 index parameter min max unit default cust id description p2.8.1 wait time 0.10 10.00 s 0.50 717 the wait time before the first reset is done. P2.8.2 trial time 0.00 60.00 s 30.00 718 when the trial...

Page 230

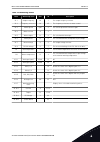

7.4.10 pump and fan control parameters (control keypad: menu m2 -> g2.9) table 102: pump and fan control parameters index parameter min max unit default cust id description p2.9.1 number of auxili- ary drives 0 4 1 1001 p2.9.2 start frequency, auxiliary drive 1 p2.9.3 320.00 hz 51.00 1002 p2.9.3 sto...

Page 231

Table 102: pump and fan control parameters index parameter min max unit default cust id description p2.9.17 analogue input selection for input pressure meas- urement 0 5 0 1021 0 = not used 1 = ai1 2 = ai2 3 = ai3 4 = ai4 5 = fieldbus signal (fbprocessda- tain3) p2.9.18 input pressure high limit 0.0...

Page 232

Table 102: pump and fan control parameters index parameter min max unit default cust id description p2.9.26 autochange inter- val 0.0 3000.0 h 48.0 1029 0.0 = test=40 s p2.9.27 autochange; max- imum number of auxiliary drives 0 4 1 1030 p2.9.28 autochange fre- quency limit 0.00 p2.1.2 hz 25.00 1031 ...

Page 233

Table 103: keypad control parameters, m3 index parameter min max unit default cust id description p3.1 control place 1 3 1 125 1 = i/0 terminal 2 = keypad 3 = fieldbus p3.2 keypad reference p2.1.1 p2.1.2 hz 0.00 p3.3 direction (on key- pad) 0 1 0 123 0 = forward 1 = reverse p3.4 pid reference 1 0.00...

Page 234: Parameter Descriptions

8 parameter descriptions on the following pages you find the parameter descriptions arranged according to the individual id number of the parameter. An asterisk after the parameter id number (e.G. 418 motor potentiometer up *) indicates that the ttf programming method must be applied to this paramet...

Page 235

Note! The use of ttf-programming method in the multi-purpose control application. Because all digital inputs are programmable you first have to assign two dins for the preset speed functions (parameters id419 and id420). Table 104: preset speed speed preset speed 1 (din4/id419) preset speed 2 (din5/...

Page 236

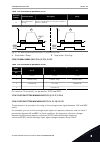

108 u/f ratio selection 234567 (2.6.3) table 105: selections for parameter id108 selection number selection name description 0 linear the voltage of the motor changes linearly as a function of the output frequency. The voltage changes from the value of zero frequency voltage (id606) to the value of ...

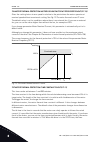

Page 237

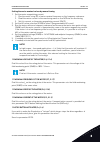

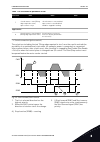

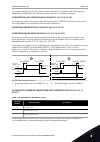

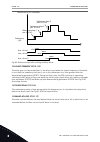

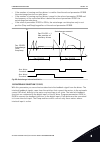

Un id603 id602 default: nominal voltage of the motor linear squared field weakening point default: nominal frequency of the motor u[v] f[hz] fig. 24: linear and squared change of the motor voltage p1 p2 p3 id604 id605 id606 default: nominal voltage of the motor field weakening point default: nominal...

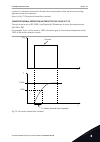

Page 238

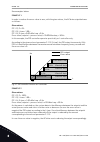

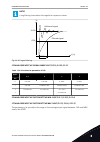

109 u/f optimisation (2.13, 2.6.2) programmable torque boost mid point frequency f n fwp zero point voltage mid point voltage fwp voltage u n linear squared fig. 26: u/f optimisation the voltage to the motor changes in proportion to required torque which makes the motor produce more torque at start ...

Page 239

Setting the motor nominal values by manual tuning 1. Set the motor magnetizing current: 1. Run the motor using 2/3 of motor nominal frequency as the frequency reference. 2. Read the motor current in the monitoring menu or use ncdrive for monitoring. 3. Set this current as the motor magnetizing curre...

