- DL manuals

- Walker

- Lawn Mower

- MS

- Owner's Manual

Walker MS Owner's Manual - Specifications

Specifications

4

MODEL

MS

TRANSMISSION (continued)

Transmission Fluid

Factory Service

Mobil 1 Synthetic Motor Oil (15W-50)

Transmission Fluid Capacity

1 qt (1 liter)

Transmission Cooling

Cooling Fan Mounted on Drive Pulley

Ground Travel Speed

Forward m.p.h. (km/h)

Reverse m.p.h. (km/h)

0-5 (0-8) Infinitely Variable

0-5 (0-8) Infinitely Variable

BLADE DRIVE

PTO Shaft

Sliding Spline Shaft with Two (2) High-Speed U-Joints

Blade Spindle

Each Blade (2) Mounts Direct on Peerless Right Angle

Gearbox with Tee Gearbox in Center Connected to PTO Shaft

(Complete Geared Drive, Peerless Model 1000 Gearboxes)

Blade Drive Clutch and Brake

Manual Belt Tightener Clutch and Scrubber Brake

(Stops Blades within Five (5) Seconds of Disengagement)

Max. Blade Speed

[22 in. (56 cm) Blade] @ 3600

RPM Engine

2900 RPM

[16700 FPM (5090 m/min)]

TIRE SIZE

Deck Caster Wheel

2.80/2.50-4 Pneumatic (4-Ply)

Deck Caster Wheel (Optional)

8.25 x 2.75 (Semi-Pneumatic)

Drive

18 x 6.50-8 (4-Ply)

Drive (Optional Wide Tire)

18 x 8.50-8 (4-Ply)

Rear

13 x 6.50-6 (4-Ply)

TIRE PRESSURE

Deck Caster Wheel

20 PSI (137 kPa)

Drive

15 PSI (103 kPa)

Rear

20 PSI (137 kPa)

DIMENSIONS (Tractor and Mower)

Length

36 in. (91 cm) GHS Model

87 in. (221 cm)

42 in. (107 cm) GHS Model

89 in. (226 cm)

Width

36 in. (91 cm) SD Model

(with Deflector)

41-3/4 in. (106 cm)

42 in. (107 cm) SD Model

(with Deflector)

47-3/4 in. (121 cm)

36 in. (91 cm) GHS Model

37 in. (94 cm)

42 in. (107 cm) GHS Model

43 in. (109 cm)

Summary of MS

Page 1

™ owner’s manual safety, assembly, operating, and maintenance instructions model ms (13 hp) please read and save these instructions effective date: 10-01-03 for safety, read all safety and operation p/n 5000-11 instructions prior to operating machine price $5.00

Page 2: Foreword

Foreword thank you. . .For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom- ers. If for any reason this product does not perform to your expectations, please contact us at (97...

Page 3: Table Of Contents

Table of contents general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations________ 1 engine serial number location ______ 2 servicing of engine and drivetrain components __________ 2 specifications ___________...

Page 4: Table Of Contents

Table of contents maintenance instructions __________ 40 maintenance schedule chart _______ 40 important tips for care of the kawasaki engine ____________________ 41 fuel system _________________________ 41 starting _____________________________ 41 cooling system ______________________ 41 air cleane...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any ser- vice requiring special training or tools be performed by an authorized walker mower dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the oper- a...

Page 6: General Information

General information 2 tractor serial number location mower deck serial number location engine serial number location the kawasaki engine model, type, and code num- bers are located on the starter side of the engine shroud. For the mower model covered by this man- ual, an engine manual is available t...

Page 7: Specifications

Specifications 3 model ms engine manufacturer/model kawasaki, fe 400d, 1 cyl. Ohv (air-cooled) displacement 24.5 cu. In. (401 cc) hp (@ 3600 rpm) 13.0 max. Rpm (no load) 4000 governed rpm 3600 max. Torque [ft-lb (n ⋅ m) @ rpm] 19.5 (26.4) @ 2500 idle rpm 1300 spark plug type ngk bpr5es spark plug ga...

