- DL manuals

- Vega

- Switch

- VEGAWAVE 63

- Operating Instructions Manual

Vega VEGAWAVE 63 Operating Instructions Manual

Summary of VEGAWAVE 63

Page 1

Operating instructions vegawave 63 - namur.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

8 dismounting 8.1 dismounting steps . . . . . . . . . . . . . . . . . . . . . . 29 8.2 disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 9 supplement 9.1 technical data. . . . . . . . . . . . . . . . . . . . . . . . . 30 9.2 dimensions . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 5: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 6

2.6 sil conformity vegawave 63 meets the requirements to the functional safety according to iec 61508. Further information is available in the safety manual "vegawave series 60". 2.7 safety instructions for ex areas please note the ex-specific safety information for installation and operation in ex a...

Page 7

L make sure that the cable gland is tight and strain-relieved. The outer diameter of the connection cable must be adapted to the cable gland. Tighten the pressure screw of the cable gland carefully. L cover unused openings for cable glands tightly l mount the instrument in such a way that the sensor...

Page 8: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l vegawave 63 level sensor l documentation - this operating instructions manual - safety manual "functional safety according to iec 61508 or iec 61511 (sil)" - supplementary instructions manual "plug connector for level sensor...

Page 9

It is designed for industrial use in all areas of process technology and is preferably used for bulk solids. Typical applications are overfill and dry run protection. Thanks to its simple and robust measuring system, vegawave 63 is virtually unaffected by the chemical and physical properties of the bu...

Page 10

On the electronics module you will find the following indicating and adjustment elements: l signal lamp for indication of the switching condition (yellow) l potentiometer for adaptation to the product density l mode switch to select the switching condition (reverse characteristics) l simulation key 3...

Page 11: 4 Mounting

4 mounting 4.1 general instructions in general, vegawave 63 can be mounted in any position. The instrument must be mounted in such a way that the vibrating element is at the height of the requested switching point. Use the recommended cables (see chapter "connecting to power supply") and tighten the...

Page 12

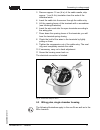

The vibrating level switch is a measuring instrument and must be treated accordingly. Bending the vibrating element will destroy the instrument. Warning: the housing must not be used to screw the instrument in! Applying tightening force on the housing can damage its rotational mechanical parts. To s...

Page 13

Fig. 3: inflowing medium vegawave 63 can be mounted with a lock fitting for height adjustment. Take note of the pressure information of the lock fitting. The vibrating element should protrude into the vessel to avoid buildup. For that reason, avoid using mounting bosses for flanges and screwed fittings. ...

Page 14

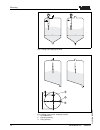

D d d 6 d 6 fig. 4: filling and emptying centered d d 6 1 2 3 fig. 5: filling in the center, emptying laterally 1 vegawave 63 2 emptying opening 3 filling opening 14 vegawave 63 - - namur mounting 32259 -en -070117.

Page 15

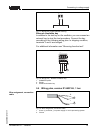

To minimise flow resistance caused by the tuning fork, vegawave 63 should be mounted in such a way that the surfaces of the blades are parallel to the product movement. 1 2 fig. 6: orientation of the tuning fork in case of flow 1 marking with screwed version 2 direction of flow in applications such as ...

Page 16

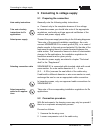

5 connecting to voltage supply 5.1 preparing the connection generally note the following safety instructions: l connect only in the complete absence of line voltage in hazardous areas you should take note of the appropriate regulations, conformity and type approval certificates of the sensors and pow...

Page 17

3 remove approx. 10 cm (4 in) of the cable mantle, strip approx. 1 cm (0.4 in) insulation from the ends of the individual wires 4 insert the cable into the sensor through the cable entry 5 lift the opening levers of the terminals with a screwdriver (see following illustration) 6 insert the wire ends...

Page 18

1 4 4 4 2 3 fig. 9: material versions, single chamber housing 1 plastic (not with eex d) 2 aluminium 3 stainless steel (not with eex d) 4 filter element for pressure compensation or blind stopper with version ip 66/ ip 68, 1 bar (not with eex d) simulation namur iec 60947-5-6 vb60n 4 5 6 1 2 3 fig. ...

Page 19

1 2 + + - - fig. 11: wiring plan, single chamber housing external simulation key in addition to the test key on the oscillator, you can connect an external key to start the test procedure. Connect the key according to the following wiring plan. In shipping condition, terminals 3 and 4 are bridged. F...

Page 20: 6 Setup

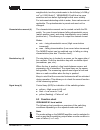

6 setup 6.1 in general the numbers in brackets refer to the following illustrations. On the electronics module you will find the following indicating and adjustment elements: l potentiometer for switching point adaptation (1) l dil switch for mode adjustment - min./max. (2) l simulation key (3) l sig...

