- DL manuals

- Xerox

- All in One Printer

- WORKCENTRE PE 220

- Service Manual

Xerox WORKCENTRE PE 220 Service Manual

Summary of WORKCENTRE PE 220

Page 1

11/05 workcentre pe 220 service manual 708p88337.

Page 2

11/05 workcentre pe 220 service documentation 708p88337 november 2005 prepared by: xerox europe, global knowledge & language services, enterprise centre, p.O. Box 17, bessemer road, welwyn garden city, hertfordshire, al7 1bu, england. © copyright 2005 by xerox ltd. Xerox, and all identifying numbers...

Page 3

Introduction workcentre pe 220 11/05 i introduction safety precautions .................................................................................................................. Iii 1. Service call procedures section contents......................................................................

Page 4

Introduction ii 11/05 workcentre pe 220 page intentionally blank.

Page 5: Introduction

Introduction workcentre pe 220 11/05 iii introduction precautions in order to prevent accidents and to prevent damage to the equipment please read the precautions listed below carefully before servicing the machine and follow them closely. Safety warning 1. Only to be serviced by appropriately quali...

Page 6

Introduction iv 11/05 workcentre pe 220 warning never operate or service the machine with the protective cover removed from laser/scanner assembly. The reflected beam, although invisible, can damage your eyes. When using this prod- uct, these basic safety pre-cautions should always be followed to re...

Page 7

Introduction workcentre pe 220 11/05 v electric shock and fire safety precautions failure to follow the following instructions could cause electric shock or potentially cause a fire. 1. Use only the correct voltage, failure to do so could damage the machine and potentially cause a fire or electric s...

Page 8

Introduction vi 11/05 workcentre pe 220 handling precautions the following instructions are for your own personal safety, to avoid injury and so as not to dam- age the machine 1. Ensure the machine is installed on a level surface, capable of supporting its weight. Failure to do so could cause the ma...

Page 9

Introduction workcentre pe 220 11/05 vii disregarding this warning may cause bodily injury 1. Be careful with the high temperature part. The fuser unit works at a high temperature. Use caution when working on the machine. Wait for the fuser to cool down before disassembly. 2. Do not put fingers or h...

Page 10

Introduction viii 11/05 workcentre pe 220 8. Maintain continuous electrical contact between the esd and the assembly into which it will be installed, until completely plugged or soldered into the circuit. 9. Minimize bodily motions when handling unpackaged replacement esds. Normal motions, such as t...

Page 11

Introduction workcentre pe 220 11/05 ix health and safety incident reporting i. Summary this section defines requirements for notification of health and safety incidents involving xerox products (equipment and materials) at customer locations. Ii. Scope xerox corporation and subsidiaries worldwide. ...

Page 12

Introduction x 11/05 workcentre pe 220 responsibilities for resolution: 1. Business groups/product design teams responsible for the product involved in the incident shall: a. Manage field bulletins, customer correspondence, product recalls, safety retrofits. B. Fund all field retrofits. 1. Field ser...

Page 13

Service call procedures workcentre pe 220 11/05 1-1 1. Service call procedures scp 1 service call actions ...................................................................................................... 1-3 scp 2 final actions ......................................................................

Page 14

Service call procedures 1-2 11/05 workcentre pe 220 page intentionally blank.

Page 15: Scp 1 Service Call Actions

Service call procedures workcentre pe 220 11/05 1-3 scp 1 service call actions procedure throughout this manual, observe the following warnings: warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. ...

Page 16: Scp 2 Final Actions

Service call procedures 1-4 11/05 workcentre pe 220 scp 2 final actions final actions are used to evaluate the total operation of the system and to identify the actions re- quired to complete the service call. Procedure • exercise the machine in all modes. • make a proof copy or print of a customer ...

Page 17

Status indicator raps workcentre pe 220 11/05 2-1 2. Status indicator raps 1 initial checks rap ................................................................................................................. 2-3 2 jam 0 rap .............................................................................

Page 18

Status indicator raps 2-2 11/05 workcentre pe 220 page intentionally blank.

Page 19: 1 Initial Checks Rap

Status indicator raps workcentre pe 220 11/05 2-3 1 initial checks rap basic check list 1. Check the power. • does "warming up" appear on the display? --> if not check power cable, switch or smps. --> does the wall socket work? • do the motors or other components initialize (listen for main motor, f...

Page 20

Status indicator raps 2-4 11/05 workcentre pe 220 initial inspection 1. Check the power. 1. The machine does not work no matter how long you wait. A. Is the power switch (machine and wall socket) turned on? B. Is the power cord connected to the machine correctly? C. Is the power cord connected to th...

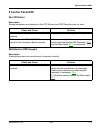

Page 21: 2 Jam 0 Rap

Status indicator raps workcentre pe 220 11/05 2-5 2 jam 0 rap description paper is not exited from the cassette. Jam-0 occurs if the paper feeds into the machine. Check and cause solution 1. Check the solenoid by using engine test mode-pick up test. 1. Replace the solenoid, pl 6 . 2. Check the paper...

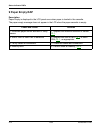

Page 22: 3 Jam 1 Rap

Status indicator raps 2-6 11/05 workcentre pe 220 3 jam 1 rap description paper is jammed in front of or just inside the fuser. Paper is jammed in the discharge roller and in the fuser just after passing through the actuator- feed. Check and cause solution 1. Check for small pieces of paper jammed i...

Page 23: 4 Jam 2 Rap

Status indicator raps workcentre pe 220 11/05 2-7 4 jam 2 rap description paper is jammed inside the fuser. Paper is jammed in the discharge roller and in the fuser just after passing through the actuator- feed. Check and cause solution 1. If the paper is completely fed out of the machine, but jam 2...

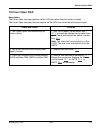

Page 24: 5 Multi-Feeding Rap

Status indicator raps 2-8 11/05 workcentre pe 220 5 multi-feeding rap description multiple sheets of paper are fed together. Check and cause solution 1. Badly cut paper. 1. Fan the paper. Recommend the use of good quality paper. 2. Solenoid malfunction (the solenoid does not work properly): perform ...

Page 25: 6 Fuser Jam Rap

Status indicator raps workcentre pe 220 11/05 2-9 6 fuser jam rap description constant jam where paper is entering fuser unit. Fuser rollers do not turn. Check and cause solution 1. Check if the fuser has overheated and melted the fuser gear. Check for heat damage to the fuser roll and the pressure ...

