- DL manuals

- WarmFlow

- Boiler

- WP18

- Instruction Manual

WarmFlow WP18 Instruction Manual

Summary of WP18

Page 1

Boiler manual wood pellet boiler ws18/wp18 for use with enplus a1 wood pellets only. Look for the enplus a1 symbol. Incorporating: user instructions installation instructions service instructions guarantee terms & conditions registration documents leave this manual with the end user.

Page 2: Commissioning

Important – read this manual in full before installing, commissioning, servicing or operating this appliance. Commissioning this appliance must be commissioned. Failure to commission the appliance will invalidate the warranty. After commissioning, ensure that the appliance registration documents are...

Page 3: Contents

Contents 1 key information 1 1.1 the clean air act 1993 and smoke control areas 4 2 user instructions 5 2.1 filling the pellet hopper 5 2.2 system pressure 6 2.3 system filling 6 2.4 user control interface 6 2.4.1 home screen icons and their meaning. 7 2.4.2 using the main menu 8 3 installation requ...

Page 4

6 appliance installation/commissioning certificate & registration. 33 7 appliance service records. 35.

Page 5: 1 Key Information

5 1 key information the appliance is rated to ip45 and has a weatherproof housing suitable for both internal and external installation. The appliance is supplied with a flue terminal which may need to be extended or adapted depending on the installation situation. It is strongly recommended that a ...

Page 6

6 once removed the service lid gives access to the heat exchanger for servicing and routine maintenance as shown in figure 2. To clean the internal surfaces of the heat exchanger, remove the main he inspection door and the he cleaning mechanism door. Caution: never attempt to remove the doors after ...

Page 7

7 the ash level in the ash pan should be checked periodically. The ash pan must never be permitted to over fill. Under normal operating conditions during the heating season the ash pan will typically require emptying on a monthly basis. The appliance should never be operated without the ash pan in p...

Page 8

8 1.1 the clean air act 1993 and smoke control areas both appliances, the ws18 and wp18 comply with the requirements of the clean air act 1993 and are suitable for installation in smoke control areas. The appliances meet the emissions limits for particulate matter and no x as stated by defra. As suc...

Page 9: 2 User Instructions

9 2 user instructions 2.1 filling the pellet hopper the wood pellets used to fuel the appliance must be compliant with the enplus a1 pellet standard. Using alternative pellets will invalidate the product warranty. It should be also noted that the warmflow wood pellet boiler appliance is suitable for...

Page 10

10 2.2 system pressure when the appliance is connected to a sealed central heating system, the system pressure should be checked periodically by means of the pressure gauge at the expansion vessel (see figure 4). The ws18 appliance comes complete with an integrated expansion vessel, pressure gauge a...

Page 11

11 the home screen appears as shown in figure 6. Boiler status icon status meaning boiler ok the appliance is functioning normally. There are no faults or alerts. Servicing is not due. Boiler alert the appliance has reached alert condition but will continue to operate as normal. This alert means tha...

Page 12

12 the main menu can be accessed by pressing once on the ‘program key’. This displays the main menu as shown in the figures 7 and 8 below. The ‘down arrow’ or the ‘up arrow’ key can then be used to scroll through the menu. Confirm selection with the ‘enter key’ when the required item is highlighted ...

Page 13

13 when an alarm is present, the ‘display active alarms’ key will flash red. Pressing the flashing key or entering the alarm menu will then display one or more active alarms or faults. The ‘down arrow’ or the ‘up arrow’ key can then be used to scroll through the alarms. Selecting one with the ‘enter...

Page 14

14 this screen indicates that the appliance is ready to clean and that care should be taken as some parts including the combustion pot, ash pan and heat exchanger may be hot. Appropriate protective wear including gloves should be worn when handling such items. The combustion door can now be opened. ...

Page 15

15 this screen prompts for confirmation that cleaning has been performed and that both the combustion pot and ash pan have been reinstalled. This is confirmed by the ‘enter key’. This returns the display to the home screen and resets the cleaning scheduler. Only when this process has been fully comp...

Page 16

16 temperature: selecting the temperature submenu enters the screen from which the appliances flow temperature may be adjusted. The flow temperature is the temperature at which the heating system water which leaves the appliance and enters the central heating circuit. This can be adjusted between 6...

Page 17

17 mode description standby awaiting heat demand system check ensuring that the appliance is ready and safe to start preload loading the combustion pot with pellets ignition igniting the pellets in the combustion pot stabilisation ensuring that the flame is given time to establish power band 1,2,3,...

Page 18

18 engineer: figure 20: flow chart..

Page 19

19 selecting the engineer menu enters a submenu which has a number of information and setting screens intended for an approved engineer only. For this reason the engineer utility is password protected. The password should be entered as shown in figure 21. As an authorised engineer and having entere...

Page 20

20 3 installation requirements the installation must comply with regional building regulations. The maximum noise level generated by the appliance is well within the residential noise limitations and is similar to that of a high efficiency oil boiler. 3.1 general requirements 3.1.1 hearth the applia...

Page 21

21 accordance with the cleanser/inhibitor manufacturers’ instructions. The system must be dosed to the concentrations specified by the inhibitor manufacturer. Inhibitor concentrations must be monitored and maintained on an ongoing basis. Failure of components such as, but not limited to, pumps, auto...