Page 8: Specifications

Specifications 4 model ms transmission (continued) transmission fluid factory service mobil 1 synthetic motor oil (15w-50) transmission fluid capacity 1 qt (1 liter) transmission cooling cooling fan mounted on drive pulley ground travel speed forward m.P.H. (km/h) reverse m.P.H. (km/h) 0-5 (0-8) inf...

Page 9: Specifications

Specifications 5 model ms dimensions (continued) height sd model 37-1/2 in. (95 cm) ghs model 44-1/2 in. (112 cm) wheel base (tractor) 42-1/4 in. (107 cm) tread width (tractor) standard tires 28-1/4 in. (72 cm) optional tires 29-3/4 in. (76 cm) mower deck width of cut sd/ghs 36 or 42 in. (91 or 107 ...

Page 10: Specifications

Specifications 6 model ms ghs system (optional) blower 3 1/2 x 9 x 1/4 in. (9 x 23 x 1 cm) three-blade paddle wheel (driven by mower engine) blower brake belt scrubber brake (works in combination with pto clutch, stops blower within five (5) seconds of pto disengagement) max. Blower speed 3600 rpm g...

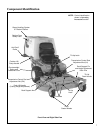

Page 11: Component Identification

Component identification 7 front view and right side view footrests deck caster wheels deck lift handle (cutting height adjustment) transmission control rod adjustment nut (rh) tilt-up latch grass handling system 6.7 bushel catcher catcher door safety latch anti-scuff roller counterweight spring and...

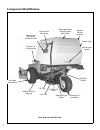

Page 12: Component Identification

Component identification 8 rear view and left side view left hand drive wheel catcher lift/ dump handle catcher door tailwheel fork and wheel fuel filter muffler exhaust opening oil filter rotating engine screen anti-scuff rollers catcher exhaust deflector removable grass catcher screen (not visible...

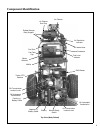

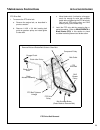

Page 13: Component Identification

Component identification 9 top view (body raised) lh hydrostatic transmission positive (+) battery cable fuel tank cap air cleaner dust cup starter solenoid rubber bumper body support muffler tractor pto gearbox rh hydrostatic transmission rh transmission lockout lever air cleaner air restriction in...

Page 14: Safety Instructions

Safety instructions 10 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail- ure to comply with safety instructions may result in personal injury...

Page 15: Safety Instructions

Safety instructions 11 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this machine while wearing shorts; always wear adequate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable and required by some l...

Page 16: Safety Instructions

Safety instructions 12 9. Watch for holes, rocks, and roots in the terrain and for other hidden hazards. When mowing tall grass, mow higher than desired to expose any hidden obstacles. Then, clean the area and mow to the desired height. 10. Avoid sudden starts or stops. Before backing the machine up...

Page 17: Safety Instructions

Safety instructions 13 3. Keep all nuts, bolts, and screws tight to ensure the machine is in a safe, working condition. Check the blade mounting nuts frequently, mak- ing sure they are tight. 4. Perform only maintenance instructions de- scribed in this manual. Unauthorized main- tenance operations o...

Page 18: Safety Instructions

Safety instructions 14 gear axle (5810-1) safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part n...

Page 19: Safety Instructions

Safety instructions 15 each end of mower deck (5808) sd deck discharge shield (5848) adjacent to blower discharge chute through body (5804) rh fender (5802-1) lh fender (5802-2) safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are m...

Page 20: Assembly Instructions

Assembly instructions 16 setup instructions walker mowers are shipped partially assembled. After uncrating the tractor and mower deck, initial setup is required. Note: during the process of unpacking, any dam- aged or missing parts should be noted and reported to the delivering carrier immediately (...

Page 21: Assembly Instructions

Assembly instructions 17 battery charging 1. Charge the battery at 15 amps for 10 minutes. Do not exceed 20 amps maximum recom- mended charging rate. Charge until specific gravity is at least 1.250. Total charging time should not exceed one (1) hour. 2. After charging the battery, adjust the electro...

