- DL manuals

- Vega

- Accessories

- VEGAFLEX 65

- Operating instructions manual

Vega VEGAFLEX 65 Operating instructions manual

Summary of VEGAFLEX 65

Page 1

Operating instructions vegaflex 65 4 … 20 ma/hart - four-wire d ocument id: 31846 g uided microwave.

Page 2: Contents

Contents 1 about this document 1.1 f unction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 s ymbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 a uthor...

Page 3

8.2 r emove interferences . . . . . . . . . . . . . . . . . . . . . . . . 34 8.3 e xchanging the electronics module . . . . . . . . . . . . . . 35 8.4 s oftware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 8.5 i nstrument repair . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: About This Document

1 about this document 1 .1 function t his operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and kee...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. D uring work on and with the device the required personal protective equipment must always be worn. 2...

Page 6

2 .5 safety label on the instrument t he safety approval markings and safety tips on the device must be observed. 2 .6 ce conformity t his device fulfills the legal requirements of the applicable ec guidelines. By attaching the ce mark, vega provides a confirmation of successful testing. You can find t...

Page 7: Product Description

3 product description 3 .1 structure t he scope of delivery encompasses: l l evel sensor vegaflex 65 l d ocumentation - this operating instructions manual - s afety manual 31339 "vegaflex series 60 - 4 … 20 ma/ hart" ( optional) - o perating instructions manual 27835 "indicating and adjust- ment mod...

Page 8

L s erial number l t echnical data l a rticle numbers, documentation l sil identification (with sil rating ex works) w ith the serial number, you can access the delivery data of the instrument via www.Vega.Com, "vega tools" and "serial number search". In addition to the type label outside, you can al...

Page 9

3 .4 packaging, transport and storage y our instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test according to din en 24180. T he packaging of standard instruments consists of environment- friendly, recyclable cardboard. For...

Page 10: Mounting

4 mounting 4 .1 general instructions m ake sure that all parts of the instrument exposed to the process, in particular the sensor element, process seal and process fitting, are suitable for the existing process conditions. These include above all the process pressure, process temperature as well as t...

Page 11

Fig. 2: measures against moisture penetration t he reference plane for the measuring range of the sensors is the seal surface of the thread. K eep in mind that a min. Distance must be maintained below the reference plane and possibly also at the end of the probe - measurement in these areas is not p...

Page 12

I n vessels with conical bottom it can be advantageous to mount the sensor in the center of the vessel, as measurement is then possible down to the lowest point of the vessel bottom. Fig. 3: vessel with conical bottom m ake sure that the probe is not subjected to strong lateral forces. M ount vegafl...

Page 13

More than 1 m (3.281 in) length, you must secure the probe by fastening a suitable isolated brace or guy directly above the end of the rod. Vegaflex 65 • 4 … 20 ma/hart - four-wire 13 4 m ounting 31846 - en -120329.

Page 14

5 connecting to power supply 5 .1 preparing the connection a lways keep in mind the following safety instructions: l c onnect only in the complete absence of line voltage l i f overvoltage surges are expected, overvoltage arresters should be installed tip: w e recommend using vega overvoltage arrest...

Page 15

I f potential equalisation currents are expected, the connection on the processing side must be made via a ceramic capacitor (e. G. 1 nf, 1500 v). T he low frequency potential equalisation currents are thus suppressed, but the protective effect against high frequency interfer- ence signals remains. W...

Page 16

6 i nsert the wire ends into the open terminals according to the wiring plan 7 p ress down the opening levers of the terminals, you will hear the terminal spring closing 8 c heck the hold of the wires in the terminals by lightly pulling on them 9 c onnect the screen to the internal ground terminal, ...

Page 17

1 3 2 display 1 2 5 6 7 8 i2c fig. 6: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 3 1 2 3 4 1 2 l 1 n 4... 20ma i s gnd fig. 7: connection compartment double cham...

Page 18

4 ... 20 ma pe / l / n l1 n gnd 1 2 1 2 3 4 4...20ma is fig. 8: wiring plan, double chamber housing 1 voltage supply 2 signal output wiring plan 18 vegaflex 65 • 4 … 20 ma/hart - four-wire 5 c onnecting to power supply 31846 -en -120329.

Page 19: Module Plicscom

6 set up with the indicating and adjustment module plicscom 6 .1 short description t he indicating and adjustment module is used for measured value display, adjustment and diagnosis. It can be mounted in the following housing versions and instruments: l a ll sensors of the plics ® instrument family,...

Page 20

Fig. 9: insert indicating and adjustment module note: i f you intend to retrofit the instrument with an indicating and adjustment module for continuous measured value indication, a higher cover with an inspection glass is required. 20 vegaflex 65 • 4 … 20 ma/hart - four-wire 6 s et up with the indica...

Page 21

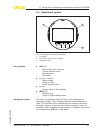

6 .3 adjustment system 2 3 1 1.1 fig. 10: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - m ove to the menu overview - c onfirm selected menu - e dit parameter - s ave value l [->] key to select: - m enu change - s elect list entry ...

