- DL manuals

- Xerox

- Printer

- WorkCentre PE120

- Service Manual

Xerox WorkCentre PE120 Service Manual

Summary of WorkCentre PE120

Page 1

Service manual.

Page 3: Workcentre

Workcentre ® pe120/120i service manual warning the following servicing instructions are for use by qualified service personnel only. To avoid personal injury, do not perform any servicing other than that contained in the operating instructions, unless you are qualified to do so. First printing: sept...

Page 4

Copyright © 2004 xerox corporation. All rights reserved. Unpublished rights reserved under the copyright laws of the united states. Contents of this publication may not be reproduced in any form without permission of xerox corporation. Copyright protection claimed includes all forms of matters of co...

Page 5

Table of contents i contents 1 precautions 1.1 safety warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.2 safety cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-...

Page 6

Table of contents ii 4.3 main controller board (pba) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11 4.3.1 asic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12 4.3.2 memory . . . . . . . . . . . ....

Page 7

Table of contents iii 5.17 cover mid front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17 5.18 transfer assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18 5.19 feed assembly. . . . ....

Page 8

Table of contents iv 7.2 system malfuction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 7.2.1 lcd display is defective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 7.2.2 defective control panel keypad . ...

Page 9

Service manual 1-v 7.9 software problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21 7.9.1 the printer is not responding to the print command . . . . . . . . . . . . . . . . 7-21 7.8.2 the printer is not responding to a print command or str...

Page 10

1-vi workcentre pe 120/120i.

Page 11: 1.1 Safety Warnings

Precautions service manual 1-1 in order to prevent accidents and to prevent damage to the system, please read the precautions listed below carefully before servicing the system. 1.1 safety warnings 1. Only to be serviced by appropriately qualified service engineers. High voltages and lasers inside t...

Page 12: 1.2 Safety Cautions

Precautions 1-2 workcentre pe 120/120i 1.2 safety cautions 1.2.1 toxic material this product contains toxic materials that can cause illness if ingested. 1. Please keep toner cartridges away from children. The toner powder contained in the toner cartridge can be harmful and if swallowed you should c...

Page 13

Precautions service manual 1-3 1.2.3 handling precautions the following instructions are for personal safety, to avoid injury, and to avoid damaging the system: 1. Ensure the system is installed on a level surface, capable of supporting its weight. Failure to do so could cause the system to tip or f...

Page 14

Precautions 1-4 workcentre pe 120/120i 1.2.5 bodily injury warnings 1. Use caution around internal components. The fuser unit works at a high temperature. Use caution when working on the system. Wait for the fuser to cool down before disassembly. 2. Use caution when working around rotating parts or ...

Page 15: 1.3 Esd Precautions

Precautions service manual 1-5 1.3 esd precautions some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by electro-static discharge (esd). These components include integrated circuits (ics), large-scale integrated circuits (lsis), field-effect ...

Page 16

Precautions 1-6 workcentre pe 120/120i.

Page 17: Reference Information

Reference information service manual 2-1 this section contains a tools list, list of abbreviations used in this manual, and a clearance required specification when installing the workcentre pe120/120i. 2.1 tools for troubleshooting the system the following tools are recommended for safe and easy tro...

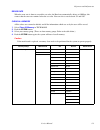

Page 18

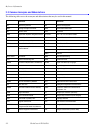

Reference information 2-2 workcenter pe 120/120i 2.2 common acronyms and abbreviations the following table covers the acronyms and abbreviations that may be used in this manual. Definition definition ac alternating current ep electro photographic adc analog-to-digital converter epp enhanced parallel...

Page 19

Reference information service manual 2-3 lan local area network ppm pages per minute lb. Pound(s) ps postscript lbp laser beam system ptl pre-transfer (erase) lamp lcd liquid crystal display pwm pulse width moduration led light emitting diode q’ty quantity lsu laser scanner unit ram random access me...

Page 20

Reference information 2-4 workcenter pe 120/120i 2.3 selecting a location for the system ■ leave enough room to open the adf, system trays, covers, and allow for proper ventilation ■ provide the proper environment ■ a sturdy, level surface ■ away from the direct airflow of air conditioners, heaters,...

