- DL manuals

- Waldorf

- Oven

- RN8110G

- Installation And Operation Manual

Waldorf RN8110G Installation And Operation Manual

Summary of RN8110G

Page 1

1 i n s t a l l a t i o n a n d o p e r a t i o n m a n u a l rn8110g target top static oven/range date purchased serial number dealer service provider 228682-8 for use in gb & ie.

Page 2

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in writing by the manufacturer. In line with policy to continually develop and improve its products, moffat ltd. Reserves the right to change the specifications and desig...

Page 3

1 waldorf gas target top static oven range rn8110g gas target top static oven range. Introduction .............................................................................................. 2 specifications .............................................................................................

Page 4

2 we are confident that you will be delighted with your waldorf target top gas static oven range, , and it will become a most valued appliance in your commercial kitchen. To ensure you receive the utmost benefit from your new waldorf appliance, there are two important things you can do. Firstly: ple...

Page 5

3 specifications model numbers covered in this specification rn8110g gas target top static oven range. General a commercial heavy duty, general purpose fully modular, gas fired target top static oven range, having a high output, two stage double-ring iron cast burner offering accurate temperature co...

Page 6

4 specifications gas connection gas supply connection point is located 130mm from the right hand side, 35mm from the rear and 655mm from the floor and is reached from beneath the appliance. (refer to the ‘dimensions’ section). Connection is ¾" bsp male thread..

Page 7

5 dimensions rn8110g.

Page 8

6 installation requirements note: • it is most important that this appliance is installed correctly and that operation is correct before use. Installation shall comply with local gas and health and safety requirements. • this appliance shall be installed with sufficient ventilation to prevent the oc...

Page 9

7 clearances note: only non-combustible materials can be used in close proximity to this appliance. Assembly note: • all models are delivered completely assembled. No further assembly is required. Refer to the information below for assembly instructions. • this appliance is fitted with adjustable fe...

Page 10

8 note: a manual isolation valve must be fitted to the individual appliance supply line. 4. Correctly locate the appliance into its final operating position and using a spirit level, adjust the legs so that the appliance is level and at the correct height. 5. Connect the gas supply to the appliance....

Page 11

9 operation operation guide 1. Waldorf appliances have been designed to provide simplicity of operation and 100% safety protection. 2. Improper operation is therefore almost impossible, however bad operation practices can reduce the life of the appliance and produce a poor quality product. To use th...

Page 12

10 operation lighting the pilot burner - (target top) 1. Remove centre casting with the casting removal tool. 2. Depress the control knob and rotate anti-clockwise to the ‘pilot’ position. 3. With the control knob depressed, manually light the pilot burner located in front of the main burner. 4. Hol...

Page 13

11 lighting the pilot burner - (oven) this oven is fitted with a pilot as a standard option and flame failure protection, which is incorporated by way of a thermo-electric system for the main burner. Flame failure protection will shut off the gas supply to the burner in the event that the pilot burn...

Page 14

12 general clean the target top regularly. A clean appliance looks better, will last longer and will perform better. Carbonised grease on the cooking surface will hinder the transfer of heat from the cooking surface to the food. This will result in loss of cooking efficiency. Do not use water on the...

Page 15

13 c. Do not use water on the castings while they are still hot as cracking may occur. Should it be necessary to clean the castings,allow the castings to cool and then remove for cleaning. Clean using a soft cloth moistened with a mild detergent and hot water solution and a scrubbing brush. Dry thor...

Page 16

14 fault finding this section provides an easy reference guide to the more common problems that may occur during the operation of your appliance. The fault finding guide in this section is intended to help you correct, or at least accurately diagnose problems with your appliance. Although this secti...

Page 17

15 gas conversion and specifications conversion procedure note: • these conversions should only be carried out by qualified persons. All connections must be checked for leaks before re-commissioning the appliance. • adjustment of components that have adjustments / settings sealed (e.G. Paint sealed)...

Page 18

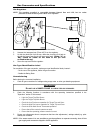

16 gas conversion and specifications target top - pilot burner 1. To remove the pilot burner, disconnect the gas supply tube from the base of the pilot burner. 2. Remove the bolt securing the retaining plate holding the pilot burner and thermo couple to the mounting bracket. Remove the retaining pla...

Page 19

17 gas conversion and specifications add shot of low fire adjustment point fig 15 oven injector: 1. With the gas supply turned off at the main supply, unscrew and remove the 6 screws securing the lower lintel to the front of the oven. 2. Open the oven door and remove the vitreous enamelled tray from...

Page 20

18 gas regulator note: the regulator supplied is convertible between natural gas and lpg, but it’s outlet pressure is fixed ex-factory and is not to be adjusted. 1. Ensure that the gas supply is turned ‘off’ at the mains. 2. Unscrew the hexagonal cap (23mm a/f) from the regulator. 3. Un-clip the pla...

Page 21

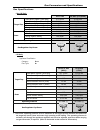

19 gas specifications - non-uk only - uk only appliance classification category: ii 2h3p. Flue type: a 1. * the burner operating pressure is to be measured at the target top hob manifold test point with the target top burner (inner and outer ring) operating at full setting. The operating pressure is...

Page 22

20 replacement parts list when ordering replacement parts, please quote the part number and the description as listed below. If the part required is not listed below, request the part by description and quote model number and serial number which is shown on the rating plate. Target top controls 2281...

Page 23

21 general 227012 centre casting. 227013 half plate casting. 014997 casting removal tool. 227892 oven side rack lh. 227893 oven side rack rh. 227896 oven rack. Gas conversion kits accessories 228921 rear roller kit. 228800 ranges 900 mm plinth kit. Replacement parts list model gas type to convert to...

Page 24

22.

Page 25

23.