- DL manuals

- Vega

- Accessories

- VEGAFLEX 67

- Operating Instructions Manual

Vega VEGAFLEX 67 Operating Instructions Manual

Summary of VEGAFLEX 67

Page 1

O perating i nstructions vegaflex 67 - 200 … + 400 ° c p ro fi bus pa d ocument id : 32313 g uided m icrowave.

Page 2: Ontents

C ontents 1 a bout this document 1 . 1 f unction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 3 s ymbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 f or your safety ...

Page 3

8 m aintenance and fault recti fi cation 8 . 1 m aintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 8 . 2 r emove interferences . . . . . . . . . . . . . . . . . . . . . . . . 37 8 . 3 e xchanging the electronics module . . . . . . . . . . . . . . 39 8 . 4 s oftware update . . ...

Page 4: Bout This Document

1 a bout this document 1 . 1 f unction t his operating instructions manual provides all the information you need for mounting , connection and setup as well as important instructions for maintenance and fault recti fi cation . P lease read this information before putting the instrument into operation...

Page 5: Or Your Safety

2 f or your safety 2 . 1 a uthorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator . D uring work on and with the device the required personal protective equipment must always be wor...

Page 6

2 . 5 ce conformity t his device ful fi lls the legal requirements of the applicable ec guidelines . B y attaching the ce mark , vega provides a con fi rmation of successful testing . Y ou can fi nd the ce conformity declaration in the download area of " www . Vega . Com " . 2 . 6 f ul fi llment of namu...

Page 7: Roduct Description

3 p roduct description 3 . 1 s tructure t he scope of delivery encompasses : l l evel sensor vegaflex 67 l d ocumentation - this operating instructions manual - o perating instructions manual 27835 " i ndicating and adjust - ment module plicscom " ( optional ) - s upplementary instructions manual 31...

Page 8

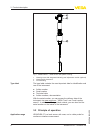

1 2 3 f ig . 1 : vegaflex 67 - cable version with plastic housing 1 h ousing cover with integrated indicating and adjustment module ( optional ) 2 h ousing with electronics 3 p rocess fi tting t he type label contains the most important data for identi fi cation and use of the instrument : l a rticle ...

Page 9

I t is designed for industrial use in all areas of process technology and can be used in liquids . H igh frequency microwave impulses are guided along a steel cable or rod or a rod inside a steel tube . W hen reaching the product surface , a part of the microwave impulses is re fl ected . T he other ...

Page 10

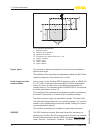

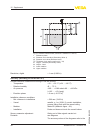

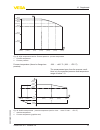

Ts d1 h1 h2 d2 1 l2 l1 f ig . 2 : i nterface measurement 1 r eference plane d 1 d istance to the interface d 2 d istance to the level ts t hickness of the upper medium ( d 1 - d 2 ) h 1 h eight - i nterface h 2 h eight - l evel l 1 l ower medium l 2 u pper medium t he interface is directly processed...

Page 11

Also fi nd the appropriate certi fi cates . I n a pdm environment , an edd ( e lectronic d evice d escription ) is also required to enable the full range of sensor functions ( also available as a download ). A cd with the appropriate fi les can be ordered via e - mail under info @ de . Vega . Com or by...

Page 12: Ounting

4 m ounting 4 . 1 g eneral instructions m ake sure that all parts of the instrument exposed to the process , in particular the sensor element , process seal and process fi tting , are suitable for the existing process conditions . T hese include above all the process pressure , process temperature as...

Page 13

F ig . 3 : m easures against moisture penetration t he reference plane for the measuring range of the sensors is the sealing surface of the thread or fl ange . K eep in mind that a min . Distance must be maintained below the reference plane and possibly also at the end of the probe - measurement in t...

Page 14

Keep in mind that measurement down to the tip of the probe is not possible . T he exact value of the min . Distance ( lower dead band ) is stated in chapter " t echnical data " . F ig . 4 : v essel with conical bottom m ake sure that the probe is not subjected to strong lateral forces . M ount vegaf...

Page 15

More than 1 m ( 3 . 281 in ) length , you must secure the probe by fastening a suitable insulated brace or guy directly above the end of the rod . Vegaflex 67 should be integrated in the vessel insulation . T his prevents the electronics from strong heating or cooling by temperature radiation . M ak...

