- DL manuals

- Watkiss

- Printer Accessories

- Vario

- Operating Manual

Watkiss Vario Operating Manual

Summary of Vario

Page 1

Operating manual is sue 3.

Page 3: Contents

Contents welcome..............................................1 quick start ..........................................5 control panel ......................................9 friction bins .....................................27 slimvac bins ...................................33 suction bins ...........

Page 5: Welcome

1 welcome congratulations, you have just purchased the very finest of collators, the watkiss vario. Your vario has been designed to make collating efficient, productive and above all, easy. About your manual this operating manual (issue 3) covers machines fitted with a gui (graphical user interface)...

Page 6

2 emergency stop the emergency stop button should only be used when an immediate stop of the machine is required. Under normal circumstances the machine should be stopped by touching the stop button on the control panel. If the emergency stop button is used, the collator will not restart until the b...

Page 7

3 switched off it retains the control panel settings in memory. Getting help we are confident that your vario will give many years of trouble-free production. If you have any queries or prob- lems, in the first instance please refer to the problem solving section in this book. Should you require fur...

Page 8: This Page Is

4 this page is intentionally blank.

Page 9: Quick Start

5 1 quick start this section is intended only as a brief operating guide. Detailed operating procedures are included in subse- quent chapters. Plug the collator into a mains supply of the correct voltage. Switch on the mains on/off switch. Operating the touch screen in normal use, the touch-screen c...

Page 10

6 there are also six ‘control’ buttons along the top of the screen. To display help text about any of the machine’s functions, touch help and then touch the required button. Tip load the default template to return the control panel to its default factory settings: • touch end job • touch load & save...

Page 11

7 loading the bins with paper remove any unwanted paper from the bins and press inch to check that there is no paper left in the conveyor from the previous job. Touch end job to tell the vario that the previous job has finished. The job should be organised either with the sheets face uppermost, and ...

Page 12

8 slimvac bins • initially set the tray height lever to its mid position • angle the suction feeder down • set the corrugation adjustment (on the feeder) to the mid-position suction bins • initially set the edge flick control to the mid position. Stacker adjust the stacker for paper size. Starting t...

Page 13: Control Panel

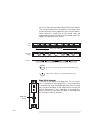

9 2 control panel your vario will be fitted with a gui (graphical user interface) control panel. The control panel has an 8.2" colour touch-screen, which offers a user-friendly interface for operators. There are start and stop buttons mounted on the control panel’s frame, these buttons are also repe...

Page 14

10 ‘control’ buttons there are six main ’control’ buttons listed across the top of the screen: start/stop the button is used to start the machine. When the machine is running, this button changes to which stops the machine. These are duplicated by the start/stop buttons above the touch screen. Inch ...

Page 15

11 5 seconds, the conveyor continues to run. The pause time can be altered on the machine options page. End job touch end job when you want to set the machine up for a new job, or alter an existing job. When a job is loaded, some of the machine settings cannot be changed, to prevent accidental chang...

Page 16

12 some sections of help text have a ’right’ arrow next to them. This indicates that there is more text available, explaining a related function in more detail. Touch the ’right’ arrow to view this text. A ’left’ arrow will then also appear: touch this to return to the previous text. When you are vi...

Page 17

13 errors in other modules are indicated in red. C touching c resets the set counter to 0. Sph sph shows the actual production speed of the vario, in sets per hour. The production speed is affected by paper size, online finishing equipment and the job setup. Mimic diagram.

Page 18

14 the ‘basic’ window the basic window contains settings that regularly need to be altered when setting up a new job. Sets per hour sets per hour allows the production rate of the vario to be set. This is automatically limited according to the machine configuration. Auto: selecting auto allows the v...

Page 19

15 if you are running mixed stocks on friction bins, individual air taps on each bin allow the air to be independently controlled. Preset preset is used if an exact number of sets are required. Touch preset and enter the number of sets required on the number pad. The counter in the main area of the ...

Page 20

16 the ‘advanced’ window the advanced window allows advanced machine set- tings to be altered. These settings may be altered to optimise the quality and productivity of a job. Drive speed drive speed alters the drive speed of the conveyor rollers and therefore the speed at which the sheets exit the ...

Page 21

17 if an offset is required, it is usual for the bottom sheet of the set to lead: select a negative offset when feeding to the rear of the vario and a positive offset when feeding to the front of the vario. A small offset can make jogging more effective when using a booklet maker. Detector position ...