Page 21: Specifications

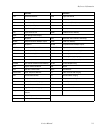

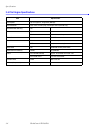

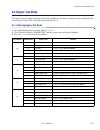

Specifications service manual 3-1 the specifiations in this manual are correct at the time of printing. Product specifications are subject to change without notice. 3.1 general specifications 3 specifications item specification major functions fax, copy, print, scan, adf, direct print, scan-to-usb m...

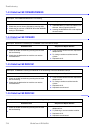

Page 22

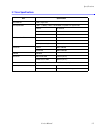

Specifications 3-2 workcentre pe 120/120i 3.2 electrical specifications 3.3 environmental specifications 3.4 routine maintenance items and consumables item specification input voltage 110 ~ 127 vac 220 ~ 240 vac input range 90 ~ 135 vac 180 ~ 270 vac input frequency: 50/60 hz 50/60 hz frequency tole...

Page 23

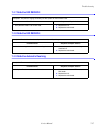

Specifications service manual 3-3 3.5 media specifications for more information on sizes, weights and approved media support for this system see the user manual.. Item specification input capacity tray 1 optional tray 2 250 sheets mp/bypass tray 50 sheets adf 50 sheets output capacity face down 150 ...

Page 24

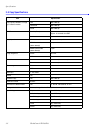

Specifications 3-4 workcentre pe 120/120i 3.6 print engine specifications item specification print speed up to 22 ppm/ltr, 20 ppm/a4 (600 dpi) print emulation gdi, pcl6, pcl5e (std), postscript level 3 (pe120i only) auto emulation sensing yes font type number 45 scalable, 1 bitmap power save yes on/...

Page 25

Specifications service manual 3-5 3.7 scan specifications item specification scan method color, single ccd scan speed adf usb 1.1, 300 dpi, letter, 128 mb ram, all speeds are approximate line art 75 seconds grayscale 75 seconds color 150 seconds scan speed on platen lineart 75 seconds grayscale 75 s...

Page 26

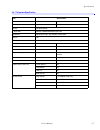

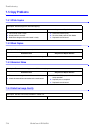

Specifications 3-6 workcentre pe 120/120i 3.8 copy specifications item specification copy quality selection or image type selection modes text 600 x 300 dpi text/photo 600 x 300 dpi photo 600 x 600 dpi fcot standby/ready approx. 10 seconds from platen approx. 15 seconds from adf cold status 50 secon...

Page 27

Specifications service manual 3-7 3.8.1 telephone specification item specification handset no on-hook dial yes search yes (phonebook) 1-touch dial 40 each: 20 dedicated buttons plus shift speed dial 200 locations (00 - 99), including 1-touch dials tad i/f yes tone/pulse selectable in technical mode ...

Page 28

Specifications 3-8 workcentre pe 120/120i 3.9 fax specification item specification compatibility itu-t g3 communication system pstn/pabx modem speed 33.6 kbps tx speed 3 seconds compression mh/mr/mmr/jbig/jpeg color fax yes; send only ecm yes resolution standard 203 x 96 dpi fine 203 x 196 dpi super...

Page 29: Product Summary

Product summary service manual 4-1 this section describes the functions and operating principals of the systems main components. 4.1 printer components - front view 4 product summary document guides document input tray document cover automatic document feeder toner cartridge optional paper tray (tra...

Page 30

Product summary 4-2 workcentre pe 120/120i 4.1.2 rear view control board cover parallel connector usb connector network port ( workcentre pe120i only) tray 2 cable connector ext jack the figure above shows the workcentre pe120i. Rear output slot (face up) power switch ac power cord connector line ja...

Page 31

Product summary service manual 4-3 4.1.3 control panel 1 allows you to store frequently-dialed fax numbers and dial them with the touch of a few buttons. Allows you to shift the one-touch buttons to the numbers 21 through 40. 2 scan allows you to access a list of your pc software programs that an im...

Page 32

Product summary 4-4 workcentre pe 120/120i 5 uses to scroll through the available options for the selected menu item. Confirms the selection on the display. Enters menu mode and scrolls through the menus available. Sends you back to the upper menu level. Stops an operation at any time. In standby mo...

