- DL manuals

- WEG

- Power Supply

- CFW-11

- User Manual

WEG CFW-11 User Manual

Summary of CFW-11

Page 2

03/2009 series: cfw-11 language: english document: 10000280997 / 00 models: 142...211 a / 220...230 v 105...211 a / 380...480 v frequency inverter manual.

Page 3

2 revision description chapter 1 first edition - summary of revisions.

Page 4

Index chapter 1 safety instructions 1.1 safety warnings in the manual .....................................................................................................1-1 1.2 safety warnings in the product .............................................................................................

Page 5

Index chapter 4 keypad and display 4.1 integral keypad - hmi-cfw11 ....................................................................................................4-1 4.2 parameters organization ........................................................................................................

Page 6

Safety instructions 1-1 1 safety instructions this manual provides information for the proper installation and operation of the cfw-11 frequency inverter. Only trained and qualified personnel should attempt to install, start-up, and troubleshoot this type of equipment. 1.1 safety warnings in the man...

Page 7

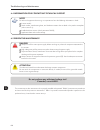

Safety instructions 1-2 1 1.3 preliminary recommendations danger! Only trained personnel, with proper qualifications, and familiar with the cfw-11 and associated machinery shall plan and implent the installation, starting, operation, and maintenance of this equipment. The personnel shall follow all ...

Page 8

Safety instructions 1-3 1 attention! Operation of this equipment requires detailed installation and operation instructions provided in the user's manual, software manual and manual/guides for kits and accessories. Only user's manual is provided on a printed version. The other manuals are provided on...

Page 9

Safety instructions 1-4 1.

Page 10

General instructions 2-1 2 general instructions 2.1 about the manual this manual exposes how to install, to start-up in v/f (scalar) mode, the main characteristics and shows how to troubleshoot the most common problems of the cfw-11 inverter series frame size e models. It is also possible to operate...

Page 11

General instructions 2-2 2 dc bus: inverter intermediate circuit; dc voltage obtained from the rectification of the ac input voltage or from an external power supply; feeds the output inverter bridge with igbts. Power modules u, v, and w: set of two igbts of the inverter output phases u, v, and w. I...

Page 12

General instructions 2-3 2 plc: programmable logic controller. °c: celsius degree. °f: fahrenheit degree. Ac: alternated current. Amp, a: ampères. Cfm: cubic feet per minute; unit of flow. Cm: centimeter. Dc: direct current. Ft: foot. Hp: horse power = 746 watts; unit of power, used to indicate the ...

Page 13

General instructions 2-4 2 2.3 about the cfw-11 the cfw-11 frequency inverter is a high performance product designed for speed and torque control of three- phase induction motors. The main characteristic of this product is the “vectrue” technology, which has the following advantages: scalar control ...

Page 14

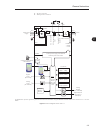

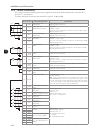

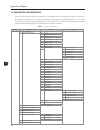

General instructions 2-5 2 figure 2.1 - block diagram for the cfw-11 analog inputs (ai1 and ai2) flash memory module digital inputs (di1 to di6) control power supply and interfaces between power and control usb pc power control three-phase rectifier dcl+ dcl- motor u/t1 r/l1 s/l2 t/l3 v/t2 w/t3 inve...

Page 15

General instructions 2-6 2 a – keypad b – control rack cover c – cc11 control board d – flash memory module e – control accessory module (refer to the section 7.2) f – anybus-cc accessory module (refer to the section 7.2) g – bottom front cover h – heatsink fan i – mounting supports (for through the...

Page 16

General instructions 2-7 2 usb connector usb led off: no usb connection on/flashing: usb communication is active status led green: normal operation with no fault or alarm yellow: alarm condition flashing red: fault condition 1 2 3 2.4 identification labels for the cfw-11 there are two nameplates on ...

Page 17

General instructions 2-8 2 1 figure 2.5 - location of the nameplates nameplate affixed to the side of the heatsink nameplate under the keypad 1 2.

Page 18

General instructions 2-9 2 inverter model a v ailable option kits (can be inst alled in the product from the f a ct or y) refer to the cfw -11 series frame size e model list in the chapter 8, where the technical specifications of the inverters are also presented refer to chapter 8 to check option ki...