Page 22

18 turn should reduce errors during the job. The default value is 186.2mm (7.35") during the test set, thereafter the feed length is automatically set to suit the paper size. Auto: touch auto to set the clutch feed length to the default value of 186.2mm (7.35"). Short: short will decrease the clutch...

Page 23

19 the ‘batch’ window the batch window allows sets to be grouped into batch- es, with an action at the end of each batch (stop, pause, oscillate or insert sheets). ‘batch’ window..

Page 24

20 number of sets touch number of sets to enter the number of sets in each batch. Entering 0 on the keypad will turn the batch mode off. Inserts inserts allows sheets from the top bin and/or bottom bin to be inserted at the beginning or end of each batch. If the inserted sheet is not part of the job...

Page 25

21 when feeding to the rear of the collator, select bottom to feed a sheet from the bottom bin with the last set of each batch. The inserted sheet will be at the bottom of the batch pile, as the backing board for a pad for example. Oscillate oscillate , when selected from the batch window, off- sets...

Page 26

22 the ‘finishing’ window the finishing window controls the settings for the book- let maker and trimmer. Paper size touch paper size to alter the settings of the booklet maker and trimmer to suit the input paper size. Re-ref: if you suspect the booklet maker or trimmer adjustment system is not cali...

Page 27

23 stitch and fold the position of the stitch and fold can be offset relative to the centre of the paper. Stitch and fold allows this position to be adjusted up to 20mm in either direction, in increments of 0.2mm. Stitch: touching stitch opens a choice of stitch op- tions. This window allows sheets ...

Page 28

24 stitch delay: increasing the stitch delay value will cause a delay between the set arriving on the stitch latch and it being stitched. This allows more time for the sheets to settle. The default delay is 1ms. Pre fold jogging the pre fold jogging window has options to alter the way sets are jogge...

Page 29

25 the ‘load & save’ window the load & save window allows job settings to be saved and reloaded at the touch of a button. Each job is given a name, and the jobs are listed on the screen. To select a job, highlight it by either touching it or by using the up and down arrows. Save touch save to save t...

Page 30

26 enter the new job name and then touch ok or close . The original job is unchanged. If the job name is not changed before touching ok or close , the job will be saved with the current name, suffixed by an asterisk. Job details touching job details shows the settings for each saved job. Select the ...

Page 31: Friction Bins

27 3 friction bins each vario tower may have any number of friction feed bins between 1 and 16. Additional bins can be added if required even after the machine has been installed. For operation of suction and slimvac bins please refer to the relevant chapters. Bin controls and indicators feed bins a...

Page 32

28 for on-line booklet making at the rear of a bench top machine, use method 1. When using the vario rear corner stapler, use method 2, with the corner to be stapled loaded outermost. Tray extenders for large sheet sizes (over a4, 8½ x 11") or when running a4 (a4, 8½ x 11") portrait it will be neces...

Page 33

29 loading the bins slide the stock into the bin between the sidelays. Push in the sidelays to centralise the paper in the bin and so that they hold the paper securely. Switching bins on & off before a test set is produced, individual bins will auto- matically switch on and off as they are loaded an...

Page 34

30 moving the lever to its highest position disengages the separator. This position is used for the improved feeding of heavy cardstocks. Tray pressure increasing the tray pressure gives the feed wheels greater force on the paper; too much will result in double feeds and increases the possibility of...

Page 35

31 air. Moving the lever towards you so that it is parallel with the sidelay shuts off the air. Too much air into the side of the stack can cause the paper to skew as it feeds. Any bins that are not being used should have the air tap shut off on the sidelay to preserve overall system air. Remember t...

Page 36

32 particularly heavy or opaque stock such as a straw board backing sheet may cause the bin sensor to go ’over- range’. This means that the sheet is too optically dense for the sensor to ’see’ through it. Double feeds will not be detected but misses, trailing sheets and jams will be detected as norm...

Page 37: Slimvac Bins

33 4 slimvac bins each vario tower may have any number of slimvac feed bins between 1 and 16. Additional bins can be added if required even after the machine has been installed. For operation of suction and friction bins please refer to the individual chapters. Bin controls and indicators feed bins ...

Page 38

34 1. Load the sheets face up and with the first page in the uppermost bin to give face up de- livery to the rear or face down delivery to the front. 2. Load the sheets face down and with the first page in the bottom bin to give face down deliv- ery to the rear or face up delivery to the front. For ...

