- DL manuals

- Vacuubrand

- Controller

- CVC 3000

- Instructions For Use Manual

Vacuubrand CVC 3000 Instructions For Use Manual

Summary of CVC 3000

Page 1

Page 1 of 80 vacuum controller instructions for use technology for vacuum systems cvc 3000

Page 2: After Sales Service:

Page 2 of 80 after sales service: contact your local dealer or call +49 9342 808-5500 dear customer, your vacuubrand controllers are designed to provide you with many years of trouble-free service with optimal performance. Our many years of practical experience allow us to provide a wealth of applic...

Page 3

Page 3 of 80 de achtung: die vorliegende betriebsanleitung ist nicht in allen eu-sprachen verfügbar. Der anwender darf die beschriebenen geräte nur dann in betrieb nehmen, wenn er die vorliegende anleitung versteht oder eine fachlich korrekte Übersetzung der voll- ständigen anleitung vorliegen hat. ...

Page 4

Page 4 of 80 da bemærk: denne manual foreligger ikke på alle eu sprog. Brugeren må ikke be- tjene apparatet hvis manualen ikke er forstået. I det tilfælde skal en teknisk korrekt oversættelse af hele manual stilles til rådighed. Manual skal være gennemlæst og forstået før apparatet betjenes og alle ...

Page 5

Page 5 of 80 hu figyelem! Ez a kezelési utasítás nem áll rendelkezésre az eu összes nyelvén. Ha a felhasználó nem érti jelen használati utasítás szövegét, nem üzemeltetheti a készüléket. Ez esetben a teljes gépkönyv fordításáról gondoskodni kell. Üzembe helyezés előtt a kezelőnek végig kell olvasnia...

Page 6

Page 6 of 80 nl attentie: deze gebruiksaanwijzing is niet in alle talen van de eu verkrijgbaar. De gebruiker moet niet met dit apparaat gaan werken als voor hem/haar de gebruiks- aanwijzing niet voldoende duidelijk is. Bij gebruik van deze apparatuur is het nood - zakelijk een technisch correcte ver...

Page 7

Page 7 of 80 se varning: denna instruktion är inte tillgänglig på alla språk inom eu. Användaren får inte starta utrustningen om hon/han inte förstår denna instruktion. Om så är fallet måste en tekniskt korrekt instruktion göras tillgänglig. Instruktionen måste läsas och förstås helt före utrustning...

Page 8: 1 Switch Off

Page 8 of 80 portuguê Ρyccкий polski nederl. Suomi 日本語 中文 한국어 cvc 3000 v2.0 deutsch english français italiano español türkçe reset / language selection 1 switch off 2 press both 3 turn 4 press portuguê Ρyccкий polski nederl. Suomi 日本語 中文 한국어 cvc 3000 v2.0 deutsch english français italiano español tü...

Page 9: Contents

Page 9 of 80 contents reset / language selection ............................................. 8 safety information! ........................................................... 11 important information! ........................................................................11 general information .....

Page 10

Page 10 of 80 gauge head vsp 3000 (accessory) ................................. 54 readjustment of the gauge head vsp 3000 ................... 56 connecting several external gauge heads..................... 57 manual switching between pressure transducers ............................. 58 measuring d...

Page 11: Safety Information!

Page 11 of 80 safety information! Important information! + keep this manual complete and accessible to per- sonnel at all times! + read this manual carefully before installing or op- erating the equipment. Observe the instructions contained in this manual. + do not modify the equipment without autho...

Page 12: Notice

Page 12 of 80 ➨ danger indicates a hazardous situation which, if not avoided, will result in death or serious injury. + warning indicates a hazardous situation which, if not avoided, could result in death or serious injury. • caution indicates a hazardous situation which, if not avoided, could resul...

Page 13: General Information

Page 13 of 80 general information remove all packing material from the packing box. Re- move the product from its packing-box and retain all pack- aging until the equipment is inspected and tested. Inspect the equipment promptly and carefully. If the equipment is damaged, notify the supplier and the...

Page 14: Only As Intended

Page 14 of 80 +40°c), or for short periods up to +176°f (+80°c) at the pressure transducer (gas temperature). Periodical- ly check maximum temperatures if installing the con- troller in a cabinet or a housing. Make sure ventilation is adequate to maintain recommended operating tem- perature. Install...