Page 19

General instructions 2-10 2 2.5 receiving and storage the cfw-11 frame size e models are supplied packed in wooden boxes. There is an identification label affixed to the outside of this package, the same one that is affixed to the side of the cfw-11 inverter. Follow the instructions below to remove ...

Page 20

Installation and connection 3-1 3 installation and connection this chapter provides information on installing and wiring the cfw-11. The instructions and guidelines listed in this manual shall be followed to guarantee personnel and equipment safety, as well as the proper operation of the inverter. 3...

Page 21

Installation and connection 3-2 3 attention! When arranging two or more inverters vertically, respect the minimum clearance a + b (figure 3.2) and provide an air deflecting plate so that the heat rising up from the bottom inverter does not affect the top inverter. Attention! Provide conduit for phys...

Page 22

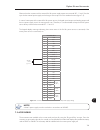

Installation and connection 3-3 3 figure 3.2 - free spaces for ventilation, above, below, at the front and at the sides of the inverter tolerance: ±1.0 mm (±0.039 in) a b c d model mm (in) mm (in) mm (in) mm (in) cfw11 0142 t 2 100 (3.94) 130 (5.12) 20 (0.78) 40 (1.57) cfw11 0180 t 2 150 (5.91) 250 ...

Page 23

Installation and connection 3-4 3 3.1.3 cabinet mounting there are two possibilities for mounting the inverter: through the wall mounting or flange mounting (the heatsink is mounted outside the cabinet and the cooling air of the power module is kept outside the enclosure). The following information ...

Page 24

Installation and connection 3-5 3 figure 3.3 - repositioning the mounting supports 6 5 4 3 2 1 3.1.4 installation of the inverter hoisting eyes two hoisting eyes for the inverter lifting, which are mounted at the inverter sides (rear part), are supplied. By inverting their position, as showed in the...

Page 25

Installation and connection 3-6 3 3.1.5 installation of the inverter with nema1 kit (optional, cfw11xxxxtxon1) on a wall fixing holes position and diameter according to the figure 3.1. External dimensions of the inverter with nema1 kit according to the section 8.4. Fasten the inverter. Install the n...

Page 26

Installation and connection 3-7 3 figure 3.7 - bottom front cover removal in order to get access to the power terminal block, the bottom front cover must be removed, as showed in the figure 3.7. 2 1 at the cfw11 0180 t 2 o n1, cfw11 0211 t 2 o n1, cfw11 0180 t 4 o n1 and cfw11 0211 t 4 o n1 inverter...

Page 27

Installation and connection 3-8 3 3.1.7 removal of the cable passage plate when it is not necessary neither ip20 nor nema1 protection degree, the cable passage plate may be removed in order to make the inverter electric installation easier. Remove the 4 m4 screws, according to the procedure presente...

Page 28

Installation and connection 3-9 3 3.2 electrical installation danger! The following information is merely a guide for proper installation. Comply with applicable local regulations for electrical installations. Danger! Make sure the ac power supply is disconnected before starting the installation. At...

Page 29

Installation and connection 3-10 3 3.2.2 power / grounding wiring and fuses attention! Use proper cable lugs for the power and grounding connection cables. Attention! Sensitive equipment such as plcs, temperature controllers, and thermal couples shall be kept at a minimum distance of 0.25 m (9.84 in...

Page 30

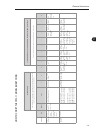

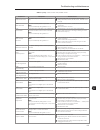

Installation and connection 3-11 3 table 3.2 - recommended wire size/ fuses - use only copper wire [75 ºc (167 °f)] model frame power terminal over- load class wire size fuse [a] fuse i 2 t [a 2 s] terminals bolt (wrench/screw head type) recommended torque n.M (lbf.In) mm 2 awg terminals cfw11 0142 ...

Page 31

Installation and connection 3-12 3 table 3.3 (a) - recommended cable lugs for power connections (cable gauges in mm²) wire size [mm 2 ] stud size manufacturer ring lug, p/n crimping (installation) tool p/n number of crimps 25 m5 hollingsworth rm 25 -5 h 6.500 1 tyco 33468 59975-1 1 m8 hollingsworth ...

