- DL manuals

- Vega

- Accessories

- VEGAFLEX 67

- Operating Instructions Manual

Vega VEGAFLEX 67 Operating Instructions Manual

Summary of VEGAFLEX 67

Page 1

Operating instructions vegaflex 67 400 °c/160 bar profibus pa.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

7.2 parameter adjustment with pactware™. . . . . . 37 7.3 parameter adjustment with pdm. . . . . . . . . . . . 38 7.4 saving the parameter adjustment data . . . . . . . 38 8 maintenance and fault rectification 8.1 maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 39 8.2 rectify faults ....

Page 4: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 5: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 6

2.6 fulfilling namur recommendations with regard to interference resistance and interference emission, vegaflex 67 fulfils namur recommendation ne 21. Vegaflex 67 and its indicating and adjustment components fulfill namur recommendation ne 53 in respect to compat- ibility. Vega instruments are generall...

Page 7

Max. Increase of the surface temperature during operation: 15 k (individual components in the instrument) with an ambient temperature of 70 °c (158 °f) on the housing and a process temperature of 70 °c (158 °f), the max. Ambient temperature during operation is 85 °c (185 °f). Measures to maintain ex...

Page 8

L chapter "disposal" 8 vegaflex 67 - profibus pa for your safety 32768 -en -061227.

Page 9: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l vegaflex 67 level sensor l documentation - this operating instructions manual - safety manual "functional safety according to iec 61508/iec 61511 (sil)" - operating instructions manual "indicating and adjust- ment module" (o...

Page 10

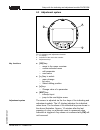

1 2 3 fig. 1: vegaflex 67 in cable version with plastic housing 1 housing cover with integrated plicscom (optional) 2 housing with electronics 3 process fitting 3.2 principle of operation vegaflex 67 is a level sensor with coax, rod or cable probe for continuous interface measurment. It is designed f...

Page 11

L the dielectric value of the upper medium must be known (input necessary). Min. Dielectric values: rod version 1.7, coax version 1.4. You will find a list of the dielectric values on our homepage: www.Vega.Com. L the composition of the upper medium must be stable, no varying products or mixtures l t...

Page 12

Power supply via the profibus dp/pa segment coupler or vegalog 571 ep cards. A two-wire cable according to profibus specification serves as carrier of both power and digital data signals for multiple sensors. The instrument profile of vegaflex 67 corresponds to profile specification version 3.0. The gsd (...

Page 13

The entered parameters are generally saved in vegaflex 67, optionally also in the indicating and adjustment module or in pactware™. 3.4 storage and transport your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test accordi...

Page 14: 4 Mounting

4 mounting 4.1 general instructions select an installation position you can easily reach for mounting and connecting as well as later retrofitting of an indicating and adjustment module. The housing can be rotated by 330° without the use of any tools. You can also install the indicating and adjustmen...

Page 15

Keep in mind that a min. Distance must be maintained below the reference plane and possibly also at the end of the probe - measurement in these areas is not possible (dead zone). Keep in mind that the cable length cannot be used up to the end because measurement in the area of the gravity weigh is n...

Page 16

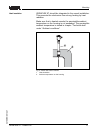

Fig. 4: vessel with conical bottom make sure that the probe is not subjected to strong lateral forces. Mount vegaflex 67 at a position in the vessel where no disturbances, e.G. From filling openings, agitators, etc., can occur. Fig. 5: lateral load excessive system vibration or shocks, e.G. Caused by...

Page 17

Vegaflex 67 should be integrated in the vessel installation. This prevents the electronics from strong heating by heat radiation. Make sure that in heated vessels the permissible ambient temperature on the housing is not exceeded. The permissible ambient temperature is stated in chapter "technical d...

Page 18

5 connecting to voltage supply 5.1 preparing the connection generally note the following safety instructions: l connect only in the complete absence of line voltage l if overvoltage surges are expected, overvoltage arresters should be installed according to profibus specification in hazardous areas yo...

Page 19

Must be connected directly to the internal ground terminal. The ground terminal outside on the housing must be connected to the potential equalisation (low impedance). In systems without potential equalisation, connect the cable screen directly to ground potential at the power supply unit and at the...