Page 15: Ments

Page 15 of 80 match in voltage, phase, and frequency. • when working with residues, aggressive or condens - able media, install a gas washing bottle if necessary. Using a wall power supply, assemble and lock the suit- able power plug (included in shipment) to the power sup- ply prior to use. The con...

Page 16: Operating Conditions

Page 16 of 80 • do not operate this product near flames. To the best of our knowledge the equipment is in com- pliance with the requirements of the applicable ec-direc- tives and harmonized standards (see ”declaration of con- formity”) with regard to design, type and model. Directive en 61010-1 give...

Page 17: Safety During Operation

Page 17 of 80 safety during operation ➨ adopt suitable measures to prevent the release of dangerous, toxic, explosive, corrosive, noxious or pol- luting fluids, vapors and gases. + never operate this controller if it has a damaged cord or plug. If the controller is not working properly, has been dro...

Page 18: Maintenance and Repair

Page 18 of 80 maintenance and repair ➨ switch off the controller. Disconnect the power supply and wait five seconds before starting mainte- nance to allow the capacitors to discharge. ➨ note : the equipment may be contaminated with chem- icals, which have been processed during operation. Ensure that...

Page 19: II 3G Iic T3 X

Page 19 of 80 ` important information: equipment marking (atex) vacuubrand equipment bearing mark (see rating plate) ` ii 3g iic t3 x internal atm. Only tech. File ref.: vac-ex01 the classification ii 3g iic t3 x according to atex is only valid for the in - ner part (wetted part, pumped gas or vapor...

Page 20: Risk.

Page 20 of 80 • the equipment is designated for an ambient and gas inlet temperature during operation of +10 to +40°c. Never exceed these ambient and gas inlet temperatures. If pumping / measuring gases which are not potentially explosive, extended gas inlet temperatures are permissible. See instruc...

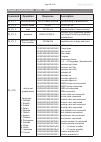

Page 21: Technical Data

Page 21 of 80 technical data technical data of controller controller cvc 3000 pressure transducer ceramic diaphragm (alumina), capacitive, absolute pressure, gas type independent display lcd graphic display, illuminated pressure units / scale (selectable) torr, mbar or hpa measuring range (absolute)...

Page 22: Controller

Page 22 of 80 we reserve the right for technical modification without prior notice! * the actual vacuum control range in your application might be reduced due to ultimate vacuum of the pump, volume of gas present, etc. ** if pumping potentially explosive atmospheres: 50 °f to 104 °f (+10°c to +40°c)...

Page 23: Wetted Parts

Page 23 of 80 wetted parts components wetted materials sensor aluminum oxide ceramic vacuum connection / hose nozzle pp sensor housing pps / glass fiber sensor seal chemically resistant fluoroelastomer venting valve seal fpm we reserve the right for technical modification without prior notice! Abbre...

Page 24: Use and Operation

Page 24 of 80 use and operation the cvc 3000 vacuubrand controller with internal pressure transduc- er and integrated venting valve can only be operated with components compatible with the vacuubrand vacuu•bus system, (see “acces - sories”, pg. 69). The cvc 3000 vacuum controller controls vacu- ubra...

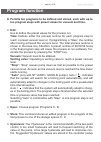

Page 25: Rear Side Cvc 3000

Page 25 of 80 connection plug of the power supply or of the vacuu • bus line to nt vario / vario-b pump jacks for connection of vacuu •bus components (e.G., coolant valve) serial interface rs-232 c rear side cvc 3000 venting connection measurement connection rating plate keys start or stop the proce...

Page 26: Selection Knob

Page 26 of 80 selection knob • press to reach the set-up menu of the function • turn to choose the parameter you want to modify • press to select the parameter you want to modify • turn to change the set value of the parameter • press to confirm change of value and to reach further parameters, or to...

Page 27: Attention

Page 27 of 80 notes on connecting and operating the controller valves and/or vacuum pumps are necessary to operate the controller. Without those components the controller can be used only as vacuum measurement device. When used as measurement device, the controller can switch a possibly connected co...

