- DL manuals

- Xerox

- Printer

- 3117 - Phaser B/W Laser Printer

- Service Manual

Xerox 3117 - Phaser B/W Laser Printer Service Manual

LASER PRINTER

Phaser 3117

LASER PRINTER

LASER PRINTER

LASER PRINTER

LASER PRINTER

The keynote of Product

- Speed : 17ppm (Ltr) / 16ppm(A4), 600dpi

- Paper Path : MPF Type Cassette

- Emulation : SPL

- Processor : 150MHz Jupiter4e CPU

- Memory : SDRAM,

8

MB,

- MP Cassette : 150 pages / Face Down

(50 pages)

- Fuser Design : Lamp Type

- I/O : USB1.1

- Machine Life : 50K(pages)

x

Manual

SERVICE

Summary of 3117 - Phaser B/W Laser Printer

Page 1

Laser printer phaser 3117 laser printer laser printer laser printer laser printer the keynote of product - speed : 17ppm (ltr) / 16ppm(a4), 600dpi - paper path : mpf type cassette - emulation : spl - processor : 150mhz jupiter4e cpu - memory : sdram, 8 mb, - mp cassette : 150 pages / face down (50 p...

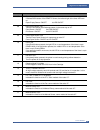

Page 2: Contents

Contents 1. Precautions 1.1 safety warning 1-1 1.2 safety caution 1-2 1.3 esd precautions 1-4 2. Product specification 2.1 product overview 2-1 2.2 specifications 2-1 2.3 model comparison table 2-5 3. System overview 3.1 system outline 3-1 3.2 h/w structure and descriptions 3-7 3.3 s/w structure and...

Page 3: Continued

5. Disassembly and reassembly 5.1 general precautions on disassembly 5-1 5.2 disassembly and reassembly 5-2 6. Troubleshooting 6.1 checking symptoms 6-1 6.2 bad discharge 6-4 6.3 malfunction 6-8 6.4 bad software environment 6-13 6.5 bad image 6-17 7. Exploded views & parts list 7.1 exploded views an...

Page 4: Continued

11. Reference information 11.1 troubleshooting tools 11-1 11.2 acronyms and abbreviations 11-2 11.3 selecting printer locations 11-4 11.4 sample tests patterns 11-5 12. Circuit description 12.1 engine controller 12-1 continued.

Page 5: 1. Precautions

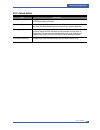

Precautions x service manual 1-1 1 1 1. Precautions the cautions below are items needed to keep in mind when maintaining and servicing. Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent the machine from getting damaged. 1.1 safety warning (1) req...

Page 6: 1.2 Safety Caution

X service manual precautions 1-2 1.2 safety caution 1.2.1 noxious material precaution the toner in a printer cartridge contains a chemical material, which may harm human body if it is swallowed. Please keep children out of reach of the toner cartridge. 1.2.2 electric shock or fire precaution it is p...

Page 7

Precautions x service manual 1-3 1.2.3 handling precautions if you ignore this information, you could harm machine and could be damaged. (1) do not install it on different levels, or slanted floor. Please confirm whether it is balanced or not after installation. If it is unbalanced, an accident can ...

Page 8: 1.3 Esd Precautions

X service manual precautions 1-4 1.3 esd precautions certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called “electrostatically sensitive (es) devices”, or esds. Examples of typical esds are: integrated circuits, some field effect transistors, a...

Page 9: 2.2 Specifications

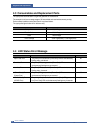

Product specifications x service manual 2-1 2 2 item descriptions remark basic model phaser 3117 series model phaser family market of sailes persnal user laser printer.(low price for small work group.) specification 16ppm (a4) ltr. 17ppm, jupiter 4e 150mhz, 2mbytes sdram toner 1k(initial), 3 k(saile...

Page 10

X service manual product specifications 2-2 item descriptions periodic replacing parts pick up roller : 50,000 pages same with machine life transfer roller : 50,000 pages fuser assembly : 50,000 pages toner sensor no toner type non-magnetic contact system toner initial 1,000 sheets@iso 5% coverage t...

Page 11

Product specifications x service manual 2-3 2.2.3 electrical specification item descriptions remark input voltage nominal input voltage 220~240 vac input voltage range 198~255 vac nominal frequency 50/60 mhz frequency tolerance +3hz power consumption printing : 300w avg(max. 500w) idling : 100w avg ...

Page 12

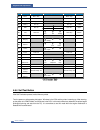

X service manual product specifications 2-4 2.2.6 paper handling specifications please refer to paper secifications on user guide. 2.2.6.1 input paper size 2.2.6.2 input capacity 2.2.6.3 output capacity paper paper size cassette a4 210 x 297 mm o letter 216 x 279(8.5 x 11") o us folio(legal13") 216 ...

