- DL manuals

- Weider

- Other

- Pro 9635

- User Manual

Weider Pro 9635 User Manual

USER'S MANUAL

QUESTIONS?

As a manufacturer, we are com-

mitted to providing complete

customer satisfaction. If you have

questions, or find that there are

missing or damaged parts, we

will guarantee you complete sat-

isfaction through direct assis-

tance from our factory.

TO AVOID UNNECESSARY

DELAYS, PLEASE CALL DIRECT

TO OUR TOLL-FREE CUSTOMER

HOT LINE. The trained techni-

cians on our customer hot line

will provide immediate assis-

tance, free of charge to you.

CUSTOMER HOT LINE:

1-800-999-3756

Mon.–Fri., 6 a.m.–6 p.m. MST

Model No. WESY96352

Serial No.

Write the serial number in the space

above for reference.

Serial Number Decal (Under Seat)

CAUTION

Read all precautions and instruc-

tions in this manual before using

this equipment. Save this manual

for future reference.

Visit our website at

www.weiderfitness.com

new products, prizes,

fitness tips, and much more!

Summary of Pro 9635

Page 1

User's manual questions? As a manufacturer, we are com- mitted to providing complete customer satisfaction. If you have questions, or find that there are missing or damaged parts, we will guarantee you complete sat- isfaction through direct assis- tance from our factory. To avoid unnecessary delays,...

Page 2: Table of Contents

2 table of contents important precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 3: Important Precautions

3 important precautions warning: to reduce the risk of serious injury, read the following important precau- tions before using the home gym system. Warning: before beginning this or any exercise program, consult your physician. This is especially important for persons over the age of 35 or persons w...

Page 4: Before You Begin

4 before you begin assembled dimensions: height: 76 in. Width: 89 in. Length: 64 in. Foot plate low pulley station high pulley station lat bar leg lever butterfly arms military press arm press arm weight stacks backrests vkr arms leg press plate thank you for selecting the versatile weider ® pro 963...

Page 5: Assembly

5 assembly 1 8 11 51 27 1 4 3 1 51 5 1. Before beginning assembly, be sure that you have read and understand the infor- mation in the box above. Locate and open the parts bag labeled “frame assembly.” press two 2” square outer caps (51) onto the indicated locations on the stabilizer (5). Press a 2” ...

Page 6

6 2. Slide the vkr upright (74) and the leg press upright (56) onto the indicated 5/16” x 2 1/2” carriage bolts (1) in the stabilizer (5). The high side of the brackets on the vkr upright and leg press upright should be on the side shown. Hand-tighten four 5/16” nylon locknuts (3) onto the carriage ...

Page 7

7 4. Press a 2” square inner cap (27) into the end of the top frame (55). Press a 1 3/4” square inner cap (44) into each end of the crossbar on the top frame. Press two 1” round inner caps (49) into the top of the crossbar. Attach the top frame (55) to the vkr upright (74) and the leg press upright ...

Page 8

8 7. Press a weight tube bumper (64) into the end of a weight tube (63). Insert the weight tube into the front stack of weights (25). Be sure that the pin on the weight tube is sit- ting in the pin grooves in the top weight. Lubricate the inside of the holes in a top weight (65). Set the top weight ...

Page 9

9 9. Attach the upper ends of the short weight guides (73) to the top frame (55) with a 5/16” x 6” bolt (60), two 1/2” x 3/4” spacers (61), and a 5/16” nylon locknut (3). Attach the upper ends of the long weight guides (62) to the top frame (55) with a 5/16” x 6” bolt (60), two 1/2” x 3/4” spacers (...

Page 10

10 12. Press a 1” round inner cap (49) into one of the press arms (46). Press a 1 3/4” square inner cap (44) into the press arm. Attach the press arm (46) to one side of the press frame (17) with two 5/16” x 2 1/2” bolts (22) and two 5/16” nylon locknuts (3). Assemble the other press arm (46) in the...

