- DL manuals

- WABECO

- Drill

- CC-F1410 LF hs

- Instruction Manual

WABECO CC-F1410 LF hs Instruction Manual

Operating Instructions

Universal drilling and milling machines

with linear guideways

F1410 LF

F1410 LF high speed

CC-F1410 LF

CC-F1410 LF high speed

Walter Blombach GmbH

Tool and Machine Factory

D-42899 Remscheid Am Blaffertsberg 13 Phone: 0049 (2191) 597-0

Fax: 0049 (2191) 597-40

E-Mail: info@wabeco-remscheid.de

D-54673 Neuerburg WABECO Str. 1-10 Phone: 0049 (6564) 9697-0 Fax: 0049 (6564) 9697-25 E-Mail: neuerburg@wabeco-remscheid.de

www.wabeco-remscheid.de

Summary of CC-F1410 LF hs

Page 1

Operating instructions universal drilling and milling machines with linear guideways f1410 lf f1410 lf high speed cc-f1410 lf cc-f1410 lf high speed walter blombach gmbh tool and machine factory d-42899 remscheid am blaffertsberg 13 phone: 0049 (2191) 597-0 fax: 0049 (2191) 597-40 e-mail: info@wabec...

Page 2: Index

2 index ec-conformity declaration 5 1. Product range 1.1 f1410 lf with trapezoid thread spindle 8 1.2 f1410 lf high speed with trapezoid thread spindle 10 1.3 f1410 lf with ball bearing spindle 12 1.4 f1410 lf high speed with ball bearing spindle 14 1.5 cc-f1410 lf 16 1.6 cc-f1410 lf high speed 18 2...

Page 3: Index

3 index 3.15 top slide cc-f1410 lf 48 3.15.1 list of parts for top slide cc-f1410 lf 49 3.16 cross slide f1410 lf with trapezoid thread spindle 50 3.16.1 list of parts for cross slide f1410 lf with trapezoid thread spindle 50 3.17 cross slide f1410 lf with ball bearing spindle 51 3.17.1 list of part...

Page 4: Index

4 index 8. Clamping and ejecting tools 82 9. Adjustment of the r.P.M. 84 9.1 adjustment of the r.P.M. Values for working aluminium and steel 84 9.2 adjustment of the r.P.M. For 1,4 kw motor 84 9.3 adjustment of the r.P.M. For 2,0 kw motor (high speed) 85 10. Feed motion 10.1 feed motions x, y and z-...

Page 5

5 ec – conformity declaration in the name of the manufacturer walter blombach gmbh tool and machine factory based in remscheid and neuerburg d-42871 remscheid postfach 12 01 61 phone: 0049 (2191) 597-0 fax: 0049 (2191) 597-40 d-54673 neuerburg wabeco str. 1-10 phone: 0049 (6564) 9697-0 fax: 0049 (65...

Page 6

6 dear customer! Congratulations on choosing the wabeco universal drilling and milling machine. We have devoted great care in its manufacture and it has passed a thorough quality control test. These operating instructions are to help you to work with it safely and properly. Therefore we request that...

Page 7

7.

Page 8: 1 Product

8 1 product range 1.1 f1410 lf with trapezoid thread spindle.

Page 9: 1 Product

9 1 product range 1.1 f1410 lf with trapezoid thread spindle 1) base machine see 3.7 page 34 2) cross slide see 3.16 page 50 3) top slide see 3.13 page 46 4) vertical slide see 3.10 page 40 5) y-spindle see 3.19 page 53 6) protective cover see 3.3 page 26 7) protective cover with electrical equipmen...

Page 10: 1 Product

10 1 product range 1.2 f1410 lf high speed with trapezoid thread spindle.

Page 11: 1 Product

11 1 product range 1.2 f1410 lf high speed with trapezoid thread spindle 1) base machine see 3.7 page 34 2) cross slide see 3.16 page 50 3) top slide see 3.13 page 46 4) vertical slide see 3.10 page 40 5) y-spindle see 3.19 page 53 6) milling head see 3.5 page 30 7) protective cover see 3.3 page 26.

Page 12: 1 Product

12 1 product range 1.3 f1410 lf with ball bearing spindle.