Page 13: 2.3 Model

Product specifications x service manual 2-5 2.3 model specification table model name phaser 3117 general company xerox printing process print method: electrophotographic laser print speed up to 16ppm in a4, up to 17ppm in letter fpot 10sec resolusion 600*600 duty cycle, monthly up to 4166 p rints pe...

Page 14: 3. System Overview

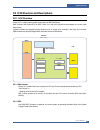

System overview samsung electronics service manual 3-1 3 3 3. System overview 3.1 system outline paper path layout bin path ❶ smps ❷ fuser ❸ toner cartridge ❹ lsu ❺ exit roller ❻ opc ❼ pick-up roller ❽ knock-up plate ❾ knock-up plate down ❿ ass’y holder pad feed sensor main pba smps hvps.

Page 15

X service manual system overview 3-2 unit layout hvps smps main pba motor lsu panel.

Page 16

System overview x service manual 3-3 3.1.1 feeding there are the c-path type, which loads papers, and the manual feeder, which supplies paper one by one.The cassette has the function pad which separates paper one by one, and it has the sensor function to check the existence of the loading paper. 1) ...

Page 17

X service manual system overview 3-4 1) heat lamp . Heat lamp terminal shape : terminal single type . Voltage 120 v : 115 + /- 5 % 220 v : 230 + /- 5 % . Capacity : 600 watt + /- 30 w . Life : 3000 hr 2) thermostat . Thermostat type : non-contact type thermostat . Control temperature : 150 5 3) ther...

Page 18

System overview x service manual 3-5 3.1.5 lsu (laser scanner unit) the lsu unit is controlled by video controller. It scans the video data received from video controller with laser beam by using the rotation principle of the polygon mirror to create the latent image on the opc drum. It is the core ...

Page 19

Samsung electronics service manual system overview 3-6 cleaning roller cleaning blade -720v -350v -550v 0.20mw max -1.4kv -100v 1 2 3 4 5 6 7 8 +5kv -150v↓ 3.1.6 toner cartridge by using the electronic photo process, it creates a visual image. In the toner cartridge, the opc unit and the developer u...

Page 20

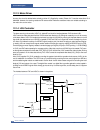

System overview x service manual 3-7 3.2 h/w structure and descriptions 3.2.1 h/w overview phaser 3117 is roughly made up main control part and smps/hvps part. Main controller uses jupiter4e for its asic, which is on chip micro controller and developed for low-end laser beam printer. Jupter4e provid...

Page 21

X service manual system overview 3-8 - main function block: completely integrated system for embedded applications, 32 bit risc architecture, efficient and powerful arm9 cpu lsu interface module for interfacing pvc with lsu 2 channel general purpose dma controller for high speed i/o dual memory bus ...

Page 22

System overview x service manual 3-9 3.2.2 main board main board are composed of engine and controller on the one-board. Main board control to send current imagedml video data to lsu to print and have motor driving and circuit for the current driving and also include paper exit sensor, cover open s/...

Page 23

X service manual system overview 3-10 u6(jupiter 4e) - it is a main cpu and an asic of jupiter4e which has a cpu core clk with over 150mhz and a system bus 45mhz. - it use 3.3v for operation voltage and i/o, it uses 80mhz for system bus clk, sdram - main memory. Sdclk is 80mhz. A3977 - it is an main...

Page 24

System overview x service manual 3-11 3.2.3 asic(spgpm) specification 3.2.3.1 introduction jupiter4e is one-chip micro-controller for low cust laser beam printer. 1. One chip laser beam printer controller - gdi only - amba ahb used for high speed bus transactions between masters and slaves - amba ap...

Page 25

X service manual system overview 3-12 8. Interrupt controller (intc) - fiq or irq mode operation selectable - programmable interrupt enable/disable 9. Usb interface - version 1.1 - four 128x8 fifos for data transmission. - interrupt based input / output interface, no dma based interface support - us...

Page 26

System overview x service manual 3-13 3.2.3.2 jupiter4e internal block diagram tms tck tdi tdo ntrst arm core ( arm940t i / c 4 kb d/ c 4 kb ) ppi pde, busy, nack, select, perror, nfault ppd[7:0] apb bri dge ahbc ( arb, dec, mux) fl ash core ( mfl130_128kx32 ) scl sda program sdramc ( ext : 2 ch) ns...

Page 27

X service manual system overview 3-14 3.2.4 sensor controller 3.2.4.1 paper feeding/width when a paper passes an actuator of a feed sensor unit after feeding a paper into a set,it detects a signal of the photo interrupter and informs the paper feeding status to cpu. After sensing the signal and cert...

