- DL manuals

- Wacker Neuson

- Power Tool

- BS 50-2

- Operator's Manual

Wacker Neuson BS 50-2 Operator's Manual

Summary of BS 50-2

Page 1

5000184075 08 0612 5 0 0 0 1 8 4 0 7 5 operator’s manual vibratory rammer bs 50-2 en.

Page 2

Copyright notice © copyright 2012 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Bs 50-2

Bs 50-2 foreword wc_tx001354gb.Fm 3 foreword save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance ...

Page 4: Foreword

Foreword bs 50-2 4 wc_tx001354gb.Fm laws pertaining to spark arresters notice: state health safety codes and public resources codes specify that in certain locations spark arresters be used on internal combustion engines that use hydrocarbon fuels. A spark arrester is a device designed to prevent ac...

Page 5: Ec Declaration of Conformity

Original declaration of conformity 20 1 2-c e- bs 50 -2 -2 i_ en .Fm ec declaration of conformity manufacturer wacker neuson production americas llc, n92w15000 anthony avenue, menomonee falls, wisconsin 53051 usa product product product category product function item number net installed power measu...

Page 7: Table of Contents

Table of contents bs 50-2 wc_bo5000184075_08toc.Fm 7 foreword 3 ec declaration of conformity 5 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. ...

Page 8: Table of Contents

Table of contents bs 50-2 wc_bo5000184075_08toc.Fm 8 5.7 cleaning the engine cooling fins .......................................................36 5.8 cleaning and checking the spark plug ...............................................37 5.9 checking and changing the ramming system oil ...............

Page 9: Bs 50-2

Wc_si000688gb.Fm 9 bs 50-2 safety information 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Noti...

Page 10: Safety Information

Wc_si000688gb.Fm 10 safety information bs 50-2 1.2 machine description and intended use this machine is a vibratory rammer. The wacker neuson rammer consists of a gasoline or diesel engine, a clutch, a fuel tank, a spring-loaded ramming system, a ramming shoe, and a handle. The engine transmits powe...

Page 11: Bs 50-2

Wc_si000688gb.Fm 11 bs 50-2 safety information 1.3 safety guidelines for operating the machine operator training before operating the machine: read and understand the operating instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of ...

Page 12: Safety Information

Wc_si000688gb.Fm 12 safety information bs 50-2 safe operating practices when operating this rammer: remain aware of the rammer’s moving parts. Keep hands, feet, and loose clothing away from the rammer’s moving parts. When working near the edges of pits, slopes, trenches and platforms, always operate...

Page 13: Bs 50-2

Wc_si000688gb.Fm 13 bs 50-2 safety information 1.5 service safety service training before servicing or maintaining the machine: read and understand the instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of all controls and safety d...

Page 14: Safety Information

Wc_si000688gb.Fm 14 safety information bs 50-2 cleaning when cleaning and servicing the machine: keep the machine clean and free of debris such as leaves, paper, cartons, etc. Keep the labels legible. When cleaning the machine: do not clean the machine while it is running. Never use gasoline or othe...

Page 15: Bs 50-2

Wc_si000688gb.Fm 15 bs 50-2 safety information 1.6 operator safety while using internal combustion engines operating safety when running the engine: keep the area around exhaust pipe free of flammable materials. Check the fuel lines and the fuel tank for leaks and cracks before starting the engine. ...

Page 16: Labels

Wc_si000408gb.Fm 16 labels bs 50-2 2 labels 2.1 label locations.

Page 17: Bs 50-2

Wc_si000408gb.Fm 17 bs 50-2 labels 2.2 label meanings wacker neuson machines use international pictorial labels where needed. These labels are described below. A to start the machine: 1. Move the throttle to the idle position. 2. Push the purge bulb 10 times. 3. Close the choke. 4. Pull the starter ...

Page 18: Labels

Wc_si000408gb.Fm 18 labels bs 50-2 d warning! Springs are compressed. Release cover slowly to avoid spring ejection. See the repair manual for proper disassembly instructions. E move lever forward to stop machine. Move lever backward to run machine. This label is molded into the cover. If the label ...

Page 19: Bs 50-2

Wc_si000408gb.Fm 19 bs 50-2 labels h the air intake system is equipped with a filter indicator, which indicates when a filter change is required. Replace main paper filter element when yellow plunger of the indicator appears in or near the red line. I a nameplate listing the model number, item numbe...

Page 20: Labels

Wc_si000408gb.Fm 20 labels bs 50-2 m this rammer engine requires a two-cycle gasoline/oil mixture (50:1). With wacker neuson 2-cycle or other fully synthetic oil meeting the nmma tc-w3, jaso fd, or iso-l-egd specification, a ratio from 50:1 to 100:1 can be used. This label is molded into the cover. ...

Page 21: Bs 50-2

Wc_tx003046gb.Fm 21 bs 50-2 lifting and transporting 3 lifting and transporting 3.1 lifting the rammer requirements lifting device (crane or hoist) capable of supporting the rammer’s weight (see the identification plate on the rammer) lifting gear (hooks, slings, and/or chains) capable of supporting...

