- DL manuals

- Ventrac

- Tractor

- HE302

- Operator's Manual And Parts List

Ventrac HE302 Operator's Manual And Parts List

Summary of HE302

Page 1

O perator ’ s m anual & p arts d rawings p ower b ucket m odel he302 / he482 revised 03/17/15 09.10067 rev. 01 original operator’s manual.

Page 2

2 500 venture drive po box 148 orrville, oh 44667 www.Ventrac.Com to the owner contact information and product identification if you need to contact an authorized ventrac dealer for information on servicing your product, always provide the product model and serial numbers. Please fill in the followi...

Page 3: Table of Contents

Table of contents 3 introduction page 5 product description ................................................................................................................................5 why do i need an operator’s manual? .............................................................................

Page 4: Table of Contents

Table of contents 4 specifications page 20 he302 dimensions ..............................................................................................................................20 he482 dimensions .................................................................................................

Page 5: Introduction

Introduction - 5 introduction product description accessories item description part num ber power bucket teeth kit (he302, he482) 70.8124 power bucket grapple kit (he482 only) 70.8123 ventrac power buckets are designed solely for the purposes of digging, scooping, and transporting materi- als such a...

Page 6: Introduction

Introduction introduction - 6 using your manual throughout this manual, you will encounter special messages and symbols that identify potential safety concerns to help you as well as others avoid personal injury or damage to the equipment. Attention this symbol identifies potential health and safety...

Page 7: Safety

Safety - 7 safety safety decals the following safety decals must be maintained on your power bucket. Keep all safety decals legible. Remove all grease, dirt, and debris from safety decals and instructional labels. If any decals are faded, illegible, or missing, contact your dealer promptly for repla...

Page 8: Safety

Safety safety - 8 general safety procedures for ventrac power units, attachments, & accessories training required • the owner of this machine is solely responsible for properly training the operators. • the owner/operator is solely responsible for the operation of this machine and prevention of acci...

Page 9: Safety

Safety safety - 9 general safety procedures for ventrac power units, attachments, & accessories • if equipped with a high/low range feature, never shift between high and low range while on a slope. Always move the machine to level ground and engage the parking brake before shifting range. • do not l...

Page 10: Safety

Safety safety - 10 general safety procedures for ventrac power units, attachments, & accessories operating on slopes • slopes can cause loss-of-control and tip-over accidents, which can result in severe injury or death. Be familiar with the emergency parking brake, along with the power unit controls...

Page 11: Safety

Safety safety - 11 general safety procedures for ventrac power units, attachments, & accessories maintenance • keep all safety decals legible. Remove all grease dirt, and debris from safety decals and instructional labels. • if any decals are faded, illegible, or missing, contact your dealer promptl...

Page 12: Safety

Safety safety - 12 general safety procedures for ventrac power units, attachments, & accessories hydraulic safety • make sure all hydraulic connections are tight and all hydraulic hoses and tubes are in good condition. Repair any leaks and replace any damaged or deteriorated hoses or tubes before st...

Page 13: Safety

Safety safety - 13 power bucket safety procedures • attachment hydraulic system may contain stored energy. Before performing maintenance or repairs on the hydraulic system, the attachment’s auxiliary hydraulic hoses must be disconnected from the power unit. Lower the attachment to the ground, shut o...

Page 14: Operational Controls

Operation - 14 operational controls operational control locations use the following images to help identify the locations of operational controls. The letter next to each control can be referenced to the list that follows these images. A. A b c primary sdla lever (power unit) b. Secondary sdla lever...

Page 15: General Operation

Operation - 15 general operation daily inspection 1. Always set the parking brake, shut off power unit engine, remove the ignition key, and ensure all moving parts have come to a complete stop before inspecting components, or attempting any repair or adjustment. Park machine on a level surface, with...

Page 16: General Operation

General operation operation - 16 for scraping a hard surface, use a bit of down pres- sure on the cutting edge by taking the primary sdla lever out of the float position and slightly lowering the bucket. Note: this will take some weight off the power unit’s front axle, reducing the power unit’s stee...

Page 17: Service

Service - 17 service cleaning and general maintenance for best results, and to maintain the finish of the power bucket, clean or wash the power bucket after each use to remove dirt, mud, stones, mulch, or other debris. Lubrication locations lubrication is required at the following locations using a ...

