- DL manuals

- Wallace International

- Gate Opener

- Kinetic DC 10FW

- Installation And Maintenance Manual

Wallace International Kinetic DC 10FW Installation And Maintenance Manual - Adjusting The Drive Height:

Installing the Drive on Gate Post

Rev: A

1-3

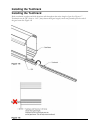

Adjusting the Drive Height:

1)

Raise the operator to the correct height so that it engages the toothrack in the gate beam.

Clearance between the toothrack and spur gear should be .11” (2.7mm); an 11ga tie wire can be

used as a gauge to set the correct clearance. See Figure 1-4.

Adjusting the Spur Gear Alignment:

1)

To adjust spur gear alignment with the toothrack, loosen but DO NOT REMOVE, the

2 - ¼-20 x 2.0” retaining bolts and lock nuts on spur gear. See Figure 1-5 & 1-6.

2)

Insert 2 – ¼-20 hex bolts into the threaded holes in the taper bushing. Alternately tighten the

hex bolts to release the taper bushing. When bushing is loose remove the 2 hex bolts.

See Figure 1-7.

3)

Adjust spur gear so it is centered on the toothrack, re-tighten the 2 -¼-20 x 2.0” retaining bolts

and lock nuts on spur gear.

Summary of Kinetic DC 10FW

Page 1

Wallace international kinetic dc 15w gate operator kinetic dcs 15w gate operator kinetic dc 10fw gate operator kinetic dcs 10fw gate operator installation and maintenance manual wallace international 90 lowson cr. Winnipeg, manitoba. R3p 2h8.

Page 2: Contents

Contents rev: a contents-1 introducing kinetic dc kinetic c omponents ....................................................................................................................................... I ntro- 1 i ntelligent f eatures s mart dc c ontroller ™ ........................................

Page 3: Contents

Contents contents-2 rev: a u sing a s olar p owered o perator ...................................................................................................................... 2 - 6 design requirements & considerations ...............................................................................

Page 4: Contents

Contents rev: a contents-3 chapter 5: bi-parting gate systems p ower r equirements ..................................................................................................................................................... 5 - 1 m aster & s lave w iring c onnections ..........................

Page 5

© 2010 d0394 rev. B product & warranty registration enter the following information to register your wallace product. Please write legibly. Today’s date: _____________________ note: to extend the operator warranty beyond 1 year, you must return this registration within 60 days of purchase. Refer to ...

Page 6: Kinetic Components

Kinetic components rev: a intro-1 kinetic components note: refer to parts & limited warranty for kinetic parts list..

Page 7: Introducing Kinetic Dc

Intelligent features: smart dc controller ™ intro-2 rev: a introducing kinetic dc thank you for purchasing our premium kinetic dc™ slide gate operator. At wallace international, we pride ourselves on quality. Our new line electromechanical gate operators include a number of unparalleled user benefit...

Page 8: Technical Support

Technical support rev: a intro-3 for technical support, call your installer or authorized wallace international distributor. Obtain the serial number of your operator before calling. Refer to kinetic components on the front page. For the name of a distributor near you, call wallace international at ...

Page 9: Installer’S Check List

Installer’s check list intro-4 rev: a installer’s check list the following list provides a high level overview of the tasks involved in installing the kinetic dc gate operator. Take a moment to review the list and check off the items as you complete the install. Make sure gate installation complies ...

Page 10: Safety Requirements

Important safety instructions rev: a s-1 safety requirements automatic gate operators provide user convenience and security. However, because these machines can produce high levels of force, it is imperative that gate operator system designers, installers and end users be aware of potential hazards ...

Page 11: Important Safety Information

Important safety information s-2 rev: a • before attaching the operator to the gate, slide the gate in both directions. Make sure it is level and moves freely. A gate that slides easily reduces strain on operator components. Gravity should play no part in the opening or closing of the gate. • in the...

Page 12

Important safety instructions rev: a s-3 safety standards – owner / user responsibility a moving gate can cause serious injury or death. Automatic gate operators move gates with high force. Make sure gates and gate operators are installed to reduce the risks of entrapment. Verify your gate and gate ...