Page 33: 4.2 System Layout

Product summary service manual 4-5 4.2 system layout the system is made up of the an automatic document feeder (adf), scanner, platen, and control panel and the print engine, which performs the systems print, power, controller and interface functions. 4.2.1 scanner paper path 4.2.2 print engine pape...

Page 34: 4.3 System Summary

Product summary 4-6 workcentre pe 120/120i 4.2.3 print engine paper path rollers 4.3 system summary the system consists of the following main functional components: 1) the firmware engine firmware controls the print, copy, scan and fax processes. 2) the image input terminal (iit) 1. Automatic docume...

Page 35

Product summary service manual 4-7 ■ effective pixel: 5,400 pixel *3 ■ voltage: 24 v and 5 v ■ pre-heating time: maximum 30 seconds (70% of light output reached) ■ the life span of a lamp: 30,000 hours (25 o c) image processor specification ■ operating frequency: 66mhz ■ image sensor interface: 200/...

Page 36

Product summary 4-8 workcentre pe 120/120i 4.3.1 paper feed the paper feed system consists of an automatic document feeder, a 250-sheet main paper tray, bypass tray (mp), pickup rollers, friction pads and feed rollers. The rollers and sensors in the paper feed path control paper registration and gui...

Page 37

Product summary service manual 4-9 if the heat lamp becomes too hot, the thermostat cuts off the power to the lamp in order to prevent overheating and any potential fire hazard is removed. 4.2.6.2 heat roller the heat roller transfers the heat from the heat lamp to the paper. The surface of the heat...

Page 38

Product summary 4-10 workcentre pe 120/120i 4.2.8 toner cartridge the toner cartridge is an integral unit containing the opc unit and toner unit. The opc unit consists of the opc drum and charge roller. The toner cartridge unit consists of the toner, supply roller, developing roller, and blade (doct...

Page 39

Product summary service manual 4-11 4.3 main controller board (pba) the engine board and controller board have been integrated into a single board consisting of the cpu and printer control functions. The cpu functions as the bus controller, i/o handler, motor driver and pc interface. The main board ...

Page 40

Product summary 4-12 workcentre pe 120/120i 4.3.1 asic ■ completely integrated system for embedded applications ■ 32 bit risc architecture, efficient and powerful arm9 core ■ lsu interface module for interfacing pvc or hpvc with lsu ■ 2 channel general purpose dma controller for high speed i/o ■ dua...

Page 41

Product summary service manual 4-13 4.3.2 memory the board has flash rom and dram memory units. There is 1 sodimm socket to enable extra dram. 4.3.3 flash memory record system program and download system program by pc interface. Fax for journal list, and memory for one touch dial, speed dial list. ■...

Page 42

Product summary 4-14 workcentre pe 120/120i 4.3.6.4 toner remaining sensing the printer does not have a toner remaining sensor. 4.3.5.5 paper exit sensing this detects paper exiting from the system using an exit sensor on the engine board (con2-24) and actuator on the frame. The cpu detects the on/o...

Page 43: Supply (Hvps)

Product summary service manual 4-15 4.4 switching mode power supply (smps) and high voltage power supply (hvps) the smps and hvps are on one integrated board. The smps supplies the dc power to the printer. It takes either 110 v or 220 v and outputs the +5 v and +24 v supplies to the main board. The ...

Page 44

Product summary 4-16 workcentre pe 120/120i 3) cleaning voltage (thv-) the cleaning voltage removes toner contamination from the rear side of the paper by sending (-) polarity to the transfer roller, forcing toner to transfer back to the opc drum. ■ output voltage: -1200v, +300v/-150v ■ error indica...

Page 45

Product summary service manual 4-17 4.4.2 switching mode power supply the smps is the power source for the entire printer system. The smps supplies dc power for driving the printer, and the ac heater control which supplies power to fuser. The smps has two output channels: 3.3 v and +24 v. 1) ac inpu...

Page 46: 4.5 Engine F/w

Product summary 4-18 workcentre pe 120/120i 4.4.3 fuser ac power control the fuser (heat lamp) is heated using ac power. The ac power is controlled by a triac (thy1), a semiconductor switch. 'on/off control' is achieved when the gate of the triac is turned on/off by a photo triac (pc1), this is an i...