Page 11

11 15. See the inset drawing. Attach the military press arm (84) to the pivot arm (101) with two 5/16” x 2 1/4” bolts (33) and two 5/16” nylon locknuts (3). Press two 1 1/2” square inner caps (32) into the indicated end of the military press arm (84). Press two 1” round inner caps (49) into the mili...

Page 12

12 18. Wrap the high cable (58) around a “v”-pulley (50). Attach the “v”-pulley and a long cable trap (31) to the indicated bracket on the front upright (42) with a 3/8” x 2 1/2” bolt (86) and a 3/8” nylon locknut (21). Be sure that the long cable trap is positioned to hold the cable in place. 19. R...

Page 13

13 22. See the inset drawing. Attach a 3 1/2” pulley (15) and a cable trap (66) to the upper hole in a long “u”-bracket (57) with a 3/8” x 2” bolt (12) and a 3/8” nylon locknut (21). Be sure that the cable trap is inside the long “u”- bracket. Note: this may come pre-assem- bled. Route the high cabl...

Page 14

14 25. Locate the low cable (23). Route the low cable under the 3 1/2” low pulley (76) attached to the lower hole in the press frame (17). Be sure that the end of the cable with the ball is on the indicated side of the press frame and that the cable is between the pulley and the crossbar on the pres...

Page 15

15 29. Attach the end of the low cable (23) to the long “u”-bracket (57) with a 1/4” nylon locknut (2) and a 1/4” flat washer (10). Do not completely tighten the nylon locknut. It should be threaded onto the end of the cable so only a couple of threads are showing above the nylon locknut, as shown i...

Page 16

16 32. Wrap the military press cable (72) around a 3 1/2” pulley (15). Attach the pulley to the top frame (55) with a 3/8” x 2” bolt (12) and a 3/8” nylon locknut (21). See the inset drawing. Wrap the long cable (72) around a 3 1/2” pulley (15). Attach the pulley and a cable trap (66) to the bracket...

Page 17

17 34. See inset drawing a. Attach a 3 1/2” pulley (15) and a cable trap (66) to the upper hole in the long “u”-bracket (57) with a 3/8” x 2” bolt (12) and a 3/8” nylon locknut (21). Be sure that the cable trap is inside the long “u”-bracket. (note: this may come pre- assembled.) route the military ...

Page 18

18 36. Attach the press bracket (94) to the leg press arm (96) with a 5/16” x 3” bolt (75) and a 5/16” nylon locknut (3). Wrap the leg press cable (99) around a 3 1/2” pulley (15). Attach the pulley to the press bracket (94) with the 3/8” x 2” bolt (12) and a 3/8” nylon locknut (21). Slide a 5/16” f...

Page 19

19 39. Attach the front backrest (41) to the front upright (42) with two 1/4” x 2 1/2” screws (43) and two 1/4” flat washers (10). The backrest must be oriented as shown. 40. Press a 1 1/2” square inner cap (32) into the front seat frame (36). Insert a 1/4” x 2” carriage bolt (38) through the center...

Page 20

20 43. Press two 3/4” round inner caps (34) into each pad tube (28). Insert a pad tube (28) into the seat frame (36). Slide a foam pad (30) onto each end of the pad tube. Insert the other pad tube (28) into the leg lever (29). Slide a foam foam pad (30) onto each end of the pad tube. 44. Locate and ...

Page 21

21 46. Remove the adhesive backing from the pro 9635 decal and apply it to the front upright (42) under the “weider” nameplate as shown. 47. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in how to use the home gym system, beginning on page 22...

Page 22

22 how to use the home gym system the instructions below describe how each part of the home gym system can be adjusted. Refer to the exercise poster accompanying this manual to see how the home gym system should be set up for each exercise. Important: when attaching the lat bar or nylon strap, make ...

Page 23

23 attaching and removing the seat to attach the seat (13), set the bracket on the seat frame (36) onto the indicated pins on the front upright (42). Attach the seat frame to the front upright with the 5/16” x 2 3/4” carriage bolt (14) and the seat knob (40). For some exercises, the seat (13) must b...

