- DL manuals

- Varian

- GPS

- TV 551

- Instruction Manual

Varian TV 551 Instruction Manual

TV 551/701

Navigator

969-8832 969-8833

969-8834 969-8835

969-8836 969-8837

969-8922 969-8923

969-8924 969-8925

969-8926 969-8927

969-8974 969-8975

MANUALE DI ISTRUZIONI

BEDIENUNGSHANDBUCH

NOTICE DE MODE D’EMPLOI

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

BEDRIJFSHANDLEIDING

INSTRUKSTIONSBOG

BRUKSANVISNING

INSTRUKSJON MANUAL

OHJEKÄSIKIRJA

ODHGIES CRHSEWS

INSTRUCTION MANUAL

87-900-934-01(D)

SEPTEMBER 2003

View our inventory

Summary of TV 551

Page 1

Tv 551/701 navigator 969-8832 969-8833 969-8834 969-8835 969-8836 969-8837 969-8922 969-8923 969-8924 969-8925 969-8926 969-8927 969-8974 969-8975 manuale di istruzioni bedienungshandbuch notice de mode d’emploi manual de instrucciones manual de instruÇÕes bedrijfshandleiding instrukstionsbog bruksa...

Page 2: Tv 551 Navigator

Tv 551 navigator tv 701 navigator.

Page 5

Istruzioni per l’uso ...................................................................................................................................1 gebrauchsanleitung ..................................................................................................................................

Page 6

Istruzioni per l'uso 1 87-900-934-01(d) informazioni generali questa apparecchiatura è destinata ad uso professionale. L'uti- lizzatore deve leggere attentamente il presente manuale di i- struzioni ed ogni altra informazione addizionale fornita dalla varian prima dell'utilizzo dell'apparecchiatura. ...

Page 7

Istruzioni per l'uso 2 87-900-934-01(d) fissaggio della pompa ! Pericolo! Se si verifica un danno al rotore, la connessione tra la pompa ed il sistema potrebbe essere sottoposta ad una coppia signifi- cativa. Se la connessione non è sufficiente per resistere alla suddetta coppia, la pompa potrebbe s...

Page 8

Gebrauchsanleitung 3 87-900-934-01(d) allgemeine informationen dieser apparat ist für den fachmännischen gebrauch bestimmt. Vor dem gebrauch hat der benutzer dieses handbuch sowie alle weiteren mitgelieferten zusatzdokumentationen genau zu lesen. Bei auch teilweiser nichtbeachtung der enthaltenen an...

Page 9

Gebrauchsanleitung 4 87-900-934-01(d) befestigung der pumpe ! Gefahr! Wenn ein läuferschaden auftritt, könnte die verbindung zwi- schen der pumpe und dem system mit einem erheblichen drehmoment belastet werden. Setzt die verbindung diesem drehmoment keinen ausreichenden widerstand entgegen, besteht ...

Page 10

Mode d’emploi 5 87-900-934-01(d) indications generales cet appareillage a été conçu en vue d'une utilisation professionnelle. Avant toute utilisation de l'appareil, il est conseillé à l'utilisateur de lire attentivement cette notice d'instructions ainsi que toute autre indication supplémentaire four...

Page 11

Mode d’emploi 6 87-900-934-01(d) fixation de la pompe ! Danger! En cas d'endommagement du rotor, la connexion pompe - système pourrait être soumise à un couple très important. Si la connexion n'est pas en mesure de résister au dit couple, la pompe peut se détacher du système ou le moteur de l'envelo...

Page 12

Instrucciones de uso 7 87-900-934-01(d) informaciÓn general este equipo es para uso profesional. El usuario ha de leer atentamente el presente manual de instrucciones y cualquier otra información suplementaria facilitada por varian antes de usar el aparato. Varian se considera libre de posibles resp...

Page 13

Instrucciones de uso 8 87-900-934-01(d) fijaciÓn de la bomba ! ¡peligro! En caso de dañarse el rotor, la conexión entre la bomba y el sistema puede ser sometida a un par de fuerza excesivo. En estas circunstancias, la conexión podría no resistir a dicho par de fuerza y, como consecuencia, la bomba p...

Page 14

InstruÇÕes de uso 9 87-900-934-01(d) informaÇÕes gerais esta aparelhagem destina-se a uso profissional. O utilizador deve ler atentamente o presente manual de instruções e todas as informações adicionais fornecidas pela varian antes de utilizar a aparelhagem. A varian não se responsabiliza pela inob...