Page 28

System overview x service manual 3-15 3.2.5 smps board (switching module power supply) the smps supplies dc power to the system. It takes 110v/220v and outputs the +5v, +24v to supply the power to the main board and other board. It is consisted of the amps part, which supplies the dc power for drivi...

Page 29

X service manual system overview 3-16 1) smps specification - ac input input rated voltage : ac 220v ~ 240v ac 120v / ac 220v(exp version) input voltage fluctuating range : ac 90v ~ 135v / ac 180v ~ 270v(exp version) rated frequency : 50/60 hz frequency fluctuating range : 47 ~ 63 hz input current :...

Page 30

System overview x service manual 3-17 - environment condition . Operating temperature range : 0 40 . Maintaining temperature range : -20 40 . Preserving humidity condition : 10% ~ 90% rh . Operating atmospheric pressure range : 1atm - emi requirement : cispr ,fcc, ce, mic, - safty requrement : iec95...

Page 31

X service manual system overview 3-18 - output voltage falling time : 50 ms max - output loading range : 10mߟ ~ 1000 - output control signal (bias-pwm) : the cpu output is hv output when pwm is low. 4) supply - output voltage : -550 v 8.6%(zener using, dev ) - input contrast of the output stability...

Page 32

System overview x service manual 3-19 3.2.7 fuser ac power control fuser(heat lamp) gets heat from ac power. The av power controls the switch with the triac, a semiconductor switch. The 'on/off control' is operated when the gate of the triac is turned on/off by phototriac (insulting part). In other ...

Page 33

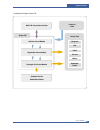

X service manual system overview 3-20 3.3 s/w structure and descriptions the purpose of this document is to describe the design specification of the engine control f/w for the phaser 3117. 3.3.1 introduction this engine control firmware is a program that controls lbp engine of the phaser 3117. This ...

Page 34

System overview x service manual 3-21 - architecture of engine control f/w main f/w of the printer controller device units fixing unit lsu hvps fan unit motors solenold & clutch power on initial interface control module engine main control module sensing & unit control module hardware devices & mech...

Page 35

X service manual system overview 3-22 3.3.3 f/w architecture of engine control firmware - the engine control module is executed every 10msec as interrupt job of main system. There are three control modules, i.E., engine main control module, engine interface module and sensing & unit control module. ...

Page 36

System overview x service manual 3-23 start global timer increment get a dc value (tempe rature, .. ) control the fixing unit & check error condition for the fixing unit control the fan unit get status value of each sensor & set present status f lag of each sensor - f/w architecture.

Page 37

X service manual system overview 3-24 ready led error led toner save led status on off n/a ready to receive the data. Slow blink off n/a receiving the data from the host. In case that toner save mode is on. Fast blink off n/a printing the page. In case that toner save mode is on. N/d n/d n/d recover...

Page 38

System overview x service manual 3-25 3.4 initial product installation 3.4.1 accessory list remove the printer and all accessories from the packing carton. Make sure that the printer has been packed with the following items: 3.4.2 installing the toner cartridge 1. Grasp the front cover and pull it t...

Page 39

X service manual system overview 3-26 2. Remove the toner cartridge from its bag and remove the paper covering the cartridge. 3. Gently shake the cartridge from side to side to distribute the toner evenly inside the cartridge. 4. Locate the cartridge slots inside the printer, one on each side..

Page 40

System overview x service manual 3-27 5. Unfold the toner cartridge handle and grasp it. Insert the cartridge in the printer until it snaps into place. 6. Close the front cover. Make sure that the cover is securely closed. If the cover is not firmly closed, printing errors may occur when you print..

Page 41

X service manual system overview 3-28 3.4.3 loading paper you can load approximately 150 sheets of paper in the tray. 1. Grasp the paper input tray and pull it toward you to open. Pinch the rear guide and pull it out to extend the tray. 2. Prepare a stack of paper for loading by flexing or fanning t...

Page 42

System overview x service manual 3-29 4. Pay attention not to overload paper. Paper overloading may cause paper jams. 5. If necessary, pinch the rear guide to adjust for the paper length and pinch the side guide and slide it to the left flush against the paper. 3.4.4 connecting a printer cable to pr...

Page 43

X service manual system overview 3-30 3.4.5 turning the printer on 1. To print from your computer, you need to connect your printer to your computer with a universal serial bus (usb) cable. 2. Plug the other end into a properly grounded ac outlet and turn on the printer using the power switch. 3.4.6...

Page 44

System overview x service manual 3-31 3.4.7 installing printer software the supplied cd-rom contains windows printing software, linux printing software, on-line user’s guide and acrobat reader to view the user’s guide. 1. If you are printing from windows - you can install the following printer softw...