Page 24: Weight Resistance Chart

24 weight resistance chart this chart shows the approximate weight resistance at each weight station. “top” refers to the 6.5 lb. Top weight. The other numbers refer to the 12.5 lb. Weight plates. The butterfly arm resistance listed is the resistance for each butterfly arm. Weight press butterfly le...

Page 25

Troubleshooting and maintenance inspect and tighten all parts each time you use the home gym system. Replace any worn parts immediately. The home gym system can be cleaned using a damp cloth and mild non-abrasive detergent. Do not use solvents. Tightening the cables woven cable, the type of cable us...

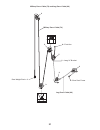

Page 26: Cable Diagrams

26 cable diagrams the cable diagrams on these pages show the proper routing of the high cable (58), the low cable (23), the military press cable (72), and the leg press cable (99). Use the diagrams to be sure that the four cables and the cable traps have been assembled correctly. If the cables have ...

Page 27

27 military press cable (72) leg press cable (99) rear weight stack— 1 2 3 4 5 3 2 4—rear seat frame 6—pivot arm 1—long “u”-bracket military press cable (72) and leg press cable (99).

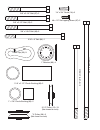

Page 28

5/16" nylon locknut (3)–33 1/4" flat washer (10)–17 5/16" flat washer (8)–8 3/8" flat washer (9)–7 1/4" x 2 1/2" screw (43)–6 3/8" nylon locknut (21)–21 1/4" x 2" machine screw (81)–5 5/16" nylon jam nut (93)–4 3/8" x 2" bolt (12)–7 5/16" x 2 1/2" bolt (22)–4 3/8" x 2 1/2" bolt (86)–3 5/16" x 2 3/4"...

Page 29

1" retainer (69)–4 3/8" x 3 1/2" bolt (16)–2 1/4" x 3/4" screw (18)–6 5/16" x 5" bolt (68)–1 3/8" x 3 3/4" bolt (88)–5 3/8" x 8" bolt (59)–1 cable clip (53)–3 1 1/8" x 2 1/2" plastic bushing (89)–2 1" x 7/8" plastic bushing (90)–2 5/16" x 6" bolt (60)–2 3 1/2" pulley (15)–13 (not shown to scale) "v"...

Page 30

1" round inner cap (49)–8 1" round cover cap (70)–2 3/4" round inner cap (34)–4 1/2" x 3/4" spacer (61)–4 1 1/2" square inner cap (32)–6 1 3/4" square inner cap (44)–6 2" square inner cap (27)–8 2" square outer cap (51)–2 1" square inner cap (6)–1.

Page 31

Part list—model no. Wesy96352 r0902a note: “#” indicates a non-illustrated part. Specifications are subject to change without notice. Key no. Qty. Description 1 10 5/16” x 2 1/2” carriage bolt 2 6 1/4” nylon locknut 3 33 5/16” nylon locknut 4 1 base 5 1 stabilizer 6 1 1” square inner cap 7 1 5/8” x ...

Page 32

60 27 21 15 55 12 1 1 8 15 12 44 88 15 58 21 44 21 3 61 62 24 3 58 71 2 65 63 64 25 26 19 21 9 3 3 49 6 22 46 46 16 3 9 15 21 59 23 21 17 27 1 4 10 43 41 42 21 3 50 31 86 70 69 69 70 21 47 44 45 44 45 48 50 31 86 13 40 38 37 18 32 34 30 28 3 49 83 33 10 2 36 14 88 15 29 35 30 34 34 30 28 21 9 32 30 ...

Page 33: Ordering Replacement Parts

Ordering replacement parts to order replacement parts, simply call our customer service department toll-free at 1-800-999-3756, monday through friday, 6 a.M. Until 6 p.M. Mountain time (excluding holidays). To help us assist you, please be pre- pared to give the following information: 1. The model n...