Page 13: 1 Product

13 1 product range 1.3 f1410 lf with ball bearing spindle 1) base machine see 3.8 page 36 2) cross slide see 3.17 page 51 3) top slide see 3.14 page 47 4) vertical slide see 3.11 page 42 5) y-spindle see 3.20 page 54 6) protective cover see 3.3 page 26 7) protective cover with electrical equipment s...

Page 14: 1 Product

14 1 product range 1.4 f1410 lf high speed with ball bearing spindle.

Page 15: 1 Product

15 1 product range 1.4 f1410 lf high speed with ball bearing spindle 1) base machine see 3.8 page 36 2) cross slide see 3.17 page 51 3) top slide see 3.14 page 47 4) vertical slide see 3.11 page 42 5) y-spindle see 3.20 page 54 6) milling head see 3.5 page 30 7) protective cover see 3.3 page 26.

Page 16: 1 Product

16 1 product range 1.5 cc-f1410 lf.

Page 17: 1 Product

17 1 product range 1.5 cc-f1410 lf 1) base maschine see 3.9 page 38 2) cross slide see 3.18 page 52 3) vertical slide see 3.12 page 44 4) top slide see 3.15 page 48 5) arm for control mechanism see 3.22 page 56 6) control station see 3.23,3.25 page 58 7) y-spindle see 3.21 page 55 8) milling head se...

Page 18: 1 Product

18 1 product range 1.6 cc-f1410 lf high speed.

Page 19: 1 Product

19 1 product range 1.6 cc-f1410 lf high speed 1) base machine see 3.9 page 8 2) cross slide see 3.18 page 52 3) vertical slide see 3.12 page 44 4) top slide see 3.15 page 48 5) arm for control mechanism see 3.22 page 56 6) control station see 3.24,3.26 page 58 7) y-spindle see 3.21 page 55 8) millin...

Page 20: 2 Technical

20 2 technical data dimensions of the milling and drilling machine installation area (trapezoid thread)………................ Width 1415 mm x depth 705 mm installation area (ball bearing spindle)....................... Width 1415 mm x depth 875 mm height 1,4 kw.............................................

Page 21: 2 Technical

21 2 technical data 2.1 dimensions trapezoid thread spindle (2 k w h=11 50 ) 4x Ø10 distance 305x225 fixing hole in the bottom plate x-axle max. X-axle max. (2 k w h=11 50 ) ball bearing spindle.

Page 22: Drawing and List of Parts

22 3 drawing and list of parts 3.1 protective cover with electrical equipment for f1410 lf.

Page 23: Drawing and List of Parts

23 3 drawing and list of parts 3.1.1 list of parts protective cover with electrical equipment for f1410 lf part-no. Pieces order-no. Designation 1 1 11200401 cap 2 1 11800005 circuit board 3 1 11200403 cover 4 4 11700001 countersunk screw 5 4 11700002 hexagonal nut 5.1 4 11700120 locking washer 6 1 ...

Page 24: Drawing and List of Parts

24 3 drawing and list of parts 3.2 protective cover with electrical equipment for cc-f1410 lf.

Page 25: Drawing and List of Parts

25 3 drawing and list of parts 3.2.1 list of parts protective cover with electrical equipment for cc-f1410 lf part-no. Pieces order-no. Designation 1 1 11200401 cap 2 1 11800005 circuit board 3 1 112004031 cover 4 4 11700001 countersunk screw 5 4 11700002 hexagonal nut 5.1 4 11700120 locking washer ...

Page 26: Drawing and List of Parts

26 3 drawing and list of parts protective cover for f1410 lf, f1410 lf high speed, cc-f1410 lf and cc-f1410 lf high speed list of parts for protective cover for f1410 lf, f1410 lf high speed, cc-f1410 lf and cc-f1410 lf high speed part-no. Pieces order-no. Designation 1 1 11270101 protective cover 2...

Page 27

27.

Page 28: Drawing and List of Parts

28 3 drawing and list of parts 3.4 milling head with 1,4 kw motor for f1410 lf and cc-f1410 lf.

Page 29: Drawing and List of Parts

29 3 drawing and list of parts 3.4.1 list of parts for milling head with 1,4 kw motor for f1410 lf and cc-f1410 lf part-no. Pieces order-no. Designation 1 1 11200101 housing 2 1 11200102 plastic ring 3 2 11810001 ball bearing 4 1 11700005 circlip 5 1 11820001 drive belt 6 1 11200106 belt pulley 7 1 ...