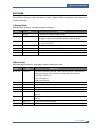

Page 45: 4.1 Sample Pattern

Alignment and adjustments x service manual 4-1 4 4 4. Alignment and adjustments 4.1 sample pattern this product has the several sample patterns for maintenance. With the sample patterns, check the existence of the abnormality. The patterns help to regularly maintain the product. 4.1.1 printing a dem...

Page 46: 4.2 Control Panel

4.2.2 on line/error and toner save leds x service manual alignment and adjustments 4-2 4.2 control panel 4.2.1 op panel if the on line/error lights green, the printer is ready to print. If the on line/error lights red, the printer is experiencing an error, such as jammed paper, no paper, the open co...

Page 47

Alignment and adjustments x service manual 4-3 4.2.3 cancel button printing demo page in ready mode, press and hold this button for about 2 seconds until all leds blink slowly, and release. Manual feeding press this button each time you load a sheet of paper in the tray, when you select manual feed ...

Page 48

X service manual alignment and adjustments 4-4 component replacement cycle pick-up roller 50,000 pages transfer roller 50,000 pages fuser 50,000 pages toner cartridge 3 ,000 pages(sales), 1,000 pages(initial) 4.3 consumables and replacement parts the cycle period outlined below is a general guidelin...

Page 49

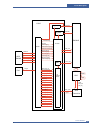

Alignment and adjustments x service manual 4-5 bin path 1 2 3 4 opc drum charge roller supply roller developing roller 5 6 7 transfer roller heat roller pressure roller 4.5 periodic defective image if the delinquent image regularly occurs in the printed-paper, it is due to delinquent or damaged roll...

Page 50: 4.6 How to Use Dcu

X service manual alignment and adjustments 4-6 4.6 how to use dcu 4.6.1 dcu setup you can examine the malfunction of the printer. To perform dcu, open the front discharge cover and leave the connect the harness wire(10 pin/4 pin) to the cn1(phaser 3117) of the main control board. Ml series diagnosti...

Page 51

4.6.2 code connect dcu to the printer and turn the power on. It show 7 segment fnd on the panel and each code tells the function of the printer. 1) normal code while printing or warming up, it indicate the position of the paper alignment and adjustments x service manual 4-7 2) error code when detect...

Page 52

X service manual alignment and adjustments 4-8 4.6.3 self diagnostic mode if error code occurs due to malfunction of the printer, perform self diagnostic mode to solve the problem. The printer works only in the self-test mode to solve the malfunction problem. To enter the self-test mode, turn the po...

Page 53

Alignment and adjustments x service manual 4-9 code description 07 paper empty sensor test : if activate the actuator of the pempty sensor, the left and right of the three leds are on. Paper empty sensor on/off 1st led on/off 08 feed & exit sensor test test the feed sensor and discharge sensor in th...

Page 54

Service manual alignment and adjustments 4-10 no. Functi on enter up/ down stop remar k 00 motor motor run motor stop 01 mhv mhv on mhv off -1300v -1000 -350v 020mv v 02 thv(-) thv negative on thv negative off 03 thv(+) thv on thv off +1300v 04 dev dev on supply dev -350v dev off 0 : -550v 0 : 05 ls...

Page 55: 4.7 Paper Path

Alignment and adjustments service manual 4-11 4.7 paper path 1) after taking order, the printer feeds the printing paper from the cassette or manual feeder. 2) the fad paper passes the paper feeding sensor. (jam 0 occurs if the sensor is not operated after certain time passes) 3) the paper passed th...

Page 56

X service manual alignment and adjustments 4-12 4.7.1 clearing paper jams occasionally, paper can be jammed during a print job. Some of causes include: • the tray is overfilled. • the front cover has been opened during a print job. • paper that does not meet paper specifications has been used. • pap...

Page 57

3. Loosen the paper if it is caught in the heat rollers. Then pull the paper gently out. 4. Close the inner cover and the top cover. 5. Open and close the front cover. Printing can be resumed. Alignment and adjustments x service manual 4-13.

Page 58

X service manual alignment and adjustments 4-14 4.7.3 in the paper feed area 1. Remove any missfeed paper by pulling it out by the visible edge from the tray. Make sure that all of the paper is properly aligned in the tray. 2. Open and close the front cover. Printing can be resumed. 4.7.4 around the...

Page 59

2. Pull the toner cartridge out and remove it from the printer. 3. Gently pull the paper toward you. 4. Check that there is no other paper in the printer. 5. Reinstall the toner cartridge, and then close the cover. Printing can be resumed. Alignment and adjustments x service manual 4-15.

Page 60

X service manual alignment and adjustments 4-16 4.7.5 tips for avoiding paper jams by selecting the correct paper types, most paper jams can be avoided. • ensure that the adjustable guides are positioned correctly. • do not overload the tray. • do not remove the paper from the tray while printing. •...

