- DL manuals

- Vaillant

- Water Heater

- ecoTEC plus SERIES

- Installation And Maintenance Instructions Manual

Vaillant ecoTEC plus SERIES Installation And Maintenance Instructions Manual

Summary of ecoTEC plus SERIES

Page 1

Installation and maintenance instructions for the competent person gb, ie installation and maintenance instructions ecotec plus vu.

Page 2

Installation and maintenance instructions ecotec plus 0020214490_00 2 5.8 electrical connection ................................................ 19 5.8.1 mains connection ...................................................... 19 5.8.2 connecting controllers .............................................

Page 3

3 installation and maintenance instructions ecotec plus 0020214490_00 contents notes on the documentation 1 observing other applicable documents you must observe all the operating and installation in- structions included with the system components. Auxiliary service equipment: the following test and...

Page 4

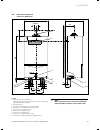

Installation and maintenance instructions ecotec plus 0020214490_00 4 2 description of the boiler 2.1 design 1 2 3 4 5 6 7 8 15 14 13 12 11 9 10 fig. 2.1 functional components legend: 1 connection for the air/flue gas duct 2 heat exchanger 3 compact thermal module 4 flow rate sensor 5 fan 6 water pr...

Page 5

5 installation and maintenance instructions ecotec plus 0020214490_00 2.2 type summary boiler type designated country (designation in accord- ance with iso 3166) category of permit type of gas nominal heat output range p (kw) vu gb 466/4-5 a gb (great britain) ie (eire) ii 2h3p natural gas h - g 20 ...

Page 6

Installation and maintenance instructions ecotec plus 0020214490_00 6 3.1.2 gas odour if you smell gas, the following safety instructions must be observed: • open doors and windows wide, provide for ventilation, stay out of rooms where smell of gas is present! • avoid naked flames, do not smoke, do ...

Page 7

7 installation and maintenance instructions ecotec plus 0020214490_00 3.2.2 installation site the location chosen for the boiler must permit the provision of a satisfactory flue termination. The location must also provide adequate space for servicing and air circulation around the boiler. The boiler...

Page 8

Installation and maintenance instructions ecotec plus 0020214490_00 8 3.3.3 standard 125 mm air/flue gas duct a concentric air/flue gas duct which has an outside diameter of 125 mm and can be extended up to a length of 21 m is available. You can also get a vertical system. For more information refer...

Page 9

9 installation and maintenance instructions ecotec plus 0020214490_00 g n n m m a ii o h h c b l j q q q k p d, e f i fig. 3.3 termination of the air/flue gas duct 2) dimension h: this clearance may be reduced to 25 mm without affecting the performance of the boiler. However, in order to ensure that...

Page 10

Installation and maintenance instructions ecotec plus 0020214490_00 10 4 assembly a caution! Flush the heating installation thoroughly before installing the boiler to remove foreign substances such as solder and flux residue, leftover sealant or dirt. 4.1 scope of delivery the vaillant ecotec is del...

Page 11

11 installation and maintenance instructions ecotec plus 0020214490_00 4.4 dimension drawing and connection dimensions a Ø 80/125 r 1 100 100 152 152 100 48 190 800 30 4 9 Ø20, r1 g 1 1 / 2 rp 1 rp 1 g 1 1 / 2 r 1 / 2 480 450 7 8 6 5 4 3 9 5, 8 1 2 fig. 4.2 connection dimensions in mm legend: 1 flue...

Page 12

Installation and maintenance instructions ecotec plus 0020214490_00 12 4.5 required minimum gaps/ installation clearances for the installation/assembly of the boiler as well as for carrying out future maintenance tasks, you need the minimum gaps and installation clearances given below: 250 350 fig. ...

Page 13

13 installation and maintenance instructions ecotec plus 0020214490_00 4.8 removing/attaching the front casing 1 2 fig. 4.5 removing the front casing to dismount the front casing of the boiler, proceed as follows: • unfasten the screw (1) on the bottom of the boiler. • push in both retaining clips (...

Page 14

Installation and maintenance instructions ecotec plus 0020214490_00 14 model article number connection sizes 1 header width a header depth b total height c insulation dimensions to boiler d to heating circuit e height from floor f maximum volume flow m 3 /hr wh 40 306720 1 1 / 4 " bsp (f) 115 115 50...