Page 15

InstruÇÕes de uso 10 87-900-934-01(d) fixaÇÃo da bomba ! Perigo! Em caso de dano no rotor, a ligação entre a bomba e o sistema corre o risco de sofrer um torque muito grande. Se a ligação não resistir de maneira suficiente ao referido torque, a bomba pode soltar-se do sistema ou o motor pode soltar-...

Page 16

Gebruiksaanwijzingen 11 87-900-934-01(d) algemene informatie deze apparatuur is bestemd voor beroepsmatig gebruik. De gebruiker wordt verzocht aandachtig deze handleiding en alle overige door varian verstrekte informatie door te lezen alvorens het apparaat in gebruik te nemen. Varian acht zich niet ...

Page 17

Gebruiksaanwijzingen 12 87-900-934-01(d) bevestiging van de pomp ! Gevaar! Als schade aan de rotor optreedt, zou de verbinding tussen de pomp en het systeem aan een behoorlijk groot koppel onderhevig kunnen zijn. Als de verbinding niet voldoende is om dit koppel te weerstaan, zou de pomp van het sys...

Page 18

Brugsanvisning 13 87-900-934-01(d) generel information dette udstyr er beregnet til professionel anvendelse. Brugeren bør læse denne brugsanvisning og anden yderligere information fra varian, før udstyret anvendes. Varian tager ikke ansvar for skader helt eller delvis som følge af tilsidesættelse af...

Page 19

Brugsanvisning 14 87-900-934-01(d) fastgØrelse af pumpe ! Advarsel! Hvis rotoren beskadiges, kan forbindelsen mellem pumpen og systemet blive udsat for et kraftigt drejemoment. Hvis forbindelsen ikke er tilstrækkelig til at modstå dette drejemoment, kan pumpen rive sig løs fra systemet eller motoren...

Page 20

Bruksanvisning 15 87-900-934-01(d) allmÄn information utrustningen är avsedd för yrkesmässig användning. Användaren bör läsa denna bruksanvisning, samt övrig dokumentation från varian före användning av utrustningen. Varian tar inget ansvar för skador helt eller delvis till följd av åsidosättande av...

Page 21

Bruksanvisning 16 87-900-934-01(d) fastsÄttning av pump ! Varning! I händelse av rotorfel kan anslutningen mellan pumpen och systemet utsättas för ett högt vridmoment. Om anslutningen inte tål ovannämnda vridmoment kan pumpen lossna från systemet eller motorn kan lossna från pumpens hölje. I så fall...

Page 22

Brukerveiledning 17 87-900-934-01(d) generell informasjon dette utstyret er beregnet til bruk av profesjonelle brukere. Brukeren bør lese denne brukerveiledningen og all annen informasjon fra varian før utstyret tas i bruk. Varian kan ikke holdes ansvarlig for hendelser som skjer på grunn av manglen...

Page 23

Brukerveiledning 18 87-900-934-01(d) festing av pumpen ! Advarsel! Dersom rotoren ødelegges, kan tilkoplingen mellom pumpen og systemet utsettes for et betydelig dreiemoment. Dersom tilkoplingen ikke er sterk nok til å tåle dette dreiemomentet, kan pumpen løsne fra systemet eller motoren kan løsne f...

Page 24

KÄyttÖohjeet 19 87-900-934-01(d) yleisiÄ tietoja tämä laite on tarkoitettu ammattimaiseen käyttöön. Ennen laitteen käyttöönottoa tulee käyttäjän lukea huolellisesti ohjekirja ja muut varianin toimittamat lisätiedot. Varian ei ota vastuuta seurauksista, jotka johtuvat laitteen käyttöohjeiden täydelli...

Page 25

KÄyttÖohjeet 20 87-900-934-01(d) pumpun kiinnitys ! Vaara! Jos roottori vaurioituu, pumpun ja järjestelmän väliseen liitäntään saattaa kohdistua huomattavaa vääntömomenttia. Ellei liitäntä kestä kyseistä momenttia, pumppu saattaa irrota järjestelmästä tai moottori pumpun kotelosta. Tällöin metallika...

Page 26

Odhgies crhshs 21 87-900-934-01(d) genikes plhrofories autÿ h suskeuÿ proor∂zetai gia epaggelmatikÿ crÿsh. O crÿsthj qa pr◊pei na diab£sei prosektik£ tij odhg∂ej tou parÒntoj egceir∂diou odhgièn kai opoiadÿpote £llh prÒsqeth plhrofor∂a pou d∂nei h varian, prin apÒ th crhsimopo∂hsh thj suskeuÿj. H va...