Page 61

Disassembly and reassembly x service manual 5-1 5 5 5. Disassembly and reassembly 5.1 general precautions on disassembly when you disassemble and reassemble components, you must use extreme caution. The close proximity of cables to moving parts makes proper routing a must. If components are removed,...

Page 62

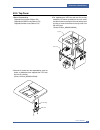

X service manual disassembly and reassembly 5-2 5.2 disassembly and reassembly 5.2.1 front cover 1.Open the front cover.(the front cover and the cas- sette tray are assembled with the same assembly.) 2.Separate the cover from the lock of the frame by pulling the right bottom of the cover toward the ...

Page 63

Disassembly and reassembly x service manual 5-3 5.2.3 smps cover 5.2.4 main cover 1.Release two screws. (screw x2:silver_m3,6003-000196) 2.Separate the lock by holding the left side of the cover and pulling it toward the arrow direction. Remove it with carefulness that the power switch is not hooked...

Page 64

X service manual disassembly and reassembly 5-4 3.Hold the both ends of the cover and pull it up bit by bit toward the arrow direction as shown as below. 4.Separate it by holding the both sides of the main cover and carefully lifting it up. 5.If necessary,remove the jam cover.Open the cover, take ou...

Page 65

Disassembly and reassembly x service manual 5-5 5.2.5 top cover 1.Before disassembling. -separate the font cover.(refer to 5.2) -separate the smps cover.(refer to 5.3) -separate the main cover.(refer to 5.4) 2.For separating the led lens and the on-line key, release the 5 screws connected to the mai...

Page 66

X service manual disassembly and reassembly 5-6 5.2.6 hvps 1.Before disassembling. -separate the font cover.(refer to 5.2) -separate the smps cover.(refer to 5.3) -separate the main cover.(refer to 5.4) 2.Remove the sheet by releasing the 5 screws which connects the hvps and the sheet. (screw x 3:go...

Page 67

Disassembly and reassembly x service manual 5-7 5.2.7 rx drive 1.Before disassembling -separate the font cover.(refer to 5.2) -separate the smps cover.(refer to 5.3) -separate the main cover.(refer to 5.4) 2.Release 2 screws (screw x 2:silver_m3,6001- 000130)connected to the engine shield and 6 scre...

Page 68

X service manual disassembly and reassembly 5-8 5.2.8 fuser rx motor motor bracket gear bracket thermister fuser 5.When separating the motor,remove the motor brack- et first by removing 4 screws as shown as below, and then remove the 2 screws from the motor bracket. 1.Before disassembling -separate ...

Page 69

Disassembly and reassembly x service manual 5-9 3.Separate the fuser by unscrewing 4 screws on the frame. (screw x 4:gold_m3,6003-000269) 4.After removing the lamp cover l/r, separate the fuser dummy cover. 5.Separate the exit roller f/down and the exit gear (drv17)by turning the left/right holder c...

Page 70

X service manual disassembly and reassembly 5-10 thermostat thermistor cover-m 7.After pulling out the thermostat as shown as below, remove the cbf harness from its left/right side. 8.Release the screw as shown as below, remove the harness from the cover, and then pull out the ther- mistor. (screw x...

Page 71

Disassembly and reassembly x service manual 5-11 5.2.9 engine shield (including main pba and smps) halogen lamp heat roller thermister clutch fuser lsu motor hvps 11.Remove the halogen lamp from the heat roller by pulling it out to the arrow direction. 1.Before disassembling -separate the font cover...

Page 72

X service manual disassembly and reassembly 5-12 engine shield (w/main pba, smps) actuator feed sensor lever smps main pba 3.Release 6 screws as shown as below, separate the harnesses from the shield,and then separate the engine shield with carefulness of the actuator feed sensor lever. (screw x 6:s...

Page 73

Disassembly and reassembly x service manual 5-13 5.2.10 lsu 5.2.11 paper path frame 1.Before disassembling -separate the font cover.(refer to 5.2) -separate the smps cover.(refer to 5.3) -separate the main cover.(refer to 5.4) 2.Release 3 screws as shown as below, lift up the lsu, and then disconnec...

Page 74

X service manual disassembly and reassembly 5-14 transfer roller 2 1 bush(l) bush solenoid-mp 3.After releasing the 2 hooks from the right side of the frame,take out the transfer roller. (screw x 2:silver-m3,6003-000196) 4.Remove the solenoid-mp by releasing the screw from the left side of the frame...

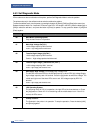

Page 75: 6. Troubleshooting

Troubleshooting x service manual 6-1 6 6 6. Troubleshooting 6.1 checking symptoms before attempting to repair the printer first obtain a detailed description of the problem from the customer. Power on indicate "lamp toggle" on-line led green ok? Print(test pattern) printing quality is nomal? Refer t...