Page 47

Product summary service manual 4-19 4.5.2 drive the main motor drives the paper feed, developing unit, and the fuser. It is driven by software which controls the acceleration, constant speed and deceleration profiles. The motor is managed with an a3977 driver ic and controlled by step and enable sig...

Page 48: 4.6 Ope (Control Panel) Pba

Product summary 4-20 workcentre pe 120/120i 4.6 ope (control panel) pba the control panel board consists of various functin keys and an lcd to display system status, operator messages, menu items, and errors. Communication between the ope and the cpu on the main board is serial. 4.7 usb host the usb...

Page 49

Product summary service manual 4-21 4.8.2 liu pba the liu board is the line interface unit. It consists of a tel_line interface circuit and telephone circuit. The tel_line circuit consists of a matching transfer to conform to the impedance of the receiving telephone line and a circuit to isolate the...

Page 50

Product summary 4-22 workcentre pe 120/120i 4.8.4 transformer circuit ■ the transformer circuit is a line impedance matching circuit which matches the internal impedance of the fax machine to the external -48volt dc impedance of the pstn system. ■ the transformer circuit insolates the fax machine el...

Page 51

Product summary service manual 4-23 4.8.7 signal ■ input signal level range : - 0dbm ~ - 48dbm ■ dp (dial pulse) dial ■ make / brake ratio : 40 : 60 ■ pulse speed : 10 ± 0.8 pps, minimum pause : above 60 msec ■ dtmf signal ■ coding format ■ transmission level l h 1209 hz 1446 hz 1477 hz 697 hz 1 2 3...

Page 52

Product summary 4-24 workcentre pe 120/120i.

Page 53: Disassembly

Disassembly service manual 5-1 5.1 precautions for disassembly/reassembly ■ use only approved xerox spare parts. Ensure that the part number, product name, any voltage, current or temperature ratings are correct. Failure to do so could result in damage to the printer, circuit overload, fire or elect...

Page 54: 5.2 Rear Cover

Disassembly 5-2 workcentre pe 120/120i 5.2 rear cover (pl 8.1.23) 1. Remove 4 screws securing the rear cover. 2. Remove the rear cover from the frame and scanner assembly. 3. Unclip the face up cover from the rear cover, as shown, then lift the face up cover out. Rear cover face up cover.

Page 55

Disassembly service manual 5-3 5.3 side covers right and left (pl 8.1.14, 21) 1. First remove: a. Rear cover, see page 5-2. B. Paper tray. 2. Open the front cover. 3. For the right side cover, remove 2 screws from the front and 1 screw on the back. 4. Release the 3 clips underneath the cover and eas...

Page 56: 5.4 Front Cover

Disassembly 5-4 workcentre pe 120/120i 5.4 front cover (pl 8.1.22) 1. Open the front cover and remove the toner cartridge. 2. Unclip the front cover from the frame and remove. 5.5 scanner assembly (pl 8.5) 1. First remove: a. Rear cover, see page 5-2. B. Side covers, see page 5-3. C. To replace the ...

Page 57

Disassembly service manual 5-5 3. Disconnect 5 connectors and the ground wire screw from the pba (main board). 4. Pull up on the scanner assembly to remove it partially from the print engine. 5. Free the scanner cable harness from the clips underneath to remove the scanner from the frame . 6. Lift t...

Page 58

Disassembly 5-6 workcentre pe 120/120i 7. Release the 3 clips on the front of the control panel, unroute the wiring harness through the frame, and remove the control panel (ope). 8. Remove 4 screws securing the scan upper. 9. Unclip the scan upper from the scan assembly by releasing 2 clips on each ...

Page 59

Disassembly service manual 5-7 13. Remove the reduction gear and idle gear. Caution when reassembling the scanner module: place the belt tension spring as close to the right side of the scanner as possible. When refitting the scan upper cover take care to ensure that the cover open switch is not tra...

Page 60: 5.6 Adf Motor Assembly

Disassembly 5-8 workcentre pe 120/120i 5.6 adf motor assembly (pl 8.3.3) 1. First remove: a. Rear cover, see page 5-2. B. Left side cover, see page 5-3. Note it is not necessary to disassembly the adf to replace the separator pad, simply open the cover and remove the pick up assembly. 1. Unclip the ...