Page 27

Odhgies crhshs 22 87-900-934-01(d) ΣΤΕΡΕΩΣΗ ΤΗΣ ΑΝΤΛΙΑΣ ! Kindunos! Αν παρουσιαστεί ζηµιά στον ρότορα, η σύνδεση ανάµεσα στην αντλία και στο σύστηµα µπορεί να εφαρµοστεί σηµαντική ροπή. Αν η σύνδεση δεν είναι επαρκής για να αντέξει σε τέτοιου είδους ροπή, η αντλία µπορεί να αποσυνδεθεί από το σύστηµ...

Page 28

Instruction manual 23 87-900-934-01(d) general information this equipment is destined for use by professionals. The user should read this instruction manual and any other additional information supplied by varian before operating the equipment. Varian will not be held responsible for any events occu...

Page 29

Instruction manual 24 87-900-934-01(d) pump fixing ! Warning! If a rotor failure occurs, the connection of the pump to the sys- tem could be subjected to a significant torque. If the connection is not sufficient to withstand that torque, the pump could detach from the system or the motor housing cou...

Page 30

Technical information description of the tv 551/701 navigator the tv 551/701 navigator pumping system con- sists of a pump with a dedicated controller fixed to it. The system is available in four models for tv 551 and two models for tv 701. The models of each group differ in the high vacuum flange. ...

Page 31

Technical information pump description the pump consists of a high frequency motor driv- ing a turbine fitted with 8 bladed stages and 4 macrotorr stages. The turbine rotates in an anti- clockwise direction when viewed from the high vacuum flange end. The turbine is made of high-strength aluminium a...

Page 32

Technical information technical specification characteristic tv 551 tv 701 pumping speed (with inlet screen) n 2 : he: h 2 : cff 6"/ iso100: 350 l/s 450 l/s 450 l/s cff 8"/ iso160: 550 l/s 600 l/s 510 l/s cff 10"/ iso200: 690 l/s 620 l/s 510 l/s compression ratio n 2 : he: h 2 : 1 x 10 9 1 x 10 7 1 ...

Page 33

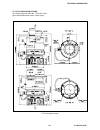

Technical information tv 551/701 navigator outline the following figures show the tv 551/701 navi- gator outlines (dimensions are in inches [mm]). Tv 551 navigator outline 28 87-900-934-01(d).

Page 34

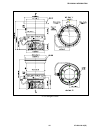

Technical information tv 701 navigator outline 29 87-900-934-01(d).

Page 35

Technical information tv 551 tv 701 graph of nitrogen pumping speed vs inlet pressure (with inlet screen) graph of compression ratio vs foreline pressure graph of nitrogen throughput vs inlet pressure using the recommended mechanical forevacuum pump 30 87-900-934-01(d).

Page 36

Technical information interconnections the following figure shows the tv 551/701 inter- connections. P3 - vent this is a dedicated 24 vdc connector to control the optional vent valve. P4 – external fan this is a dedicated 24 vdc connector to supply the optional external fan. J1 - in-out this connect...

Page 37

Technical information speed setting: pwm input signal to set the pump speed. The pwm signal characteristics must be the following: • frequency: 100 hz +/-20% • ampitude: 24 v max • duty cycle range: from 25% to 75% • corresponding to a pump speed from 272 hz to 714 hz (see the following diagram). So...

Page 38

Technical information when no external input-output device is available this connector must be closed with the supplied mating connector that short-circuits the start and interlock inputs with the ground input (see the following figure). How to connect the output open collector of the controller her...

Page 39

Technical information p2 - serial this is a 9 pin d-type serial input/output connector to control via an rs 232 or rs 485 connection the tv 551/701. Pin n. Signal name 1 spare 2 tx (rs232) 3 rx (rs232) 4 spare 5 gnd 6 a + (rs485) 7 spare 8 b – (rs485) 9 reserved note that the vent valve can also be ...

Page 40

Technical information the addressed slave will respond with an an- swer whose structure depends from the message type. When the message is a reading command, the slave will respond transmitting a string with the same structure of the message. Note using the rs 485 interface, the message structure re...