Page 26

Status indicator raps 2-10 11/05 workcentre pe 220 7 paper rolled in the print cartridge (opc drum) rap description paper is rolled up in the opc. Check and cause solution 1. Paper is too thin. 1. Recommend use normal paper. Use paper within specification. Refer to the user guide. 2. Paper curl. 2. ...

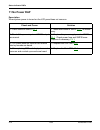

Page 27: 8 Control Panel Rap

Status indicator raps workcentre pe 220 11/05 2-11 8 control panel rap 8a lcd defect description strange characters are displayed in the lcd window and ope panel keys do not work. 8b defective ope keypad description pressing keys does not cause the set to respond correctly. Check and cause solution ...

Page 28: 9 Paper Empty Rap

Status indicator raps 2-12 11/05 workcentre pe 220 9 paper empty rap description paper empty is displayed in the lcd panel even when paper is loaded in the cassette. The paper empty message does not appear in the lcd when the paper cassette is empty. Check and cause solution 1. Deformed paper sensor...

Page 29: 10 Cover Open Rap

Status indicator raps workcentre pe 220 11/05 2-13 10 cover open rap description the cover open message appears on the lcd even when the print cover is closed. The cover open message does not appear on the lcd even when the print cover is open. Check and cause solution 1. The ‘open cover’ microswitc...

Page 30: 11 No Power Rap

Status indicator raps 2-14 11/05 workcentre pe 220 11 no power rap description when system power is turned on the lcd panel does not come on. Check and cause solution 1. Check fuses on smps, pl 1 . 1. Install new fuses or smps, pl 1 , as neces- sary. 2. Check if the power input and smps output are n...

Page 31

Status indicator raps workcentre pe 220 11/05 2-15 12 bad software environment rap 12a the machine is not working (1) description while power turned on, the machine is not working in the printing mode. Check and cause solution 1. Ensure that the customer knows how to install the correct printer driv...

Page 32

Status indicator raps 2-16 11/05 workcentre pe 220 12b the machine is not working (2) description after receiving the printing order, no response at all or the low speed of printing occurs due to wrong setup of the environment rather than malfunction of the machine itself. Check and cause solution 1...

Page 33: 13 Abnormal Printing Rap

Status indicator raps workcentre pe 220 11/05 2-17 13 abnormal printing rap description the machine is not working correctly even when there is no problem with the printer cable. If the machine will not work at all or the strange fonts are repeated, the printer driver may be de- fective or wrong set...

Page 34: 14 Spool Error Rap

Status indicator raps 2-18 11/05 workcentre pe 220 14 spool error rap description insufficient disk space to spool the document. How to delete the data in the spool manager. In the spool manager, the installed drivers and the list of the documents waiting to be printed are shown. Select the document...

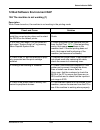

Page 35: 15 Fax & Phone Problems Rap

Status indicator raps workcentre pe 220 11/05 2-19 15 fax & phone problems rap 15a no dial tone description there is no dial tone when the manual dial key is pressed. Check and cause solution 1. Check that the telephone line cord supplied with the set is connected to tel line cor- rectly. 1. If the ...

Page 36

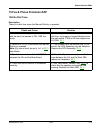

Status indicator raps 2-20 11/05 workcentre pe 220 15b defective mf dial description the mf dial is not functioning. 15c defective fax send/receive description fax send/receive is not functioning. Check and cause solution 1. Check that the telephone line cord supplied with the set is connected to te...

Page 37

Status indicator raps workcentre pe 220 11/05 2-21 15d defective fax send description receive is functioning, but fax send is not functioning or received data is corrupt. 15e defective fax receive (1) description fax send is functioning, but receive is not functioning or the received data is corrupt...

Page 38

Status indicator raps 2-22 11/05 workcentre pe 220 15f defective fax receive (2) description received data is corrupted. 15g defective fax receive (3) description the phone is ringing continuously, but the machine does not answer the call. 15h defective fax receive (4) description received data is r...

Page 39

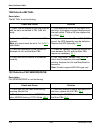

Status indicator raps workcentre pe 220 11/05 2-23 15i defective automatic receiving description the automatic receiving function is not working. Check and cause solution 1. Check that the receive mode is set to fax mode. 1. If the receive mode is set to the tel mode, reset it to the fax mode. 2. Ev...

Page 40: 16 Abnormal Noise Rap

Status indicator raps 2-24 11/05 workcentre pe 220 16 abnormal noise rap description there is noise from the adf when copying. Check and cause solution 1. Check the scanner motor, gearbox and rollers. 1. Check for correct assembly of gears and motor. Ensure no parts are damaged and there are no fore...

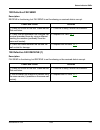

Page 41: 17 Scanning Rap

Status indicator raps workcentre pe 220 11/05 2-25 17 scanning rap 17a pc scanning problems description unable to scan using a pc. 17b poor quality of pc scanned images description poor quality of scanned to pc images. Check and cause solution 1. Check the cable (usb or parallel) is prop- erly conne...

Page 42

Status indicator raps 2-26 11/05 workcentre pe 220 18 print cartridge problems rap this section explains messages on the lcd that are related to the data stored in the eeprom in the print cartridge. Toner low - explanation: the amount of toner remaining is less than 10%. The print cartridge is almos...

Page 43: 19 Software Problems Rap

Status indicator raps workcentre pe 220 11/05 2-27 19 software problems rap 19a the machine is not working (1) description while power turned on, the machine is not working in print mode. Check and cause solution 1. Ensure that the customer knows how to install the correct printer driver and to sele...

Page 44

Status indicator raps 2-28 11/05 workcentre pe 220 19b the machine is not working (2) description after receiving the print command there is no response at all or print speed is low due to wrong setup of the environment rather than malfunction of the machine itself. Check and cause solution 1. Ensur...

Page 45

Status indicator raps workcentre pe 220 11/05 2-29 19c abnormal printing description printing does not work – even after replacing the cable machine does not work at all or strange fonts are printed. Check and cause solution 1. Set up the parallel port in the bios. 1. Ask the customer to ensure that...

Page 46

Status indicator raps 2-30 11/05 workcentre pe 220 page intentionally blank.

Page 47

Image quality workcentre pe 220 11/05 3-1 3. Image quality iq 1 vertical black line and band ............................................................................................ 3-3 iq 2 vertical white line ........................................................................................

