Wahlberg 241 User Manual - Index

5

805.241.011

Date: March 22

rd

, 2017

Index

SAFETY INFORMATION

2

INDEX

3

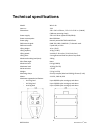

TECHNICAL SPECIFICATIONS

6

INTRODUCTION

7

P

ACKAGE CONTENT

...................................................................................................................................... 7

D

ESCRIPTION

............................................................................................................................................... 7

A

REA OF USE

............................................................................................................................................... 8

U

SING FOR THE FIRST TIME

............................................................................................................................ 8

PHYSICAL INSTALLATION

9

F

ASTENING THE WINCH TO A FLAT SURFACE

...................................................................................................... 9

M

OUNTING THE WINCH ON A TRUSS

............................................................................................................... 9

AC POWER

10

P

OWER VOLTAGE

....................................................................................................................................... 10

P

OWER CABLES AND POWER PLUG

................................................................................................................ 10

I

NSTALLING A POWER INPUT CONNECTOR ON A POWER CABLE

........................................................................... 11

DATA LINK

13

T

IPS FOR RELIABLE DATA TRANSMISSION

........................................................................................................ 13

C

ONNECTING THE DATA LINK

........................................................................................................................ 13

SETUP

13

C

OUNTERBALANCE

..................................................................................................................................... 14

MODE

SETTING

........................................................................................................................................ 14

DMX

ADDRESS

SETTING

........................................................................................................................... 16

M

ANUAL RESET

......................................................................................................................................... 17

P

OSITIONING

............................................................................................................................................. 18

R

E

-

CALIBRATING OVERLOAD

........................................................................................................................ 18

S

YNCHRONIZED MOVEMENTS OF MULTIPLE WINCHES

....................................................................................... 18

C

ONTROLLING THE TOP

-

AND BOTTOM POSITIONS

........................................................................................... 19

SERVICE AND MAINTENANCE

20

M

AINTENANCE PLAN

.................................................................................................................................. 20

O

N

-

SITE SERVICE

........................................................................................................................................ 21

L

IFE OF THE WIRE

....................................................................................................................................... 21

S

PARE PARTS

............................................................................................................................................. 21

W

IRE DEFECT

............................................................................................................................................ 22

C

HANGING WIRE

........................................................................................................................................ 23

A

PPLYING WIRE

......................................................................................................................................... 26

P

OWER DEFECT

.......................................................................................................................................... 26

WINCH 10 - CHEAT SHEET

27