Page 22

22 when measuring the expansion vessel bladder precharge pressure, using a tyre gauge, the system must be cold (less than 25°c) and the system pressure must be relieved (by manually operating the system pressure relief valve) in order to obtain an accurate reading. 3.2.2 system filling for the ws18...

Page 23

23 the drainage hose must not be affected by any blockage which could lead to condensation backfilling into the heat exchanger of the appliance causing corrosion. 3.3 figure 24: condensate trap plumbing..

Page 24

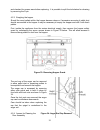

24 plumbing layout casing knockouts can be found on both sides and rear of the appliance along with cutouts in the galvanised base which allow for the pipes to exit the casing below ground level, see figure 25 and 26 below. 28mm elbows have been supplied with the appliance for connection. It is adv...

Page 25

25 all wiring must be carried out in accordance with current iee wiring regulations. It is recommended the user interface controller is mounted in an easily accessible location within the property. The wiring connection to the user interface is via a plan connection and must be wired from the wiring...

Page 26

26 3.5 flue system the appliance comes with an 80/100mm twin wall flue comprising a 1000mm long flue section and a 600mm long flue terminal. To assemble the flue supplied, insert the1000mm long flue section into the flue spigot on top of the appliance. Secure with supplied selfdrilling screws. Plac...

Page 27

27 figure 30: flue assembly..

Page 28

28 4 commissioning and servicing figure 31: flue outlet positions for solid fuel appliances..

Page 29

29 4.1 commissioning note: it is the responsibility of the installer to ensure that the appliance is properly commissioned by a trained and competent technician. Failure to do so will invalidate all warranties. Before commissioning ensure that the combustion pot and ash pan are in place as they may ...

Page 30

30 the system corrosion inhibitor level must be checked (instant onsite test kits are available from inhibitor manufacturers) and additional inhibitor must be added if the system is found to be underdosed. Refer to the inhibitor manufacturer for further guidance. Note: all product warranties will ...

Page 31

31 and checked for excess wear before replacing. It is possible to split the turbulators for cleaning by removing the r pin. 4.2.3 emptying the hopper should the wood pellets within the hopper become damp or if excessive amounts of pellet dust should accumulate in the hopper it may be necessary to e...

Page 32

32 the combustion pot sits on a shelf on the door which houses the pot grate and cleaning mechanism. The shelf must be cleaned out during the appliances annual service by a warmflow engineer or other competent technician. Refer to figure 35. To gain access to the inner part of the shelf the motor mu...

Page 33

33 periods of guarantee your wood pellet boiler (‘the boiler’), including all controls, pipework & unions, associated equipment contained within the boiler casing & flue system, if supplied by warmflow, are guaranteed against defective parts and workmanship for a period of twenty four 24 months from...

Page 34

34 your boiler must be installed, commissioned and serviced in accordance with any instructions and recommendations of the manufacturer from time to time in force as may be communicated to you. In addition: x the commissioning certificate in respect of your boiler must be returned to warmflow within...

Page 35

35 this guarantee is not transferable parts the cleaning knives, igniter, ash pan and combustion pot supplied with your boiler are deemed to be consumable items and are therefore excluded from this guarantee. Scratches, nicks, minor dents, and cosmetic damages to external surfaces and exposed parts ...

Page 36

36 (m)any problems caused by inadequate supply of services such as electricity or water to the property; claims for consequential loss or damage however caused are not covered by this guarantee. Please note that your statutory rights are not affected by this guarantee..

Page 37: Registration.

37 6 appliance installation/commissioning certificate & registration. Instructions. X complete the installation/commissioning certificate. X complete the installation/commissioning certificate overleaf. X fill out all relevant sections of the installation/commissioning certificate using block capita...

Page 38

38 installation & commissioning certificate da te of ins ta l l a ti on: 1. Installing engineer details. Mcs/seai regi s tra ti on no. Ins ta l l a ti on compa ny na me: ins ta l l a ti on compa ny addres s : conta ct tel ephone no.: (landline) (mobile) ins ta l l er’s na me: ins ta l l er's e‐ma i ...

Page 39

39 intentionally left blank.

Page 40

40 7 appliance service records. Instructions. X the appliance must be serviced in accordance with the service schedule and instructions laid out in this manual. X details of the service conducted must be fully recorded on the following service record sheets by the competent person conducting the ser...

Page 41

Please complete using block capitals. Service record 1. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 42

Please complete using block capitals. Service record 2. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 43

Please complete using block capitals. Service record 3. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 44

Please complete using block capitals. Service record 4. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 45

Please complete using block capitals. Service record 5. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 46

Please complete using block capitals. Service record 6. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 47

Please complete using block capitals. Service record 7. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 48

Please complete using block capitals. Service record 8. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 49

Please complete using block capitals. Service record 9. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installati...

Page 50

Please complete using block capitals. Service record 10. Date of servicing: 1. Service engineer details. Mcs/seai registration no. Service company name: service company address: contact telephone no.: (landline) (mobile) service engineer’s name: service engineer's's email: 2. Condition of installat...

Page 51

This manual is accurate at the date of printing (e&oe) but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued product improvement. Code 4220 issue 3 july 2014.