Page 20

Fig. 7: connection steps 6 and 7 8 press down the opening lever of the terminals, you will hear the terminal spring closing. 9 check the hold of the wires in the terminals by lightly pulling on them 10 connect the screen to the internal ground terminal and the external ground terminal to potential e...

Page 21

1 4 4 4 2 3 fig. 8: material versions, single chamber housing 1 plastic 2 aluminium 3 stainless steel 4 filter element for pressure compensation or blind stopper with version ip 66/ ip 68, 1 bar i2c display 1 2 5 6 7 8 3 4 1 2 fig. 9: electronics and connection compartment, single chamber housing 1 ...

Page 22

I2c display 1 1 2 5 6 7 8 fig. 10: wiring plan, single chamber housing 1 power supply/signal output 5.4 wiring plan, double chamber housing the following illustrations apply to the non-ex as well as to the ex ia version. 1 2 3 4 5 fig. 11: double chamber housing 1 housing cover, connection compartme...

Page 23

1 3 2 display 1 2 5 6 7 8 i2c fig. 12: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 3 1 2 display 1 2 i2c fig. 13: connection compartment, double chamber housing 1...

Page 24

I2c 1 1 2 fig. 14: wiring plan, double chamber housing 1 power supply/signal output 5.5 wiring plan, version ip 66/ip 68, 1 bar + - 1 2 fig. 15: wire assignment, connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 screen wiring plan wire assignment, connection cab...

Page 25: Adjustment Module Plicscom

6 setup with the indicating and adjustment module plicscom 6.1 short description the indicating and adjustment module is used for measured value display, adjustment and diagnosis. It can be mounted in the following housing versions and instruments: l all sensors of the plics ® instrument family, in ...

Page 26

4 screw housing cover with inspection window tightly back on removal is carried out in reverse order. The indicating/adjustment module is powered by the sensor, an additional connection is not necessary. Fig. 16: installation of the indicating and adjustment module note: if you intend to retrofit veg...

Page 27

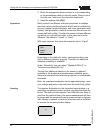

6.3 adjustment system 1.1 2 3 1 fig. 17: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key to select: - menu change - list entry - select editi...

Page 28

6.4 setup procedure after vegaflex 67 is connected to voltage supply or after voltage recurrence, the instrument carries out a self-check for approx. 30 seconds. The following steps are carried out: l internal check of the electronics l indication of the instrument type, the firmware as well as the s...

Page 29

1 move from the measured value display to the main menu by pushing [ok]. ▶ basic adjustment display diagnostics service info 2 select the menu item "basic adjustment" with [->] and confirm with [ok]. Now the menu item "dielectric value" is displayed. Dielectric value upper product 000 3 enter the dk ...

Page 30

2 enter the appropriate distance value in m (corresponding to the percentage value) for the full vessel. Keep in mind that the max. Level must lie below the dead band. 3 save the settings with [ok]. Each product has different reflective properties. In addition, there are various interfering factors wh...

Page 31

Enter the requested parameter via the appropriate keys, save your settings and jump to the next menu item with the [->] key. A linearization is necessary for all vessels in which the vessel volume does not increase linearly with the level - e.G. With a cylindrical or spherical tank - and the indicat...

Page 32

Gating out of false signals change now? Proceed as follows: 1 move from the measured value display to the main menu by pushing [ok]. 2 select the menu item "service" with [->] and confirm with [ok]. Now the menu item "false signal suppression" is displayed. 3 confirm "false signal suppression - change...

Page 33

L dielectric value the following safety-relevant data are not read out or written: l hart mode l pin l sil l sensor length/sensor type l gating out of false signals copy sensor data copy sensor data? Basic adjustment if the function "reset" is carried out, the sensor resets all settings to default. ...

Page 34

Additional adjustment and diagnosis options such as e.G. Scaling, simulation or trend curve presentation are shown in the following menu schematic. You will find a detailed description of these menu items in the operating instructions manual "indicating and adjustment module". Optional settings setup...

Page 35

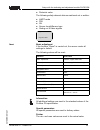

6.5 menu schematic basic adjustment 1 ▶ basic adjustment display diagnostics service info 1.1 sensor address 000 1.1 upper product dielectric value upper product enter/calculate 1.2 min. Adjustment 0.00 % = 10,000 m(d) 8,000 m(d) 1.3 max. Adjustment 100.00 % = 1,000 m(d) 2,000 m(d) 1.4 linearisation...

