4000307-15 © 2009, miles industries ltd. All rights reserved. H orizon warning: if the information in these instructions is not followed exactly, a fi re or explosion may result causing property damage, personal injury or loss of life. What to do if you smell gas • do not try to light the appliance....

2 designed and manufactured by / for miles industries ltd. 190 – 2255 dollarton highway, north vancouver b.C., canada v7h 3b1 tel. (604) 984-3496 fax (604) 984-0246 www.Valorfireplaces.Com © copyright miles industries ltd., 2009 warning hot glass will cause burns. Do not touch glass until cooled. Ne...

33 table of contents safety and warning information ..............................................................4 options .......................................................................................................7 dimensions ...............................................................

44 safety and warning information children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Do not place furniture or any ot...

55 state of california. Proposition 65 warning. Fuels used in gas, wood-burning or oil fired appliances, and the products of combustion of such fuels, contain chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. California health & safety code sec. 2...

66 venting system shall include: 1. Detailed instructions for the installation of the venting system design or the venting system components; and 2. A complete parts list for the venting system design or venting system. (d) manufacturer requirements - gas equipment venting system not provided. When ...

77 options heater engine unit #534xan is used with all natural gas installations. Heater engine unit #534xap is used with all propane gas installations. Optional features circulating fan kit #755cfk having variable speed and temperature control, it is designed to boost the natural convection process...

88 32-3/16” (817 mm) 29-3/4” (756 mm) 3” (75 mm) min. To side wall from inner frame mantel 36” (914 mm) min. See table a b 23-1/8” (587 mm) to r ear v en t c en ter 33-1/2” (850 mm) 14” (355 mm) 34-7/8” (887 mm) 31-1/8” (780 mm) 34-7/8” (887 mm) 32-1/2” (825 mm) finished wall (see location section-f...

99 specifications approvals & codes these appliances are certified by ansi z21.88b-2008 / csa 2.33b-2008 vented gas fireplace heater for use in canada and usa. These appliances are for installation directly venting through an outside wall or through the roof. Model 534xan is for use with natural gas...

10 10 location framing the framing dimensions are shown in figure 4. • a non-combustible hearth is not necessary in front of this appliance. • note that the unit is installed at the framing stage and fixed to framing using support angles. See figures 26 and 30. Wall finish is then installed over the...

11 11 minimum maximum a: from floor to top of vent duct 4’-3½” (131 cm) 9’-3½” (283 cm) b: frame front face to outside wall - 12’-5½” (380 cm) c: frame front face to inside wall 2’-5½” (75 cm) - d: vertical pipe run between elbows 12” (30.5 cm) 6’ (183 cm) e 1 +e 2 : total horizontal pipe run includ...

12 12 location rear vent connection—corner location, horizontal vent run only see figure 8. Can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak and 45° elbow will be required. See venting accessories list on pages 39–40 for allowable components....

13 13 location rear vent connection—vertical rise with offset, through the roof termination see figure 11. For situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, one 90° vent elbow, two 45° vent elbows, pipe lengths, a vertical vent termina...

14 14 minimum maximum a: from floor to top of vent duct 3’-7 9 ⁄ 16 ” (111 cm) 9’-1 9 ⁄ 16 ” (278 cm) b: frame front face to outside wall - 11’4” (345 cm) c: frame front face to inside wall 16” (40.6 cm) - d: vertical pipe run between elbows 6” (15.2 cm) 6’ (183 cm) e: total horizontal pipe run from...

15 15 top vent connection—horizontal side termination the vent pipe dimensional requirements in section top vent connection—horizontal rear termination apply. The minimum floor location is shown in figure 14. Can be used with either #551dvk standard vent kit or another terminal cap and accessories. ...

16 16 top vent connection—through the roof termination* see figure 16. Adapter #817vak, pipe lengths, a vertical vent terminal and roof flashing will be required. Various other ceiling or roof items may be necessary depending on the particular installation. See venting accessories list on pages 39–4...

17 17 rear or top outlet conversion to co-linear liners using valor #556cla co-linear adapter. (generic co-axial to co-linear adapter boxes may also be used as an alternate to the 556cla). Only for use when retrofitting a solid-fuel burning fireplace and chimney. The appliance must not be connected ...

18 18 vent location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airflow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be maintained when ...

19 19 supply gas heater engine unit #534xan is used with all natural gas installations. Heater engine unit #534xap is used with all propane gas installations. The supply pressure must be between the limits shown in the section specifications of this manual. The supply connection is ⅜” npt. The openi...

20 20 pack contents ceramic walls ceramic logs gas inlet adaptor stand-off brackets screw pack top heat shield panel type “c” type “b” type “a” ash bed support port cover appliance engine frame side fixing brackets frame top support angle side channels upper louver lower louver hinge spacers magnet ...