Page 41

Technical information n. Read/ write data type description admitted values stop) 108 r/w n baud rate 600 = 0 1200 = 1 2400 = 2 4800 = 3 9600 = 4 (default = 4) 109 w l pump life/ cycle time/ cycle num- ber reset to reset write ‘1’ 110 r/w l interlock type (default = 1) impulse = 0 continuous = 1 111 ...

Page 42

Technical information n. Read/ write data type description admitted values °c 205 r n pump status stop = 0 waiting intlk = 1 starting = 2 auto-tuning = 3 braking = 4 normal = 5 fail = 6 206 r n error code bit description: see the following figure 300 r n cycle time in minutes (zeroed by the reset co...

Page 43

Technical information the screen can be removed as shown in the fol- lowing figure. The following figure shows the overall flange di- mensions with the protection screen fitted on pump with iso flange and pump with cff flange. Heater band installation the heater band model 969-9808 and 969-9807 can ...

Page 44

Technical information switch on the heater while the turbopump is in op- eration. In the event of turbopump overheat, the pump will be automatically cut out by the thermis- tor sensor. Note the turbopump must be "baked" only when operat- ing with an inlet pressure less than 10 -4 mbar and with water...

Page 45

Technical information to fix the fan to the tv 551/701 case execute the following procedure (see the following figure): 1. Fix the fan to the suitable bracket by means of the furnished screws; 2. Fix the bracket to the pump body between the pump and the controller; 3. Connect the fan supply to the p...

Page 46

Technical information water cooling kit installation the water cooling kit mod. 969-9347 or 969-9337 must be installed when the pump is used under heavy load conditions or when air cooling is insuf- ficient. Model 969-9337 model 969-9347 the kit is assembled as shown in the figure. Two rubber or pla...

Page 47

Technical information then screw the vent valve into the pump and tighten it using a 16 mm hexagonal spanner with a torque of 2.5 nm. ! Caution do not overtighten the valve as this may damage the thread on the pump. Then connect the cable from the valve to the suit- able connector on the controller ...

Page 48

Technical information vibration isolator installation six vibration isolators for iso and cff inlet flange version pumps are available as accessories. The four model part numbers are the following: − model 969-9344 for iso 100 flange; − model 969-9345 for iso 160 flange; − model 969-9346 for iso 200...

Page 49

Technical information tv 551/701 controller installation the controller can be mounted in two position: − bottom mounting (as per the complete system) − side mounting. To install the controller execute the following pro- cedures. Bottom mounting see the following figure. 1. Turn the pump upside-down...

Page 50

Technical information typical layout diagram with navigator controller 1. Turbo-v navigator controller 2. Vent valve 3. Vacuum pump shut-off valve (optional) 4. System vent valve (optional) 5. Vacuum chamber 6. Ionization gauge 7. Fore-vacuum pump connecting flange 8. Oil mist eliminator 9. Fore-vac...

Page 51

Technical information connection a - high vacuum flange for iso-k flange connections, fix the two flanges with the clamps as shown in the figure. ! Warning! It is mandatory to connect the pump in such a way to withstand the torque specified in the "in- struction for use" section. Specifically pay at...

Page 52

Technical information connection b - fore-vacuum pump a flange kf 25 nw is available to connect the turbo-v551/701 pump to the fore-vacuum pump. A hose or vacuum approved pipe can be used. If a rigid pipe is used, any vibration generated by the mechanical pump must be eliminated through the use of b...

Page 53

Technical information pump used in presence of magnetic fields magnetic fields induce eddy currents in the rotor of a turbomolecular pump that tend to oppose to its rotation. The result is increased electrical power consump- tion by the motor, most of which is dissipated in the rotor. Since the roto...

Page 54

Request for return 1. A return authorization number (ra#) will not be issued until this request for return is completely filled out, signed and returned to varian customer service. 2. Return shipments shall be made in compliance with local and international shipping regulations (iata, dot, un). 3. T...

Page 55

Request for return failure report turbo pumps and turbocontrollers position parameters does not start noise vertical power: rotational speed: does not spin freely vibrations horizontal current: inlet pressure: does not reach full speed leak upside-down temp 1: foreline pressure: mechanical contact o...

Page 56

Sales and service offices argentina varian argentina ltd. Sucursal argentina av. Ricardo balbin 2316 1428 buenos aires argentina tel: (54) 1 783 5306 fax: (54) 1 786 5172 benelux varian vacuum technologies rijksstraatweg 269 h, 3956 cp leersum the netherlands tel: (31) 343 469910 fax: (31) 343 46996...