Page 22

6 .4 setup steps a fter connecting vegaflex 65 to power supply or after a voltage recurrence, the instrument carries out a self-check for approx. 30 seconds: l i nternal check of the electronics l i ndication of the instrument type, the firmware as well as the sensor tags (sensor designation) l o utp...

Page 23

I f you want to measure the total height of both liquids reliably, please contact our service department or use an instrument specially designed for interface measurement. S tart your parameter adjustment with the following menu items of the basic adjustment: p roceed as follows: 1 m ove from the me...

Page 24

E ach product has different reflective properties. In addition, there are various interfering factors which have to be taken into account: agitated product surfaces and foam generation (with liquids); dust generation, material cones and echoes from the vessel wall (with solids). To adapt the sensor to...

Page 25

L inearisation curve linear e nter the requested parameters via the appropriate keys, save your settings and jump to the next menu item with the [->] key. I n this menu item you can enter an unambiguous designation for the sensor, e.G. The measurement loop name or the tank or product designation. In...

Page 26

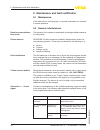

C opy sensor data c opy sensor data? Basic adjustment i f the function "reset" is carried out, the sensor resets the values of the following menu items to the reset values (see chart): 1) t he following values will be reset: function reset value m ax. Adjustment d istance, upper dead zone m in. Adju...

Page 27

A dditional adjustment and diagnosis options such as e.G. Scaling, simulation or trend curve presentation are shown in the following menu schematic. You will find a detailed description of these menu items in the operating instructions manual "indicating and adjustment module". Optional settings vega...

Page 28

6 .5 menu schematic basic adjustment 1 ▶ b asic adjustment d isplay d iagnostics s ervice i nfo 1.1 m in. Adjustment 0 .00 % = 10 .000 m(d) 8.000 m(d) 1.2 m ax. Adjustment 100 .00 % = 1 .000 m(d) 2.000 m(d) 1.3 d amping 0 s 1.4 l inearisation curve linear 1.5 s ensor-tag sensor display 2 b asic adju...

Page 29

Service 4 b asic adjustment d isplay d iagnostics ▶ s ervice i nfo 4.2 a pplication liquid ▼ standard (dk ≥ 2) ▼ 4.3 f alse signal suppression change now? 4.4 c urrent output output mode: 4-20 ma ▼ failure mode: 20.5 ma ▼ min. Current: 4 ma ▼ max. Current: 20.5 ma ▼ 4.5 s imulation start simulation?...

Page 30

6 .6 saving the parameter adjustment data w e recommended noting the adjusted data, e.G. In this operating instructions manual, and archiving them afterwards. They are thus available for multiple use or service purposes. I f vegaflex 65 is equipped with an indicating and adjustment module, the most ...

Page 31: Programs

7 set up with pactware and other adjustment programs 7 .1 connect the pc 3 1 2 fig. 11: connection of the pc via vegaconnect directly to the sensor 1 usb cable to the pc 2 vegaconnect 3 sensor 1 2 3 4 open twist usb lock fig. 12: connection via vegaconnect externally 1 i²c bus (com.) interface on th...

Page 32

N ecessary components: l vegaflex 65 l pc with pactware and suitable vega dtm l vegaconnect l p ower supply unit or processing system 1 5 2 4 3 open twist usb lo ck fig. 13: connecting the pc via hart to the signal cable 1 vegaflex 65 2 hart resistance 250 Ω (optional depending on processing) 3 conn...

Page 33

Note: k eep in mind that for setup of vegaflex 65, dtm-collection in the actual version must be used. A ll currently available vega dtms are included as a dtm collection on a cd. They can be purchased for a token fee from the responsible vega agency. In addition, the actual pactware version is also ...

Page 34

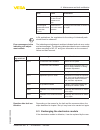

8 maintenance and fault rectification 8 .1 maintenance i f the instrument is used properly, no special maintenance is required in normal operation. 8 .2 remove interferences t he operator of the system is responsible for taking suitable measures to rectify faults. Vegaflex 65 offers maximum reliabilit...

Page 35

Error cause rectification o perating voltage too low or load resistance too high c heck, adapt if necessary c urrent signal greater than 22 ma or less than 3.6 ma e lectronics mo- dule in the sensor defective e xchange the instrument or send it in for repair i n ex applications, the regulations for t...

Page 36

I n ex applications only one instrument and one electronics module with respective ex approval may be used. I f there is no electronics module available on site, one can be ordered from the vega agency serving you. T he new electronics module must be loaded with the settings of the sensor. These are...

Page 37

A t "www.Vega.Com/downloads" go to "software". Select under "plics sensors and instruments", "firmware updates" the respective instru- ment series and software version. Load the zip file via the right mouse key with "save target as" e.G. On the desktop of your pc. Move with the right mouse key to the...