Page 39

35 incorrect usage may result in either misfeeds or double feeds. Loading the bins place a full stack of paper between the two sidelays in the base of the tray. Maximum capacity is achieved when the paper is slightly below the top of the sidelays. Slide the sidelays inwards to centralise the paper. ...

Page 40

36 or when is touched after the machine stops for any reason. Switching bins on & off before a test set is produced, individual bins will auto- matically switch on and off as they are loaded and unloaded. Bins can also be manually selected by pressing the red button alongside the bin. In addition, l...

Page 41

37 types and should be used as a starting point if in doubt for initial running. Feeder angle the angle between the feeder and the paper can be adjusted to allow the feeding of particularly heavy and/or curled stocks. Adjustment is made using the knob on the left hand side of the suction feeder. Tur...

Page 42

38 bin linking if required, two or more feed bins may be linked to operate as a single bin. When one runs out of stock, the next bin in the linked group will automatically take over. This allows reloading without stopping the machine. Bin linking can only be enabled when the bins are unlocked i.E. W...

Page 43

39 paper condition recommended settings standard settings • suction feeder angled down • tray height in mid-position • sheet corrugation in mid-position heavy or rigid stock heavy or rigid stock or board may be unable to bend sufficiently to meet the suction feeder in its lower position. • raising t...

Page 44

40 stock curling up the upward curl means the tray height detector will ‘see’ the paper before it is close enough to the feeder. • raise the tray height to lift the paper stack closer to the feeder. Lightweight porous papers the feeder may suck through one sheet and onto the next, resulting in doubl...

Page 45: Suction Bins

41 5 suction bins each vario tower may have any number of suction feed bins between 1 and 8. Additional bins can be added if required even after the machine has been installed. For operation of slimvac and friction bins please refer to the individual chapters. Bin controls and indicators feed bins a...

Page 46

42 the front of the machine and run parallel with the manifold. The suckers produce the corrugation in the sheet which ensures effective sheet separation (see x-section below). Whilst doing this, check that all the sucker cups are undamaged and that they are correctly seated (see p.75). Repeat this ...

Page 47

43 loading loading sequence there are two loading methods. Which one you use will depend upon the job in question and whether the sets are delivered to the front or rear of the machine. 1. Load the sheets face up and with the first page in the uppermost bin to give face up de- livery to the rear or ...

Page 48

44 the stack is loaded neatly and square, and then place the magnetic sidelays on all three sides. Make sure that the loaded bins are selected (remember that the bins are automatically selected as you load them, before you run the test set). Set the drive speed to 80%, the air separation to about 30...

Page 49

45 loading the default template will switch on all loaded bins. Remember that bins cannot be switched on or off when the system is locked (touch end job if necessary). Sensor overrange sensor overrange is indicated after the test set by a slow flashing red light on the bin in question. Particularly ...

Page 50

46 will raise the tray height, whilst turning it in the - direction will lower the tray height. Removing the outer edge flicks under some circumstances, especially when collating very light weight and flimsy paper, the edges of the sheets may catch on the outer edge flicks and become creased. These ...

Page 51

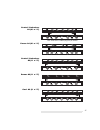

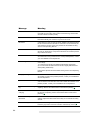

47 coated / carbonless a4 (8½ x 11") porous a4 (8½ x 11") coated / carbonless a3 (11 x 17") porous a3 (11 x 17") card a3 (11 x 17") . Note: under some conditions plugs may be omitted.

Page 52: This Page Is

48 this page is intentionally blank.

Page 53: Bench Base

49 6 bench base three different bases are available for the vario, a bench base, an oscillating bench base and a floor base. If your machine is fitted with an oscillating bench base, please refer to section 7. If your machine is fitted with a floor base, please refer to section 8. Setting up the sta...

Page 54

50 of which method is used will depend upon the collating task in question. Sheet offset separation by offsetting a single sheet in the set, the sets can be efficiently separated without any reduction in speed. Two offset sidelays are supplied with the straight stacker. The bin offset sidelay should...

Page 55

51 also be positioned at the rear, in which case it must be supported by the edge of the work bench. The deflector lever at the front of the stacker base should be pivoted upwards for delivery to the rear, and pivoted downwards for delivery to the front. Positioning the stacker tray at the rear disc...

Page 56

52 stacker full sensor when the stacker is full the collator will automatically stop and stacker full will be displayed on the control panel. The sensor only operates when feeding to the front of the collator. Paper guides there are paper guides at the delivery outfeed both at the front and at the r...