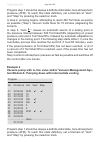

Page 28: Selected Function

Page 28 of 80 pump down / vac control / auto mode (only with nt vario pump) / program / vacuulan / configuration selected function (displayed in the upper left corner): a ”function” is one of the following operation modes of the cvc 3000 controller: 1013 . 2 mbar vac control 100 mbar / torr / hpa pr...

Page 29

Page 29 of 80 control is running warning notice (if necessary in combination with other sym- bols), flashing coolant valve switched on venting valve switched on pc symbol: controller is in remote operation time meter is running (in function ”vacuulan”); remaining time in minutes is displayed 00:00:0...

Page 30: Connected Components

Page 30 of 80 the cvc 3000 controller can be adapted to the specific application by choosing the appropriate function depending on the connected compo- nents and the requirements of the application. Automatic detection of the components when switching on the controller, the configuration of the conn...

Page 31: ”Vac Control”

Page 31 of 80 ”vac control” • with pressure preselection, switches a pump or an in-line valve to maintain that pressure in two-point control. • with pressure preselection, controls a nt vario / vario-b pump to maintain pinpoint control of that pressure. • coolant valve ”auto mode” (only available wi...

Page 32: 1013 . 2

Page 32 of 80 1013 . 2 mbar vacuulan 1013 . 2 mbar pump down pump down speed hi minimum off delay off duration off - - - - - - graphic - - - - - - - - - - - - - back - - - - - - - function pump down vac control auto mode program vacuulan configuration - - - - - - - - back - - - - - - - mode menu gui...

Page 33: 1013 . 2

Page 33 of 80 1013 . 2 mbar program 1013 . 2 mbar vac control vac control set vacuum 75 torr speed hi maximum off delay off duration off - - - - - - graphic - - - - - - - - - - - - - back - - - - - - - function pump down vac control auto mode program vacuulan configuration - - - - - - - - back - - -...

Page 34: Pump Down Function

Page 34 of 80 pump down function ➨ continuous pumping with pressure and time settings • operation of a vacuum pump via in-line valve • operation of a vacuum pump without in-line valve with vms (vac - uum management system, see “accessories”, pg. 69) • operation on demand of a speed controlled nt var...

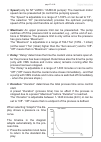

Page 35

Page 35 of 80 the screen-shot shows the factory-set values. When selecting ” graphic ” the display shows a pressure vs. Time curve. The timeline in the diagram adapts automatically to the process time. + press the selection knob twice to return to the standard display. 10 mbar 00:03:50 pump down pum...

Page 36: Vac Control Function

Page 36 of 80 vac control function ➨ vacuum control to a preset vacuum value • operation of a vacuum pump via in-line valve • operation of a vacuum pump without in-line valve with vms (vac - uum management system, see ”accessories”) • operation on demand of a speed controlled pump (nt vario / vario-...

Page 37: Speed

Page 37 of 80 + speed (only for nt vario / vario-b pumps) : the maximum motor speed can be preselected (to control the pumping speed). The ” speed ” is adjustable in a range of 1-100% or can be set to ”hi”. The selection ”hi” (recommended) provides the optimum pumping speed of the pump and therefore...

Page 38: Vac Control

Page 38 of 80 the screen-shots show the factory-set values. Vac control set vacuum 75 torr speed hi maximum off delay off duration off - - - - - - graphic - - - - - - - - - - - - - back - - - - - - - 760 torr temporarily switching from ” vac control ” to ”auto mode” while pro- cess control is runnin...

Page 39: Auto Mode

Page 39 of 80 auto mode (only nt vario / vario-b pumps) preselections + use the selection knob to set the parameters. + sensitivity : the ” sensitivity ” of the control determines the control speed. The ” sensitivity ” is adjustable to ”high”, ”normal” or ”low”. High sensitivity leads to a reduced p...

Page 40: Duration:

Page 40 of 80 + duration: ” duration ” determines the total process time since control start. The ” duration ” is adjustable between 1-1440 minutes (24 h) or can be set to ”off”. (”off” means that no endpoint for pump down is preset.) a preset ” duration ” (process time) has no effect, if the proces...

Page 41: Program Function

Page 41 of 80 program function ➨ permits ten programs to be defined and stored, each with up to ten program steps with preset values for vacuum and time. + edit: use to define the preset values for the process run: time: defines either the process runtime for each program step to reach a preset vacu...