Page 21

Weight solids, turn the potentiometer to the left stop (>0.008 g/ cm³ or 0.0003 lbs/in³). Vegawave 63 will thus be more sensitive and can detect light-weight solids more reliably. For instruments detecting solids in water, these values are not applicable. The potentiometer is preset and must not be ...

Page 22

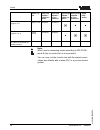

Level signal current - sensor control lamp falling characteris- tics max. >=2.2 ma falling characteris- tics max. Rising characteris- tics min. >=2.2 ma rising characteris- tics min. Failure any flashes 6.4 recurring function test according to iec 61508. Vegawave 63 is qualified in mode a (overfill pro...

Page 23

You can carry out the function test with the outputted current values also directly via a safety plc or a process control system. For measurement setups in conjunection with the namur oscillator we60n, a function test can be carried out. The integration time must be set to 0.5 s. Vegawave 63 has an ...

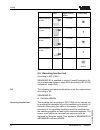

Page 24

Sensor cur- rent level relay amplifier - overfill pro- tection level relay amplifier - dry run protection signal lamp amplifier - overfill pro- tection signal lamp amplifier - dry run protection signal lamp - sensor 1. Low current (approx. 3 s) approx. 1 ma energized currentless 2. High current (approx. 1...

Page 25

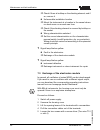

7 maintenance and fault rectification 7.1 maintenance when used as directed in normal operation, vegawave 63 is completely maintenance free. 7.2 remove interferences vegawave 63 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l se...

Page 26

à check if there is buildup on the vibrating element, and if so, remove it. L unfavourable installation location à mount the instrument at a location in the vessel where no dead zones or mounds can form. à check if the vibrating element is covered by buildup on the socket. L wrong characteristics se...

Page 27

2 1 fig. 16: loosen the screws 1 electronics module 2 screws (2 pcs.) 6 remove the old oscillator 7 compare the new oscillator with the old one. The type label of the oscillator must correspond to that of the old oscillator. This applies particularly to instruments used in hazardous areas. 8 compare...

Page 28

7.4 instrument repair if a repair is necessary, please proceed as follows: you can download a return form (23 kb) in the internet from our homepage www.Vega.Com under: "downloads - forms and certificates - repair form". By doing this you help us carry out the repair quickly and without having to call...

Page 29: 8 Dismounting

8 dismounting 8.1 dismounting steps warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in rev...

Page 30: 9 Supplement

9 supplement 9.1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting - thread 316l - process fitting - flange 316l - process seal klingersil c-4400 - tuning fork 316l - extension tube ø 43 mm (1.7 in) 316l materials, non-wetted parts - hou...

Page 31

Modes (namur output adjustable to falling or rising characteristics) - min. Rising characteristic curve (high current when immersed) - max. Falling characteristics (low current when im- mersed) ambient conditions ambient temperature on the housing -40 … +80 °c (-40 … +176 °f) storage and transport t...

Page 32

Electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 1) - single chamber housing l 1x cable entry m20x1.5 (cable-ø 5 … 9 mm), 1x blind stopper m20x1.5 or: l 1x closing cap ½ npt, 1x blind plug ½ npt or: l 1x plug (depending on the version), 1x blind plug m20x1.5 spr...

Page 33

Adjustment elements mode switch - min. Rising characteristic curve (high current when immersed) - max. Falling characteristics (low current when im- mersed) potentiometer for switching point adap- tation 0.02 … 0.1 g/cm³ (0.0007 … 0.036 lbs/in³) simulation key simulation of a line break between sens...

Page 34

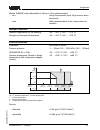

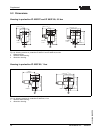

9.2 dimensions housing in protection ip 66/ip67 and ip 66/ip 68; 0.2 bar ø77mm (3 1 / 32 ") 112mm (4 13 / 32 ") 69mm (2 23 / 32 ") ø77mm (3 1 / 32 ") 69mm (2 23 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") ø84mm (3 5 / 16 ") 116mm (4 9 / 16 ") m20x1,5 m20x1,5/ ½ npt m20x1,5/ ½ npt m20x1,5/ ½ npt 1...

Page 35

22mm ( 55 / 64 ") 33mm (1 19 / 64 ") g1½a 150mm (5 29 / 32 ") l ø 43mm (1 11 / 16 ") fig. 20: vegawave 63, threaded version g1½ a l sensor length, see "technical data" supplement vegawave 63 - - namur 35 32259 -en -070117.

Page 36

ø 34 mm (1 11 / 32 ") 178 mm (7 1 / 64 ") fig. 21: temperature adapter supplement 36 vegawave 63 - - namur 32259 -en -070117.

Page 37

9.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. ...

Page 38

Supplement 38 vegawave 63 - - namur 32259 -en -070117.

Page 39

Supplement vegawave 63 - - namur 39 32259 -en -070117.

Page 40

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...