Page 57

53 deflector strip a deflector strip is provided to aid the stacking of large flimsy sheets such as ncr. As flimsy or curly sheets enter the receiving tray they may ride up against the endlay causing an untidy stack. To remedy this, clip the deflector strip to the underside of the grey tube (see abo...

Page 58: This Page Is

54 this page is intentionally blank.

Page 59: Oscillating Bench Base

55 7 oscillating bench base three different bases are available for the vario, a bench base, an oscillating bench base and a floor base. If your machine is fitted with a bench base, please refer to section 6. If your machine is fitted with a floor base, please refer to section 8. The oscillating ben...

Page 60

56 the sidelays should be positioned so that their outer edge aligns with the inner edge of the guide mark. The dotted lines in the illustration indicate the correct alignment of the sidelay with the guide mark. Straight stacking for straight stacking the appropriate solid guide marks are used for b...

Page 61

57 non-standard paper sizes for non-standard paper sizes a different method is re- quired. Straight stacking take a few sheets of the paper and align them centrally between the guide marks for the next standard size up. Position the sidelays on the base leaving a 5mm (¼”) gap between the inside corn...

Page 62

58 paper delivery direction lever paper can be delivered to the front or the rear of the machine. The direction is selected using the paper deliv- ery direction lever. This has three positions, the top position delivers paper to the oscillating tray. The bottom position delivers paper to the rear of...

Page 63: Floor Base

59 8 floor base three different bases are available for the vario, a bench base, an oscillating base and a floor base. If your machine is fitted with a bench base, please refer to section 6. If your machine is fitted with an oscillating bench base, please refer to section 7. The floor base is requir...

Page 64

60 setting up the floor base front feedout conveyor the front feedout conveyor has two positions, raised or lowered. It is secured in its raised position by a lever at the front of the base (see photo p.59). To lower, simply turn the lever clockwise. To raise, lift the conveyor up and turn the lever...

Page 65

61 air blast when stacking large and/or flimsy sheets, such as car- bonless paper, air can be directed into the jogger to aid neat stacking. The volume of air is controlled by an air tap (see p.59). Turning the tap to the right provides more air, and turning to the left reduces the air. When not usi...

Page 66

62 feeding into a jogger at the front ensure the divert catch tray (b) is fitted correctly. It should hang vertically down between the base back bar and central shaft under the conveyor. Position and set up the jogger in front of the floor base (see photo p.65). Push the rear deflector lever up to m...

Page 67

63 rear feedout conveyor (optional) the rear feedout conveyor is an option to allow rear delivery from a floor base into a jogger. Feeding to the rear when delivering to the rear of the floor base, the rear deflector lever should be pushed down so that the fingers (a) deflect the paper to the rear. ...

Page 68

64 button functions : starts the collator : stops the collator : decreases the drive speed : increases the drive speed : inches the conveyor note if using the remote control to operate a stitch fold unit off-line, the button functions are different. See the stitch fold operating manual for details t...

Page 69: Joggers

65 9 joggers there are two types of jogger available for the vario, the x-jogger and the straight jogger. The x-jogger straight or offset stacks whilst the straight jogger is used when set separation is not required. X-jogger setting up the jogger position the x-jogger under the collator as shown. C...

Page 70

66 adjust the position of the support posts by twisting anti- clockwise to release, sliding to about 5mm (¼") from the edge of the stack and then re-tightening. Adjust the position of the x-jogger itself. Slide it further in or out so that the back edge of the stack is level with the outfeed of the ...

Page 71

67 plug the jogger into the socket on the underside of the floor base via the interconnection cable. The cable will only fit in one of the sockets (see p.59). Adjust the direction of the air blast towards the bottom edge of the stack. For large sheet sizes it will be necessary to use the extension t...

Page 72

68 jogging off-line the straight jogger can also be used off-line. Connect the jogger to the mains and switch on both the mains on/off switch and the local control switch..

Page 73: Rear Corner Stapler

69 10 rear corner stapler the vario rear corner stapler (rcs) is an optional ac- cessory that may be fitted onto your vario. This unit fits onto the rear of the collator. Loading the collator the sheets should be loaded face down and with the top page in the bottom bin. The corner to be stapled shou...

Page 74

70 • ensure that the rcs bypass lever is in the down position (in the up position sets will still be delivered to the rear of the collator, but will feed out below the rcs). Adjusting the collator move the set divert lever to the upper position (for delivery to the rear). Error messages various erro...