Page 42: Editing:

Page 42 of 80 the screen-shot shows the factory-set values. Editing: + to select row: turn and press selection knob. + to adjust parameter: turn the selection knob. + to confirm parameter: press selection knob. Controller will accept change and jump to the next parameter in the same row. + after 5 s...

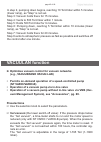

Page 43: Example 1

Page 43 of 80 example 1 nt vario vacuum pump with speed control (e.G., with a rotary evap- orator): degassing and automatic distillation with timing program no hh:mm:ss vac vent. Step auto 01 00:00:00 atm ✔ ✔ 02 00:10:00 300 ✔ 03 01:00:00 2 * 04 00:01:00 atm ✔ ✔ 05 00:00:00 0 06 00:00:00 0 07 00:00:...

Page 44: Example 2

Page 44 of 80 program step 1 should be always a definite initial state, here atmospheric pressure (atm). To reach this state definitely, set a tickmark at ”vent.” and ”step” by pressing the selection knob. In step 2, pumping begins, attempting to reach 300 torr/mbar as quickly as possible (”step”). ...

Page 45: Vacuulan Function

Page 45 of 80 in step 2, pumping down begins, reaching 10 torr/mbar within 5 minutes (linear ramp), as ”step” is not set. Step 3: vacuum holds there for 15 minutes. Step 4: vents to 500 torr/mbar within 1 minute. Step 5: holds 500 torr/mbar for 9 minutes. Step 6: pumping down, reaching 5 torr/mbar w...

Page 46: Switch On

Page 46 of 80 this screen-shot shows the factory-set values. Vacuulan 40 mbar 00:13:00 vacuulan set vacuum 19 torr switch on 150 torr delay 15 min - - - - - - graphic - - - - - - - - - - - - - back - - - - - - - 760 torr when selecting ” graphic ” the display shows a pressure vs. Time curve. The tim...

Page 47: Assembly of A Vacuum System

Page 47 of 80 assembly of a vacuum system + assemble vacuum connection lines between cvc 3000 controller or an external pressure transducer, vacuum pump (nt vario / vario-b pump or diaphragm pump with in-line valve or vacuum-management- system) and vacuum application. + assemble electrical connectio...

Page 48: Pump Down

Page 48 of 80 + select ” pump down ” function. ” speed ” (only with nt vario / vario- b pumps) ”hi” is recommended. For gel dryers set a lower speed if necessary (if the gels tend to crack). + set ”minimum” to prevent volatile components from evaporating. The process is stopped automatically as soon...

Page 49: System

Page 49 of 80 alternatively: for diaphragm pump with in-line valve and/or vacuum-management- system + select ” vac control ” function. + set ”set vacuum” (and ” hysteresis ”, if necessary) depending on the solvent and the bath temperature. + considering the hysteresis and the bath temperature, set ”...

Page 50: Auto Mode”

Page 50 of 80 alternatively: fully automatic determination and adaptation of the boiling point with nt vario / vario-b diaphragm pumps (recommended) + select ” auto mode” . + start process by pressing ”start/stop” key. + the ”auto mode” allows a fully automatic distillation even if the boiling vacuu...

Page 51: Configuration

Page 51 of 80 configuration in the ”configuration” menu the device parameters are preselected. After 20 seconds without action the function ”configuration” and its sub - menus (except submenu ”sensors”) are quit automatically without stor- ing any possibly changed parameter. + adjustment : adjustmen...

Page 52: Autostart

Page 52 of 80 this screen-shot shows the factory-set values. + autostart : if ” autostart ” is set to ”on” the controller restarts a running process automatically after a mains failure. If this is unwanted, set ” autostart ” to ”off”. Attention: if ” autostart ” is preselected, the process starts im...

Page 53: 760 Torr

Page 53 of 80 adjustment at atmospheric pressure an adjustment at atmospheric pressure is only possible if the pressure is higher than 525 torr (700 mbar). ➨ vent the measurement connection of the cvc 3000 or in case that of a connected optional external gauge head vsk 3000. Make sure that the press...