Page 32

Installation and connection 3-13 3 table 3.3 (b) - recommended cable lugs for power connections (cable gauges in awg) wire size [awg/ kcmil] stud size manufacturer ring lug, p/n crimping tool p/n number of crimps 4 m5 hollingsworth r 410 h 6.500 1 burndy (fci) ya4cl2 dieless tool: my29-3 or y644 or ...

Page 33

Installation and connection 3-14 3 3.2.3.1 input connections danger! Provide a disconnect device for the input power supply of the inverter. This device shall disconnect the input power supply for the inverter when needed (for instance, during servicing). Attention! A contactor or another device tha...

Page 34

Installation and connection 3-15 3 3.2.3.1.1 it networks attention! In order to be able to use the frame size e cfw-11 inverter in it networks (neutral conductor not grounded or grounded via a high ohmic value resistor) or in corner-grounded delta systems, it is necessary to remove the rfi filter ca...

Page 35

Installation and connection 3-16 3 3.2.3.1.2 command fuses besides the rfi filter capacitors and the mov’s, the prt1 board also has 3 fuses for protecting the inverter command circuit. The prt1 board location is presented in the figure 3.13 (a). The location of the prt1 fuses is presented in the fig...

Page 36

Installation and connection 3-17 3 3.2.3.2.1 sizing the braking resistor the following application data shall be considered for the adequate sizing of the braking resistor: - desired deceleration time; - load inertia; - braking duty cycle. In any case, the effective current value and the maximum bra...

Page 37

Installation and connection 3-18 3 power supply thermostat braking resistor thermal relay control power supply contactor cfw-11 br dc+ figure 3.14 - braking resistor connection r s t note! Dc current flows through the thermal relay bimetal strip during braking. 3.2.3.2.2 installation of the braking ...

Page 38

Installation and connection 3-19 3 3.2.3.3 output connections attention! The inverter has an electronic motor overload protection that shall be adjusted according to the driven motor. When several motors are connected to the same inverter, install individual overload relays for each motor. Attention...

Page 39

Installation and connection 3-20 3 keep motor cables away from other cables (signal cables, sensor cables, control cables, etc.), according to table 3.5. The grounding system shall be well interconnected among the several installation locations such as the grounding points of the motor and the inver...

Page 40

Installation and connection 3-21 3 3.2.4 grounding connections danger! Do not share the grounding wiring with other equipment that operate with high currents (ex.: high power motors, soldering machines, etc.). When installing several inverters, follow the procedures presented in figure 3.17 for the ...

Page 41

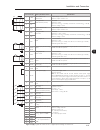

Installation and connection 3-22 3 figure 3.18 (a) - signals at connector xc1 - digital inputs working as 'active high' connector xc1 factory default function specifications 1 +ref positive reference for potentiometer output voltage:+5.4 v, ±5 %. Maximum output current: 2 ma 2 ai1+ analog input #1: ...

Page 42

Installation and connection 3-23 3 figure 3.18 (b) - signals at connector xc1 - digital inputs working as 'active low' connector xc1 factory default function specifications 1 +ref positive reference for potentiometer output voltage:+5.4 v, ±5 %. Maximum output current: 2 ma 2 ai1+ analog input #1: s...

Page 43

Installation and connection 3-24 3 the analog inputs and outputs are factory set to operate in the range from 0 to 10 v; this setting may be changed by using dip-switch s1. Figure 3.19 - connector xc1 and dip-switches for selecting the signal type of the analog inputs and outputs signal factory defa...

Page 44

Installation and connection 3-25 3 table 3.7 - minimum separation distances between wiring 4) the adequate connection of the cable shield is shown in figure 3.20. Figure 3.21 shows how to connect the cable shield to the ground. Figure 3.20 - shield connection 5) relays, contactors, solenoids or coil...

Page 45

Installation and connection 3-26 3 start/stop connector xc1 1 + ref 2 ai1+ 3 ai1- 4 - ref 5 ai2+ 6 ai2- 7 ao1 8 agnd (24 v) 9 ao2 10 agnd (24 v) 11 dgnd* 12 com 13 24 vdc 14 com 15 di1 16 di2 17 di3 18 di4 19 di5 20 di6 21 nc1 do1 (rl1) 22 c1 23 no1 24 nc2 do2 (rl2) 25 c2 26 no2 27 nc3 do3 (rl3) 28 ...