Page 22: Assembly Instructions

Assembly instructions 18 deck caster wheel installation note: if semi-pneumatic wheels are installed, make sure the spacer washers fit over the spacer tube and are not caught between the fork and the end of the tube. The washers should move freely on the axle spacer tube. 5. Grease the caster wheel ...

Page 23: Assembly Instructions

Assembly instructions 19 tilt-up spring and roller wheel installation on rear discharge deck mower deck lnstallation on tractor deck installation 1. Lightly grease each deck support arm (2) on the tractor. Refer to mower deck installation photo for location of deck support arm. 2. Engage the deck ca...

Page 24: Assembly Instructions

Assembly instructions 20 deck counterweight spring installation 6. Raise mower body (instead of lifting the front of deck) and clip the counterweight springs to the receptacle on front of body. Lower the body to tension the springs. (refer to deck counter- weight spring installation photo.) 7. With ...

Page 25: Assembly Instructions

Assembly instructions 21 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 4 in. (102 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions . Note: a block of wood cut 4 in....

Page 26: Assembly Instructions

Assembly instructions 22 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 27: Assembly Instructions

Assembly instructions 23 check gear axle oil level (if equipped) refer to gear axle lubrication in maintenance instructions . Inspect three (3) drive belts engine, pto, and hydrostatic ground drive. Check hydrostatic transmission oil level refer to lubrication for checking hydrostatic transmission f...

Page 28: Operating Instructions

Operating instructions 24 control identification, location, and function ignition switch the ignition switch is located on the right front of the body and is used to start and stop the engine. The switch has three positions: “o” is the off position, run is the position the key returns to after start...

Page 29: Operating Instructions

Operating instructions 25 engine choke the choke control lever (black knob) is located on the left side of the seat. To start a cold engine, move the choke control forward to the on position. After engine starts, move choke control toward the off position, keeping enough choke to allow the engine to...

Page 30: Operating Instructions

Operating instructions 26 parking brake the parking brake functions by locking a pin into the hydrostatic transmission pinion gear teeth. Moving the lever forward engages the parking brake; moving the lever backward releases the brake. Important: stop the tractor completely before engaging the parki...

Page 31: Operating Instructions

Operating instructions 27 operating controls (top view from drivers point of view) throttle blade clutch (pto) parking brake left wheel steering lever forward position (no control change) neutral-park position reverse drive wheel motion position right wheel steering lever the forward speed control a...

Page 32: Operating Instructions

Operating instructions 28 starting the engine 1. Before attempting to start the engine, make sure the operator is in the seat, the forward speed control is in neutral-park position, and the blade clutch and parking brake are disengaged. Note: release parking brake to prevent extra load on the starte...

Page 33: Operating Instructions

Operating instructions 29 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold for- ward on steering levers. It is not necessary to hold the fsc lever in position since a friction lock maintains the selected lever position (and forward travel speed). Note: this is e...

Page 34: Operating Instructions

Operating instructions 30 note: smooth action on the steering levers will produce smooth mower operation. Remem- ber to keep the engine and ground speed slow until learning the control response. 4. The fsc may be adjusted forward for faster ground speed and backward for slower ground speed. When mow...

Page 35: Operating Instructions

Operating instructions 31 stopping the machine 1. Slow the engine to idle; put the throttle in the idle position. 2. Pull the steering levers to the neutral-park position and then move the fsc lever backward to the neutral-park position. 3. Disengage the blade clutch. Important: do not disengage the...

Page 36: Operating Instructions

Operating instructions 32 transmission lockout important: do not tow this mower with the transmission lockout engaged. Towing can produce excessive internal pressure and damage the transmission. To move the mower with the engine not running (dead battery, maintenance, etc.), the hydrostatic transmis...

Page 37: Operating Instructions

Operating instructions 33 • make sure the mower is leveled properly for a smooth cut. Refer to deck leveling in assembly instructions . • use an alternating stripe mowing pattern for best appearance and vary the direction of the stripe each time the grass is mowed to avoid wear patterns in the grass...

Page 38: Operating Instructions

Operating instructions 34 pto and blade gear drive rear discharge mower deck deck discharge chute blower body chute assembly grass catcher catcher door spring catcher door exhaust deflector exhaust screen (removable) catcher door safety latch grass-pak ® vane switch “full” signal horn actuator rod p...