Page 36

3.1.1 pointer interface distance min.: 0.464 m(d) distance max.: 5.385 m(d) 3.1.2 pointer total level distance min.: 0.234 m(d) distance max.: 5.385 m(d) 3.2 sensor status ok 3.3 curve selection echo curve 3.4 echo curve presentation of the echo curve service 4 basic adjustment display diagnostics ▶...

Page 37: Adjustment Programs

7 setup with pactware™ and other adjustment programs 7.1 connecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 fig. 18: connection directly to the sensor 1 rs232 connection 2 vegaflex 67 3 i²c adapter cable for vegaconnect 3 necessary components: l vegaflex 67 l pc with pactware™ ...

Page 38

All currently available vega dtms are provided in the dtm collection on cd and can be obtained from the responsible vega agency for a token fee. This cd includes also the up-to- date pactware™ version. The basic version of this dtm collection incl. Pactware™ is also available as a free-of- charge do...

Page 39

8 maintenance and fault rectification 8.1 maintenance when used as directed in normal operation, vegaflex 67 is completely maintenance free. 8.2 rectify faults vegaflex 67 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l sensor l...

Page 40

? In simatic s7 the measured value is always presented as 0 l only four bytes are consistently loaded in the plc à use function component sfc14 to load 5 bytes consistently ? Measured value on the indicating and adjustment module does not correspond to the value in the plc l the menu item "display -...

Page 41

? E017 l adjustment span too small à carry out a fresh adjustment and increase the distance between min. And max. Adjustment ? E036 l no operable sensor software à carry out a software update or send the instrument for repair ? E042/e043 l hardware error, electronics defective à exchange instrument ...

Page 42

The oscillators are adapted to the respective sensor and differ in their signal output or in their power supply. You can find a suitable oscillator in the following overview. Electronics module fx-e.67p suitable for vegaflex 67 - profibus pa: l fx-e.67px (x = without approvals) l fx-e.67pc (c = approva...

Page 43: 9 Dismounting

9 dismounting 9.1 dismounting procedure warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in...

Page 44: 10 Supplement

10 supplement 10.1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - version -110 … +400 °c (-166 … +752 °f) - process fitting - coax version 316l and aluminium oxide-ceramic 99.7 % (al₂o₃), hastelloy c22 (2.4602) and aluminium oxide-ceramic 99.7 % (a...

Page 45

Lengths (l) - tube ø 21.3 mm (0.84 in) 0.3 … 6 m (1 … 20 ft) - rod ø 6 mm (0.24 in) 0.3 … 4 m (1 … 13 ft) - cable ø 4 mm (0.16 in) 1 … 32 m (3 … 105 ft) lateral load - tube ø 21.3 mm (0.84 in) 60 nm (44 lbf ft) - rod ø 6 mm (0.24 in) 4 nm (3 lbf ft) max. Tensile load - cable ø 4 mm (0.16 in) 2.5 kn ...

Page 46

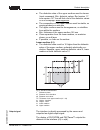

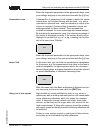

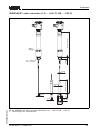

2 4 3 1 fig. 19: measuring range of vegaflex 67 - coax version 1 reference plane 2 probe length 3 measuring range 4 upper dead band min. Dielectric figure - rod, cable version ε r >1,7 dead band - rod version - top 80 mm (3.1 in) - bottom 0 mm dead band - cable version - top 150 mm (5.9 in) - bottom ...

Page 47

2 4 5 3 1 2 4 3 1 fig. 20: measuring ranges of the vegaflex 67 - rod and cable version 1 reference plane 2 probe length 3 measuring range 4 upper dead band 5 lower dead band (only with cable versions) accuracy (similar to din en 60770-1) reference conditions according to din en 61298-1 - temperature...

Page 48

Deviation in characteristics and characteristics reference installation conditions - flange dn 100 - min. Distance to installations 500 mm (20 in) reference reflector metal plate ø 1 m (ø 40 in) not with coax version temperature drift (current output) 0.06 %/10 k relating to the max. Measuring range ...