Page 76

X service manual troubleshooting 6-2 6.1.1 basic check list 1. Check the power. • does "warming up" appear on the display? --> if not check power cable, switch or smps. --> does the wall socket work? • do the motors or other components initialize (listen for main motor, fan and lsu sounds)? --> if n...

Page 77

Troubleshooting x service manual 6-3 6.1.2 initial inspection 1. Check power part 1. The printer does not work no matter how long you wait. A. Is the power switch (printer and wall socket) turned on ? B. Is the power cord connected to the printer correctly ? C. Is the power cord connected to the wal...

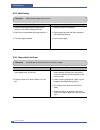

Page 78: 6.2 Bad Discharge

X service manual troubleshooting 6-4 • description printing begins at wrong position on the paper. Check and cause solution wrong sense time caused by defective feed sensor actuator. Replace the defective actuator check and cause solution 1. Check the solenoid by using dcu diagnostic mode 06. 2. Che...

Page 79

Troubleshooting x service manual 6-5 check and cause solution 1. If the recording paper is jammed in front of or inside the fuser. (perform dcu diagnostic code 08) 2. If the recording paper is stuck in the discharge roller and the fuser just after passing through the actuator- feed, feed actuator ma...

Page 80

X service manual troubleshooting 6-6 6.2.5 multi-feeding • description multiple sheets of paper are fed at once. Check and cause solution 1. Solenoid malfunction(the solenoid does not work properly): perform dcu diagnostic code 06. 2. Pad-friction is contaminated with foreign matter.(oil...) 3. The ...

Page 81

Troubleshooting x service manual 6-7 6.2.7 paper rolled in the toner cartridge (opc drum) • description paper is rolled up in the opc. Check and cause solution 1. Paper is too much thin. 2. The face of paper is curled. 1. Recommend to use normal paper. 2. How to remove the rolled in the opc drum. • ...

Page 82: 6.3 Malfunction

X service manual troubleshooting 6-8 6.3 malfunction 6.3.1 all leds blinking (fuser error) • description 1. All the lamps on the operator panel blink. 2. Gear of the fuser does not work and breaks away melt away. When printing, motor breaks away from its place due to defective fuser gear. Check and ...

Page 83

Troubleshooting x service manual 6-9 6.3.3 not function of the gear of the fuser due to melting away • description the motor breaks away from its place due to gear melting away. Check and cause solution dcu mode : check if the error states '60' '62' '68' occur. Check the operation of fuser erasing l...

Page 84

X service manual troubleshooting 6-10 6.3.6 cover open • description the error lamp is on even when the print cover is closed. Check and cause solution 1. The hook lever in the top cover may be defective. 2. Check the connector (engine b’d ↔ hvps) and circuit of the cover switch department in the ma...

Page 85

Troubleshooting x service manual 6-11 6.3.8 defective motor operation • description main motor is not driving when printing, and paper does not feed into the printer, resulting 'jam 0'. Check and cause solution 1. Motor harness or sub pcb may be defective. 2. Perform dcu diagnostic code 00 and check...

Page 86

X service manual troubleshooting 6-12 6.3.10 vertical line getting curved • description when printing, vertical line gets curved. Check and cause solution 1. If the supply of +24v is unstable in the main control board linking with lsu, check drive by dcu mode : lsu check -05- lsu motor on. 1. Replac...

Page 87

Troubleshooting x service manual 6-13 6.4 bad software environment 6.4.1 the printer is not working (1) • description while power turned on, the printer is not working in the printing mode. Check and cause solution 1. Run self-test mode : turn the power on while pressing the test printing button for...

Page 88

X service manual troubleshooting 6-14 6.4.2 the printer is not working (2) • description after receiving the printing order, no response at all or the low speed of printing occurs due to wrong setup of the environment rather than malfunction of the printer itself. Check and cause solution 1. Secure ...

Page 89

Troubleshooting x service manual 6-15 6.4.3 abnormal printing • description the printing is not working properly even when the cable has no problem. (even after the cable is replaced) if the printer won't work at all or the strange fonts are repeated, the printer driver may be defec- tive or wrong s...

Page 90

X service manual troubleshooting 6-16 6.4.4 spool error • description to spool which stands for "simultaneous peripheral operations online" a computer document or task list (or "job") is to read it in and store it, usually on a hard disk or larger storage medium so that it can be printed or otherwis...

Page 91: 6.5 Bad Image

Troubleshooting x service manual 6-17 6.5 bad image 6.5.1 vertical black line and band • description 1. Straight thin black vertical line occurs in the printing. 2. Dark black vertical band occur in the printing. Digital printer digital printer digital printer digital printer digital printer check a...

Page 92

X service manual troubleshooting 6-18 6.5.3 horizontal black band • description 1. Dark or blurry horizontal stripes occur in the printing periodically. (they may not occur periodically.) digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Bad ...

