- DL manuals

- Vaillant

- Water Heater

- ecoTEC plus SERIES

- Instructions For Installation And Servicing

Vaillant ecoTEC plus SERIES Instructions For Installation And Servicing

Summary of ecoTEC plus SERIES

Page 1

For the installer instructions for installation and servicing ecotec plus gb wall hung open vent condensing boiler.

Page 2

Installation and servicing ecotec plus 2 contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 notes on the documentation . . . . . . . . . . . . 4 1.1.1 other instructions supplied with this appliance . . . . . . . . . . . . . . . . . . . . . 4 1.1.2 retention of docum...

Page 3

Installation and servicing ecotec plus 3 contents page contents 9 combustion analysis . . . . . . . . . . . . . . . . . . . 37 9.1 check co 2 content. . . . . . . . . . . . . . . . . . . . . 37 10 trouble shooting . . . . . . . . . . . . . . . . . . . . . . . 38 10.1 logical fault finding procedure....

Page 4

Installation and servicing ecotec plus 4 1.1 notes on the documentation. To ensure clarity of information in instructions a new european standard of advice and symbols is being introduced. To ensure compliance with this new standard the following details are included. The following information is in...

Page 5

Installation and servicing ecotec plus 5 1.4 general information thank you for choosing a vaillant boiler. The information given in this booklet will enable you to obtain the best performance from your boiler. The benchmark logbook should be completed by the installer and/or commissioning engineer a...

Page 6

Installation and servicing ecotec plus 6 1.4.13 protection against freezing the boiler has a built in frost protection programme as long as the electricity and gas are left switched on. This device operates the burner and system pump when the temperature inside the boiler falls to 3°c. Any other exp...

Page 7

Installation and servicing ecotec plus 7 1.5 statutory requirements the appliance is suitable only for installation in gb and ie and should be installed in accordance with the rules in force. In gb the installation of the boiler must be carried out by a competent person as described in the following...

Page 8

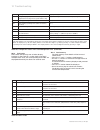

Installation and servicing ecotec plus 8 2 boiler specifications 2 boiler specifications 2.1 technical data description unit ecotec plus 415 ecotec plus 418 ecotec plus 428 ecotec plus 438 maximum ch heat input (net) kw 15.3 18.9 28.6 38.4 ch heat output (80/60 °c) kw 5.0 - 15.0 5.0 - 18.6 5.3 - 28....

Page 9

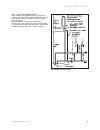

Installation and servicing ecotec plus 9 48 26 33 176 160 340 113 375 133 30 15mm gas connection 53 161 6 10 1 2 3 7 4 5 6 outside wall face boiler cl flue cl flue cl flue cl flue cl boiler cl 56 2.1.2 dimensions boiler specifications 2 legend: 1 heating return pipe Ø 22 2 heating flow pipe Ø 22 3 g...

Page 10

Installation and servicing ecotec plus 10 3 general requirements 3 general requirements 3.1 preliminary remarks for room sealed appliances this appliance should only be installed with a vaillant flue system. Install the flue system as detailed in the separate flue installation instructions supplied ...

Page 11

Installation and servicing ecotec plus 11 65 13 30 405 - 610 48 general requirements 3 3.4 gas supply the gas supplier should ensure the availability of an adequate supply of gas. A gas meter may only be connected to the service pipe by the supplier of gas or their contractor. An existing meter shou...

Page 12

Installation and servicing ecotec plus 12 3 general requirements 3.5.1 flue termination the following details refer to both flue systems. A. The terminal must be located where the combustible substances can escape freely at all times. B. A plume of water vapour will sometimes be visible from the flu...

Page 13

Installation and servicing ecotec plus 13 general requirements 3 3.8 domestic hot water cylinder caution! Single feed indirect cylinders are not suitable. The domestic hot water cylinder must be of the double feed fully indirect coil type. It must be suitable for working at a gauge pressure of 0.35 ...

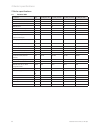

Page 14

Installation and servicing ecotec plus 14 3 general requirements ecotec plus 415 pressure loss graph ecotec plus 428 pressure loss graph ecotec plus 418 pressure loss graph ecotec plus 438 pressure loss graph fig. 3.8 pressure loss.

Page 15

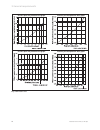

Installation and servicing ecotec plus 15 general requirements 3 fig. 3.9 open vented system 3.16 open vented heating system the boiler must be supplied from an unrestricted water supply taken from a feed and expansion cistern situated at a maximum height of 27 metres (90ft) above the boiler. The co...

Page 16

Installation and servicing ecotec plus 16 3 general requirements fig. 3.10 typical installation 3.17 sealed water systems the installation must comply with the appropriate requirements of the current issue of bs4814, bs5449, bs6759, bs6798 and bs7074 part 1 and 2. For ie your attention is drawn to t...