Page 240

117 i/o frequency reference selection 12346 (2.14, 2.1.11) defines which frequency reference source is selected when controlled from the i/o control place. Table 106: selections for parameter id117 applic. 1 to 4 6 sel. 0 analogue input 1 (ai1) analogue input 1 (ai1). See id377 1 anlogue input 2 (ai...

Page 241

119 pid controller i-time 57 (2.1.13) the parameter id119 defines the integration time of the pid controller. If this parameter is set to 1.00 s, a change of 10% in the error value causes the controller output to change by 10.00%/s. If the parameter value is set to 0.00 s, the pid controller will op...

Page 242

123 keypad direction (3.3) table 108: selections for parameter id123 selection number selection name description 0 forward the rotation of the motor is forward, when the keypad is the active control place. 1 reverse the rotation of the motor is reversed, when the keypad is the active control place. ...

Page 243

130 preset speed 7 46 (2.1.21) these parameters can be used to determine frequency references that are applied when appropriate combinations of digital inputs are activated. In multi-step speed application (application 4), digital inputs din4, din5 and din6 are assigned to preset speed functions. Th...

Page 244

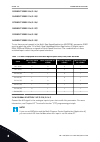

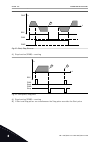

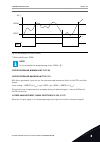

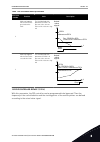

See examples below. Example 1: in order to reduce the error value to zero, with the given values, the ac drive output behaves as follows: given values: p2.1.12, p = 0% p2.1.13, i-time = 1.00 s p2.1.14, d-time = 0.00 smin freq. = 0 hz error value (setpoint – process value) = 10.00%max freq. = 50 hz i...

Page 245

Hz t pid output error value d-part i- pa rt i-p art d-part p-part=5 hz error=10% d-part p-part= -5 hz error= -10% fig. 28: pid output curve with the values of example 2 example 3 given values: p2.1.12, p = 100% p2.1.13, i-time = 0.00 s p2.1.14, d-time = 1.00 smin freq. = 0 hz error value (setpoint –...

Page 246

135 preset speed 10 4 (2.1.24) 136 preset speed 11 4 (2.1.25) 137 preset speed 12 4 (2.1.26) 138 preset speed 13 4 (2.1.27) 139 preset speed 14 4 (2.1.28) 140 preset speed 15 4 (2.1.29) to use these preset speeds in the multi-step speed application (asfiff04), parameter id301 must be given the value...

Page 247

142 ai3 signal filter time 567 (2.2.41, 2.2.4.2) when this parameter is given a value greater than 0.0 the function that filters out disturbances from the incoming analogue signal is activated. Long filtering time makes the regulation response slower. See parameter id324. 143 ai3 signal range 567 (2...

Page 248

154 ai4 signal range 567 (2.2.43, 2.2.5.3) see id143. 155 ai4 custom setting minimum 67 (2.2.5.3, 2.2.5.4) 156 ai4 custom setting maximum * 67 (2.2.5.4, 2.2.5.5) see ids 144 and 145. 162 ai4 signal inversion 567 (2.2.44, 2.2.5.5, 2.2.5.6) see id151. 164 motor control mode 1/2 6 (2.2.7.22) contact is...

Page 249

170 fieldbus din 5 (fbfixedcontrolword, bit 7) 6 (2.3.3.28) the data from the fieldbus can be led to the digital outputs of the ac drive. See the used fieldbus manual for more details. 179 scaling of motoring power limit 6 (2.2.6.7) the motoring power limit is equal to id1289 if value 0 'not used' i...

Page 250

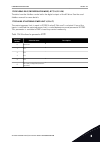

300 start/stop logic selection 2346 (2.2.1, 2.2.1.1) table 115: selections for parameter id300 selection din1 din2 din3 0 closed contact = start forward closed contact = start reverse see fig. 30. 1 closed contact = startopen contact = stop closed contact = reverseopen contact = forward see fig. 31....

Page 251