Page 48

Image quality 3-2 11/05 workcentre pe 220 page intentionally blank.

Page 49

Image quality workcentre pe 220 11/05 3-3 iq 1 vertical black line and band description straight thin black vertical line occurs in the printing. Dark black vertical band occur in the printing. Check and cause solution 1. Dirty cvt glass. 1. Clean the cvt glass. 2. Damaged develop roller in the deve...

Page 50: Iq 2 Vertical White Line

Image quality 3-4 11/05 workcentre pe 220 iq 2 vertical white line description white vertical voids in the image. Check and cause solution 1. Foreign matter stuck onto the window of internal lenses of lsu mirror. 1. Clean the lsu window with rec- ommended cleaner (ipa). Clean the window with a clean...

Page 51: Iq 3 Horizontal Black Band

Image quality workcentre pe 220 11/05 3-5 iq 3 horizontal black band description dark or blurry horizontal stripes on print. Check and cause solution 1. Bad contacts of the voltage ter- minals to developer. 1. Clean each voltage terminal of the charge, supply, develop and transfer roller. (remove th...

Page 52: Iq 4 Black/white Spot

Image quality 3-6 11/05 workcentre pe 220 iq 4 black/white spot description dark or blurry black spots on the print. White spots occur on the print. Check and cause solution 1. If dark or blurry black spots occur periodically, the rollers in the devel- oper may be contaminated with for- eign matter ...

Page 53: Iq 5 Light Image

Image quality workcentre pe 220 11/05 3-7 iq 5 light image description the printed image is light, with no ghost. Check and cause solution 1. Develop roller is contaminated when the print cartridge is almost consumed. 1. Install a new print cartridge, pl 1 . 2. Ambient temperature is below than 10°c...

Page 54

Image quality 3-8 11/05 workcentre pe 220 iq 6 dark image or black image description the printed image is dark. Check and cause solution 1. Identify if the problem is caused by the scanner or the lsu / xero- graphics. 1. Perform pattern test, gp 4 . If pat- tern is good, check the scanner. If patter...

Page 55: Iq 7 Uneven Density

Image quality workcentre pe 220 11/05 3-9 iq 7 uneven density description print density is uneven. Check and cause solution 1. The pressure force on the left and right springs of the transfer roller is not even, the springs are damaged, the transfer roller is improperly installed, or the transfer ro...

Page 56: Iq 8 Background

Image quality 3-10 11/05 workcentre pe 220 iq 8 background description light dark background on the print. Check and cause solution 1. Has the customer been making a lot of prints at less than 2% area coverage? Note: the print cartridge is basi- cally designed to print 3,000 sheets with 5% image. 1....

Page 57: Iq 9 Ghost (1)

Image quality workcentre pe 220 11/05 3-11 iq 9 ghost (1) description ghost occurs at 75.5 mm intervals of the opc drum on the print. Iq 10 ghost (2) description ghost occurs at 75.5 mm intervals of the opc drum on the print. (when printing on card stock or transparencies using manual feeder) check ...

Page 58: Iq 11 Ghost (3)

Image quality 3-12 11/05 workcentre pe 220 iq 11 ghost (3) description white ghost occurs in the black image printing at 47.5mm intervals. Iq 12 ghost (4) description ghost occurs at 47.5mm(or 63.9mm) intervals. Check and cause solution 1. The life of the developer may be expired. 1. Install a new p...

Page 59

Image quality workcentre pe 220 11/05 3-13 iq 13 contamination on the face of page description the background on the face of the printed page is contaminated. Iq 14 contamination on back of page description the back of the page is contaminated at 47 mm intervals. Check and cause solution 1. Toner le...

Page 60

Image quality 3-14 11/05 workcentre pe 220 iq 15 blank page print out (1) description blank page is printed. Iq 16 blank page print out (2) description blank page is printed. One or several blank pages are printed. When the machine turns on, several blank pages print. Check and cause solution 1. Bad...

Page 61: Iq 17 Misregistration

Image quality workcentre pe 220 11/05 3-15 iq 17 misregistration description printing begins at wrong position on the paper. Check and cause solution wrong sense time caused by defective feed sensor actuator. Replace the defective actuator, pl 6 ..

Page 62

Image quality 3-16 11/05 workcentre pe 220 iq 18 printed vertical lines not straight description when printing, vertical lines are not straight. Check and cause solution 1. Check stability of 24v supply to lsu. 1. 24v stable - replace lsu, pl 1 . 24v unstable replace smps, pl 1 . If the problem pers...

Page 63: Iq 19 Blurred Image

Image quality workcentre pe 220 11/05 3-17 iq 19 blurred image description image is blurred. Check and cause solution 1. Check the gap between original and platen glass. 1. A gap of more than 0.5 mm can cause a blurred image. Ensure rollers and cover close correctly. Replace as necessary, pl 1 ..

Page 64

Image quality 3-18 11/05 workcentre pe 220 page intentionally blank.

Page 65

Repairs/adjustments workcentre pe 220 11/05 4-1 4. Repairs/adjustments rep 1 mp tray ........................................................................................................................ 4-3 rep 2 pick up roller ........................................................................

Page 66

Repairs/adjustments 4-2 11/05 workcentre pe 220 page intentionally blank.

Page 67: Rep 1 Mp Tray

Repairs/adjustments workcentre pe 220 11/05 4-3 rep 1 mp tray 1. Open the front cover. Figure 1 2. Remove the print cartridge. Figure 2 3. Hold the mp tray and pull it in the direc- tion of the arrow. Figure 3.

Page 68: Rep 2 Pick Up Roller

Repairs/adjustments 4-4 11/05 workcentre pe 220 rep 2 pick up roller 1. Before you remove the pick up roller, you should remove: - mp tray (refer to rep 1 ) 2. To exchange the pick up sponge, pull apart pick up housing u while pressing the hooks on both sides of pick up hous- ing b. Figure 1 rep 3 f...

Page 69: Rep 4 Cassette Tray

Repairs/adjustments workcentre pe 220 11/05 4-5 rep 4 cassette tray 1. Open the cassette tray. Figure 1 2. To remove the cassette tray, carefully lift the knob in the direction of the arrow while holding the set (left). Figure 2 rep 5 rear cover 1. Remove four screws securing the rear cover. Figure ...