Page 39: Operating Instructions

Operating instructions 35 general information the grass handling system (ghs) consists of a rear discharge mower deck connected to a 9 in. (23 cm) blower and a rear mounted grass catcher with 6.7 bushel (238 liters) capacity. The ghs blower oper- ates any time the mower blade clutch is engaged and m...

Page 40: Operating Instructions

Operating instructions 36 clogging checklist in case of clogging, there will be a distinct change in the sound of the blower, i.E., the blower sound will stop. Also, the mower deck will begin to leave a trail of grass clippings. When this occurs, stop the engine, disconnect the spark plug wire, and ...

Page 41: Operating Instructions

Operating instructions 37 • check that the openings in the air exhaust screen in the grass catcher are not plugged. If the screen is clogged, refer to cleaning the ghs exhaust screen in this section. Remember, anything that restricts airflow or material flow along the entire path from the mower deck...

Page 42: Operating Instructions

Operating instructions 38 dumping the catcher for dumping, the catcher either tailgate dumps into a disposal area or dumps into the optional dump bag. The dump bag is a reusable nylon fabric bag designed to conveniently move grass clippings from the catcher to a remote disposal area or container. Ta...

Page 43: Operating Instructions

Operating instructions 39 positioning dump bag on catcher 6. Close the door by holding the door handle with the left hand and releasing the safety latch on the door hinge mechanism with the right hand. The safety latch is released by pressing in on the top of the latch. Then, the door should close s...

Page 44: Maintenance Instructions

Maintenance instructions 40 maintenance schedule chart - recommended service intervals - model ms service item daily 25 hours 50 hours 100 hours yearly every 2years ref. Page check engine crankcase oil level x 42 check/clean engine air cooling system* x 50 clean grass buildup under deck x 52 clean g...

Page 45: Maintenance Instructions

Maintenance instructions kawasaki tips 41 important tips for care of the kawasaki engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. • clean the fuel filter on a regular basis and when contamination is suspected or found in the fuel. Starting • start engine with...

Page 46: Maintenance Instructions

Maintenance instructions lubrication 42 lubrication proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machine quieter and easier to operate. Engine oil engine break-in oil no special break-in oil is required. The engine is ser- viced with 10w-30, service class...

Page 47: Maintenance Instructions

Maintenance instructions lubrication 43 changing engine crankcase oil/oil filter change the engine crankcase oil after every 50 hours of operation and the oil filter after every 100 hours of operation as follows: 1. Park the mower on a level surface with the engine stopped. The engine oil should be ...

Page 48: Maintenance Instructions

Maintenance instructions lubrication 44 ident lubrication no. No. Location type places ident lubrication no. No. Location type places 'hfn&dvwhu:khho)run3lyrw *uhdvh %odgh'ulyh*hduer[ 2lo 7hh*hduer['hfn 2lo 'hfn&dvwhu:khho%hdulqj*uhdvh 3726kdiw*xdug+lqjh 2lo 8qlyhuvdo-rlqw6kdiw$vvhpeo\ *uhdvh 3lyrw$...

Page 49: Maintenance Instructions

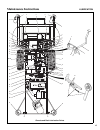

Maintenance instructions lubrication 45 2 3 1 4 40 7 8 7 9 35 36 29 & 37 28 & 38 17 35 15 39 10 26 28 29 30 31 32 34 33 27 27 26 22 23 25 10 16 17 18 20 21 21 19 15 6 7 8 7 9 5 4 2 1 11 11 12 13 14 24 24 chassis and deck lubrication points.

Page 50: Maintenance Instructions

Maintenance instructions lubrication 46 mower deck gearbox lubrication the mower deck gearboxes (tee gearbox and blade drive gearboxes) are connected as a unitized assembly, and oil flows freely between them. The gearboxes are permanently lubricated (oil filled) and sealed requiring no scheduled lub...

Page 51: Maintenance Instructions

Maintenance instructions lubrication 47 gear axle lubrication • the gear axle oil lubrication is sae 80w-90 (api gl-5) gear lube. • check the axle oil level after every 100 hours of operation by removing the oil level plug. If additional oil is needed, remove the breather vent on top of ax- le and f...