Page 16: Onnecting To Power Supply

5 c onnecting to power supply 5 . 1 p reparing the connection a lways keep in mind the following safety instructions : l c onnect only in the complete absence of line voltage l i f voltage surges are expected , overvoltage arresters should be installed according to p ro fi bus speci fi cations t ip : ...

Page 17

I n systems without potential equalisation , connect the cable screen directly to ground potential at the power supply unit and at the sensor . I n the connection box or t - distributor , the screen of the short stub to the sensor must not be connected to ground potential or to another cable screen ...

Page 18

7 i nsert the wire ends into the open terminals according to the wiring plan f ig . 7 : c onnection steps 6 and 7 8 p ress down the opening levers of the terminals , you will hear the terminal spring closing 9 c heck the hold of the wires in the terminals by lightly pulling on them 10 c onnect the s...

Page 19

I²c display 1 2 5 6 7 8 3 4 1 2 f ig . 8 : e lectronics and connection compartment , single chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 s pring - loaded terminals for connection of the external indication vegadis 61 3 g round terminal for connection of the cable screen 4 ...

Page 20

1 3 2 display 1 2 5 6 7 8 i2c f ig . 10 : e lectronics compartment , double chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 i nternal connection cable to the connection compartment 3 t erminals for vegadis 61 1 2 3 d isp la y 1 2 i2c f ig . 11 : c onnection compartment double...

Page 21

I2c 1 1 2 f ig . 12 : w iring plan , double chamber housing 1 v oltage supply , signal output 5 . 5 w iring plan - version ip 66 / ip 68 , 1 bar 1 2 f ig . 13 : w ire assignment connection cable 1 brown ( + ) and blue (-) to power supply or to the processing system 2 s hielding w iring plan w ire as...

Page 22: Module

6 s et up with the indicating and adjustment module plicscom 6 . 1 s hort description t he indicating and adjustment module is used for measured value display , adjustment and diagnosis . I t can be mounted in the following housing versions and instruments : l a ll sensors of the plics ® instrument ...

Page 23

F ig . 14 : i nsert indicating and adjustment module n ote : i f you intend to retro fi t the instrument with an indicating and adjustment module for continuous measured value indication , a higher cover with an inspection glass is required . Vegaflex 67 • p ro fi bus pa 23 6 s et up with the indicati...

Page 24

6 . 3 a djustment system 2 3 1 1.1 f ig . 15 : i ndicating and adjustment elements 1 lc display 2 i ndication of the menu item number 3 a djustment keys l [ ok ] key : - m ove to the menu overview - c on fi rm selected menu - e dit parameter - s ave value l [- > ] key to select : - m enu change - s e...

Page 25

6 . 4 s etup steps a fter vegaflex 67 is connected to voltage supply or after voltage recurrence , the instrument carries out a self - check for approx . 30 seconds . T he following steps are carried out : l i nternal check of the electronics l i ndication of the instrument type , the fi rmware as we...

Page 26

▶ b asic adjustment d isplay d iagnostics s ervice i nfo 2 s elect the menu item " b asic adjustment " with [- > ] and con fi rm with [ ok ] . N ow the menu item " d ielectric value " is displayed . D ielectric value u pper medium 000 3 e nter the dielectric fi gure ( dk value ) of the upper medium an...

Page 27

E ach product has di ff erent re fl ective properties . I n addition , there are various interfering factors which have to be taken into account : agitated product surfaces and foam generation ( with liquids ); dust generation , material cones and echoes from the vessel wall ( with solids ). T o adapt...

Page 28

L inearisation curve l inear e nter the requested parameters via the appropriate keys , save your settings and jump to the next menu item with the [- > ] key . I n this menu item you can enter an unambiguous designation for the sensor , e . G . The measurement loop name or the tank or product design...

Page 29

N ote : c heck the distance to the product surface , because if an incorrect ( too large ) value is entered , the existing level will be saved as false signal . T he fi lling level would then no longer be detectable in this area . T his function enables reading out parameter adjustment data as well a...

Page 30

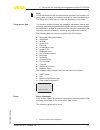

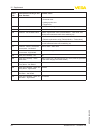

F unction r eset value m ax . Adjustment d istance , upper dead zone m in . Adjustment d istance , supplied sensor length m in . Adjustment - c able version d istance , lower dead zone d amping ti 0 s l inearisation l inear s ensor - tag s ensor d isplay pa - o ut 1 c hannel ( pv ) lin % a dditional...

