- DL manuals

- Water Right

- Water Dispenser

- ISP1-1044

- Installation instructions & owner's manual

Water Right ISP1-1044 Installation instructions & owner's manual

Summary of ISP1-1044

Page 1

Installation instructions & owner’s manual iron soft plus ™ series water conditioners.

Page 2

Table of contents : installation instructions page 3-4 start-up procedures page 5-6 programming the iron soft plus timer page 6-8 light/alarm operation page 9 water conditioner flow diagrams page 9-10 troubleshooting page 11-12 parts & assembly diagrams page 13-18 blank page 19 capacity & physical s...

Page 3

3 pre - installation instructions : although the iron soft plus series water conditioner is shipped complete, some assembly may be required. 1. After unboxing the unit, please note that on most models the control valve is installed on the tank. If not, remove “split flange” from control valve adapte...

Page 4

2. Notice on the casting, the inlet and outlet markings, make sure the incoming water is plumbed to the inlet and outlet is plumbed to service (fig. 3). Your water softener must be installed with a bypass valve. If your conditioner is not equipped with one, make a provision in the plumbing system fo...

Page 5

5 • after installation is complete, rotate bypass handles to bypass mode (see “valves closed” in fig.3). • turn on water and check for leaks. • fully open a cold water faucet — preferably a laundry sink or bathtub with no aerator. • allow water to run until clear to rid pipes of debris which may hav...

Page 6: ’

6 caution: damage or destruction to the media may occur if salts containing additives are used with the iron soft plus models. Most “solar” and/or “block” salts do not contain additives detrimental to this unit. If unsure, please check with manufacturer. Many “pellet” or “cube” type salts are formul...

Page 7

7 timer operation : set time of day when the timer is in service, push either the set up or set down button once to adjust the time of day by one digit. Push and hold to adjust by several digits. Manually initiating a regeneration 1. When timer is in service, press the extra cycle button for five se...

Page 8

8 programming the electronic controller : 1. Enter 3200nt programming mode press and hold both the set up and set down buttons for five (5) seconds to enter programming mode. When the program mode is entered, the program light illuminates. 2. Set feed water hardness the feed water hardness setting d...

Page 9

9 light / alarm operation : light panel operation with audio alarm: on the right side of the control valve there are 3 lights — green, yellow and red. 1. The green light indicates the unit is in the service position delivering soft water. 2. The red light indicates the unit is in the regeneration cy...

Page 10

10 3b. Slow rinse position: chlorine generator is turned off, raw water enters control head and flows down through the zeolite mineral, rinsing chlorine and brine to drain. 3a. Brine rinse position: raw water enters control head flowing through the injector, drawing brine from the brine tank. Microp...

Page 11: Problem

Problem cause correction 1. Softener fails to regenerate a. Electrical service to unit has been interrupted a. Assure permanent electrical service (check fuse, plug, pull chain or switch) b. Timer is defective b. Replace timer c. Power failure c. Reset time of day d. Timer programming bad d. Check p...

Page 12: Problem

12 problem cause correction 6. Iron in conditioned water a. Fouled mineral bed a. Check backwash, brine draw and brine tank fill — increase frequency of regeneration 7. Excessive water in brine tank a. Plugged drain line flow control a. Clean flow control b. Brine valve failure b. Replace brine valv...

Page 13

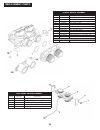

Replacement parts : 13 plastic bypass assembly item no. Part no. Description 1 fp9452k83 o-ring - 119 2 fp13255 mounting clip 3 fp13314 screw, hex washer head, 8-18x5/8 4a fp18706 yoke, plastic 1” npt 4b fp13708 yoke, 3/4” brass fp13708-40 yoke, 1” sweat fp13708-45 yoke, 3/4” sweat fp18706-02 yoke, ...

Page 14

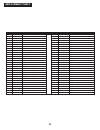

14 replacement parts :.

Page 15

Replacement parts : 15 control valve assembly item no. Part no. Description item no. Part no. Description 1 fp19328 2510 valve body 1" fp12090 3.5 gpm dlfc button 2 fp10757 end spacer fp12091 4.0 gpm dlfc button 3 fp10545 seal ring fp12092 5.0 gpm dlfc button 4 fp11451 spacer fp12408 7.0 gpm dlfc bu...

Page 16

16 replacement parts :.

Page 17

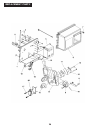

17 replacement parts : power head assembly no. Part no. Description 1 fp40264 back plate 2 fp17967 fitting, liquid tight 3 fp17845-02 pin, hinge 4 fp10300 screw 5 fp41062 3200nt timer assembly 6 fp60219-02 cover assembly, black w/ clear window 7 fp15742 screw cover 8 fp12576 cam, drive stf518 9 fp10...

Page 18

18 replacement parts : safety float assembly item no. Part no. Description 1 ch4650-01 474 safety elbow 3/8" 2 ch4655 474 .5 gpm flow control 3 ch4615 elbow locking clip 4 ch4640-32 474 float assembly 32" w/ grommets 5 ch4500-48 474 aircheck assembly 1/2" x 48" 6 ch4600 474 safety brine valve w/ 3/8...

Page 19: Blank

19 blank.

Page 20

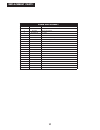

Capacity & physical specifications : 1 all isp water conditioners are pre-factory set at medium salting. Note: influent waters must be at least 3 gpg hardness and 80 tds. A calcite or corsex unit may be needed for correct operation. 2 iron removal may vary depending on form of iron, ph and other loc...