Page 93

Troubleshooting x service manual 6-19 6.5.5 light image • description the printed image is light, with no ghost. Digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Develop roller is stained when the toner of developer cartridge is almost con- ...

Page 94

X service manual troubleshooting 6-20 6.5.7 uneven density • description print density is uneven between left and right. Check and cause solution 1. The pressure force on the left and right springs of the transfer roller is not even, the springs are damaged, the transfer roller is improperly install...

Page 95: Digital Printer

Troubleshooting x service manual 6-21 6.5.9 ghost (1) • description ghost occurs at 75.5 mm intervals of the opc drum in the whole printing. Digital printer digital printer digital printer digital printer digital printer digital printer 75.5mm check and cause solution 1. Bad contacts caused by conta...

Page 96: Digital Printer

X service manual troubleshooting 6-22 6.5.11 ghost (3) • description white ghost occurs in the black image printing at 47.5mm intervals. Digital printer digital printer digital printer digital printer digital printer digital printer 47.5mm check and cause solution 1. The life of the developer may be...

Page 97

Troubleshooting x service manual 6-23 6.5.14 stains on back of page • description the back of the page is stained at 47 mm intervals. Digital digital pri digital printer digital printer digital printer check and cause solution 1. Transfer roller is contaminated. 2. Pressure roller is contaminated. 1...

Page 98

Exploded views & parts list x service manual 7-1 7 7 7.1 main assembly p.7-2 7.2 frame assembly p.7-3 7.3 fuser unit p.7-4 7.4 paper path assembly p.7-5 7. Exploded views and parts list contents part number & description format. There are two types of part number format. Part numbers and description...

Page 99: 7.1 Main Assembly

X service manual exploded views & parts list 7-2 7.1 main assembly 0 2 1 12 4 9 6 7 11 8 18 19 10 20 14 5 15-1 15-2 15 16 17 13 2-4 2-6 2-7 2-8 2-3 24 2-1 2-2 2-5 3 3-1 3-2 3-3 3-4.

Page 100: 7.2 Frame Assembly

Exploded views & parts list x service manual 7-4 7.2 frame assembly 1 2 20 4 4 5 8 7 9 10 10 11 12 13 14 17 15 16 2-1 2-2 2-3 2-3 2-4 0 19 6 5-1 5-3 5-2 5-4 5-5.

Page 101: 7.3 Fuser Unit

X service manual exploded views & parts list 7-5 7.3 fuser unit 0 1 2 33 4 32 3 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 34 25 24 23 20 21 22 26 27 28 29 30 31 6 7.

Page 102: 7.4 Paper Path Unit

Exploded views & parts list x service manual 7-6 7.4 paper path unit 0 1 2 3 4 5 25 6 7 8 9 9-1 9-2 9-3 10 10 11 11-1 11-2 11-3 12 13 14 16 16 15 17 18 19 20 21 24 23 24 22 26.

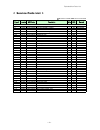

Page 103

Explodedview parts list draw# location sec.Code description qt'y svc remark 7.1-0 - phaser 3117 set - - 7.1-1 f2090 jc96-03349a ela unit-frame_lower 1 sa 001n00465 7.1-2 t4062 jc97-02177a mea unit-cover main 1 sa 7.1-2-1 z5090 jc61-01155a guide-m-stacker_rx 1 sa 002n02426 7.1-2-2 z5092 jc61-01156a g...

Page 104

Draw# location sec.Code description qt'y svc remark ▣ sa: service available, sna: service not available 7.2-0 f2090 jc96-03349a ela unit-frame_lower 1 sa 001n00466 7.2-1 b0080 jc61-01152a frame-m-base 1 sna 7.2-2 k3602 jc97-02218a mea unit-plate knock_up 1 sa 015n00560 7.2-2-1 k5002 jc61-01158a plat...

Page 105

Draw# location sec.Code description qt'y svc remark ▣ sa: service available, sna: service not available 7.3-0 f4038 jc96-03401a ela hou-fuser 220v 1 sa ☞ 126n00245 7.3-0 f4038 jc96-03400a ela hou-fuser 110v 1 sa ☞ 7.3-1 f2122 jc61-01162a frame-p-fuser 1 sna 7.3-2 z2149 jc63-00615a cover-m_fuser 1 sn...

Page 106

Draw# location sec.Code description qt'y svc remark ▣ sa: service available, sna: service not available 7.4-0 b0101 jc97-02175a mea unit-frame paper path 1 sa 7.4-1 g2069 jc61-01161a guide-m-paper path 1 sa 038n00463 7.4-2 e7006 jc66-00814a lever-actuator feed sensor 1 sa 130n01408 7.4-3 z4209 jb61-...