Page 22: Lifting and Transporting

Wc_tx003046gb.Fm 22 lifting and transporting bs 50-2 3.2 transporting the rammer overview this rammer can be transported in a vehicle, or manually, depending on job site conditions and distance to be traveled. Notice: do not tow this rammer. Requirements engine stopped and cool to the touch lifting ...

Page 23: Bs 50-2

Wc_tx003047gb.Fm 23 bs 50-2 operation 4 operation 4.1 preparing the machine for first use preparing for first use to prepare your machine for first use: 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If there is visi...

Page 24: Operation

Wc_tx003047gb.Fm 24 operation bs 50-2 4.2 recommended fuel overview this rammer engine does not have a separate lubrication system. Instead, it requires a two-cycle gasoline/oil mixture. Two-cycle oil must be mixed with the gasoline so that the engine is lubricated as it burns fuel. Notice: use only...

Page 25: Bs 50-2

Wc_tx003047gb.Fm 25 bs 50-2 operation 4.3 refueling the machine requirements machine shut down engine cool machine standing upright on the ramming shoe fresh, clean fuel supply procedure perform the procedure below to refuel the machine. 1. Remove the fuel cap (a). 2. Fill the fuel tank until the fu...

Page 26: Operation

Wc_tx003047gb.Fm 26 operation bs 50-2 4.4 position of the operator for optimal control, performance, and minimal hand/arm vibration, follow the guidelines below when using the machine. Grasp the handle with both hands as shown. Stand behind the rammer, walking slowly and guiding the direction of tra...

Page 27: Bs 50-2

Wc_tx003047gb.Fm 27 bs 50-2 operation 4.6 starting, operating, and stopping the machine requirements rammer is in serviceable condition and has been properly maintained there is fuel in the tank starting the machine perform the procedure below to start the machine. 1. Move the throttle to the idle p...

Page 28: Operation

Wc_tx003047gb.Fm 28 operation bs 50-2 continued from the previous page. Operating the machine perform the procedure below to operate the rammer. 1. Move the throttle to the full position (c3). The choke will open automatically. 2. Guide the rammer’s direction of travel. Allow the rammer to pull itse...

Page 29: Bs 50-2

Wc_tx003047gb.Fm 29 bs 50-2 operation 4.7 emergency shutdown procedure procedure if a breakdown or accident occurs while the machine is operating, follow the procedure below: 1. Reduce engine speed to idle. 2. Stop the engine. 3. Close the fuel valve. 4. Contact the rental yard or machine owner for ...

Page 30: Maintenance

Wc_tx003048gb.Fm 30 maintenance bs 50-2 5 maintenance 5.1 maintaining the emission control system normal maintenance, replacement, or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repairs must be performed by a dealer/ser...

Page 31: Bs 50-2

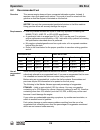

Wc_tx003048gb.Fm 31 bs 50-2 maintenance 5.2 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Daily before starting afte...

Page 32: Maintenance

Wc_tx003048gb.Fm 32 maintenance bs 50-2 5.3 servicing the air cleaner when the air intake system is equipped with a duel element filter. Check the condition of the air filter elements daily before operating the machine. Clean or replace the elements as needed. Requirements engine stopped and cool to...

Page 33: Bs 50-2

Wc_tx003048gb.Fm 33 bs 50-2 maintenance continued from the previous page. 2. Remove the min paper filter element (b) and prefilter (c) and inspect them for holes or tears. Replace the elements if they are damaged. A. Main paper filter element (b): replace the main paper filter element if it appears ...

Page 34: Maintenance

Wc_tx003048gb.Fm 34 maintenance bs 50-2 5.4 checking the fuel lines and fittings when daily before starting the machine procedure 1. Check the fuel lines (a) and fittings (b) for cracks and leaks. 2. Repair or replace components as needed. Result the fuel lines and fittings have now been checked. 5....

Page 35: Bs 50-2

Wc_tx003048gb.Fm 35 bs 50-2 maintenance 5.6 inspecting the machine when after the first five hours, and every week or every 25 hours thereafter (whichever comes first) requirements engine stopped machine cool to the touch replacement parts as needed (refer to the parts book) procedure 1. Perform a w...

Page 36: Maintenance

Wc_tx003048gb.Fm 36 maintenance bs 50-2 5.7 cleaning the engine cooling fins when every week, or every 25 hours (whichever comes first) background clean engine cooling fins allow fresh air to freely circulate around the combustion chamber. Free air circulation is necessary to prevent the engine from...

Page 37: Bs 50-2

Wc_tx003048gb.Fm 37 bs 50-2 maintenance 5.8 cleaning and checking the spark plug when every week, or every 25 hours (whichever comes first) requirements engine stopped and cool to the touch spark plug wrench spark plug gap tool wire brush replacement spark plug as needed (see technical data) procedu...

Page 38: Maintenance

Wc_tx003048gb.Fm 38 maintenance bs 50-2 5.9 checking and changing the ramming system oil background lubricating oil is distributed throughout the ramming system by the vibrating action of the rammer. Holes drilled in the piston carry oil from the bottom of the rammer to the crankcase as the rammer o...