Page 46

Installation and connection 3-27 3 control connection #3 - 3 - wire start/stop function. Enabling the start/stop function with 3 wire control. Parameters to set: set di3 to start p0265=6 set di4 to stop p0266=7 set p0224=1 (dix) for 3 wire control in local mode. Set p0227=1 (dix) for 3 wire control ...

Page 47

Installation and connection 3-28 3 control connection #4 - forward/reverse. Enabling the forward/reverse function. Parameters to set: set di3 to forward p0265=4 set di4 to reverse p0266=5 when the forward/reverse function is set, it will be active either in local or remote mode. At the same time, th...

Page 48

Installation and connection 3-29 3 3.3 installation according to the european directive of electromagnetic compatibility the frame size e cfw-11 inverters have an internal rfi filter for the reduction of the electromagnetic interference. These inverters, when properly installed, meet the requirement...

Page 49

Installation and connection 3-30 3 3.3.2 standard definitions iec/en 61800-3: “adjustable speed electrical power drives systems” - environment: first environment: includes domestic premises. It also includes establishments directly connected without intermediate transformer to a low-voltage power su...

Page 50

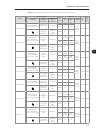

Installation and connection 3-31 3 table 3.9 - conducted and radiated emission levels and further information inverter model (with built-in rfi filter) without external rfi filter with external rfi filter conducted emission - maximum motor cable length radiated emission - without metallic cabinet ex...

Page 51

Installation and connection 3-32 3 table 3.10 - required rfi filters for unshielded motor cable installations and further information on conducted and radiated levels (1) the output filter is of the sinusoidal type, i.E., the motor voltage waveform is approximately sinusoidal, not pulsed as in the a...

Page 52

Keypad and display 4-1 4 keypad and display this chapter describes: - the operator keys and their functions; - the indications on the display; - how parameters are organized. 4.1 integral keypad - hmi-cfw11 the integral keypad can be used to operate and program (view / edit all parameters) of the cf...

Page 53

Keypad and display 4-2 4 1 2 3 cover for battery access press the cover and rotate it counterclockwise remove the cover 4 5 6 remove the battery with the help of a screwdriver positioned in the right side hmi without the battery install the new battery positioning it first at the left side 7 8 press...

Page 54

Keypad and display 4-3 4 run loc 1800rpm 12:35 menu 1800 rpm 1.0 a 60.0 hz installation: the keypad can be installed or removed from the inverter with or without ac power applied to the inverter. The hmi supplied with the product can also be used for remote command of the inverter. In this case, use...

Page 55

Keypad and display 4-4 4 table 4.1 - groups of parameters 4.2 parameters organization when the right soft key ("menu") is pressed in the monitoring mode, the display shows the first 4 groups of parameters. An example of how the groups of parameters are organized is presented in table 4.1. The number...

Page 56

First time power-up and start-up 5-1 5 first time power-up and start-up this chapter describes how to: - check and prepare the inverter before power-up. - power-up the inverter and check the result. - set the inverter for the operation in the v/f mode based on the power supply and motor information ...

Page 57

First time power-up and start-up 5-2 5 5.2 start-up the start-up procedure for the v/f is described in three simple steps by using the oriented start-up routine and the basic application group. Steps: (1) set the password for parameter modification. (2) execute the oriented start-up routine. (3) set...

Page 58

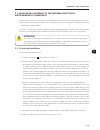

First time power-up and start-up 5-3 5 5.2.2 oriented start-up there is a group of parameters named ”oriented start-up” that makes the inverter settings easier. Inside this group, there is a parameter – p0317 – that shall be set to enter into the oriented start-up routine. The oriented start-up rout...

Page 59

First time power-up and start-up 5-4 5 figure 5.2 (cont.) - oriented start-up step action/result display indication 10 - if needed, change the value of p0296 according to the line rated voltage. To do so, press "select". This modification will affect p0151, p0153, p0185, p0321, p0322, p0323, and p04...

