- DL manuals

- Vega

- Switch

- VEGAWAVE 61

- Operating Instructions Manual

Vega VEGAWAVE 61 Operating Instructions Manual

Summary of VEGAWAVE 61

Page 1

Operating instructions vegawave 61 - namur document id: 32249 vibration.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

9 supplement 9.1 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 9.2 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 supplementary documentation information: supplementary documents appropriate to the ordered version come with the delivery. You...

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

2 .5 safety label on the instrument the safety approval markings and safety tips on the device must be observed. 2 .6 ce conformity this device fulfills the legal requirements of the applicable ec guidelines. By attaching the ce mark, vega provides a confirmation of successful testing. You can find the...

Page 7: Product Description

3 product description 3 .1 structure the scope of delivery encompasses: l vegawave 61 point level switch l documentation - this operating instructions manual - safety manual "functional safety (sil)" (optional) - supplementary instructions manual "plug connector for level sensors" (optional) - ex-sp...

Page 8

3 .2 principle of operation vegawave 61 is a point level sensor with tuning fork for level detection. It is designed for industrial use in all areas of process technology and is preferably used for bulk solids. Typical applications are overfill and dry run protection. Thanks to its simple and robust ...

Page 9

L potentiometer for adaptation to the product density l mode switch to select the switching condition (reverse character- istics) l simulation key 3 .4 storage and transport your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured b...

Page 10: Mounting

4 mounting 4 .1 general instructions make sure that all parts of the instrument exposed to the process, in particular the sensor element, process seal and process fitting, are suitable for the existing process conditions. These include above all the process pressure, process temperature as well as th...

Page 11

The max. Permissible pressure is specified in chapter "technical data" or on the type label of the sensor. The vibrating level switch is a measuring instrument and must be treated accordingly. Bending the vibrating element will destroy the instrument. Warning: the housing must not be used to screw th...

Page 12

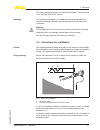

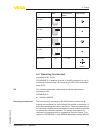

To achieve a very precise switching point, you can install vegawave 61 horizontally. However, if the switching point can have a tolerance of a few centimeters, we recommend mounting vegawave 61 approx. 20° inclined to the vessel bottom to avoid buildup. 20° fig. 4: horizontal installation if vegawav...

Page 13

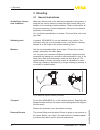

1 2 fig. 5: flow orientation of the tuning fork 1 marking with screwed version 2 direction of flow in case of horizontal mounting in adhesive products, the surfaces of the tuning fork should be vertical in order to reduce buildup on the tuning fork. On the screwed version you will find a marking on th...

Page 14

> 125 mm (> 5") > 1 2 0 mm (> 4 .7 ") fig. 7: baffle for protection against mechanical damage 14 vegawave 61 • - namur 4 mounting 32249 -en -120418.

Page 15

5 connecting to power supply 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage in hazardous areas you must take note of the respective regulations, conformity and type approval certificates of the sensors and po...

Page 16

5 lift the opening levers of the terminals with a screwdriver (see following illustration) fig. 8: connection steps 5 and 6 6 insert the wire ends into the open terminals according to the wiring plan 7 press down the opening levers of the terminals, you will hear the terminal spring closing 8 check ...

Page 17

1 4 4 4 2 3 fig. 9: material versions, single chamber housing 1 plastic (not with eex d) 2 aluminium 3 stainless steel (not with eex d) 4 filter element for pressure compensation or blind stopper with version ip 66/ ip 68, 1 bar (not with eex d) for connection of the amplifier according to namur (iec...

Page 18

+ - + - 1 2 3 4 3 2 1 fig. 11: wiring plan - external simulation key 1 namur amplifier 2 bridge 3 external simulation key 5 .4 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 12: wire assignment connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 shielding wire a...

Page 19: Set Up

6 set up 6 .1 general information the figures in brackets refer to the following illustrations. On the electronics module you will find the following indicating and adjustment elements: l potentiometer for adaptation to the product density (1) l dil switch for mode adjustment - min./max. (2) l simulat...

Page 20

By default, the potentiometer of vegawave 61 is set to the right stop (> 0.02 g/cm³ or 0.0008 lbs/in³). In case of very light-weight solids, turn the potentiometer to the left stop (> 0.008 g/cm³ or 0.0003 lbs/in³). Vegawave 61 will thus be more sensitive and can detect light-weight solids more reli...

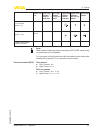

Page 21

Level signal current - sensor control lamp falling characteris- tics max. ≥ 2.4 ma falling characteris- tics max. ≤ 1 ma rising characteris- tics min. ≥ 2.4 ma rising characteris- tics min. ≤ 1 ma malfunction any ≤ 1 ma flashes 6 .4 recurring function test according to iec 61508. Vegawave 61 is quali...