Page 31

6 . 5 m enu schematic b asic adjustment 1 ▶ b asic adjustment d isplay d iagnostics s ervice i nfo 1 . 1 s ensor address 000 1 . 1 u pper medium d ielectric fi gure of the upper medium enter / calculate 1 . 2 m in . Adjustment 0 . 00 % = 10 . 000 m ( d ) 8 . 000 m ( d ) 1 . 3 m ax . Adjustment 100 . ...

Page 32

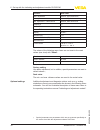

D iagnostics 3 b asic adjustment d isplay ▶ d iagnostics s ervice i nfo 3 . 1 . 1 p eak value i nterface d istance min .: 0 . 464 m ( d ) d istance max .: 5 . 385 m ( d ) 3 . 1 . 2 p eak value t otal level d istance min .: 0 . 234 m ( d ) d istance max .: 5 . 385 m ( d ) 3 . 2 s ensor status ok 3 . ...

Page 33

I nfo 5 b asic adjustment d isplay d iagnostics s ervice ▶ i nfo 5 . 2 i nstrument type s erial number 12345678 5 . 2 c alibration date 4 . J uly 2007 s oftware version 3 . 50 5 . 3 l ast change using pc 4 . J uly 2007 5 . 5 s ensor characteristics d isplay now ? Vegaflex 67 • p ro fi bus pa 33 6 s e...

Page 34

6 . 6 s aving the parameter adjustment data w e recommended noting the adjusted data , e . G . In this operating instructions manual , and archiving them afterwards . T hey are thus available for multiple use or service purposes . I f vegaflex 67 is equipped with an indicating and adjustment module ...

Page 35: Et Up With

7 s et up with pact ware and other adjustment programs 7 . 1 c onnect the pc 3 1 2 f ig . 16 : c onnection of the pc via vegaconnect directly to the sensor 1 usb cable to the pc 2 vegaconnect 3 s ensor 1 2 3 4 open twist usb lock f ig . 17 : c onnection via vegaconnect externally 1 i ² c bus ( com ....

Page 36

N ecessary components : l vegaflex 67 l pc with pact ware and suitable vega dtm l vegaconnect l p ower supply unit or processing system 7 . 2 p arameter adjustment with pact ware f urther setup steps are described in the operating instructions manual " dtm c ollection / pact ware " attached to each ...

Page 37: fi

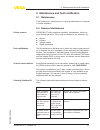

8 m aintenance and fault recti fi cation 8 . 1 m aintenance i f the instrument is used properly , no special maintenance is required in normal operation . 8 . 2 r emove interferences vegaflex 67 o ff ers maximum reliability . N evertheless , faults can occur during operation . T hese may be caused by ...

Page 38

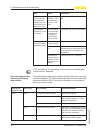

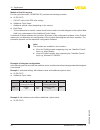

E rror c ause r ecti fi cation m easured value on the indicating and adjustment module does not correspond to the value in the plc t he menu item " d isplay - d is - play value " is not set to " pa - o ut " c heck values and correct , if neces - sary n o connection between plc and pa network i ncorre...

Page 39

S tatus accor - ding to ne 107 e rror code t ext message c ause / r ecti fi cation e 042 h ardware error , electronics defec - tive e xchange the instrument or send it in for repair e 043 h ardware error , electronics defec - tive e xchange the instrument or send it in for repair e 113 c ommunication...

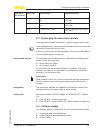

Page 40

Y ou can view all software histories on our website www . Vega . Com . M ake use of this advantage and get registered for update information via e - mail . T he following components are required to update the sensor software : l s ensor l v oltage supply l vegaconnect l pc with pact ware l c urrent ...

Page 41

L p lease ask the agency serving you for the address of your return shipment . Y ou can fi nd the respective agency on our website www . Vega . Com under : " c ompany - vega worldwide " vegaflex 67 • p ro fi bus pa 41 8 m aintenance and fault recti fi cation 32313 - en - 120329.

Page 42: Ismounting

9 d ismounting 9 . 1 d ismounting steps w arning : b efore dismounting , be aware of dangerous process conditions such as e . G . Pressure in the vessel , high temperatures , corrosive or toxic products etc . T ake note of chapters " m ounting " and " c onnecting to power supply " and carry out the ...