Page 60

First time power-up and start-up 5-5 5 step action/result display indication 1 - monitoring mode. - press “menu” (right soft key). Ready loc 0rpm 15:45 menu 0 rpm 0.0 a 0.0 hz 2 - group “00 all parameters” has been already selected. Ready loc 0rpm return 15:45 select 00 all parameters 01 parameter g...

Page 61

First time power-up and start-up 5-6 5 parameter name description setting range factory setting user setting p0100 acceleration time - defines the time to linearly accelerate from 0 up to the maximum speed (p0134). - if set to 0.0 s, it means no acceleration ramp. 0.0 to 999.0 s 20.0 s p0101 deceler...

Page 62

First time power-up and start-up 5-7 5 table 5.2 - main read only parameters parameter description setting range p0001 speed reference 0 to 18000 rpm p0002 motor speed 0 to 18000 rpm p0003 motor current 0.0 to 4500.0 a p0004 dc link voltage (ud) 0 to 2000 v p0005 motor frequency 0.0 to 300.0 hz p000...

Page 63

First time power-up and start-up 5-8 5 step action/result display indication 1 monitoring mode. - press “menu” (right soft key). Ready loc 0rpm 16:10 menu 0 rpm 0.0 a 0.0 hz 2 - group “00 all parameters” is already selected. Ready loc 0rpm return 16:10 select 00 all parameters 01 parameter groups 02...

Page 64

First time power-up and start-up 5-9 5 5.5 how to connect a pc notes! - always use a standard host/device shielded usb cable. Unshielded cables may lead to communication errors. - recommended cables: samtec: usbc-am-mb-b-b-s-1 (1 meter); usbc-am-mb-b-b-s-2 (2 meters); usbc-am-mb-b-b-s-3 (3 meters). ...

Page 65

Troubleshooting and maintenance 6-1 6 troubleshooting and maintenance this chapter: - lists all faults and alarms that may occur. - indicates the possible causes of each fault and alarm. - lists most frequent problems and corrective actions. - presents instructions for periodic inspections and preve...

Page 66

Troubleshooting and maintenance 6-2 6 fault/alarm description possible causes f006: imbalance or input phase loss mains voltage imbalance too high or phase missing in the input power supply. Note: - if the motor is unloaded or operating with reduced load this fault may not occur. - fault delay is se...

Page 67

Troubleshooting and maintenance 6-3 6 fault/alarm description possible causes f071: output overcurrent the inverter output current was too high for too long. Excessive load inertia or acceleration time too short. Settings of p0135, p0169, p0170, p0171, and p0172 are too high. F072: motor overload th...

Page 68

Troubleshooting and maintenance 6-4 6 fault/alarm description possible causes a130: anybus access error alarm that indicates an access error to the anybus-cc communication module. Defective, unrecognized, or improperly installed anybus-cc module. Conflict with a weg option board. A133: can not power...

Page 69

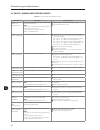

Troubleshooting and maintenance 6-5 6 6.3 solutions for the most frequent problems table 6.2 - solutions for the most frequent problems problem point to be verified corrective action motor does not start incorrect wiring connection 1. Check all power and control connections. For instance, the digita...

Page 70

Troubleshooting and maintenance 6-6 6 6.4 information for contacting technical support note! For technical support and servicing, it is important to have the following information in hand: inverter model; serial number, manufacturing date, and hardware revision that are listed in the product namepla...

Page 71

Troubleshooting and maintenance 6-7 6 table 6.3 - preventive maintenance maintenance interval instructions fan replacement after 50000 operating hours. (1) replacement procedure shown in figures 6.1 and 6.2. Keypad battery replacement every 10 years. Refer to chapter 4. Electrolytic capacitors if th...

Page 72

Troubleshooting and maintenance 6-8 6 fan cover locks release fan grill screws removal fan removal fan removal cable disconnection cable disconnection (a) cfw11 0105 t 4 model (a) cfw11 0105 t 4 model (b) cfw11 0142 t 2, cfw11 0180 t 2, cfw11 0211 t 2, cfw11 0142 t 4, cfw11 0180 t 4 and cfw11 0211 t...

Page 73

Option kits and accessories 7-1 7 option kits and accessories this chapter presents: the option kits that can be incorporated to the inverter from the factory: - braking igbt; - safety stop according to en 954-1 category 3; - external 24 vdc power supply for control and keypad. Instructions for the ...