Page 54: 0...15 Torr

Page 54 of 80 adjustment at a reference pressure instead of adjustment under vacuum to a pres- sure ly known reference pressure within the range of 0..... 15 torr (20 mbar) is possible. ➨ evacuate the measurement connection of the cvc 3000 or in case that of a connected optional external gauge head ...

Page 55: ”Auto Mode”

Page 55 of 80 note: the active pressure transducer (vsp 3000) is not displayed in the sta- tus line of the controller display! When operating the cvc 3000 with the external vsp 3000 pressure transduc- er, vacuum control is not possible in the ”auto mode” and ” vacuulan” functions. 1.0 x 10 3 mbar ”p...

Page 56: Notice

Page 56 of 80 the vacuum gauge head vsp 3000 was adjusted using factory standards, which are traceable through regular calibration in an accredited laboratory (dakks calibration laboratory) to the german national pressure standard. Depending on the process and/or accuracy requirements, check the adj...

Page 57: Adjustment Under Vacuum

Page 57 of 80 adjustment under vacuum an adjustment under vacuum is only possible in the lower pressure range. ➨ evacuate the measurement connection of the vsp 3000 pressure transducer preferably below 7.5x10 -4 torr (1x10 -3 mbar), e.G., by ap- plying a high vacuum pump. Allow the pressure transduc...

Page 58

Page 58 of 80 manual switching between pressure transducers ➨ select the menu item ”sensors” in the menu ” configuration ”. + connected gauge heads are displayed in the order of their vacuu•bus address: vsk 1 - vsp 1 - vsk 2 - vsp 2 - ... - vsp 4. ➨ select the desired gauge head by turning and press...

Page 59: Reconfiguring The Gauge Head

Page 59 of 80 + this requires the external gauge head to be defined as reference (vacuu•bus address ”ref. 1”) and no gauge head vsk 1 to be con - nected. ➨ the displayed pressure value is: (”pressure value of ref. 1” minus ”pressure value of sensor”) torr (mbar). ➨ in case of negative differential p...

Page 60: Calibration In The Factory

Page 60 of 80 calibration in the factory to order dakks calibration of the cvc 3000 pressure transducer, order number: .............................................................................. 900215 control of measuring equipment the vacuubrand dakks calibration laboratory is accredited by the...

Page 61: Interface Parameters

Page 61 of 80 interface parameters the cvc 3000 controller is equipped with a serial interface (rs 232c, nine-pin sub-d-plug). + plug-in or remove the cable (cable rs 232c) from the interface only if the equipment is switched off. + the interface is not electrically isolated from the measuring circu...

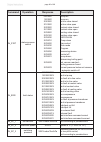

Page 62: Command

Page 62 of 80 command operation response description in_pv_1 current pressure xxxx mbar/ torr/hpa unit according to preselections in_pv_2 current frequency xx.X hz pump speed in_cfg device set preselections 0xxxx 1xxxx 2xxxx 3xxxx x0xxx x1xxx xx0xx xx1xx vacuu •lan continuous pumping vacuum control ...

Page 63: Write Commands

Page 63 of 80 write commands ” cvc 2000 ” command operation parameter description out_mode function 1 2 3 30 31 32 continuous pumping vacuum control without automatic vacuum control with automatic optional: sensitivity: low optional: sensitivity: normal optional: sensitivity: high out_sp_1 set vacuu...

Page 64: Command

Page 64 of 80 ** if remote operation is selected or deselected, the user has to ensure that no dangerous status of the system can occur due to the change of the mode of operation, and must take appropriate safety precautions, especially if selecting remote operation interferes with a locally oper- a...

Page 65: Read Commands

Page 65 of 80 read commands ” cvc 3000 ” command operation response description in_pv_1 current pressure xxxx.X mbar/torr/hpa unit according to preselections in_pv_2 current speed xxx% 1-100% or ”hi” in_pv_3 time xx:xx h:m process runtime (hours:minutes) in_pv_x pressure xxxx.X xxxx.X ... Pressure o...

Page 66: Command

Page 66 of 80 command operation response description in_stat status process control 0xxxxx 1xxxxx x0xxxx x1xxxx xx0xxx xx1xxx xxx0xx xxx1xx xxxx0x xxxx1x xxxx2x xxxx3x xxxx4x xxxx5x xxxxx0 xxxxx1 xxxxx2 xxxxx3 pump off pump on in-line valve closed in-line valve open coolant valve closed coolant valv...