Page 43: Upplement

10 s upplement 10 . 1 t echnical data g eneral data m aterial 316 l corresponds to 1 . 4404 or 1 . 4435 m aterials , wetted parts - version - 200 … + 400 ° c (- 328 … + 752 ° f ) - p rocess fi tting - coax version 316 l and a luminium oxide - ceramic 99 . 7 % ( a l ₂ o ₃ ), h astelloy c 22 ( 2 . 4602...

Page 44

- r od : ø 16 mm ( 0 . 63 in ) approx . 1600 g / m ( 17 oz / ft ) - c able : ø 6 mm ( 0 . 236 in ) approx . 170 g / m ( 1 . 8 oz / ft ) - g ravity weight approx . 730 g ( 25 . 8 oz ) p robe length l ( from seal surface ) - t ube : ø 43 mm ( 1 . 693 in ) up to 6 m ( 19 . 69 ft ) - t rimming accuracy ...

Page 45

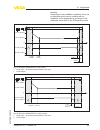

2 4 3 5 1 f ig . 18 : m easuring ranges of vegaflex 67 - coax version 1 r eference plane 2 p robe length 3 m easuring range ( default setting refers to the measuring range in water ) 4 u pper dead band ( see diagrams under a ccuracy - grey section ) 5 l ower dead band ( see diagrams under a ccuracy ...

Page 46

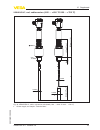

2 4 3 5 1 2 4 5 3 1 f ig . 19 : m easuring ranges of the vegaflex 67 - rod and cable version 1 r eference plane 2 p robe length 3 m easuring range 4 u pper dead band ( see diagrams under a ccuracy - grey section ) 5 l ower dead band ( see diagrams under a ccuracy - grey section ) 46 vegaflex 67 • p ...

Page 47

1 0 m (3 2 .82 ft ) 1 1 m (3 6 .09 ft ) 1 2 m (3 9 .37 ft ) 1 3 m (4 2 .65 ft ) 1 4 m (4 5 .93 ft ) 1 5 m (4 9 .21 ft ) 1 6 m (5 2 .49 ft ) 1 7 m (5 5 .77 ft ) 1 8 m (5 9 .06 ft ) 2 3 m (7 5 .46 ft ) 1 9 m (6 2 .34 ft ) 2 4 m (7 8 .74 ft ) 2 6 m (8 5 .31 ft ) 2 0 m (6 5 .62 ft ) 2 1 m (6 8 .91 ft ) ...

Page 48

Ts d1 h1 h2 d2 1 l2 l1 f ig . 21 : i nterface measurement ( interface is between l 1 and l 2 ) 1 r eference plane d 1 d istance to the interface ( s econdary v alue 2 ) d 2 d istance to the level ( d istance l evel ) ts t hickness of the upper medium ( d 1 - d 2 ) h 1 h eight - interface ( s econdar...

Page 49

Interface . D epending on the installation conditions , there can be deviations which can be recti fi ed with an adaptation of the adjustment or a change of the measured value o ff set in the dtm service mode . L 0 -25 mm (-0.984 ") -10 mm (-0.394 ") 10 mm (0.394 ") 25 mm (0.984 " ) 0,2 m (7.874 ") 0,...

Page 50

L 0 -10 mm (-0.394 ") 10 mm (0.394 ") 0,1 m (3.937 " ) 0,15 m (1.968 ") 1 1 f ig . 24 : d eviation vegaflex 67 in coax version 1 d ead zone - no measurement possible in this area l p robe length i n fl uence of the ambient temperature to the sensor electronics t emperature drift 0 . 03 % / 10 k relat...

Page 51

2 1 -100°c (-148°f) -200°c (-328°f) 100 bar (1450 psig) 200 bar (2900 psig) 300 bar (4350 psig) 400 bar (5800 psig) 380 bar (5510 psig) 350 bar (5070 psig) 0°c (32°f) 200°c (392°f) 100°c (212°f) 400°c (752°f) 300°c (572°f) f ig . 25 : h igh temperature version : p rocess pressure - process temperatu...

Page 52

E lectromechanical data - version ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar c able entry / plug 4 ) - s ingle chamber housing l 1 x cable gland m 20 x 1 . 5 ( cable : ø 5 … 9 mm ), 1 x blind stopper m 20 x 1 . 5 or : l 1 x closing cap m 20 x 1 . 5 ; 1 x blind stopper m 20 x 1 . 5 or : l 1 x closin...