Page 75

71 • push the red spring firmly to the left until it clicks into place on the cartridge. It is essential that the cartridge is securely held each staple cartridge holds 5,000 staples. When it is nearly empty, staples low is displayed on the control panel. This operates from an inbuilt counter, there...

Page 76: This Page Is

72 this page is intentionally blank.

Page 77: Maintenance

73 11 maintenance service interval it is recommended that your vario is serviced by an approved watkiss engineer at six month intervals. Please contact your watkiss supplier or the manufacturer for further details. Operator maintenance as with all machinery, your vario will benefit from periodic cle...

Page 78

74 replacement interval will depend upon the usage level and the type of papers used. • remove the feed wheel shaft by pushing it to the left against the spring pressure and lifting the right end clear. • locate the separator and lift it out vertically. • clean or replace the separator as required. ...

Page 79

75 • replace the shaft. • select cleaning in the menu, user settings win- dow and press the red button on the bin controls to turn the feed wheel shaft. Visually check that each wheel runs true. To straighten a wheel, gently hold a flat edge against the wheel whilst it turns. Suction feed bins sucke...

Page 80

76 • press and hold the red button on the bin controls to drop the manifold for access. • whilst continuing to hold the red button, deselect cleaning in the menu, user settings window so that the manifold remains in the down position. • remove the sucker cups, inspect, and replace any that appear wo...

Page 81

77 • insert the new cable, noose end first, into the hole in the shaft and pull through (note that the entry hole is larger than the exit hole). • ensure that the cable is wrapped around the shaft to match the cable on the other side of the tray. Fitting the shear pin • open the noose in the end of ...

Page 82: This Page Is

78 this page is intentionally blank.

Page 83: Problem Solving

79 a1 problem solving as far as possible the vario has been designed to be self-explanatory. In most cases problems or errors will be identified on the control panel. The following is a further guideline to help solve any problems. If a problem persists, please call the watkiss service department or...

Page 84

80 friction feed problems problem cause solution double feeds too much tray pressure reduce by moving handle in by one notch at a time (see p.30) too little separation pressure increase by moving the lever down by one notch at a time (see p.29) insufficient air separation increase the value of air b...

Page 85

81 trailing feed (on a trailing sheet the machine stops immediately. You need to look carefully to identify which of the following is the cause. The faulty set can be inched through by touching and holding inch ) late feeding double sheet treat as double feed above slow feeding sheet treat as miss f...

Page 86

82 miss feeds not enough air separation increase the value of air blow in the basic window too much sheet corrugation reduce the sheet corrugation (see p.36) the tray is too low raise the tray height (see p.37) heavy and/or rigid sheets raise the angle of the suction feeder (see p.37) paper has curl...

Page 87

83 suction feed problems problem cause action double feeds incorrectly positioned sucker plugs check the positioning of the plugs (see p.41) porous paper refer to section on porous paper (see p.44) too little edge flick increase the edge flick depth by lowering the control (see p.42) the tray is too...

Page 88

84 ’bin # lift error' message and small green light is flashing quickly (• • • •) too much paper has been loaded into the bin (note that the grey button will not raise or lower the tray) remove the stock and reload a smaller quantity: sheet size to: max load 340x520mm 100mm 13¼"x20¼" 4" 364x520mm 88...

Page 89

85 replacing fuses your vario is fitted with two fuses at the mains input. If either of these fail the machine will not power up. • unplug the mains input lead and open the flap on the fuse holder. • pull out each fuse casing in turn and check the fuse. • replace if necessary with a fuse of the corr...

Page 90

86 bin # lift error (suction feed bin only) too much paper has been loaded into the bin (note that the grey button will not raise or lower the tray). Remove the stock and reload a smaller quantity. Bin # miscal a feed/sensor error has occurred during the test set. The bin will recali- brate automati...

Page 91

87 cannot start tray empty one of the switched-on bins was empty when was touched. Fill the bin with paper and touch again. Cannot start trim axis changing the trim axis (size adjustment) of the trimmer is in the process of adjusting. Wait for the trimmer to finish before pressing . Cannot start wid...

Page 92

88 power fail the mains supply has been interrupted. Switch the collator off and on again. Psu voltage error: there is a voltage error. Contact your local watkiss service department. Rear cover open check the rear cover/guard is fitted and is actuating the safety switch correctly. Remote stop the co...