Page 74

Option kits and accessories 7-2 7 figure 7.1 - location of the srb2 board in the frame size e cfw-11 inverters operation: 1. The safety stop function is activated by disconnecting the 24 vdc voltage from the safety relay coil (xc25:1(+) and 2(-); xc25:3(+) and 4(-)). 2. Upon activation of the safety...

Page 75

Option kits and accessories 7-3 7 observe that the inverters with the external 24 vdc power supply option use terminals xc1:11 and 13 as the input for the external power supply and no longer as an output as in the standard inverter (figure 7.2). In case of interruption of the external 24 vdc power s...

Page 76

Option kits and accessories 7-4 7 the code and model of each availabe accessory is presented in the table 7.2. The accessories can be ordered separately and will be shippe in an individual package containing the components and the manual with detailed instructions for the product installation, opera...

Page 77

Technical specifications 8-1 8 technical specifications this chapter describes the technical specifications (electric and mechanical) of the cfw-11 inverter series frame size e models. 8.1 power data power supply: voltage tolerance: -15 % to +10 %. Frequency: 50/60 hz (48 hz to 62 hz). Phase imbalan...

Page 78

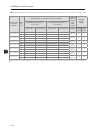

Technical specifications 8-2 8 note: (1) steady-state rated current in the following conditions: - indicated carrier frequencies. For operation with higher switching frequencies (carrier frequency) it is necessary to derate output current according to the tables 8.2 to 8.5. - surrounding air tempera...

Page 79

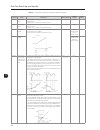

Technical specifications 8-3 8 (2) table 8.1 presents only two points of the overload curve (activation time of 1 min and 3 s). The complete information about the igbts overload for normal and heavy duty cycles is presented below. (a) igbts overload curve for the normal duty (nd) cycle (b) igbts ove...

Page 80

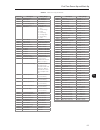

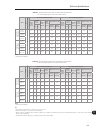

Technical specifications 8-4 8 (7) if the inverter is to be provided with this option, it should be specified in the intelligent identification code of the inverter. Table 8.2 - specifications of the cfw-11 series frame size e models for a switching frequency of 5 khz and ta=45 °c table 8.3 - specif...

Page 81

Technical specifications 8-5 8 table 8.4 - specifications of the cfw-11 series frame size e models for a switching frequency of 10 khz and ta=45 °c model frame number of power phases use with normal duty (nd) cycle use with heavy duty (hd) cycle rated output current (1) [arms] overload current (2) [...

Page 82

Technical specifications 8-6 8 8.2 electrical / general specifications voltage source type of control: - v/f (scalar); - vvw: voltage vector control; - vector control with encoder; - sensorless vector control (without encoder). Pwm svm (space vector modulation); full digital (software) current, flux...

Page 83

Technical specifications 8-7 8 8.2.1 codes and standards ul 508c - power conversion equipment. Ul 840 - insulation coordination including clearances and creepage distances for electrical equipment. En61800-5-1 - safety requirements electrical, thermal and energy. En 50178 - electronic equipment for ...

Page 84

Technical specifications 8-8 8 8.3 mechanical data frame e figure 8.2 - inverter dimensions - frame e - mm [in] r4.6 [0.18] r4.60 [0.18] 52.5 [2.07] m8 (4x) 10.0 [0.39] 15.0 [0.59] 14.0 [0.55] 216.0 [8.50] 280.0 [11.02] 675.0 [26.57] 15.1 [0.59] 205.4 [8.09] 488.1 [19.22] 619.8 [24.40] 650.0 [25.59]...

Page 85

Technical specifications 8-9 8 828.9 mm [32.63 in] 111.8 mm [4.40 in] 82.0 mm [3.23 in] 735.0 mm [28.94 in] 82.0 mm [3.23 in] - weight of the kn1e-02 kit: 4.3 kg (9.48 lb) (b) frame e with the nema1 kit kn1e-02 - cfw11 0180 t 2 o n1, cfw11 0211 t 2 o n1, cfw11 0180 t 4 o n1 and cfw11 0211 t 4 o n1 m...