Page 17

Installation and servicing ecotec plus 17 boiler installation sequence 4 4 boiler installation sequence 4.1 boiler location note! This boiler is not suitable for outdoor installation. This boiler may be installed in any room, although particular attention is drawn to the installation of a boiler in ...

Page 18

Installation and servicing ecotec plus 18 4.1.4 contents included with delivery the vaillant ecotec plus is delivered pre-mounted in a package unit. Check that all the parts have been delivered intact (see fig. 4.2 and table 4.1. Do not remove the boiler from the polystyrene base at this stage. Plac...

Page 19

Installation and servicing ecotec plus 19 160 fig. 4.3 boiler hanging bracket boiler installation sequence 4 fig. 4.4 removing front casing retaining dowel (2 off) front casing screw (2 off) 4.3 fitting the boiler hanging bracket reposition the wall template over the flue hole ensuring the template ...

Page 20

Installation and servicing ecotec plus 20 4 boiler installation sequence 4.3.3 gas connection danger! The gas connection may only be made by a competent person. The legal directives and the local regulations for gas supply companies must be observed. Caution! Ensure a stress-relief assembly of the g...

Page 21

Installation and servicing ecotec plus 21 coupling fig. 4.5 gas and condense connections 22mm compression is the recommended fixing for servicing. Fig. 4.6 water connections 4.4 electrical connections danger! This appliance must be earthed. Electrocution caused by touching live parts can be fatal. B...

Page 22

Installation and servicing ecotec plus 22 fig. 4.8 mains supply connection fig. 4.7 mains supply connection 4.4.1 connection to the main supply • lower the electronics box, see fig. 4.7. Opening the electronics box • unclip the bottom of the electronics box cover and hinge back to reveal the connect...

Page 23

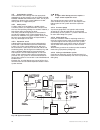

Installation and servicing ecotec plus 23 fig. 4.9 connection wiring x20 x2 - + bus 24v 230v 7 8 9 l n 3 4 5 x40 x41 x31 caution: do not connect supply voltage! Risk of damage to electronics! Room thermostat 24v: connection 7, 8 and 9 no bi-directional interface (analogue only) mains supply: 230v / ...

Page 24

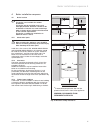

Installation and servicing ecotec plus 24 fig. 4.10 mains supply connection ntc flow x 20/8 blue x 20/16 blue (earth) green/yellow fuse t2e 250 volts green/yellow green/yellow x 20/18 red (24 vdc) x 20/9 blue (earth) x 20/4 grey(pwm) x 20/3 black (hall signal) x 20/17 red (24 vdc) black link x 20/5 ...

Page 25

Installation and servicing ecotec plus 25 4.4.4 controls table 4.2 vaillant controls (used in conjunction with the vr 65 accessory) controls item no. Connection vrc 400 (1-circuit controller, weather-controlled) 00 2001 0843 installation in electronics box or wall-mounted (plug-and play) vrt 360 (ro...

Page 26

Installation and servicing ecotec plus 26 5 commissioning (part i) 5 commissioning (part i) please ensure the “benchmark” commissioning check list is completed and left with the user. 5.1 preliminaries - all systems a competent person should carry out commissioning, in accordance with the current is...

Page 27

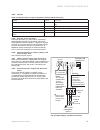

Installation and servicing ecotec plus 27 1 3 2 4 pressure test point electrical plug gas control valve throttle offset adjustment fig. 5.3 gas control valve 5 commissioning (part i) 5.1.2 initial lighting the lighting procedure of the boiler is fully automated. To prepare the boiler for initial lig...

Page 28

Installation and servicing ecotec plus 28 6 natural gas to lpg conversion 6 natural gas to lpg conversion the ecotec plus is able to be field adjusted for use on lpg – propane g31 gas. To enable conversion the use of a combustion analyser is necessary. Caution! After converting from natural gas to l...

Page 29

Installation and servicing ecotec plus 29 7 functional checks commissioning (part ii) commissioning and service log. 7 functional checks commissioning (part ii) functional checks procedure: after installing and checking the gas supply pressure, perform a function check before commissioning the appli...

Page 30

Installation and servicing ecotec plus 30 7.1.3 final flush of the heating system (hot) • operate the appliance until the heating system is up to temperature. • check the heating system for leaks. • connect a hose to the drain valve located at the lowest position of the heating system. • shut off th...

Page 31

Installation and servicing ecotec plus 31 8 inspection and maintenance 8.1 initial inspection to ensure the continued safe and efficient operation of the boiler it is recommended that it is checked and serviced as necessary at regular intervals. The frequency of servicing will depend upon the partic...