Page 15

15 installation and maintenance instructions ecotec plus 0020214490_00 hydraulic schematic drawing: heating circuit connection using low loss header 1 2 3 4 fig. 5.2 heating circuit connection using low loss header legend: 1 boiler with internal pump 2 low loss header 3 external heating pump 4 consu...

Page 16

Installation and maintenance instructions ecotec plus 0020214490_00 16 the low loss header ensures, in conjunction with the boiler circulation pump, that a sufficiently high minimum quantity of water is always circulating through the boiler. 5.3 heating mode and cylinder charging mode h note! Also o...

Page 17

17 installation and maintenance instructions ecotec plus 0020214490_00 5.4 gas connection d danger! Danger of injury to persons and/or material damage due to improper installation! The vaillant ecotec boiler may only be installed by a recognised skilled trade company who also assumes the responsibil...

Page 18

Installation and maintenance instructions ecotec plus 0020214490_00 18 5.6 expansion relief valve (safety group), heating installation bar 1 2 3 4 fig. 5.10 fitting the expansion relief valve the ecotec is equipped ex factory with connections for a safety group: • expansion relief valve (1) • pressu...

Page 19

19 installation and maintenance instructions ecotec plus 0020214490_00 the connection to the stack should not be made in a way that could cause cross flow into any other branch pipe, or from that branch pipe into the condensate drainage pipework. This can be achieved by maintaining an offset between...

Page 20

Installation and maintenance instructions ecotec plus 0020214490_00 20 2 3 4 1 fig. 5.12 opening back wall of the electronic box 9 8 7 + - 5 4 3 n l bus 9 8 7 + - 5 4 3 n l bus fig. 5.13 example for cable routing • remove the front casing of the boiler (see chapter 4.8) and tilt the electronic box (...

Page 21

21 installation and maintenance instructions ecotec plus 0020214490_00 connection terminals 7, 8, 9) the bridge between terminal 3 and 4 must remain inserted. • close the rear cover of the electronic box until it audibly engages. • lift the electronic box up and press the two clips on the left and r...

Page 22

Installation and maintenance instructions ecotec plus 0020214490_00 22 5.8.5 wiring diagrams brown black black black black black black black blue blue green/yellow grau red red red green black blue red red green orange violet x 2 x20 low-voltage plug 14 10 4 2 5 9 11 12 13 1 17 3 4 16 igniter x14 5 ...

Page 23

23 installation and maintenance instructions ecotec plus 0020214490_00 1 6 0 0 dcf rf af fb x13 x11 fan 230v~ cylinder charging pump n l n l grey n l blue green x18 5 4 3 n l 9 8 7 + 2 1 - turqoise violet white red blue mains voltage low voltage edge connector x1 x41 x22 x6 pink n l boiler enable co...

Page 24

Installation and maintenance instructions ecotec plus 0020214490_00 24 6 start-up a caution! The boiler may only be permanently operated with its casing properly closed! Otherwise, under unfavourable conditions, it can result in material damage or even injury or death. H note! When starting up parti...

Page 25

25 installation and maintenance instructions ecotec plus 0020214490_00 provided the national regulations and technical stand- ards do not stipulate more stringent requirements, the following applies: • you must condition the heating water in the following cases: - if the entire filling and supplemen...

Page 26

Installation and maintenance instructions ecotec plus 0020214490_00 26 appears in the display. Fill the system up with water before you start up the boiler again. This message also appears if you switch the boiler on when it is empty and disappears automatically when it is filled. A caution! Risk of...

Page 27

27 installation and maintenance instructions ecotec plus 0020214490_00 • adjust the gas setting as described below (see sections 6.3.1 to 6.3.3). The combustion of this boiler has been checked, adjusted and preset at the factory for operation on the type of gas defined on the identification plate. N...

Page 28

Installation and maintenance instructions ecotec plus 0020214490_00 28 6.3.3 checking the gas inlet working pressure • ensure that the gas inlet working pressure can be obtained with all other gas appliances in the property working. • remove the front casing from the boiler. • close the gas isolatio...