Page 61: 5.7 Ope (Control Panel)

Disassembly service manual 5-9 5. Remove 2 screws securing the upper cover, and remove the cover. 6. Unplug 1 connector and remove 5 screws securing the adf motor assembly. Remove the motor. Note before removing the motor assembly, note the position of the ferrite and harness routing. Replacement no...

Page 62

Disassembly 5-10 workcentre pe 120/120i 5.8 middle cover and exit roller (pl 8.6) and (pl 8.7.63) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. C. Scanner assembly, see page 5-4. 2. Remove 4 screws securing the middle cover. 3. Remove 2 screws securing th...

Page 63

Disassembly service manual 5-11 5.9 controller shield assembly (pl 8.1.7) 1. First remove: a. Rear cover, see page 5-2. B. Right side cover, see page 5-3.\ 2. Remove all the connectors and 5 screws. Remove the shield. 3. Remove the network card if equiped (2 screws). 4. Remove 3 screws to remove the...

Page 64

Disassembly 5-12 workcentre pe 120/120i 5.10 engine shield and exit board (pl 8.1.10) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. 2. Unplug the exit, ac, liu, and fan connectors. 3. Remove 11 screws securing the engine shield and tilt to one side. 4. Un...

Page 65: 5.11 Smps and Liu

Disassembly service manual 5-13 5.11 smps and liu (pl 8.1.6 and pl 8. 1.13) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. C. Engine shield assembly, see page 5-12. 2. Remove 2 screws securing the inlet bracket. 3. Remove 1 screw from the engine shield gro...

Page 66: 5.12 Fuser Assembly

Disassembly 5-14 workcentre pe 120/120i 5.12 fuser assembly (pl 8.8) 1. First remove: a. Rear cover, see page 5-2. 2. Unplug 2 connectors, one to the main board and one to the smps. 3. Remove 4 screws securing the fuser assembly. Thermostat 1. Remove 2 bolts securing the thermostat, take care not to...

Page 67: 5.13 Fan

Disassembly service manual 5-15 thermistor 1. Unroute the thermistor wiring harness. 2. Remove 1 screw securing the thermistor. 5.13 fan (pl 8.1.27) 1. First remove: a. Rear cover, see page 5-2. B. Right side cover, see page 5-3. 2. Unplug the connector from the smps to the exhaust fan. 3. Remove 1 ...

Page 68: 5.15 Crum Board

Disassembly 5-16 workcentre pe 120/120i 5.14 laser scanner unit (lsu) (pl 8.1.4) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. C. Scanner assembly, see page 5-4. D. Front cover, see page 5-4. E. Middle cover, see page 5-10. 2. Remove 4 screws securing the...

Page 69: 5.16 Drive Assembly

Disassembly service manual 5-17 5.16 drive assembly (pl 8.2) 1. First remove: a. Rear cover, see page 5-2. B. Side cover, see page 5-3. C. Controller shield, see page 5-11. 2. Remove 5 screws securing the drive assembly. 3. Take out the drive assembly then unplug the connector from the motor board. ...

Page 70: 5.18 Transfer Assembly

Disassembly 5-18 workcentre pe 120/120i 5.18 transfer assembly (pl 8.1.7) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. C. Scanner assembly, see page 5-4. D. Front cover, see page 5-4. E. Middle cover, see page 5-10. F. Laser unit, see page 5-16. 2. Remov...

Page 71

Disassembly service manual 5-19 3. Remove the screws on the left and right sides of the paper guide to remove the guides and the spring as shown. 4. Remove the 3 screws securing the feed bracket and remove the bracket. 5. Remove the feed gear 2. 6. Remove the feed gear 1. 7. Remove feed roller and f...

Page 72: 5.20 Pick Up Assembly

Disassembly 5-20 workcentre pe 120/120i 5.20 pick up assembly (pl 8.7) 1. First remove: a. Rear cover, see page 5-2. B. Left and right side covers, see page 5-3. C. Front cover, see page 5-4 d. Scanner assembly, see page 5-4. E. Middle cover, see page 5-10. F. Controller shield, see page 5-11. G. En...