Page 13: Important Safety Information

Important safety information s-4 rev: a hazardous materials and proper disposal the kinetic operator uses sealed, state-of-the-art absorbed glass mat (agm) batteries wallace international highly recommends replacing used batteries with new agm-type batteries. The batteries used with the kinetic gate...

Page 14

Secondary entrapment protection sensors rev: a s-5 secondary entrapment protection sensors kinetic is equipped with a primary, type a, inherent entrapment sensor (ies). Ul 325 safety standard compliance requires installation of secondary entrapment protection sensors, the number of which, depends on...

Page 15: Class

Secondary entrapment protection sensors s-6 rev: a identifying gate operator category & usage class the kinetic operator, according to ul 325 safety standards, falls in the slide gate and vertical barrier arm category for gate operators. Its usage class is determined by the area that the vehicular g...

Page 16

Secondary entrapment protection sensors rev: a s-7 choosing secondary entrapment protection the site designer or installer must determine which secondary entrapment sensor devices will be installed with the kinetic operator to meet ul compliance. The type of entrapment sensor device systems are desc...

Page 17: Emergency Stop Button

Secondary entrapment protection sensors s-8 rev: a emergency stop button an emergency stop button that is accessible from the outside of the operator is a requirement for compliance with ul 325 safety standards. The red emergency stop button is located inside a hole cutout on the kinetic cover. Pres...

Page 18: Safety Notices

Safety notices rev: a s-9 safety notices the following four levels of safety notices are used where applicable within this manual; each notice contains information specific to the situation. Indicates death or serious injury will occur if the hazardous situation is not avoided. Indicates death or se...

Page 19: Common Industrial Symbols

Common industrial symbols s-10 rev: a this page left intentionally blank.

Page 20: Site Overview & Planning

Site overview & planning rev: a 1-1 installation chapter 1 site overview & planning kinetic dc 15w kinetic dc 10fw duty cycle: continuous duty cycle: continuous power: single phase, switch selectable power: single phase, switch selectable 115 volts, 3 amps, 50/60 hertz 115 volts, 3 amps, 50/60 hertz...

Page 21

Installing the drive on gate post 1-2 rev: a installing the kinetic operator on gate posts rh & lh mounting options can be configured by the following steps: 1) remove the 4 - 10x1.5 x 20mm button head screws on the side of the operator that will be mounted to the gate post. See figure 1-2. Discard ...

Page 22: Adjusting The Drive Height:

Installing the drive on gate post rev: a 1-3 adjusting the drive height: 1) raise the operator to the correct height so that it engages the toothrack in the gate beam. Clearance between the toothrack and spur gear should be .11” (2.7mm); an 11ga tie wire can be used as a gauge to set the correct cle...

Page 23: Installing The Toothrack

Installing the toothrack 1-4 rev: a installing the toothrack: hook toothracks together and slide them into rail throughout the entire length of gate. See figure 1-7 toothracks can be .80” (2cm) to 1.18” (3cm) shorter than gate length; it must not protrude past the end of the gate beam. See figure 1-...

Page 24

Installing the drive on gate post rev: a 1-5 connecting the battery and turn dc power on: 1. Connect the red battery wire to its spade terminal. See figure 1-10 2. Turn dc power on. The usage class appears when power is first supplied to the operator. 3. To navigate within the setup menu, use the se...

Page 25

Installing the drive on gate post 1-6 rev: a programming the initial setup menu: several sequential displays present information which must be configured before kinetic operator will function. Once the configuration is complete, the information is retained even when a power loss occurs. Table 1-1. M...

Page 26

Installing the drive on gate post rev: a 1-7 establishing the open & close limits the learn limits display automatically appears after you set the gate weight. To set the open and close limits, take the following steps: 1. Hold the open button until the gate slides to full open. Release the open but...

Page 27: Installing The Target Magnet

Installing the drive on gate post 1-8 rev: a installing the target magnet figure 1-13 1. With the gate closed, mark the gate beam directly across from target sensor that is closest to the trailing edge of the gate. See figure 1-13. 2. Press the open button to move the gate a few feet and then press ...

Page 28

Installing the drive on gate post rev: a 1- 9 8. To verify that the operator recognizes the target magnet, turn off both dc and ac power switches and watch the display go blank. Then, turn both switches on. The operator beeps indicating limit relearn mode. The gate then travels about 6 inches (15cm)...