Page 70: Rep 6 Right Cover

Repairs/adjustments 4-6 11/05 workcentre pe 220 3. To remove the rear cover, make sure the right power switch does not get jammed to the rear cover. Figure 3 4. If necessary, remove the jam cover in the direction of arrow. Figure 4 rep 6 right cover 1. Before you remove the right cover, you should r...

Page 71: Rep 7 Left Cover

Repairs/adjustments workcentre pe 220 11/05 4-7 rep 7 left cover 1. Before you remove the left cover, you should remove: - front cover (refer to rep 3 ) - rear cover (refer to rep 5 ) 2. Remove the screw securing the left cover. Figure 1 3. Apply light pressure to the back of the left cover and pull...

Page 72: Rep 8 Scan Assembly

Repairs/adjustments 4-8 11/05 workcentre pe 220 rep 8 scan assembly 1. Before you remove the scan assembly, you should remove: - rear cover (refer to rep 5 ) - right cover (refer to rep 6 ) - left cover (refer to rep 7 ) 2. Remove two screws from the middle cover and remove the screw securing the gr...

Page 73: Rep 9 Adf Housing

Repairs/adjustments workcentre pe 220 11/05 4-9 rep 9 adf housing 1. Before you remove the adf housing, you should remove: - scan assembly (refer to rep 8 ) 2. Open the adf housing and insert a flat- blade screwdriver into the slot and remove the cap-hinge from the platen housing and adf housing. Fi...

Page 74

Repairs/adjustments 4-10 11/05 workcentre pe 220 5. If necessary, remove two screws securing the tx stacker assembly. Figure 4 6. Open the open cover and remove the open cover in the direction of the arrow. Figure 5 7. Pull and rotate the bushing until it reaches the slot, then lift the pick up unit...

Page 75: Rep 10 Ope Unit

Repairs/adjustments workcentre pe 220 11/05 4-11 9. Unplug the connector from the adf pba and remove four screws securing the adf motor housing and remove it in the direc- tion of the arrow. Figure 8 rep 10 ope unit 1. Open the adf housing and insert a flat- blade screwdriver into the crack and remo...

Page 76: Rep 11 Platen Housing

Repairs/adjustments 4-12 11/05 workcentre pe 220 rep 11 platen housing 1. Before you remove the platen housing, you should remove: - scan assembly (refer to rep 8 ) - adf housing (refer to rep 9 ) - ope unit (refer to rep 10 ) 2. Remove five screws from the scan upper and remove it from the scan low...

Page 77

Repairs/adjustments workcentre pe 220 11/05 4-13 6. Remove two screws securing the scan motor assembly and remove it. Figure 5 7. If necessary, remove two screws securing the scan motor and remove it. Figure 6 8. Using a flat-blade screwdriver remove the full sensor. Figure 7.

Page 78: Rep 12 Middle Cover

Repairs/adjustments 4-14 11/05 workcentre pe 220 rep 12 middle cover 1. Before you remove the middle cover, you should remove: - scan assembly (refer to rep 8 ) 2. Remove five screws securing the middle cover. Figure 1 3. Carefully release the middle cover from the main pba. Figure 2 4. If necessary...

Page 79: Rep 13 Hvps

Repairs/adjustments workcentre pe 220 11/05 4-15 rep 13 hvps 1. Before you remove the hvps, you should remove: - scan assembly (refer to rep 8 ) - middle cover (refer to rep 12 ) 2. Remove five screws securing the hvps and remove it with the hvps ground. Figure 1 3. Unplug the connector from the hvp...

Page 80: Rep 15 Rx Drive

Repairs/adjustments 4-16 11/05 workcentre pe 220 rep 15 rx drive 1. Before you remove the rx drive, you should remove: - scan assembly (refer to rep 8 ) - middle cover (refer to rep 12 ) - main pba (refer to rep 14 ) 2. If necessary, remove bracket port, bracket main pba and ground. Figure 1 3. Remo...

Page 81: Rep 16 Fuser

Repairs/adjustments workcentre pe 220 11/05 4-17 5. Release the four gears (rdcn, opc, fuser, feed) from the frame. Figure 4 6. Remove four screws securing the motor bracket and remove it. Then remove two screws securing the motor and remove it. Figure 5 rep 16 fuser 1. Before you remove the fuser, ...

Page 82

Repairs/adjustments 4-18 11/05 workcentre pe 220 4. Remove the lever-m-act exit in the direc- tion of arrow. Figure 3 5. Remove the cover-m-safety. Figure 4 6. Remove the cover-m-guide exit. Figure 5.

Page 83

Repairs/adjustments workcentre pe 220 11/05 4-19 7. Rotate the holder in the direction of the arrow which is attached to the exit roller f/down and exit gear (drv17). (the roller_main, roller_fr, f/down holder, spring will come out at the same time.) figure 6 note: if you don't follow the direction ...

Page 84

Repairs/adjustments 4-20 11/05 workcentre pe 220 11. Release the cbf harness from the halo- gen lamp and remove two screws secur- ing the halogen lamp. Figure 10 12. Remove two screws securing the cover- m and remove it. Figure 11 caution do not touch the lamp body (glass). Contami- nation from your...

Page 85: Rep 17 Engine Shield (Liu

Repairs/adjustments workcentre pe 220 11/05 4-21 rep 17 engine shield (liu pba, smps) 1. Before you remove the engine shield, you should remove: - scan assembly (refer to rep 8 ) - middle cover (refer to rep 12 ) 2. Unplug all connectors from the smps and liu pba. Figure 1 3. Remove six screws secur...

Page 86: Rep 18 Lsu

Repairs/adjustments 4-22 11/05 workcentre pe 220 rep 18 lsu caution do not touch the lsu glass window. Con- tamination on the lsu glass window can lead to image quality problems. 1. Before you remove the lsu, you should remove: - scan assembly (refer to rep 8 ) - middle cover (refer to rep 12 ) 2. R...

Page 87: Rep 19 Paper Path Frame

Repairs/adjustments workcentre pe 220 11/05 4-23 rep 19 paper path frame 1. Before you remove the paper path frame, you should remove: - scan assembly (refer to rep 8 ) - middle cover (refer to rep 12 ) - fuser (refer to rep 16 ) - engine shield (refer to rep 17 ) 2. Remove four screws securing the ...

Page 88

Repairs/adjustments 4-24 11/05 workcentre pe 220 page intentionally blank.

Page 89

Spare parts list workcentre pe 220 11/05 5-1 5. Spare parts list pl 1 main assembly ................................................................................................................. 5-2 pl 2 adf assembly ...................................................................................