Page 53

- m in . Bending radius 25 mm ( 0 . 984 in ) with 25 ° c ( 77 ° f ) - d iameter approx . 8 mm ( 0 . 315 in ) - c olour - standard pe b lack - c olour - standard pur b lue - c olour - e x - version b lue i ndicating and adjustment module v oltage supply and data transmission through the sensor i ndic...

Page 54

P rotection class ii a pprovals i nstruments with approvals can have di ff erent technical data depending on the version . T hat ' s why the associated approval documents have to be noted with these instruments . T hey are part of the delivery or can be downloaded under www . Vega . Com via " vega t ...

Page 55

10 . 2 p ro fi bus pa i nstrument master fi le t he instrument master fi le ( gsd ) contains the characteristic data of the p ro fi bus pa instrument . T hese data are , e . G . The permissible transmission rates as well as information on diagnostics values and the format of the measured value outputted...

Page 56

M odule of the pa sensors f or the cyclic data tra ffi c , vegaflex 67 provides the following modules : l ai ( pa - out ) - pa - out value of the fb 1 after scaling l a dditional c yclic v alue - a dditional cyclical value ( depending on the source ) l f ree p lace - t his module must be used if a val...

Page 57

L f ree p lace byte-no. 1 2 3 4 5 status status (fb1) ieee-754- floating point value pa-out (fb1) format value d ata format of the output signal byte4 byte3 byte2 byte1 byte0 status value (ieee-754) f ig . 30 : d ata format of the output signal t he status byte corresponds to pro fi le 3 . 0 " p ro fi...

Page 58

S tatus code d escription according to p ro - fi bus standard p ossible cause 0 x 0 c bad - sensor failure l h ardware error l c onverter error l l eakage pulse error l t rigger error 0 x 10 bad - sensor failure l m easured value generation error 0 x 1 f bad - out of service constant " o ut of s ervi...

Page 59

10 . 3 d imensions t he following dimensional drawings represent only an extract of the possible versions . D etailed dimensional drawings can be downloaded on www . Vega . Com under " d ownloads " and " d rawings " . P lastic housing ~ 69 mm (2.72") ø 79 mm (3.03") 1 1 2 mm (4 .4 1 ") m20x1,5/ ½ np...

Page 60

A luminium housing in protection rating ip 66 / ip 68 , 1 bar 1 2 0 mm (4 .7 2 ") ~ 105 mm (4.13") 1 16 m m (4.57 ") ~ 150 mm (5.91") ø 84 mm (3.31") ø 84 mm (3.31") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 1 s ingle chamber version 2 d ouble chamber version s tainless steel housing ~ 69 mm (2.72"...

Page 61

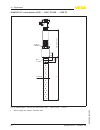

Vegaflex 67 , rod , cable version (- 200 … + 400 ° c /- 328 … + 752 ° f ) sw60 g1½ / 1½ npt ø 16mm ( 5 / 8 ") ø 30mm (1 3 / 16 ") ø 6mm ( 15 / 64 ") l 292mm (11 1 / 2 ") 35mm (1 3 / 8 ") 185mm (7 9 / 32 ") 150mm (5 29 / 32 ") f ig . 36 : vegaflex 67 , cable , rod version with thread (- 200 … + 400 °...

Page 62

Vegaflex 67 , coax version (- 200 … + 400 ° c /- 328 … + 752 ° f ) g1½ / 1½ npt ø 42,4 mm (1.67") l 2 9 2 mm (1 1 .4 5 ") 5 7 mm (2 .2 4 ") 3 5 mm (1 .3 8 ") sw 60 mm (2.36") f ig . 37 : vegaflex 67 , coax version with thread (- 200 … + 400 ° c /- 328 … + 752 ° f ) l s ensor length , see chapter " t...

Page 63

10 . 4 i ndustrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit gesch ü tzt durch gewerbliche schutzr...

Page 64

Vega g rieshaber kg a m h ohenstein 113 77761 s chiltach g ermany p hone + 49 7836 50 - 0 f ax + 49 7836 50 - 201 e - mail : info . De @ vega . Com www . Vega . Com p rinting date : iso 9001 a ll statements concerning scope of delivery , application , practical use and operating conditions of the se...