Page 52: Maintenance Instructions

Maintenance instructions lubrication/cleaning 48 changing hydrostatic transmission fluid the hydrostatic fluid should be changed every 1000 hours or two (2) years. Also, the fluid should be changed if the natural color of the fluid has become black or milky (indicating possible overheating or water ...

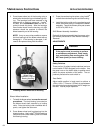

Page 53: Maintenance Instructions

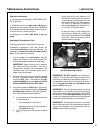

Maintenance instructions lubrication/cleaning 49 air restriction gauge location clean and inspect the paper element after every 100 hours of service and replace the element yearly or after six (6) cleanings (or when dirty or damaged). More frequent cleaning may be required when operating in extremel...

Page 54: Maintenance Instructions

Maintenance instructions cleaning 50 9. Install the cover with the word "top" properly oriented to the top of the canister. Give the cover a slight twist as it reaches the canister to make sure the tab inside the cover goes into a slot, otherwise the cover will not fit properly. Make sure both the t...

Page 55: Maintenance Instructions

Maintenance instructions cleaning 51 engine air intake screen cylinder head cooling fins it is essential for performance and longevity of the air-cooled engine to keep the cylinder head cooling fins clean and free of obstruction. After every 8 hours of operation, check the performance of the cooling...

Page 56: Maintenance Instructions

Maintenance instructions cleaning 52 grass buildup in mower housing 1. Raise the deck lock lever handle on each side of the carrier frame and pull out to release carrier frame for tilting action. 2. Using the carrier frame lift handle, raise deck to the tilt-up position and insert the deck hook into...

Page 57: Maintenance Instructions

Maintenance instructions cleaning 53 2. Use a pressure washer or water spray, and direct the spray inside the blower housing against the blower blades. Water pressure will cause the blower wheel to begin to spin, and the combination of spinning action and water will effectively wash the inside of th...

Page 58: Maintenance Instructions

Maintenance instructions 54 checking/servicing checking/servicing security of air filtration components note: the following inspection is only an external inspection and should be done without “disturb- ing” the filtration components. On a daily basis, visually inspect the external condi- tion of th...

Page 59: Maintenance Instructions

Maintenance instructions checking/servicing 55 check the battery charge by measuring the specific gravity of electrolyte; if specific gravity is less than 1.225, the battery will need to be charged as follows: 1. Charge the battery at 15 amps for 10 minutes. Do not exceed 20 amps maximum recom- mend...

Page 60: Maintenance Instructions

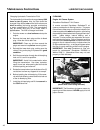

Maintenance instructions checking/servicing 56 mower blade profile for sharpening blade balanced on magnetic wall-mounted balancer 7. Mount the blade with wing tips pointing up into the housing. Reinstall the blade, washer, lock washer, and nut. Tighten the nut to 60 ft-lb (81.3 n · m). Note: when r...

Page 61: Maintenance Instructions

57 maintenance instructions checking/servicing/ replacing/repairing blade brake action check the function of the cutter blade brake (and blower brake on ghs models) by engaging the blade clutch (pto), operating the engine at full throttle, then disengaging the clutch and measuring how quickly the bl...

Page 62: Maintenance Instructions

Maintenance instructions replacing/repairing 58 engine belt 1. To remove the engine belt: a. Relax the belt by depressing the spring- loaded idler arm. B. Roll the belt off the compound pulley and remove the belt. Engine belt (engaged) engine belt (disengaged) compound pulley idler pulley belt tight...

Page 63: Maintenance Instructions

Maintenance instructions replacing/repairing 59 pto drive belt 1. To remove the pto drive belt: a. Remove the engine belt, as described in previous section. B. Remove 1/4-20 x 3/4 bolt locating belt guide on gearbox pulley and rotate guide to clear belt. C. Move blade clutch (in direction of engage-...

Page 64: Maintenance Instructions

Maintenance instructions replacing/repairing 60 ground drive belt 1. To remove the ground drive belt: a. Raise the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Raise idler pulley to relax belt transmission drive pulley ground drive belt tension spring idler p...