Page 67: Write Commands

Page 67 of 80 write commands ” cvc 3000 ” attention (out_mode): if control is running, it is only possible to switch either from 1 to 2, or from 2 to 3, or from 3 to 2. The set vacuum is adopted in each case. Command operation response description in_sp_4 delay xx:xx h:m hours:minutes (00:00 = off) ...

Page 68: Command

Page 68 of 80 command operation parameter description out-sp_1 set vacuum xxxx unit according to preselection; see re- spective function for parameter range out_sp_v set vacuum with venting xxxx unit according to preselection; see re- spective function for parameter range out_sp_2 speed xxx speed in...

Page 69: Accessories

Page 69 of 80 * if remote operation is selected or deselected, the user has to ensure that no dangerous status of the system can occur due to the change of the mode of operation, and must also take appropriate safety precau- tions, especially if selecting remote operation interferes with a locally o...

Page 70: Vacuubrand-Valve With Din

Page 70 of 80 use vacuu•bus y-adapters and extension cables to connect further components. When connecting an external pressure transducer, it is used automatically. Further information on how to use several sensors simultaneously is available on request. Conversion of vacuubrand valves with din plu...

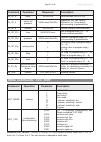

Page 71: Fault

Page 71 of 80 fault possible cause remedy ❑ no display. ➨ power supply not plugged in (wall plug)? ✔ plug in power supply. ➨ cvc 3000 controller switched off? ✔ switch on controller. ➨ vacuu • bus cable of power supply not plugged in at cvc 3000 controller? ✔ plug in vacuu • bus cable at cvc 3000 co...

Page 72: Fault

Page 72 of 80 fault possible cause remedy ❑ warning triangle and black valve symbol are flash - ing, two blips*. ➨ external venting valve removed or defective? ✔ connect valve or replace with a new one or recon- figure without valve. ❑ warning triangle and valve symbol are flashing, three blips*. ➨ ...

Page 73: Fault

Page 73 of 80 * only if ” sound ” ”on” is selected ** vms: vacuum management system to switch non-vario pumps fault possible cause remedy ❑ ”vac control” func- tion: control stops, ”arrow up” is flash - ing. ➨ preset maximum pres- sure exceeded? ✔ confirm by pressing start/stop key. Change maximum p...

Page 74: Repair

Page 74 of 80 repair - maintenance - return - calibration every employer (user) is held responsible for the health and safety of his employees. This also applies to service personnel performing repair, maintenance, return or cali- bration. The health and safety clearance form informs the con- tracto...

Page 75: Quotation

Page 75 of 80 if you do not wish a repair on the basis of our quotation , the device may be returned to you disassembled and at your expense. In many cases, the components must be cleaned in the factory prior to repair. For cleaning we use an environmentally friendly water based process. Unfortunate...

Page 76: Warranty

Page 76 of 80 vacuubrand shall be liable for insuring that this prod- uct, including any agreed installation, has been free of de- fects at the time of the transfer of risk. Vacuubrand shall not be liable for the consequences of improper handling, use, servicing or operation of this product or the c...

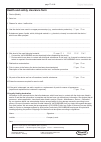

Page 77

Page 77 of 80 health and safety clearance form health and safety clearance form 1. Device (model): .................................................................................................................................................. 2. Serial no.: ..........................................

Page 78

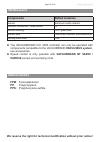

Page 78 of 80 hersteller / manufacturer / fabricant: vacuubrand gmbh + co kg · alfred-zippe-str. 4 · 97877 wertheim · germany hiermit erklärt der hersteller, dass das gerät konform ist mit den bestimmungen der richtlinien: hereby the manufacturer declares that the device is in conformity with the di...

Page 79

Page 79 of 80 this certificate is only valid for pumps with the respective mark (li - censed test mark) on the pump rating plate..

Page 80: Vacuubrand Gmbh + Co Kg

Page 80 of 80 disclaimer: our technical literature is only intended to inform our cus- tomer. The applicability of general empirical values and results obtained under lab conditions to your specific operations depends on a number of factors beyond our control. It is, therefore, strictly the users’ r...