Page 29

29 installation and maintenance instructions ecotec plus 0020214490_00 start-up 6 fig. 6.6 tightness check 6.4.1 heating • switch on the boiler. • make sure that a heat requirement is applied. • push "i" to activate the status indicator. As soon as there is a heat requirement, the boiler goes throug...

Page 30

Installation and maintenance instructions ecotec plus 0020214490_00 30 • show the operator the correct (economical) temperature, controller and thermostat valve settings. A caution! The boiler may only be permanently operated with its casing properly closed! Otherwise, under unfavourable conditions,...

Page 31

31 installation and maintenance instructions ecotec plus 0020214490_00 7 adapting the boiler to the heating installation the ecotec boilers are equipped with a digital information and analysis system (dia system). 7.1 selection and setting of parameters in the diagnosis mode, you can change various ...

Page 32

Installation and maintenance instructions ecotec plus 0020214490_00 32 display meaning adjustable parameters factory setting boiler-specific setting d. 0 heating partial load 12.5 - 45 kw 35 kw d. 1 overrun time of internal pump for heat- ing mode 2 - 60 min 5 mins d. 2 maximum burner anti-cycling t...

Page 33

33 installation and maintenance instructions ecotec plus 0020214490_00 7.2.1 setting the heating partial load the output of the boilers is set at 35 kw in the factory. You can specify a value that corresponds to the kw output of the boiler under diagnosis point "d. 0“. 7.2.2 setting of pump overrun ...

Page 34

Installation and maintenance instructions ecotec plus 0020214490_00 34 7 adapting the boiler to the heating installation t flow (target) [°c] set maximum burner anti-cycling time [min] 1 5 10 15 20 25 30 35 40 45 50 55 60 20 2.0 5,0 10,0 15,0 20,0 25,0 30,0 35,0 40,0 45,0 50,0 55,0 60,0 25 2.0 4,5 9...

Page 35

35 installation and maintenance instructions ecotec plus 0020214490_00 inspection and maintenance 8 8 inspection and maintenance 8.1 inspection and maintenance intervals danger! Risk of injury and risk of damage to property due to neglected inspection and maintenance! Neglected inspection and mainte...

Page 36

Installation and maintenance instructions ecotec plus 0020214490_00 36 - visual, the integrity of the boiler combustion circuit and relevant seals. - the gas inlet working pressure at maximum rate as described in section 6.3.3. - the gas flow rates as described in section 6.3.2. - correctness of ele...

Page 37

37 installation and maintenance instructions ecotec plus 0020214490_00 • wait at least 5 minutes until the boiler reaches its operating temperature. • measure the co 2 concentration at the flue gas analysis point (1). Compare the measured value with the corresponding value in table 8.1. • if all the...

Page 38

Installation and maintenance instructions ecotec plus 0020214490_00 38 . 8.1.5 inspection and maintenance work steps no. Activity column 1 inspection must be carried out each year column 2 maintenance must be carried out at regular intervals – but no longer than 5 years 1 check the air flue gas inst...

Page 39

39 installation and maintenance instructions ecotec plus 0020214490_00 8.2 filling/draining the boiler and heating installation 8.2.1 filling the boiler and the heating installation a description of how to fill the boiler and heating installation is provided in chapter 6.2. 8.2.2 draining of the boi...

Page 40

Installation and maintenance instructions ecotec plus 0020214490_00 40 a caution! Damage to gas supply! Under no circumstance may the compact thermal module dangle on the flexible corrugated gas pipe. 7 2 3 1 5 6 4 fig. 8.3 dismounting compact thermal module • remove the two plugs for the ignition (...

Page 41

41 installation and maintenance instructions ecotec plus 0020214490_00 8.3.4 installing the compact thermal module • renew the seals (1) and (3) in the burner door (see fig. 8.5). H danger! Danger of combustion and damage due to escaping hot flue gases! Both seals (1) and (2) and the self-locking nu...

Page 42

Installation and maintenance instructions ecotec plus 0020214490_00 42 8.5 cleaning the condensate ducts 2 1 fig. 8.8 dismounting the condensate siphon • completely remove the condensate siphon to clean the condensate ducts by pulling out the clamp (1). This allows access to the condensate discharge...