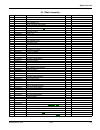

Page 90: Pl 1 Main Assembly

Spare parts list 5-2 11/05 workcentre pe 220 pl 1 main assembly.

Page 91

Spare parts list workcentre pe 220 11/05 5-3 pl 1 main assembly item part number description qt’y remark 0 set 1 ela hou-frame lower (refer to pl 8 ) 1 2 122n00243 unit-lsu 1 3 cbf harness-lsu 1 4 initial(1k) print cartridge 1 5 101n01380 fuser_110v (refer to pl 7 ) 1 5 101n01381 fuser_220v (refer t...

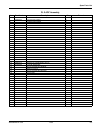

Page 92: Pl 2 Adf Assembly

Spare parts list 5-4 11/05 workcentre pe 220 pl 2 adf assembly.

Page 93

Spare parts list workcentre pe 220 11/05 5-5 pl 2 adf assembly item part number description qt’y remark 0 002n02441 ela hou-adf 1 1 002n02444 ela hou-adf lower 1 1-1 cover-m-adf lower 1 1-2 002n02445 ela hou-adf motor 1 1-2-1 gear-idle 35 adf 3 1-2-2 007n01369 gear-clutch 39 1 1-2-3 gear-swing 31/20...

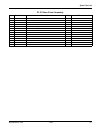

Page 94: Pl 3 Platen Cover Assembly

Spare parts list 5-6 11/05 workcentre pe 220 pl 3 platen cover assembly.

Page 95

Spare parts list workcentre pe 220 11/05 5-7 pl 3 platen cover assembly item part number description qt’y remark 0 002n02448 mea-cover platen 1 1 002n02436 cover-m-platen 1 2 095n00274 sheet-white sponge 1 3 038n00405 pmo-tx stacker 1 4 38n00410 pmo-doc guide(r) 1 5 38n00406 pmo-doc guide(l) 1 6 028...

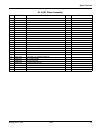

Page 96: Pl 4 Adf Platen Assembly

Spare parts list 5-8 11/05 workcentre pe 220 pl 4 adf platen assembly.

Page 97

Spare parts list workcentre pe 220 11/05 5-9 pl 4 adf platen assembly item part number description qt’y remark 0 002n02443 ela hou-platen 1 1 002n02449 ela hou-scan lower 1 1-1 002n02450 cover-m-scan lower 1 1-2 101n01345 ela hou-scan motor 1 1-2-1 bracket-m-scan motor 1 1-2-2 127n07398 motor step-s...

Page 98: Pl 5 Ope Unit

Spare parts list 5-10 11/05 workcentre pe 220 pl 5 ope unit.

Page 99

Spare parts list workcentre pe 220 11/05 5-11 pl 5 ope unit item part number description qt’y remark 0 002n02442 ela hou-ope(xerox) 1 1 002n02437 cover-m-ope 1 2 110n01390 rubber-tel 1 3 110n01391 rubber-scroll 1 4 140n63042 pba sub-ope 1 5 003n00972 key-m_shift 1 6 029n00367 key-m_status 1 7 003n00...

Page 100: Pl 6 Paper Path Assembly

Spare parts list 5-12 11/05 workcentre pe 220 pl 6 paper path assembly.

Page 101

Spare parts list workcentre pe 220 11/05 5-13 pl 6 paper path assembly item part number description qt’y remark 0 paper-path assem 1 1 038n00463 guide-m-paper path 1 2 130n01408 lever-actuator feed sensor 1 3 009n01519 spring etc-lever sensor 1 4 015n00558 ipr-plate saw 1 5 not used 6 ground-p-zener...

Page 102: Pl 7 Fuser Unit

Spare parts list 5-14 11/05 workcentre pe 220 pl 7 fuser unit.

Page 103

Spare parts list workcentre pe 220 11/05 5-15 pl 7 fuser unit item part number description qt’y remark 0 101n01381 fuser_220v 1 0 101n01380 fuser_110v 1 1 frame-p-fuser 1 2 cover-m_fuser 1 3 019n00839 holder-m-exit r 2 4 007n01377 gear-exit_drv17 1 5 holder-m-exit f/down 3 6 spring-cs 2 7 013n13843 ...

Page 104: Pl 8 Main Frame Assembly

Spare parts list 5-16 11/05 workcentre pe 220 pl 8 main frame assembly.

Page 105

Spare parts list workcentre pe 220 11/05 5-17 pl 8 main frame assembly item part number description qt’y remark 0 ela hou-frame lower 1 1 frame-m-base 1 2 015n00560 mea unit-plate knock_up 1 2-1 015n00561 plate-m-knock_up 1 2-2 shaft-p-core 1 2-3 pmo-idle knock up mp 2 2-4 019n00835 mpr-pad knock up...

Page 106: Pl 9 Mp Tray Assembly

Spare parts list 5-18 11/05 workcentre pe 220 pl 9 mp tray assembly.

Page 107

Spare parts list workcentre pe 220 11/05 5-19 pl 9 mp tray assembly item part number description qt’y remark 0 050n00478 mea unit-mp tray 1 1 015n00562 plate-m_mp 1 2 026n00766 adjust-m _mp l 1 3 026n00767 adjust-m_mp r 1 4 007n01178 gear-pinion 1 5 002n02451 sheet-mp 1.

Page 108

Spare parts list 5-20 11/05 workcentre pe 220 pl 10 common hardware & general service items pl 10 common hardware & general service items item part number description qt’y remark 0 026n00768 screw taptite 3 1 026n00769 screw taptite 1 2 105n02072 ac power cord (us ver) 1 3 117n01620 telephone line c...

Page 109

General procedures / information workcentre pe 220 11/05 6-1 6. General procedures/information gp 1 product specifications ..................................................................................................... 6-3 gp 2 system overview .....................................................

Page 110

General procedures / information 6-2 11/05 workcentre pe 220 page intentionally blank.

Page 111: Gp 1 Product Specifications

General procedures and information workcentre pe 220 11/05 6-3 gp 1 product specifications product overview table 1: item description remark basic model pe220 4 in 1 mfp target user soho, economical (speed/price) customer customer benefits (sales points) - compact size - 20ppm/a4, 20ppm/letter faste...

Page 112

General procedures and information 6-4 11/05 workcentre pe 220 specifications product specifications are subject to change without notice. See below for product specifications. General specifications table 2: item description major features copier, print, scan, fax net dimension (wxdxh) 438(w)*374(d...