Page 49

0,03 m (0,98 ft) 6 m (20 ft) 3mm ( 1 / 8 ") -3mm (- 1 / 8 ") 10mm ( 25 / 64 ") -10mm (- 25 / 64 ") fig. 23: accuracy - coax version -110 … +400°c (-166 … +752°f) ambient conditions ambient, storage and transport tem- perature -40 … +80 °c (-40 … +176 °f) process conditions process pressure -1 … 160 ...

Page 50

Electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 3) - single chamber housing l 1x cable entry m20x1.5 (cable-ø 5 … 9 mm), 1x blind stopper m20x1.5 or: l 1x closing cap ½ npt, 1x blind plug ½ npt or: l 1x plug (depending on the version), 1x blind plug m20x1.5 - d...

Page 51

Connection cable - wire cross-section 0.5 mm² - wire resistance - tensile strength >1200 n (270 lbf) - standard length 5 m (16.4 ft) - max. Length 1000 m (3280 ft) - min. Bending radius 25 mm (1 in) at 25 °c (77 °f) - diameter approx. 8 mm (0.3 in) - colour - standard pe black - colour - standard pu...

Page 52

Power supply by/max. Number of sensors - dp/pa segment coupler max. 32 (max. 10 with ex) - vegalog 571 ep card max. 15 (max. 10 with ex) electrical protective measures protection - plastic housing ip 66/ip 67 - alu and stainless steel standard ip 66/ip 68 (0.2 bar) 5) - alu and stainless housing (op...

Page 53

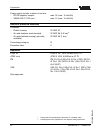

10.2 profibus pa instrument master file the instrument master file (gsd) contains the characteristic data of the profibus pa instrument. These data are, e.G. The permissible transmission rates as well as information on diagnostics values and the format of the measured value outputted by the pa instrumen...

Page 54

M(d) % lin% min-max adjustment linearization profibus pa-output primary value secondary value 2 secondary value 1 target mode failure mode alarms scaling source for scaling t i integration pa-out tb fb select additional cyclic value dist. Interface dist. Level fig. 25: vegaflex 67: block diagram wit...

Page 55

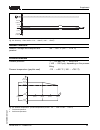

Examples of telegram configuration in the following you will see how the modules can be combined and how the appendant data telegram is structured. Example 1 (standard setting) with distance value and additional cyclical value: l ai (pa-out) l additional cyclic value byte-no. 1 2 3 4 5 6 7 8 9 10 sta...

Page 56

Byte n byte n+1 bit 7 vz exponent bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit 0 2 bit 7 2 bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit 0 2 sign bit significant 7 6 5 4 3 2 1 0 -1 -2 -3 -4 -5 -6 -7 byte n+2 byte n+3 bit 7 2 significant bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bi...

Page 57

Status code description according to profi- bus standard possible cause 0x8e good (non-cascade) - active crit- ical alarm - high limited hi-hi-alarm supplement vegaflex 67 - profibus pa 57 32768 -en -061227.

Page 58

10.3 dimensions housing in protection ip 66/ip67 and ip 66/ip 68; 0.2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5 / 16 ") ø 8...

Page 59

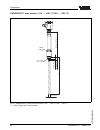

Vegaflex 67, cable, rod version (-110 … +400 °c/-166 … +752 °f) l 150 mm (5 29 / 32 ") 53 mm (2 3 / 32 ") ø 6 mm ( 15 / 64 ") 12 mm ( 15 / 32 ") ø 54 mm (2 1 / 8 ") ø 20 mm ( 25 / 32 ") ø 4 mm ( 5 / 32 ") ø 30 mm (1 3 / 16 ") 271 mm (10 5 / 8 ") 22 mm ( 55 / 64 ") sw 50 ( 1 31 / 32 ") g1 / 1”npt, g1...

Page 60

Vegaflex 67, coax version (-110 … +400 °c/-166 … +752 °f) l 271 mm (10 5 / 8 ") 18 mm ( 45 / 64 ") 29 mm (1 9 / 64 ") ø 21,1 mm ( 53 / 64 ") sw 50 ( 1 31 / 32 ") g1 / 1”npt, g1½ / 1½”npt fig. 31: vegaflex 67, coax version with thread (-110 … +400 °c/-166 … +752 °f) l sensor length, see "technical da...

Page 61

10.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte....

Page 62

Supplement 62 vegaflex 67 - profibus pa 32768 -en -061227.

Page 63

Supplement vegaflex 67 - profibus pa 63 32768 -en -061227.

Page 64

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...