Page 22

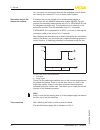

You can carry out the function test with the outputted current values also directly via a safety plc or a process control system. A function test can be carried out for measurement setups in conjunction with the namur electronics module we60n. For this purpose, the switching delay must be set to 0.5...

Page 23

Sensor cur- rent level relay amplifier - overflow protection level relay amplifier - dry run pro- tection signal lamp amplifier - overflow protection signal lamp amplifier - dry run pro- tection signal lamp - sensor 1. Low current (approx. 3 s) approx. 1 ma energized currentless 2. High current (approx. 1...

Page 24

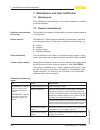

7 maintenance and fault rectification 7 .1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. 7 .2 remove interferences the operator of the system is responsible for taking suitable measures to rectify faults. Vegawave 61 offers maximum reliability....

Page 25

Error cause rectification wrong characteristic se- lected set the correct characteristics on the characteristics reversal switch (overflow protection, dry run protection). Wiring should be carried out according to the quiescent current principle. Signal lamp flashes yellow error on the vibrating ele- m...

Page 26

2 1 fig. 30: loosening the holding screws 1 electronics module 2 screws (2 pcs.) 6 pull out the old electronics module 7 compare the new electronics module with the old one. The type label of the electronics module must correspond to that of the old electronics module. This applies particularly to i...

Page 27

You can download a return form (23 kb) from our homepage at www. Vega.Com under: "downloads - forms and certificates - repair form". By doing this you help us carry out the repair quickly and without having to call back for needed information. L print and fill out one form per instrument l clean the i...

Page 28: Dismounting

8 dismounting 8 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in reve...

Page 29: Supplement

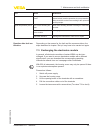

9 supplement 9 .1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting - thread 316l - process fitting - flange 316l - process seal klingersil c-4400 - tuning fork 316l - extension tube ø 43 mm (1.7 in) 316l materials, non-wetted parts - pl...

Page 30

Output variable output two-wire namur output current consumption - falling characteristics (max.) ≥ 2.4 ma uncovered/≤ 1 ma covered - rising characteristics (min.) ≤ 1 ma uncovered/≥ 2.4 ma covered - fault message ≤ 1 ma necessary processing system namur processing system according to iec 60947-5-6 ...

Page 31

Product density - standard > 0.02 g/cm³ (0.0007 lbs/in³) - adjustable > 0.008 g/cm³ (0.0003 lbs/in³) granular size max. 10 mm (0.4 in) electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 1) - single chamber housing l 1 x cable gland m20 x 1.5 (cable: ø 5 … 9 mm), 1...

Page 32

Simulation key simulation of a line break between sensor and processing unit voltage supply operating voltage (characteristics according to standard) for connection to an amplifier according to namur iec 60947-5-6, approx. 8.2 v off-load voltage u 0 approx. 8.2 v shortcircuit current i u approx. 8.2 m...

Page 33

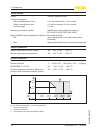

9 .2 dimensions housing in protection ip 66/ip 67 and ip 66/ip 68; 0.2 bar 3 2 1 4 ~ 69 mm (2.72") ø 79 mm (3.11") 1 1 7 mm (4 .6 1 ") m20x1,5/ ½ npt ~ 59 mm (2.32") ø 80 mm (3.15") 1 1 2 mm (4 .4 1 ") m20x1,5/ ½ npt ~ 69 mm (2.72") ø 79 mm (3.03") 1 1 2 mm (4 .4 1 ") m20x1,5/ ½ npt ~ 116 mm (4.57")...

Page 34

22mm ( 55 / 64 ") 33mm (1 19 / 64 ") 220mm (8 21 / 32 ") 150mm (5 29 / 32 ") g1½a ø 43mm (1 11 / 16 ") fig. 35: vegawave 61, threaded version g1½ a (din iso 228/1) 34 vegawave 61 • - namur 9 supplement 32249 -en -120418.

Page 35

ø 34 mm (1 11 / 32 ") 1 7 8 mm (7 1 / 6 4 ") fig. 36: temperature adapter vegawave 61 • - namur 35 9 supplement 32249 - en -120418.

Page 36

9 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte...

Page 37

Vegawave 61 • - namur 37 9 supplement 32249 - en -120418.

Page 38

38 vegawave 61 • - namur 9 supplement 32249 -en -120418.

Page 39

Vegawave 61 • - namur 39 9 supplement 32249 - en -120418.

Page 40

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...