Page 113

General procedures and information workcentre pe 220 11/05 6-5 print specifications scan specifications table 3: item description method laser beam printing speed up to 20ppm in a4 (20ppm in letter) emulation gdi power save yes (interval option: 5, 10,15, 30, 45 minute) resolution normal 600 x 600 d...

Page 114

General procedures and information 6-6 11/05 workcentre pe 220 copy specifications table 5: item description copy speed up to 20ppm in a4 (20ppm in letter) resolution optical 600*600 dpi (scan:600*600dpi, print: 600*600dpi) - text & text/photo mode: 600*300dpi(adf, platen) - photo mode: 600*600dpi (...

Page 115

General procedures and information workcentre pe 220 11/05 6-7 telephone specifications table 6: item description handset no manual dial yes search yes (phone book) 1-touch dial 10 ea (0~9) speed dial 90 locations(10~99) tad i/f yes tone/pulse tone - default, pulse - changing in tech mode pause yes ...

Page 116

General procedures and information 6-8 11/05 workcentre pe 220 fax specifications table 7: item description compatibility itu-t g3 modem speed 33.6kbps tx speed 3sec compression mh/mr/mmr/jpeg color fax yes (tx only) ecm yes resolution std 203*98dpi fine 203*196dpi s.Fine 300*300dpi photo 203*196dpi...

Page 117

General procedures and information workcentre pe 220 11/05 6-9 paper handling specifications software table 8: item description input capacity and types 150-sheet cassette tray (75 g/m 2 ,20 lbs) output capacity and types 50-sheet face down, (75 g/m 2 , 20 lbs) manual tray 1 sheet media size a4, a5,...

Page 118

General procedures and information 6-10 11/05 workcentre pe 220 accessories consumables table 10: item description quick start guide yes (some countries) s/w cd rom 1cd (contents: print driver, twain driver, rcp) 2cd (electronic user manual) 3cd (scansoft cd) print cartridge 1 ea power cable 1 ea te...

Page 119: Gp 2 System Overview

General procedures and information workcentre pe 220 11/05 6-11 gp 2 system overview system layout main control, operation panel, scanner, line interface and power supply. Each component is modular with focus on common and standard design of different products. Main control adopting fax & lbp printe...

Page 120

General procedures and information 6-12 11/05 workcentre pe 220 feeding section there is a universal cassette which automatically loads paper and the manual feed which supplies paper single sheet at a time. The cassette has a friction pad which separates paper to ensure sin- gle sheet feeding, and i...

Page 121

General procedures and information workcentre pe 220 11/05 6-13 safety features to prevent overheating - 1st protection device: hardware cuts off when overheated - 2nd protection device: software cuts off when overheated - 3rd protection device: thermostat cuts off mains power to the lamp. Safety de...

Page 122

General procedures and information 6-14 11/05 workcentre pe 220 scanner figure 2.

Page 123

General procedures and information workcentre pe 220 11/05 6-15 engine h/w specification 1) printing method: lsu (laser scanning unit) 2) printing speed: 20ppm (in continuing printing base letter, printing pages from 2nd to last during 1min) 3) printing resolution: 600 dpi 4) cassette capa.: cassett...

Page 124

General procedures and information 6-16 11/05 workcentre pe 220 • parallel interface control. • uart(2-channel) • synchronous serial interface control. • a/d converter(10-bit, 2channel). • general i/o port control. • tone generator. • rtc with calendar function. • s/w assistant function (rotator) - ...

Page 125

General procedures and information workcentre pe 220 11/05 6-17 • 256 gray scale 3) cis driving - cis supply voltage: +3.3v - cis max frequency: 5mhz - cislinetime • fax/copy - 1.5ms • pc-scan - 4.5ms - white output volt.: max 0.8v 4) adf driving: driving adf stepper motor, and the maximum motor spe...

Page 126

General procedures and information 6-18 11/05 workcentre pe 220 exceed the tims out level. 3) speaker driving unit analog switch(mc14053bd) makes a path for fax tone, ring, key click sound and analog mux (mc14051) makes a different signal level so that the speaker driver chip(mc34119) can drive the ...

Page 127

General procedures and information workcentre pe 220 11/05 6-19 lsu figure 1 figure 2.

Page 128

General procedures and information 6-20 11/05 workcentre pe 220 developer process - developing method: non magnetic 1 element contacting method - toner: non magnetic 1 element shatter type toner - toner qty:35gf /60gf (1k/3k) - the life span of toner 1k/3k sheets (iso 5% coverage) - toner residual s...

Page 129

General procedures and information workcentre pe 220 11/05 6-21 scanner 600dpi color cis module for flat bed, uses the cis scanning method 1) cis spec - scanning size: 216 mm (width for letter-size) - light source: led - scanning sensor: cis 600/300 dpi - scanning mode: color scan / mono scan - mtf:...

Page 130

General procedures and information 6-22 11/05 workcentre pe 220 7) motor driver speed & method (a) fax transmission - normal mode: 2000 pps - fine mode: 1000 pps - super fine mode: 667 pps (b) copy job: 667 pps, 2-2 - max(30sheets): 50gf - min(1sheets): 20gf 8) document detect sensor (a) type: photo...

Page 131

General procedures and information workcentre pe 220 11/05 6-23 ope (operational panel equipment) 1) ope panel ope panel has a micom chip on it and communicates with main cpu using serial com- munication line (sio). Ope panel consists of micom, key matrix part, led driving part and lcd part. 2) key ...

Page 132

General procedures and information 6-24 11/05 workcentre pe 220 smps & hvps it is the power supply for the entire system. It is assembled as an independent module, so it is possible to use for common use. It is mounted at back of the machine. Power part is divided by two independent pbas - smps pba ...

Page 133

General procedures and information workcentre pe 220 11/05 6-25 3) consumption power 4) power cord length: 1830 +/- 50mm 5) power cord switch: exist 6) feature - withstand resistance: 100 or more (at dc 500v) - insulating revisiting pressure: must be no problem within 1 min. (at1000vac,10ma) - leaki...

Page 134

General procedures and information 6-26 11/05 workcentre pe 220 - transfer variation voltage on environment variation: +500 v ~ +5000v - control method on environment: thv-pwm active, transfer active signal, of environment sensing voltage is input and get feed back current, and recalculate it to res...