Page 32

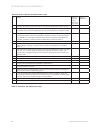

Installation and servicing ecotec plus 32 no. Activity column 1 inspection must be carried out once a year column 2 maintenance 1 check the air/ gas flue system and ensure it is not blocked, damaged and is fitted correctly. X 2 measure the gas rate during operation (see table 5.1. Inside section 5 c...

Page 33

Installation and servicing ecotec plus 33 8.1.4 general all routine servicing requirements can be achieved by the removal of the front casing, inner case and chassis panel only. Remove the two screws on the underside of the front casing and lift off. Remove the two screws on the front of inner case ...

Page 34

Installation and servicing ecotec plus 34 fig. 8.5 gas service cock fig. 8.4 gas service cock 8 inspection and maintenance 8.1.5 spark electrode disconnect the ignition lead and earth lead from the igniter unit and two securing screws at the spark electrode. Withdraw the spark electrode carefully fr...

Page 35

Installation and servicing ecotec plus 35 8 inspection and maintenance fig. 8.6 fan, gas valve and burner note! If the burner has to be removed it will require a new gasket when refitted. Note! When replacing ensure that the sealing grommet, situated below the gas valve is correctly re-seated. 8.1.7...

Page 36

Installation and servicing ecotec plus 36 fig. 8.8 insulation fig. 8.9 panels 8 inspection and maintenance inner casing seal front casing 8.1.8 condensate drain the condense drain does not normally need removing during servicing. To flush the condense drain carefully pour water into the heat exchang...

Page 37

Installation and servicing ecotec plus 37 combustion analysis 9 9 combustion analysis note! The boiler is fitted with a combustion analysis test point. A suitable combustion analyser can be connected to this point to establish the combustion performance of the boiler. 9.1 check co 2 content refer to...

Page 38

Installation and servicing ecotec plus 38 10 troubleshooting 10 troubleshooting 10.1 logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section 4 ‘wiring system’). 2. Check that the external el...

Page 39

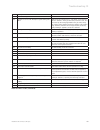

Installation and servicing ecotec plus 39 troubleshooting 10 display meaning charge hot water cylinder (when accessories are fitted): s.20 warmstart demand s.21 fan running s.22 pump running s.23 ignition sequence s.24 burner ignited s.25 fan and water pump running s.26 fan over run s.27 pump over r...

Page 40

Installation and servicing ecotec plus 40 display meaning display value/adjustable value d. 0 heating part load adjustable heating part load in kw (factory setting: max. Output) d. 1 water pump over run time for heating mode 2 - 60 min (factory setting: 5 min) d. 2 max. Burner anti cycling period at...

Page 41

Installation and servicing ecotec plus 41 display meaning display value/adjustable value d.17 heating flow/return regulation change over 0 = flow, 1 = return (factory setting: 0) d.18 pump mode (return) 0 = return, 1 = nonstop, 2 = winter (factory setting: 0) d.19 operating modes of the two-speed he...

Page 42

Installation and servicing ecotec plus 42 table 10.3 diagnostics codes of the second diagnostic level (continued) code meaning cause f. 0 flow–ntc open circuit ntc broken, ntc cable broken, defective connection at ntc, defective connection at electronics f. 1 return–ntc open circuit ntc broken, ntc ...

Page 43

Installation and servicing ecotec plus 43 code meaning cause f.27 incorrect sensing of flame flame detector defective f.28 appliance does not start: attempts to ignite during start failed faults in the gas supply such as:- - gas meter or gas pressure detector defective - air in gas- gas flow pressur...

Page 44

Installation and servicing ecotec plus 44 10.2 test programs special functions can be triggered on the appliances by activating various test programs. These programs are given in detail in the table 10.5. • the test programs p.0 to p.6 will be started when “power on” is turned on and the “+” key is ...

Page 45

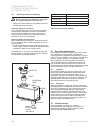

Installation and servicing ecotec plus 45 parts replacement 11 note! The ecotec plus 428 and 438 fan is secured through an extension piece with two securing screws, check and replace any seals or gaskets if necessary. 11.5 replacing the heat exchanger for access refer to section 8.1.4. Remove the ga...

Page 46

Installation and servicing ecotec plus 46 fig. 11.3 condense trap spigot bung (remove and discard) spigot adapter condense trap float screw 12 recycling and disposal the design of all vaillant products takes into account the subsequent recycling and/or eventual safe scrapping of each component used....

Page 47

Installation and servicing ecotec plus 47 appendix 14.

Page 48

Installation and servicing ecotec plus 48.

Page 49

Installation and servicing ecotec plus 49.

Page 50

Installation and servicing ecotec plus 50 notes.

Page 51

Installation and servicing ecotec plus 51 notes.

Page 52

00 2 00 2 08 2 8_0 2 gb /08 /2 006 · s u b je ct t o a lt e ra ti o n.