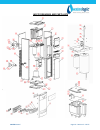

WaterLogic WL270 Service Manual

WL270 Manual

Page 12 – Revision 2‐2‐2017

SERVICE REQUIREMENTS

WARNING!

Read and understand the contents of this manual before attempting to service

WL270 Water Treatment System. Failure to follow the instructions in this manual could

result in death, serious personal injury, or severe property damage. Only trained and

qualified technicians should attempt to install, maintain, or service Waterlogic Equipment.

1. Visually inspect all electrical and water connections for signs of wear or damage.

DANGER!

HIGH VOLTAGE ELECTRICAL HAZARD. Unplug before inspection and service.

2. Waterlogic recommends changing the UV Lamp Assembly and the UV Lamp Wiring Harness must

be replaced every 12 months.

WARNING!

ULTRAVIOLET RADIATION. Protect your skin and eyes against ultraviolet rays.

Never look directly at an operating UV light. Disconnect before removing UV Lamp.

CAUTION!

UV LAMPS ARE HAZARDOUS. Lamps are considered Hazardous Waste and must

be disposed of accordingly. Refer to Product MSDS sheet for details.

3. Clean the Quartz Sleeve that surrounds the UV lamp with a non‐abrasive cloth, descaling

solution, or ultrasonic bath if needed when changing UV Lamps.

CAUTION!

UV SYSTEM IS FRAGILE. Never handle the UV lamp or Quartz Sleeve with bare

hands. UV Lamp and quartz sleeve must be free of oils and contaminants to ensure proper

operation. Use a soft non‐abrasive cloth to clean.

4. Inspect the Quartz Sleeve O‐ring for wear or damage and replace as necessary.

NOTE:

When replacing the UV Lamp the UV Lamp

wiring harness must also be replaced.

NOTE:

The Glow Starter shown may appear blackened

which is normal.