Page 135

General procedures and information workcentre pe 220 11/05 6-27 fuser ac power control the fuser (heat lamp) gets heat from ac power. The ac power controls the switch with the triac, a semiconductor switch. The 'on/off control' is operated when the gate of the triac is turned on/off by phototriac. I...

Page 136: Gp 3 User Mode

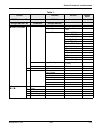

General procedures and information 6-28 11/05 workcentre pe 220 gp 3 user mode table 1 below shows the map of user settings available in user mode. These are fully described in the user guide and are not included here. Table 1: 1st level 2nd level 3rd level default value return w -- return left/righ...

Page 137

General procedures and information workcentre pe 220 11/05 6-29 3.Copy setup w default-change x 1 default-change lighten/darken normal/dark/light original type text, text/photo, photo reduce/enlarge [original(100%)] [lgl - ltr(78%)] [lgl - a4(83%)] [a4 - a5](71%)] [a4 - ltr(94%)] [exe - ltr(104%)] [...

Page 138

General procedures and information 6-30 11/05 workcentre pe 220 5. Fax setup w default-change x 1 default-change resolution standard/fine/super fine/photo/color standard 2 ring to answer 1~7 2 3 lighten/darken normal/darken/light normal 4 redial term 1~15min 3minutes 5 redials 1~13times 7times 6 msg...

Page 139

General procedures and information workcentre pe 220 11/05 6-31 9. Sound/volume w speaker x 1 speaker on, off, comm. Comm. 2 ringer off, low,med,high med 3 key sound on, off off 4 alarm sound on, off on 10. Maintenance w clean drum x 1 clean drum on,off off 2 notify toner on,off off 3 clear memory c...

Page 140

General procedures and information 6-32 11/05 workcentre pe 220 gp 4 tech mode and setting how to enter tech mode in service (tech) mode the technician can check the machine and perform various tests to help with failure diagnosis. When in tech mode the machine still performs all normal operations. ...

Page 141

General procedures and information workcentre pe 220 11/05 6-33 setting-up system in tech mode . Table 1: 1st level 2nd level 3rd level default value return w -- return left/right && enter -- x 14 character left/right && enter 1 tech mode w data setup x 1 data setup send level -9~-15 -12 dtmf level ...

Page 142

General procedures and information 6-34 11/05 workcentre pe 220 setting changing the display language to change the language that displays on the control panel, follow these steps: 1. Press menu until “machine setup” appears on the top line of the display. 2. Press the scroll key (w or x ) until “la...

Page 143

General procedures and information workcentre pe 220 11/05 6-35 note: the date format may differ from country to country. You can also use the scroll key (w or x) to move the cursor under the digit you want to cor- rect and enter a new number. 4. To select “am” or “pm” for 12-hour format, press the ...

Page 144

General procedures and information 6-36 11/05 workcentre pe 220 speaker, ringer, key sound, and alarm sound 1. Press menu until “sound/volume” appears on the top line of the display. 2. Press the scroll key (w or x) to scroll through the options. Press enter when you see the desired sound option. 3....

Page 145

General procedures and information workcentre pe 220 11/05 6-37 this method is for parallel port or usb port. Connect the pc and activate the rcp (remote control panel) to upgrade the firmware. How to update firmware using rcp 1. Connect pc and printer with a parallel cable or a usb cable. 2. Run th...

Page 146

General procedures and information 6-38 11/05 workcentre pe 220 machine test switch test use this feature to test all keys on the operation control panel. The result is displayed on the lcd window each time you press a key. Modem test use this feature to hear various transmission signals to the tele...

Page 147

General procedures and information workcentre pe 220 11/05 6-39 note: when you test the cis, make sure that the cover is closed. Figure 1 report protocol list this list shows the sequence of the ccitt group 3 t.30 protocol during the most recent sending or receiving operation. Use this list to check...

Page 148: Gp 5 Control Panel

General procedures and information 6-40 11/05 workcentre pe 220 gp 5 control panel control panel functions figure 1 lighten/darken adjusts the brightness of the documents for the current copy job. Original type selects the document type for the current copy job. Reduce/enlarge makes a copy smaller o...

Page 149

General procedures and information workcentre pe 220 11/05 6-41 gp 6 lcd status error messages table 1: status lcd display descriptions document jam document jam when document jam occurred at adf module. Door open or jam cover open [front or rear] [cover open] when machine’ front side cover or jam c...

Page 150

General procedures and information 6-42 11/05 workcentre pe 220 load document load document you have attempted to set up a sending operation with no document loaded. Memory full and canel the job cancel? 1:yes 2:no when the machine has encountered the memory full during storing the document into mem...

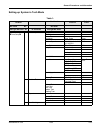

Page 151: Gp 7 Engine Test Mode

General procedures and information workcentre pe 220 11/05 6-43 gp 7 engine test mode the engine test mode supplies useful functions to check the condition of the print engine. It tests the condition of each device and displays the result of the test on the lcd. It is divided into 5 func- tions (0~4...

Page 152

General procedures and information 6-44 11/05 workcentre pe 220 detail description (engine test mode) table 1: 01.Motor test the main motor starts when the execution key is pressed and stops when the stop key is pressed. Main motor on/off 02.Pick up test automatically stops, when the execution is ch...

Page 153

General procedures and information workcentre pe 220 11/05 6-45 gp 8 paper path and clearing paper jams scan document path figure 1.

Page 154

General procedures and information 6-46 11/05 workcentre pe 220 printer paper path 1) after receiving a print command, the printer feeds paper from the main cassette or manual feed- er as required. 2) the paper being fed passes the paper feed sensor. (jam 0 occurs if the sensor is not operated withi...

Page 155

General procedures and information workcentre pe 220 11/05 6-47 clearing paper jams when a paper jam occurs, “paper jam” appears on the display. Refer to the table below to locate and clear the paper jam. To avoid tearing the paper, pull out the jammed paper gently and slowly. Follow the instruction...

Page 156

General procedures and information 6-48 11/05 workcentre pe 220 in the fuser area or around the print cartridge note: the fuser area is hot. Take care when removing paper from the machine. 1. Open the front door and pull the print cartridge out, lightly pushing it down. Figure 1 2. Remove the jammed...

Page 157

General procedures and information workcentre pe 220 11/05 6-49 in the paper exit area 1. Open and close the front door. The jammed paper automatically exits the machine. If the paper does not exit, continue to step 2. 2. Gently pull the paper out of the output tray. Figure 1 3. If there is any resi...