Page 30: Drawing and List of Parts

30 3 drawing and list of parts 3.5 milling head high speed with 2,0 kw motor for f1410 lf high speed.

Page 31: Drawing and List of Parts

31 3 drawing and list of parts 3.5.1 list of parts for milling head high speed with 2,0 kw motor for f1410 lf high speed part-no. Pieces order-no. Designation 1 1 11202101 housing 2 1 11200102 plastic ring 3 1 11700011 hexagonal socket screw 4 1 11700005 circlip 5 1 11820010 drive belt 6 1 11202106 ...

Page 32: Drawing and List of Parts

32 3 drawing and list of parts 3.6 milling head high speed with 2,0 kw motor for cc-f1410 lf high speed.

Page 33: Drawing and List of Parts

33 3 drawing and list of parts list of parts milling head high speed with 2,0 kw motor for cc-f1410 lf high speed part-no. Pieces order-no. Designation 1 1 11202101 housing 2 1 11200102 plastic ring 3 1 11700011 hexagonal socket screw 4 1 11700005 circlip 5 1 11820010 drive belt 6 1 11202106 belt pu...

Page 34: Drawing and List of Parts

34 3 drawing and list of parts 3.7 base machine f1410 lf with trapezoid thread spindle.

Page 35: Drawing and List of Parts

35 3 drawing and list of parts 3.7.1 list of parts base machine f1410 lf with trapezoid thread spindle part-no. Pieces order-no. Designation 1 1 112003226 bevel gear z30 1.1 1 112003182 bevel gear z15 2 1 16400203 base plate 3 1 16400301 z-stand 4 4 11700033 hexagon cylinder screw 5 4 11700034 washe...

Page 36: Drawing and List of Parts

36 3 drawing and list of parts 3.8 base machine f1410 lf with ball bearing spindle.

Page 37: Drawing and List of Parts

37 3 drawing and list of parts 3.8.1 list of parts base machine f1410 lf with ball bearing spindle part-no. Pieces order-no. Designation 1 1 112003226 bevel gear z30 1.1 1 112003182 bevel gear z15 2 1 16400203 base plate 3 1 16400301 z-stand 4 4 11700033 hexagon cylinder screw 5 4 11700034 washer 6 ...

Page 38: Drawing and List of Parts

38 3 drawing and list of parts 3.9 base machine cc-f1410 lf.

Page 39: Drawing and List of Parts

39 3 drawing and list of parts 3.9.1 list of parts base machine cc-f1410 lf part-no. Pieces order-no. Designation 1 1 112003226 bevel gear z30 1.1 1 112003182 bevel gear z15 2 4 11900017 limiting switch 3 1 16410204 cover limiting switch y-axis 3.1 1 16400206 rubber plate 3.2 3 11700031 hexagon cyli...

Page 40: Drawing and List of Parts

40 3 drawing and list of parts 3.10 vertical slide f1410 lf with trapezoid thread spindle.

Page 41: Drawing and List of Parts

41 3 drawing and list of parts 3.10.1 list of parts vertical slide f1410 lf with trapezoid thread spindle part-no. Pieces order-no. Designation 1 1 11860003 concertina cover z-axis, top 2 1 16400302 jam 4 1 11860003 concertina cover z-axis, base 5 1 16400303 vertical slide 6 4 11810026 guidance sled...

Page 42: Drawing and List of Parts

42 3 drawing and list of parts 3.11 vertical slide f1410 lf with ball bearing spindle.

Page 43: Drawing and List of Parts

43 3 drawing and list of parts 3.11 list of parts vertical slide f1410 lf with ball bearing spindle part-no. Pieces order-no. Designation 1 1 11860003 concertina cover z-axis, top 2 1 11860003 concertina cover z-axis, base 3 1 16400302 jam 3.1 1 16400319 jam plate 3.2 1 11840004 jam lever 3.3 1 1640...

Page 44: Drawing and List of Parts

44 3 drawing and list of parts 3.12 vertical slide cc-f1410 lf.

Page 45: Drawing and List of Parts

45 3 drawing and list of parts 3.12.1 list of parts vertical slide cc-f1410 lf part-no. Pieces order-no. Designation 1 1 11860003 concertina cover z-axis, top 3 2 16400227 cam lever 3.1 2 11700112 hexagon cylinder screw 4 1 11860003 concertina cover z-axis, base 5 1 16400303 vertical slide 6 4 11810...