Page 93

89 staple head error there has been a staple head error in the bookmaster. The heads should self-clear. If they do not, turn the bookmaster off and on again to free the head. If this does not work contact your local watkiss service department. Staple heads offline the staple heads are not selected o...

Page 94: This Page Is

90 this page is intentionally blank.

Page 95: Advanced Functions

91 a2 advanced functions there are several advanced functions that can be selected on the vario. These functions should only be used if the standard adjustments detailed in the previous chapters fail to give the desired effect. To access the advanced functions, touch menu on the control panel. User ...

Page 96

92 length: sheet length as measured by the emitter/sensor during the test set. Normally zero before the test set has bee n completed. A small variation from bin to bin in the reported sheet size is normal. Ref: the amount of light passed through the sheet by the emitter/sensor on the test set. The h...

Page 97: Specifications

93 a3 specifications intended use the watkiss vario is intended for the collation of materials as specified below operating conditions 10-35°c at 35-85% relative humidity gui control panel dimensions (w,d,h): 245, 25, 205mm; (3.3 kg), 9.6, 1.0, 8.1"; (7.3 lb) weights include control panel, cable and...

Page 98

94 suction feed bin rel. D configuration: up to 8 bins per tower production: up to 4,000 feeds per hour capacity: 100mm (4") for stock up to 340mm (13¼") wide 88mm (3½") for stock over 340mm (13¼") wide sheet sizes: 130 x 160mm to 364 x 520mm, 5¼ x 6¼" to 14¼ x 20¼" stock range: 40 to 300gsm, 11# bo...

Page 99

95 x-jogger production: straight stacking up to 7,200 sets per hour offset stacking up to 3,500 sets per hour capacity: 100mm, 4" sheet sizes: straight stacking 130 x 160mm to 364 x 520mm, 5¼ x 6¼" to 14¼ x 20¼" offset stacking 148 x 210mm to 364 x 520mm, 6 x 8¼" to 14¼ x 20¼" sensing: optical stack...

Page 100: This Page Is

96 this page is intentionally blank.

Page 101: Declaration of Conformity

97 a4 declaration of conformity manufacturer’s name watkiss automation limited manufacturer’s address watkiss house blaydon road sandy, bedfordshire, uk. Sg19 1rz declares that the product product name watkiss vario product number wa/var/2450 onwards (230v versions only) product variants friction fe...

Page 102: This Page Is

98 this page is intentionally blank.

Page 103: Index

Index 99 a access level 91 action buttons end job 11 help 11 inch 10 menu 12 start/stop 10 test set 11 advanced functions 91 access level 91 cleaning 92 current language 91 darker 91 feeder info 91 inter tower distance 92 lighter 91 machine options 92 measurement 92 network settings 92 pause time 92...

Page 104: Index

Index 100 difficult papers slimvac 38 suction 44 divert 15 double detection 17 double jog 23 drive speed 16 e edge flick, suction bins 42, 46, 83 emergency stop button 2 end job 11 f feed clutch 17 feed wheels, friction bins 74 feeder angle, slimvac bins 37, 82 feeder info 91 finishing window book t...

Page 105: Index

Index 101 l language 91 lighter 91 load 26 load and save window delete 26 job details 26 load 26 padlock symbol 26 save cancel 25 replace 25 save new 25 view of job list 26 a->z 26 by use 26 loading the bins 27, 33, 43 locking jobs 26 m machine options 92 mains input 2 mains on/off switch 2 maintena...

Page 106: Index

Index 102 staple counter 71 rear feedout conveyor 63 rear guard 1 remote control 63 repairing overloaded suction trays 76 re-ref 22 restart batch 21 rubber endlays, slimvac bins 34 s safety 1 save 25 screen contrast 91 separator pressure, friction bins 80, 81 sets per hour 14 sheet corrugation, slim...

Page 107: Index

Index 103 u units of measurement 92 unlocking jobs 26 user settings 91 v view of job list 26 w window system 9 x x-jogger 65 jogging adjustment 66 problem solving 84 setting up the jogger 65 straight stack liner 66.

Page 108: Index

Index 104 this page is intentionally blank.

Page 110

Watkiss automation limited watkiss house, blaydon road, middlefield ind. Est., sandy, bedfordshire. Sg19 1rz england. Tel: +44 (0)1767 682177 fax: +44 (0)1767 691769 email: info@watkiss.Com web: http://www.Watkiss.Com operator manual, vario, english issue 3, march 2001. Part no. 960-341.