Page 158

General procedures and information 6-50 11/05 workcentre pe 220 4. Remove the jammed paper by gently pulling it straight out. Figure 3 note: inside of the machine is hot. Take care when removing paper from the machine 5. Close the rear door. Figure 4 6. Open and close the front door to resume printi...

Page 159

General procedures and information workcentre pe 220 11/05 6-51 tips for avoiding paper jams when printing on the a5-sized paper if paper jams occur frequently when you print on a5-sized paper: 1. Load the paper into the tray, as shown below. Figure 1 2. Open the printer’s properties window, set the...

Page 160

General procedures and information 6-52 11/05 workcentre pe 220 gp 9 general precautions on disassembly when you disassemble and reassemble components, you must use extreme caution. The close proximity of cables to moving parts makes proper routing a must. If components are removed, any cables distu...

Page 161: Gp 10 Tools

General procedures and information workcentre pe 220 11/05 6-53 gp 10 tools the following tools are recommended. Dvm (digital volt meter) standard: indicates more than 3 digits. Driver standard: "-" type, "+" type (m3 long, m3 short, m2 long, m2 short). Tweezers standard: for general home use, small...

Page 162

General procedures and information 6-54 11/05 workcentre pe 220 gp 11 acronyms and abbreviations the table below explains the abbreviations and acronyms used in this service manual. Where ab- breviations or acronyms are used in the text please refer to this table. Table 1: acronyms and abbreviations...

Page 163

General procedures and information workcentre pe 220 11/05 6-55 lan local area network lb pound(s) lbp laser beam printer lcd liquid crystal display led light emitting diode liu line interface unit l/l low temperature and low humidity lsu laser scanning unit mb megabyte mhz megahertz mpf multi purpo...

Page 164

General procedures and information 6-56 11/05 workcentre pe 220 gp 12 selecting printer locations leave enough room to open the printer trays, covers, and allow for proper ventilation. (see dia- gram below) provide the proper environment: - a firm, level surface - away from the direct airflow of air...

Page 165: Gp 13 Sample Test Pattern

General procedures and information workcentre pe 220 11/05 6-57 gp 13 sample test pattern the sample pattern shown below is the standard test pattern used in the factory. The life of the print cartridge, developer cartridge and printing speed are measured with the pat- tern shown below of 5% area co...

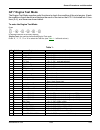

Page 166: Gp 14 Service Log

General procedures and information 6-58 11/05 workcentre pe 220 gp 14 service log service log use the service log to record all service procedures. Figure 1 ..

Page 167

General procedures and information workcentre pe 220 11/05 6-59 service log.

Page 168

General procedures and information 6-60 11/05 workcentre pe 220 page intentionally blank.

Page 169

Wiring diagrams workcentre pe 220 11/05 7-1 7. Wiring data wd 1 system block diagram .................................................................................................... 7-3 wd 2 pj locations................................................................................................

Page 170

Wiring diagrams 7-2 11/05 workcentre pe 220 page intentionally blank.

Page 171: Wd 1 System Block Diagram

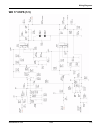

Wiring diagrams workcentre pe 220 11/05 7-3 wd 1 system block diagram.

Page 172: Wd 2 Pj Locations

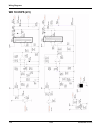

Wiring diagrams 7-4 11/05 workcentre pe 220 wd 2 pj locations.

Page 173

Wiring diagrams workcentre pe 220 11/05 7-5 wd 3 connection diagram (1/2).

Page 174

Wiring diagrams 7-6 11/05 workcentre pe 220 wd 4 connection diagram (2/2).

Page 175: Wd 5 Main Board (1/7)

Wiring diagrams workcentre pe 220 11/05 7-7 wd 5 main board (1/7).

Page 176: Wd 6 Main Board (2/7)

Wiring diagrams 7-8 11/05 workcentre pe 220 wd 6 main board (2/7).

Page 177: Wd 7 Main Board (3/7)

Wiring diagrams workcentre pe 220 11/05 7-9 wd 7 main board (3/7).

Page 178: Wd 8 Main Board (4/7)

Wiring diagrams 7-10 11/05 workcentre pe 220 wd 8 main board (4/7).

Page 179: Wd 9 Main Board (5/7)

Wiring diagrams workcentre pe 220 11/05 7-11 wd 9 main board (5/7).

Page 180: Wd 10 Main Board (6/7)

Wiring diagrams 7-12 11/05 workcentre pe 220 wd 10 main board (6/7).

Page 181: Wd 11 Main Board (7/7)

Wiring diagrams workcentre pe 220 11/05 7-13 wd 11 main board (7/7).

Page 182: Wd 12 Liu

Wiring diagrams 7-14 11/05 workcentre pe 220 wd 12 liu.

Page 183: Wd 13 Ope

Wiring diagrams workcentre pe 220 11/05 7-15 wd 13 ope.

Page 184: Wd 14 Lsu

Wiring diagrams 7-16 11/05 workcentre pe 220 wd 14 lsu.

Page 185: Wd 15 Adf

Wiring diagrams workcentre pe 220 11/05 7-17 wd 15 adf.

Page 186: Wd 16 Smps

Wiring diagrams 7-18 11/05 workcentre pe 220 wd 16 smps.

Page 187: Wd 17 Hvps (1/3)

Wiring diagrams workcentre pe 220 11/05 7-19 wd 17 hvps (1/3).

Page 188: Wd 18 Hvps (2/3)

Wiring diagrams 7-20 11/05 workcentre pe 220 wd 18 hvps (2/3).

Page 189: Wd 19 Hvps (3/3)

Wiring diagrams workcentre pe 220 11/05 7-21 wd 19 hvps (3/3).

Page 190

Wiring diagrams 7-22 11/05 workcentre pe 220 page intentionally blank.

Page 191

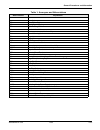

X page 1 of 2 form eh&s-700 (08nov2000) appendix a: health & safety incident report involving a xerox product customer identification customer name: name of customer contact person: telephone : address: e-mail: fax : customer service engineer identification name: employee : pager : location: phone :...

Page 192

X page 2 of 2 form eh&s-700 (08nov2000) product description model no. Or product name: product serial : serial number(s) of accessory (ies): installation date: total copy meter: date of last service maintenance: list damaged and affected part(s) of the machine by description and part number: descrip...