Page 46: Drawing and List of Parts

46 3 drawing and list of parts 3.13 top slide f1410 lf with trapezoid thread spindle 3.13.1 list of parts top slide f1410 lf with trapezoid thread spindle part-no. Pieces order-no. Designation 1 1 164002103 spindle bearing 2 1 16400201 top slide 3 2 11810028 guide rail 700 mm 4 26 11700031 cylinder ...

Page 47: Drawing and List of Parts

47 3 drawing and list of parts 3.14 top slide f1410 lf with ball bearing spindle 3.14.1 list of parts top slide f1410 lf with ball bearing spindle part-no. Pieces order-no. Designation 1 1 164002103 spindle bearing 2 1 16400201 top slide 3 2 11810028 guide rail 700 mm 4 26 11700031 cylinder head scr...

Page 48: Drawing and List of Parts

48 3 drawing and list of parts 3.15 top slide cc-f1410 lf.

Page 49: Drawing and List of Parts

49 3 drawing and list of parts 3.15.1 list of parts top slide cc-f1410 lf part-no. Pieces order-no. Designation 1 1 11800003 step motor 2 2 11900017 limit switch 3 1 16400201 top slide 4 2 11810028 guide rail 700 mm 5 26 11700031 cylinder head screw 6 1 16400212 spindle bearing extension 7 2 1170004...

Page 50: Drawing and List of Parts

50 3 drawing and list of parts 3.16 cross slide f1410 lf with trapezoid thread spindle 3.16.1 list of parts cross slide f1410 lf with trapezoid thread spindle part-no. Pieces order-no. Designation 1 1 11860004 concertina cover, rear 2 1 11860004 concertina cover, front 3 1 11810029 clamper unit 5 1 ...

Page 51: Drawing and List of Parts

51 3 drawing and list of parts 3.17 cross slide f1410 lf with ball bearing spindle 3.17.1 list of parts cross slide f1410 lf with ball bearing spindle part-no. Pieces order-no. Designation 1 1 11860004 concertina cover, rear 2 1 11860004 concertina cover, front 3 1 11810029 clamper unit 5 1 16400202...

Page 52: Drawing and List of Parts

52 3 drawing and list of parts 3.18 cross slide cc-f1410 lf 3.18.1 list of parts cross slide cc-f1410 lf part-no. Pieces order-no. Designation 1 1 11860004 concertina cover 2 1 11860004 concertina cover 3 4 16400227 switch cams 4 1 16400202 cross slide 5 8 11810026 guide carriage 6 32 11700031 cylin...

Page 53: Drawing and List of Parts

53 3 drawing and list of parts 3.19 y-spindle f1410 lf with trapezoid thread spindle 3.19.1 list of parts y-spindle f1410 lf with trapezoid thread spindle part-no. Pieces order-no. Designation 1 1 164002103 spindle bearing 2 2 11810007 self aligning bearing 3 1 112002105 set collar 4 1 11840005 hand...

Page 54: Drawing and List of Parts

54 3 drawing and list of parts 3.20 y-spindle f1410 lf with ball bearing spindle 3.20.1 list of parts y-spindle f1410 lf with ball bearing spindle part-no. Pieces order-no. Designation 1 1 164002103 spindle bearing 2 2 11810007 self aligning bearing 3 1 112002105 set collar 4 1 11840005 handwheel 5 ...

Page 55: Drawing and List of Parts

55 3 drawing and list of parts 3.21 y-spindle cc-f1410 lf 3.21 list of parts y-spindle cc-f1410 lf part-no. Pieces order-no. Designation 1 1 164002103 spindle bearing 2 1 16400220-2 ball bear spindle 3 2 164002101 adjusting nut 4 1 16400218 toothed belt disc 5 1 11700087 headless pin m6x16 din914 6 ...

Page 56: Drawing and List of Parts

56 3 drawing and list of parts 3.22 arm for control station 3.22.1 list of parts for the arm of control station part-no. Pieces order-no. Designation 1 1 16400501 arm retainer 2 1 16400502 arm retainer 3 4 16400503 spacer 4 2 11840004 clamping lever 5 1 16400500 control panel arm 6 2 16400504 ring e...

Page 57

57.

Page 58: Drawing and List of Parts

58 3 drawing and list of parts 3.23 control station milling plus 1,4 kw.