Page 65: Maintenance Instructions

Maintenance instructions replacing/repairing 61 blade overload shear bolts the cutting blade is keyed to the blade hub by two (2) shear bolts (10-24 x 5/8 in. Stainless steel ma- chine screws). These bolts are designed to shear and protect the blade drive gearbox from damage if the blade encounters ...

Page 66: Maintenance Instructions

Maintenance instructions replacing/repairing 62 • examine ends of the blade carefully, especially the intersection where the flat section of the blade turns up to form the “wing tip” (refer to mower blade pro- file for sharpening illustration in sharpen mower blades instructions). Since sand and abr...

Page 67: Maintenance Instructions

Maintenance instructions replacing/repairing 63 9. Position the gear drive assembly on the deck and install the 3/8-16 bolts mounting the entire assembly. Leave the mount bolts finger-tight. 10. Torque all the connector tube bolts to 80 in-lb (9 n ⋅ m); then tighten the deck mount bolts. Note: this ...

Page 68: Maintenance Instructions

Maintenance instructions replacing/repairing 64 3. Press blower wheel out of the housing using a wheel puller hooked to lugs on the bearing hous- ing. The bearings have been secured in the housing with a retaining compound - loctite ® rc/680, and considerable force will be re- quired to break this b...

Page 69: Maintenance Instructions

Maintenance instructions adjustments 65 fsc neutral-park switch 1. Place the fsc in neutral-park position. 2. Adjust switch to the point where the starter en- gages when the ignition switch is turned to the start position. 3. Adjust switch position forward an additional 1/2 to 1 turn of the panel nu...

Page 70: Maintenance Instructions

Maintenance instructions adjustments 66 scrubber brake adjustment - ghs scrubber brake adjustment - sd use “trial and error” to adjust scrubber braking action and achieve a stopping time of approximately 4 to 5 seconds after disengaging clutch with full throttle. Do not exceed five (5) seconds. Avoi...

Page 71: Maintenance Instructions

Maintenance instructions adjustments 67 steering lever end play adjustment - step 2 1. Position the fsc lever to the most forward position. 2. Loosen the adjustment nut on each steering le- ver actuator until end play develops between the lever actuator and the adjustment nut (sliding on transmissio...

Page 72: Maintenance Instructions

Maintenance instructions adjustments 68 straight ground travel adjustment forward speed control friction lock the fsc friction lock is adjusted to hold the selected forward speed when the steering levers are moved and yet the friction is not too heavy to make moving the control difficult (too much f...

Page 73: Maintenance Instructions

Maintenance instructions adjustments 69 carburetor carburetor adjustments are required to compensate for differences in altitude, temperature, and fuel. Once the carburetor has been set, no further adjust- ments should be required. However, if the engine exhibits any of the following symptoms, the c...

Page 74: Maintenance Instructions

Maintenance instructions adjustments 70 6. Recheck idle speed after the final idle mixture adjustment. Ghs “full” signal horn with grass-pak switch if the ghs “full” signal horn is not sounding or is not adjusted to sound when the catcher is full, the fol- lowing troubleshooting and adjustment instr...

Page 75: Maintenance Instructions

Maintenance instructions electrical system 71 wiring diagram g m s b starter solenoid starter fuel solenoid voltage regulator alternator magneto 20 amp fuse engine powerfil motor grass pak switch r r horn optional light chassis ground battery optional lights pto interlock switches hour meter seat sw...

Page 76

72 '$7( 6(59,&( (1*,1( ,7(0 +2856 8vhrqo\jhqxlqh:donhu uhsodfhphqwsduwv 0$,17(1$1&($1'6(59,&(5(&25'6+((7 bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb...

Page 77: Operator’S Notes

73 operator’s notes.

Page 78: Operator’S Notes

74 operator’s notes.

Page 79

75 limited warranty for walker commercial rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) ye...

Page 80: 0.4G

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 100103 printed in usa www.Walkermowers.Com © 2004 walker mfg. Co sound - model ms sound test sound test conducted was in accordance with 79/113/eec and was performed on 22 march 96 under the conditions listed: g...