Page 18: Service

Service service - 18 removing power bucket teeth 1. Park the power unit and power bucket on a level surface and raise the power bucket high enough to place blocks underneath. 2. Place 4” blocks or other supports under the power bucket and lower the bucket until it is resting on the blocks. 3. Shut o...

Page 19: Service

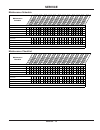

Service service - 19 maintenance schedule maintenance schedule # of lo ca tio ns # of pu m ps as ne ed ed da ily at 50 ho ur s at 10 0 ho ur s at 15 0 ho ur s at 20 0 ho ur s at 25 0 ho ur s at 30 0 ho ur s at 35 0 ho ur s at 40 0 ho ur s at 45 0 ho ur s at 50 0 ho ur s at 55 0 ho ur s at 60 0 ho ur...

Page 20: Specifications

Specifications - 20 specifications specifications he302 dimensions overall height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 inches (40.6 cm) overall length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.50 inches (85 cm) overall length w/teeth . . . . ....

Page 21

Blank page.

Page 22: Parts

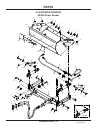

Illustrated parts - 22 use only original ventrac replacement parts. Illustrated drawing he302 power bucket parts 12 10 9 7 11 8 13 13 16 15 30 31 32 34 33 35 17 17 29 29 21 21 22 22 22 22 1 1 23 14 2 3 28 27 20 5 5 19 19 18 18 4 4 4 4 4 4 4 4 4 4 6 6 6 6 6 6 25 25 25 25 26 24 24 24 24 23.0130 60 60

Page 23: Parts

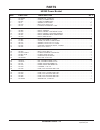

Parts illustrated parts - 23 use only original ventrac replacement parts. Ref. Part no. Description qty. 1 . . . . . . . . . 29.Gf0001 . . . . . . . . . . . . . . . . .Grease ftg, 1/4 sae st . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2 . . ....

Page 24: Parts

Parts illustrated parts - 24 use only original ventrac replacement parts. 11 8 7 5 9 6 20 20 13 12 29 30 31 32 33 34 14 14 28 28 24 24 25 25 25 25 2 2 26 10 3 4 1 27 17 16 16 16 16 18 18 15 15 15 15 15 15 15 15 15 15 19 19 19 19 19 19 23 23 23 23 21 22 22 22 22 23.0130 60 60 illustrated drawing he48...

Page 25: Parts

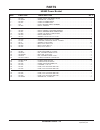

Parts illustrated parts - 25 use only original ventrac replacement parts. Ref. Part no. Description qty. 1 . . . . . . . . . 62.1343 . . . . . . . . . . . . . . . . . . . .Frame, scoop weldment he482. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 . . . . . . ....

Page 26: Parts

Parts illustrated parts - 26 use only original ventrac replacement parts. 3 3 3 3 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 illustrated drawing 70.8124 power bucket teeth kit.

Page 27: Parts

Parts illustrated parts - 27 use only original ventrac replacement parts. Ref. Part no. Description qty. 1 . . . . . . . . . 97.0610 . . . . . . . . . . . . . . . . . . . .Bolt, carriage 3/8 x 1-1/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2 ....

Page 28: Parts

Parts illustrated parts - 28 use only original ventrac replacement parts. 1 22 19 19 7 8 26 27 3 3 25 10 10 11 11 11 2 2 2 23 24 12 12 12 12 14 14 13 13 20 5 5 5 18 18 18 18 15 17 16 16 16 16 4 4 4 4 21 21 21 21 6 6 9 9 9 28 28 28 28 28 28 28 28 23.0130 50 50 illustrated drawing 70.8123 power bucket...

Page 29: Parts

Parts illustrated parts - 29 use only original ventrac replacement parts. Ref. Part no. Description qty. 1 . . . . . . . . . N/a . . . . . . . . . . . . . . . . . . . . . . .Plate, ventrac serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 . . . . ....

Page 30: Warranty

Limited warranty - ventrac turf equipment warranty venture products, inc. (shall be referred to as v.P.I.) warrants on the terms and conditions herein, that it will repair, replace, or adjust any part manufactured by venture products inc. And found by venture products inc. To be defective in materia...

Page 31: Warranty

Warranty limited warranty - ventrac turf equipment or that has altered, modified or affected the turf equipment so as to change the intended use of the product; (g) repair or replacement necessitated by the use of parts, accessories or supplies, including gasoline, oil or lubricants, incom- patible ...