Page 38: Dismounting

9 dismounting 9 .1 dismounting steps warning: b efore dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. T ake note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in re...

Page 39: Supplement

10 supplement 10 .1 technical data general data m aterial 316l corresponds to 1.4404 or 1.4435 m aterials, wetted parts - p rocess fitting 316l and tfm pctfe +25 %gf, hastelloy c22 (2.4602) and tfm pctfe +25 %gf - p rocess seal on the instrument side ( tube leadthrough) fkm (shs fpm 70c3 glt), ffkm (...

Page 40

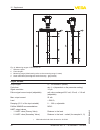

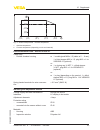

2 4 5 3 1 2 4 5 3 1 fig. 14: measuring ranges of vegaflex 65 1 reference plane 2 probe length l 3 measuring range (default setting refers to the measuring range in water) 4 upper dead band (see diagrams under accuracy - grey section) 5 lower dead band (see diagrams under accuracy - grey section) out...

Page 41

R esolution, digital > 1 mm (0.039 in) accuracy (according to din en 60770-1) p rocess reference conditions according to din en 61298-1 - t emperature + 18 … +30 °c (+64 … +86 °f) - r elative humidity 45 … 75 % - a ir pressure + 860 … +1060 mbar/+86 … +106 kpa (+12.5 … +15.4 psig) i nstallation refe...

Page 42

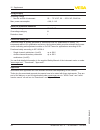

L 0 -2 mm (-0.079 ") 2 mm (0.079 ") 10 mm (0.394 ") 5 mm (0.197 ") -5 mm (-0.197 ") 0,15 m (5.906 " ) 0,1 m (3.937 " ) 0,15 m (5.906 ") 0,1 m (3.937 ") 1 1 fig. 16: deviation vegaflex 65 in coax version in oil 1 dead zone - no measurement possible in this area l probe length influence of the ambient ...

Page 43

0 °c (32 °f) 40 °c (104 °f) 20 °c (58 °f) 60 °c (140 °f) 80 °c (176 °f) 50 °c (122 °f) -40 °c (-40 °f) 100 °c (212 °f) 150 °c (302 °f) 1 2 fig. 17: ambient temperature - process temperature 1 ambient temperature 2 process temperature (depending on the seal material) electromechanical data - version ...

Page 44

Voltage supply o perating voltage - n on-ex and ex-d instrument 20 … 72 v dc, 20 … 253 v ac, 50/60 h z m ax. Power consumption 4 va; 2.1 w electrical protective measures p rotection rating ip 66/ip 67 o vervoltage category iii p rotection class i functional safety (sil) f unctional safety is already...

Page 45

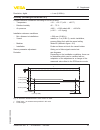

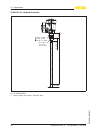

10 .2 dimensions t he following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded on www.Vega.Com under "downloads" and "drawings". Housing ø 84mm ~ 87mm (3 27 / 64 ") 120mm (4 23 / 32 ") * 129mm (5 5 / 64 ") (3 5 / 16 ") m20x1,5...

Page 46

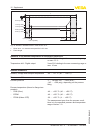

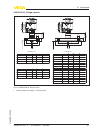

Vegaflex 65 , threaded version l 36 (g¾, ¾ npt) 41 (g1, 1 npt) 46 (g1½, 1½ npt) g¾, ¾ npt, g1, 1 npt, g1½, 1½ npt 4 6 mm (1 .8 1 ") 2 7 mm (1 .0 6 ") ø 21,3 mm (0.84") fig. 19: vegaflex 65 l sensor length, see chapter "technical data" 46 vegaflex 65 • 4 … 20 ma/hart - four-wire 10 s upplement 31846 ...

Page 47

Vegaflex 65 , flange version l b l b d d d d k k 6 8 mm (2 .6 8 ") 4 6 mm (1 .8 1 ") d b k d dn 25 pn 40 115 18 85 4x ø 14 dn 40 pn 40 150 18 110 4x ø 18 1" 150 lb 108 14,2 78,2 4x ø 15,7 1" 300 lb 124 17,5 88,9 4x ø 19,1 d b k d dn 50 pn 40 165 20 125 4x ø 18 dn 80 pn 40 200 24 160 8x ø 18 dn 100 pn...

Page 48

10 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrecht...

Page 49

Vegaflex 65 • 4 … 20 ma/hart - four-wire 49 10 s upplement 31846 - en -120329.

Page 50

50 vegaflex 65 • 4 … 20 ma/hart - four-wire 10 s upplement 31846 -en -120329.

Page 51

Vegaflex 65 • 4 … 20 ma/hart - four-wire 51 10 s upplement 31846 - en -120329.

Page 52

Vega g rieshaber kg a m hohenstein 113 77761 s chiltach g ermany p hone +49 7836 50-0 f ax +49 7836 50-201 e- mail: info.De@vega.Com www.Vega.Com p rinting date: iso 9001 a ll statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing s...