Page 43

43 installation and maintenance instructions ecotec plus 0020214490_00 • fill the expansion vessel with air at a pressure of less than 0.75 bar according to the static head of the heating installation. • if water is discharged at the testing nozzle of the expansion vessel the vessel must be replaced...

Page 44

Installation and maintenance instructions ecotec plus 0020214490_00 44 display meaning heating mode s.0 heating no heat demand s.1 heating mode fan start-up s.2 heating mode pump pre-run s.3 heating mode ignition s.4 heating mode burner on s.5 heating mode pump/fan overrun s.6 heating mode fan overr...

Page 45

45 installation and maintenance instructions ecotec plus 0020214490_00 display meaning display value/adjustable value d.0 heating part load adjustable heating part load in kw (factory setting: approx. 70% of maximum output) d.1 pump overrun for heating mode 2 - 60 minutes (factory setting: 5) d.2 ma...

Page 46

Installation and maintenance instructions ecotec plus 0020214490_00 46 display meaning display value/adjustable value d.14 pump speed target value target value of internal pump in % possible settings: 0 = auto (factory setting) 1 = 53% 2 = 60% 3 = 70% 4 = 85% 5 = 100% d.17 heating flow/return regula...

Page 47

47 installation and maintenance instructions ecotec plus 0020214490_00 display meaning display value/adjustable value d.81 operating hours hot water generation in h 1) d.82 burner start-ups in heating mode number/100 1) (3 equals 300) d.83 burner start-ups in hot water mode number/100 1) (3 equals 3...

Page 48

Installation and maintenance instructions ecotec plus 0020214490_00 48 code meaning cause f. 0 break flow ntc ntc plug not plugged in or has come loose, multiple plug on the pcb not plugged in correctly, interruption in cable harness, ntc de- fective f. 1 break return ntc ntc plug not plugged in or ...

Page 49

49 installation and maintenance instructions ecotec plus 0020214490_00 code meaning cause f.74 failure water pressure sensor signal outside correct range (too high) line to water pressure sensor has short-circuited at 5v/24v or internal failure in water pressure sensor f.75 failure pump/water lack w...

Page 50

Installation and maintenance instructions ecotec plus 0020214490_00 50 10 replacing components the tasks listed below in this section may be carried out only by a qualified heating engineer. The original components of the product were also certi- fied as part of the ce declaration of conformity. If ...

Page 51

51 installation and maintenance instructions ecotec plus 0020214490_00 1 2 3 4 fig. 10.2 dismantling the fan with gas valve • pull the plug (4) out of the gas valve. • pull the plugs (2) out of the fan. • unfasten the four screws (3) on the compact thermal module (1). • remove the complete unit "gas...

Page 52

Installation and maintenance instructions ecotec plus 0020214490_00 52 10.5 replacing pcb and display d danger! Before replacing the component, observe the safety information in chapter 10.1. E danger! Risk of fatal electric shock through contact with live connections! Disconnect the boiler from the...

Page 53

53 installation and maintenance instructions ecotec plus 0020214490_00 13 technical data ecotec vu gb 466/4-5 a unit heat output range (heating 50/30 °c) 12,9 - 46,4 kw heat output range (heating 80/60 °c) 12,3 - 44,1 kw maximum heat input (net) 45 kw net efficiency at 100% load 98,4 % net efficienc...

Page 54: Www.Centralheating.Co.Uk

© heating and hotwater industry council (hhic) www.Centralheating.Co.Uk benchmark commissioning and servicing section it is a requirement that the boiler is installed and commissioned to the completed in full..

Page 55

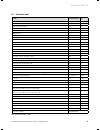

This commissioning checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating compliance with the appropriate building regulations and then handed to the customer to keep for future reference. Gas boiler system commissioning checklist control...

Page 56

It is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider service record service 01 and ² % and ² % service 02 and ² % and ² % service 03 and ² % and ² % service 04 and ² % and ² % service 05 and ² % and ² % servi...

Page 57

Prior to co and combustion ratio check the boiler manufacturer’s installation instructions should have been followed, gas type verified and gas supply pressure/rate checked as required prior to commissioning. As part of the installation process, especially where a flue has been fitted by persons oth...

Page 60

0 0202 14 4 90_00 gbie 0 3 2 014 – s ubject t o change manufacturer supplier.