Page 107

Block diagram service manual 8-1 x 8 8 8. Block diagram 8.1 system block diagram.

Page 108: 8.2 System Timing Chart

Service manual block diagram 8-2 x 8.2 system timing chart.

Page 109

Connection diagram service manual 9-1 x 9 9 9. Connection diagram main b’d smps regi sensor main motor jam cover micro switch exit sensor hvps cover micro switch exi t sensor lsu main cl utch zener motor cn11 cn12 cn8 cn7 cn10 cn5 cn4 cn1 con2 con1 cn1 tact s/w led usb 1.1 usb therm 1.+ 24vs1 2.+ 24...

Page 110

10 10 schematic diagram service manual 10-1 this document can not be used without authorization. X 10. Schematic diagrams 10.1 main board(1/4).

Page 111

Schematic diagram service manual 10-2 this document can not be used without authorization. X main board(2/4).

Page 112

Schematic diagram service manual 10-3 this document can not be used without authorization. X main board(3/4).

Page 113

Schematic diagram service manual 10-4 this document can not be used without authorization. X main board(4/4).

Page 114

Service manual schematic diagram) service manual 10-5 x 10-2 connector circuit diagram.

Page 115

Schematic diagram service manual 10-6 this document can not be used without authorization. X 10-3 smps circuit diagram.

Page 116

Schematic diagram service manual 10-7 this document can not be used without authorization. X 10-4 hvps circuit diagram(1/3).

Page 117

Schematic diagram service manual 10-8 this document can not be used without authorization. X hvps circuit diagram(2/3).

Page 118

Schematic diagram service manual 10-9 this document can not be used without authorization. X 10-4 hvps circuit diagram(3/3).

Page 119: 11. Reference Information

Reference information x service manual 11-1 1 1 1 1 11. Reference information this chapter describes the reference information for applying this training manual, and it is consist-ed of the tool list, the abbreviation table, the outline of model, and so on. 11.1 troubleshooting tool the following to...

Page 120

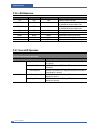

Service manual reference information 11-2 x 11.2 acronyms and abbreviations(1) the table below explains the abbreviations and acronyms used in this service manual. Where abbreviations or acronyms are used in the text please refer to this table. Abbreviations explanation ap access point ac alternatin...

Page 121

Reference information x service manual 11-3 acronyms and abbreviations(2) abbreviations explanation ieee institute of electrical and electronics engineers. Inc ipa isopropy alcohol ipm images per minute lan local area network lb pound(s) lbp laser beam printer lcd liquid crystal display led light em...

Page 122

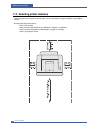

Service manual reference information 11-4 x 11.3 selecting printer locations • leave enough room to open the printer trays, covers, and allow for proper ventilation. (see diagram below) • provide the proper environment : - a firm, level surface - away from the direct airflow of air conditioners, hea...

Page 123: 11.4 Sample Tests Patterns

Reference information x service manual 11-5 11.4 sample tests patterns the sample patterns shown below are the standard test patterns used in the factory. The life of the toner cartridge, developer cartridge and printing speed are measured with the pattern shown below (5%). The a4 iso 19752 standard...

Page 124: 12. Circuit Description

Circuit description x service manual 12-1 12 12 12. Circuit description 12.1 engine controller the engine controller module consists of a motor controller, a pwm controller, a lsu i/f controller, and an adc i/f controller. 12.1.1 heater control the heat lamp radiates heat by using ac power. The ac p...

Page 125

X service manual circuit description 12-2.

Page 126

Circuit description x service manual 12-3 explanation about the condition of normal operation if the fuser (p3.7) port becomes high, the q6 is activated. A heat lamp starts operating by the activity. As the temperature of the heat lamp is increased, the resistance value of the thermister is decrease...

Page 127

X service manual circuit description 12-4 12.1.3 motor driver a motor drive circuit is decided when selecting a driver ic. (supplied by vendor) phaser 3117 uses the motor driver ic of an44060. However, the sensing resistance rs value and the vreference resistance value are variable according to the ...

Page 128

Circuit description x service manual 12-5 ls usfr psel penable paddr[4:0] pwdata[31:0] nlready digifilter nhsync_fo digifilter lsu con lsucontrol[8:0] windowontime[20:0] windowofftime[20:0] ldofftime[20:0] ldontime[20:0] patternduty[9:0] lsuclkduty[18:0] flagclear lsu_vdo lsu_clk npsync nlreadyflag ...

Page 129

X service manual circuit description 12-6 the main signals used in lsu controller are shown in the table. 12.1.5 adc controller jupiter4e adc controller has 3 analog input channels. It automatically converts the 3 channels in turns with 10 bit 500ksps adc1275x_pc, and also it makes the conversion on...