Page 59: Drawing and List of Parts

59 3 drawing and list of parts 3.23.1 list of parts for control station milling plus 1,4 kw part-no. Pieces order-no. Designation 1 1 11800009 circuit board of cnc control 2 1 11800008 emergency off switch 3 1 11800004 potentiometer 4 1 11800001 main switch 5 1 11800005 circuit board 6 1 11200504 co...

Page 60: Drawing and List of Parts

60 3 drawing and list of parts 3.24 control station milling plus 2,0 kw.

Page 61: Drawing and List of Parts

61 3 drawing and list of parts 3.24.1 list of parts for control station milling plus 2,0 kw part-no. Pieces order-no. Designation 1 1 11800009 circuit board of cnc control 2 1 11800008 emergency off switch 3 1 11800026 potentiometer 4 1 11200504 control unit housing 5 1 11200501 ventilation 6 1 1120...

Page 62: Drawing and List of Parts

62 3 drawing and list of parts 3.25 control station nccad 1,4 kw.

Page 63: Drawing and List of Parts

63 3 drawing and list of parts 3.25.1 list of parts for control station nccad 1,4 kw part-no. Pieces order-no. Designation 1 1 11800024 4-axis control circuit board 3 1 11800008 emergency off switch 4 1 11800004 potentiometer 5 1 11800001 main switch 6 1 11800019 speed conrol board 7 1 11200504 cont...

Page 64: Drawing and List of Parts

64 3 drawing and list of parts 3.26 control station nccad 2,0 kw.

Page 65: Drawing and List of Parts

65 3 drawing and list of parts 3.26.1 list of parts for control station nccad 2,0 kw part-no. Pieces order-no. Designation 1 1 11800024 4-axis control circuit board 3 1 11800008 emergency off switch 4 1 11800026 potentiometer 5 1 11200504 control unit housing 6 1 11800025 ring transformer 7 1 112005...

Page 66: Drawing and List of Parts

66 3 drawing and list of parts 3.27 mounting for linear measuring scales.

Page 67: Drawing and List of Parts

67 3 drawing and list of parts 3.27.1 list of parts mounting for linear measuring scales part-no. Pieces order-no. Designation 1 1 16410217 cover limit switch z-axis 2 2 16400219 spacer linear scale 3 2 16400210 spacer end switch 4 2 11700002 hexagon nut 5 2 11700121 cylinder head screw 6 2 11700121...

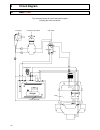

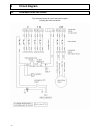

Page 68: 4 Circuit

68 4 circuit diagram 4.1 motor 1,4 kw this document shows all units of the electrical parts including the mains connection 1.1 emergency off switch control electronics danger potentiometer 1 3 2 4 5 date mains plug l n 1 1 2 2 motor 2.2/2.1 3.2/3.1 12(k) a2 11 22(i) 21 main switch.

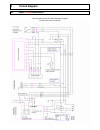

Page 69: 4 Circuit

69 4 circuit diagram 4.2 high speed motor 2,0 kw this document shows all units of the electrical parts including the mains connection.

Page 70: 4 Circuit

70 4 circuit diagram 4.3 motor 1,4 kw with safety cabin this document shows all units of the electrical parts including the mains connection.

Page 71: 4 Circuit

71 4 circuit diagram 4.3.1 high speed motor 2,0 kw with safety cabin this document shows all units of the electrical parts including the mains connection.

Page 72: 4 Circuit

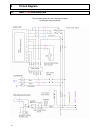

72 4 circuit diagram 4.4 drive motor of the cnc control this document shows all units of the electrical parts including the mains connection.

Page 73: 4 Circuit

73 4 circuit diagram 4.5 motor 1,4 kw nccad control this document shows all units of the electrical parts including the mains connection.

Page 74: 4 Circuit

74 4 circuit diagram 4.5.1 high speed motor 2,0 kw nccad control this document shows all units of the electrical parts including the mains connection.

Page 75: Delivery and Installation

75 5. Delivery and installation the drilling and milling machines are carefully packed in our factory. Please check the following upon receipt of delivery: 1. Whether the packaging has been damaged and/or: 2. Whether the drilling and milling machine shows signs of transport damage or if there are re...