Page 39: Bs 50-2

Wc_tx003048gb.Fm 39 bs 50-2 maintenance continued from the previous page. 2. Remove the sightglass. Clean the threads of the sightglass, then wrap the threads with teflon tape. 3. Add oil to the machine through the sightglass opening in the housing. 4. Reinstall the sightglass, but do not torque it ...

Page 40: Maintenance

Wc_tx003048gb.Fm 40 maintenance bs 50-2 5.10 adjusting the idle speed requirements tachometer phillips screwdriver procedure perform the procedure below to adjust the idle speed. 1. Remove the guard (c). 2. Start the engine and allow it to warm up to operating temperature. 3. Using the tachometer, s...

Page 41: Bs 50-2

Wc_tx003048gb.Fm 41 bs 50-2 maintenance 5.11 inspecting and cleaning the fuel filter when every year or every 1200 hours (whichever comes first) requirements engine stopped fuel tank empty clean, dry, lint-free cloth replacement fuel filter (as needed) procedure perform the procedure below to clean ...

Page 42: Maintenance

Wc_tx003048gb.Fm 42 maintenance bs 50-2 5.12 long-term storage introduction this machine requires preventive maintenance before long-term storage. Performing preventive maintenance helps to preserve machine components and ensures that the machine will be ready for future use. When prepare your machi...

Page 43: Bs 50-2

Wc_tx003048gb.Fm 43 bs 50-2 maintenance 5.13 machine disposal / decommissioning introduction this machine must be properly decommissioned at the end of its service life. Responsible disposal of recyclable components, such as plastic and metal, ensures that these materials can be reused—conserving la...

Page 44: Basic Troubleshooting

Wc_tx003049gb.Fm 44 basic troubleshooting bs 50-2 6 basic troubleshooting problem cause remedy engine does not start, or stalls. No fuel in tank add fuel. Spark plug fouled clean or replace spark plug. Engine does not accelerate, is hard to start, or runs erratically. Improper fuel mix: too much oil...

Page 45: Bs 50-2

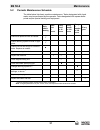

Wc_td000287gb.Fm 45 bs 50-2 technical data 7 technical data 7.1 rammer engine power rating net power rating per 80/1269/eec and iso 3046-1. Actual power output may vary due to conditions of specific use. Bs 50-2 0620025 0620048 0009413 0009411 0620609 0620610 0009384 0009410 0620733 operating weight...

Page 46: Technical Data

Wc_td000287gb.Fm 46 technical data bs 50-2 7.2 sound measurements products are tested for sound pressure level in accordance with en iso 11204. Sound power level is tested in accordance with european directive 2000/14/ec - noise emission in the environment by equipment for use outdoors. The sound pr...

Page 47: Bs 50-2

Wc_td000287gb.Fm 47 bs 50-2 technical data 7.4 dimensions mm (in.) wc_gr007411 machine item number a mm (in.) b mm (in.) bs 50-2 0009384 0009410 0009411 0009413 0620025 0620048 0620609 0620610 0620733 250 (9.84) 280 (11.03) 250 (9.84) 280 (11.03) 165 (6.50) 190 (7.50) 250 (9.84) 280 (11.03) 280 (11....

Page 48: Technical Data

Wc_td000287gb.Fm 48 technical data bs 50-2 notes.

Page 49

Emission control systems information and warranty wc_tx001768gb.Fm 49 8 emission control systems information and warranty the emission control warranty and associated information is valid only for the u.S.A., its territories, and canada. 8.1 emission control system background information introductio...

Page 50

Emission control systems information and warranty wc_tx001768gb.Fm 50 tampering and altering tampering with or altering the emission control system may increase emissions beyond the legal limit. If evidence of tampering is found, wacker neuson may deny a warranty claim. Among those acts that constit...

Page 51

Emission control systems information and warranty wc_tx001768gb.Fm 51 applicable epa regulations. All defective parts replaced under this warranty become property of wacker neuson. Exhaust emissions * indicates expendable maintenance items. Warranted only to first scheduled replacement point. Evapor...

Page 52

Emission control systems information and warranty wc_tx001768gb.Fm 52 what is not covered failures other than those resulting from defects in material or workmanship. Any systems or parts which are affected or damaged by owner abuse, tampering, neglect, improper maintenance, misuse, improper fueling...

Page 53

Emission control systems information and warranty wc_tx001768gb.Fm 53 for owners located more than 100 miles from an authorized dealer/service center (excluding the states with high-altitude areas as identified in 40 cfr part 1068, appendix iii), wacker neuson will pay for pre-approved shipping cost...

Page 54

Emission control systems information and warranty wc_tx001768gb.Fm 54 notes:.

Page 56

Wacker neuson produktion gmbh & co. Kg, preußenstraße 41, d-80809 münchen, tel.: +49-(0)89-3 54 02-0 fax: +49 - (0)89-3 54 02-390 wacker neuson production americas llc, n92w15000 anthony ave., menomonee falls, wi 53051 tel. : (262) 255-0500 fax: (262) 255-0550 tel.: (800) 770-0957 wacker neuson limi...