21 21 appliance preparation window removal see figure 20. 1. Turn the top two spring-loaded window bolts through 90° to release the window from the firebox. 2. Remove the bottom two spring-loaded window bolts. 3. Detach the chain from the top right corner of the window. 4. Carefully lift the window ...

22 22 appliance preparation #817vak pipe adapter fitting if installing fl at on wall with valor terminal unit #551dvk, ignore this stage. See fi gure 23. 1. Fit the adapter #817vak over the appliance vent collars pushing on fi rmly. 2. For rear vent outlet connection, align the adapter so that the s...

23 23 appliance preparation top heat shield & stand-offs fitting see figures 24 & 25. 1. If installing appliance with top vent outlet, remove the plate covering the vent hole in the top heat shield by unscrewing four screws. If installing with rear vent outlet, the plate must remain, covering the ho...

24 24 type “a” maximum opening type “a” minimum opening type “b” & “c” hole(s) at top type “a” type “b” type “c” vent terminal appliance vent outlet vertical vent pipe run use restrictor type port opening set at horizontal through wall with vertical rise top less than 3’ (91 cm) a maximum from 3’ (9...

25 25 appliance preparation attaching rear ceramic support see figure 29. Fit the rear ceramic support to the firebox back panel with three screws. Attaching appliance to the framing see figure 30. 1. Place the heater in position in the framing. 2. Secure the side support angles to the side studding...

26 26 installations with horizontal termination—installing to wall see location section for full range of horizontal termination applications. Flat on wall installation with valor #551dvk terminal 1. Cut the vent terminal pipe unit to size. See figure 31. Important! The drain hole must be clearly ou...

27 27 13” 12-1/4” 10” 10” drain hole installations with horizontal termination—installing to wall wall opening • where applicable, fit all the required pipes and elbows up to the wall. See the manufacturer’s instructions supplied with the venting sections. • check the wall opening position. • make w...

28 28 2 - 3” liners ‘h’ horizontal overhang vertical wall termination cap storm collar roof flashing plumber’s tape fixed to wall strap wall strap ceiling firestop ceiling support offset elbows min. 18” overhang should not extend beyond vent if within 48” of termination cap min. 24” (unvented soffit...

29 29 remote control installation caution! Don’t connect the batteries to the remote control receiver until the wires are connected to the burner control unit, as short circuit could result in destruction of the electrical components. When installing the remote control, please refer to figures 37 an...

30 30 gas supply installation • the gas supply pipe should enter the appliance case through the opening at the rear left side. The supply pipe should be connected to the appliance gas inlet pipe situated at the left side of the control valve. Supply line connection to the inlet pipe is 3/8” npt ( fe...

31 31 ceramic fuel bed installation ceramic walls installation 1. Locate the ceramic rear wall in the channel at back of the firebox and flat against the back of the firebox. See figure 41. 2. Locate the sidewalls against the sides of the firebox. Make sure that they are behind the raised edges of t...

32 32 window refitting & checking 1. Refit the window with the bottom two bolts. The bolts should be screwed in securely. 2. Refit the chain to the top right corner of the window. 3. Refit the top two bolts securing by turning them through 90°. 4. Pull the top of the window forward and release to ch...

33 33 front installation #601sfb standard metal front 1. Fit the lower louver unit using the hinge studs and hinge spacers as shown in figure 51. 2. Fix the two adhesive backed magnet counter plates to the tabs at the firebox sides, which line up with the magnets on the lower louver. See figure 51. ...

34 34 operating your fireplace for your safety, this appliance is fitted with a flame supervision device which will shut-off the gas supply if, for any reason, the pilot flame goes out. This device incorporates a fixed probe, which senses the heat from the pilot flame. If the probe is cool, the devi...

35 35 thermocouple probe must be in flame checks • a periodic check of the pilot and burner flames should be made. Check after the fire has been on for at least 30 minutes. The pilot flame must cover the tip of the thermocouple probe. The main burner flame pattern will vary from appliance to applian...

36 36 remote control operation setting the time the first thing to do is to set the time. 1. With your thumb, hold down both the auto and timer buttons until f flashes. Let go. 2. Note the digital clock on the bottom right hand corner. The ▲ button sets the hour; the ▼button sets the minutes. Set th...

37 37 remote control operation setting the flame use this setting when you want a particular flame level. For instance, you want to watch flames burn at their highest level and you don’t mind if the room is too hot. 1. To raise the flame, press and hold the ▲ button until the flame gets to the desir...

38 38 lighting instructions thermocouple probe must be in flame lighting instructions to turn off gas to appliance for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A...

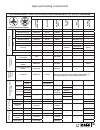

39 39 approved venting components approved direct vent suppliers for valor models 530, 534, 535, and mf28 venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries miles industries termination caps horizontal co-...

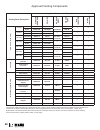

40 40 approved venting components venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries miles industries pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — black 46dva-06b 4dt-...

41 41 warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in...