Page 76: Starting-Up and Maintenance

76 6. Starting-up and maintenance after the machine has been professionally installed and securely mounted it must be connected to the mains supply: 1. A qualified electrician must connect the supply lead of the drilling and milling machine to the local power supply 2. A sufficient supply of lubrica...

Page 77: Starting-Up and Maintenance

77 6. Starting-up and maintenance spindle nut with trapezoid thread spindle: the spindle nuts of the milling machines are adjustable. Should at some time a spindle nut of one of the three axes show some play, proceed as follows: x-axis : to adjust spindle nuts move the cross table as far as it will ...

Page 78: Starting-Up and Maintenance

78 6. Starting-up and maintenance z-axis: to adjust the spindle nuts of the z-axis, you have to unscrew the cover plate. The further procedure is as for the x-axis. Spindle nuts with ball rolling spindle: an adjustment is not necessary and also not possible..

Page 79

79 7. Safety devices and recommendations in order to make working with our drilling and milling machines safe, we have equipped them with the following safety devices and are thus in accordance with the relevant european safety regulations. 1. Protective cover (protective partition) attached to the ...

Page 80

80 7. Safety devices and recommendations we would like to draw your attention to the following safety recommendations which are a result of a combination of the european standards and our own experience: 1. Workpieces must be secured in such a way that they cannot be propelled out of position by the...

Page 81

81 7. Safety devices and recommendations 7.1 cc-f1410 lf with safety machine cabin the cnc-milling machine can be operated manually but also in cnc operation. Conventional operation requires the door to be open. Cnc requires the door of the safety machine cabin to be closed. A limit switch which is ...

Page 82: Clamping and Ejecting Tools

82 8. Clamping and ejecting tools hexagon socket screw key tool retaining/forcing screw work spindle holding pin clamping chuck.

Page 83: Clamping and Ejecting Tools

83 8. Clamping and ejecting tools this is the core of the wabeco clamp and ejection system, the tool retaining/forcing screw . It operates on the principle of the screw having a fine thread located at its head and a coarse thread on the shank. Due to this construction, a special procedure has to be ...

Page 84: Adjustment of The R.P.M.

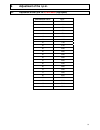

84 9. Adjustment of the r.P.M. A specific cutting speed is needed when milling different materials (e.G. Steel, aluminium etc.) the r.P.M. Of the work spindle can be infinitely varied from 140-3000 min -1 or 100–7500 min -1 on the potentiometer respectively so that the appropriate speed for the mate...

Page 85: Adjustment of The R.P.M.

85 9. Adjustment of the r.P.M. 9.2 adjustment of the r.P.M. For 2,0 kw motor (high speed) potentiometer rate % r.P.M. -1 2 50 3 100 4 200 5 350 10 700 15 1000 20 1400 25 1700 30 2100 35 2500 40 2900 45 3200 50 3600 55 4050 60 4500 65 4800 70 5200 75 5600 80 6050 85 6500 90 6900 95 7200 100 7500

Page 86: 10. Feed

86 10. Feed motion 10.1 feed motion x,y and z-axis the traverse and longitudinal motion of the cross support (x,y-axis) is accomplished by turning the handwheels (parts-no. 4 and 12). Both slides can be blocked with the aid of clamping levers (parts-no. 21 and 3). The feed motion – drilling and mill...

Page 87: 11.

87 11. Recommendations for application and operation we recommend the following: the drill should be inserted and clamped with the chuck key in such a way that the drill is positioned exactly between the three clamping jaws of the toothed ring chuck, the quick action chuck or the drawing-in attach...

Page 88: 11.

88 11. Recommendations for application and operation 11.1 swivelling of the milling head in order to produce bore holes and chamfering at an angle which diverges from the normal vertical position of the milling head, the milling head can be swivelled up to 90° either to the right or to the left. If ...

Page 89: 12.

89 12. Unit for lubrication coolant the unit for lubrication coolant consists of: 1. Tray with lubrication coolant sump which collects the lubrication coolant mixture fort he feed pump. Content: coolant unit order no. 11264 13 litres safety machine cabin order no. 1640090 42 litres 2. Feed pump with...

Page 90

90 13. Declaration of noise levels in accordance with din en 24871 (german industrial standard) noise levels while running idle acoustic capacity level 78 db (a) sound pressure level on operator’s ear 62 db (a) the stated values reflect emission levels and not necessarily working levels. Although th...