Page 73

Disassembly service manual 5-21 mp or main cassette pick rollers 1. Remove the main paper tray, toner cartridge, and front cover, see page 5-4. Main cassette 1. Release the white catch and slide the locking piece as far to the side as possible. 2. Slide the white collar as far to the side as possibl...

Page 74

Disassembly 5-22 workcentre pe 120/120i.

Page 75: 6.1 Paper Path

Alignment and adjustments service manual 6-1 this chapter describes some of the main service procedures including: using edc mode, clearing paper jams and test patterns. Much of this chapter is also included in the user's guide. 6.1 paper path 1. After receiving a print command, the printer feeds pa...

Page 76: Scanner Part

Alignment and adjustments 6-2 workcentre pe 120/120i 6.1.2 copy and scan paper path 6.1.3 printer paper path scanner part ccd-module white-sheet white-sheet white-sheet 1 2 3 4 8 5 6 7 5 6 7 sensor - scan sensor - regi feed roller 8 exit roller 1 2 3 4 doc. Paper (50 sheets) pickup roller adf roller...

Page 77: 6.2 Clearing Paper Jams

Alignment and adjustments service manual 6-3 6.2 clearing paper jams if a paper jam occurs, an error message appears on the lcd display. Remove any visible jammed paper in the system. If there is no paper visible, look inside the printer. If the paper tears while removing a jam, ensure that all frag...

Page 78

Alignment and adjustments 6-4 workcentre pe 120/120i 6.2.1 clearing adf jams “document jam” appears on the display if a jam has occured while feeding paper through the adf. 6.2.1.1 adf misfeed 1. Open the top cover and gently pull the document gently to the right and out the adf 2. Close the adf top...

Page 79

Alignment and adjustments service manual 6-5 6.2.2 jam 0 - paper in the feed area 6.2.3 jam 1 - paper in the fuser area or around the toner cartridge 1. Open and close the front cover, this causes the jammed paper to automatically exit the system. 2. If the paper does not exit the system, open the p...

Page 80

Alignment and adjustments 6-6 workcentre pe 120/120i 6.2.4 jam 2 - paper in the exit area 6.2.5 mp tray jam - paper in the bypass tray this jam occurs when using the mpt or bypass tray. The system does not detect paper in the tray due to the absence of media or improper loading. 1. Open and close th...

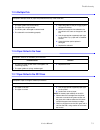

Page 81: 6.3 Control Panel Menu

Alignment and adjustments service manual 6-7 6.3 control panel menu 1.Paper setting copy tray fax tray paper tray paper size 3.Copy setup change default timeout 4.Fax setup receive mode ring to answer lighten/darken redial term redials msg confirm. Auto report auto reduction discard size rcv start c...

Page 82: 6.4 Tech Mode

Alignment and adjustments 6-8 workcentre pe 120/120i 6.4 tech mode in tech (service) mode the technician can check the system and perform various tests to help with diagnosing problems. While in tech mode the system still performs all normal operations. 6.4.1 entering tech mode 1. Press the followin...

Page 83

Alignment and adjustments service manual 6-9 error rate when the error rate is about to exceed the set value, the baud rate automatically adjusts to 2400 bps, this ensures that the error rate remains below the set value. You can select a rate between 5% and 10%. Clear all memory all the values are r...

Page 84

Alignment and adjustments 6-10 workcentre pe 120/120i 6.4.4 machine test switch test this feature is used to test all the buttons/keys on the control panel. The results are displayed on the lcd each time a button/key is pressed. Modem test this is used to hear various transmission signals to the tel...

Page 85: 6.5 Engine Test Mode

Alignment and adjustments service manual 6-11 6.5 engine test mode the engine test mode supplies functions to check the condition of each device in the print engine and displays the result of the test on the lcd. It is divided into 5 functions (0 - 4). 6.5.1 entering engine test mode 1. Press the fo...

Page 86

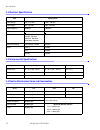

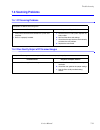

Alignment and adjustments 6-12 workcentre pe 120/120i 6.5.3 detailed description engine test mode function name description display 01. Motor test the main motor starts when executed and stops when the stop key is pressed. Main motor on/off 02. Pick up test automatically stops, when the execution ke...

Page 87: 6.6 Identify Sale Date

Alignment and adjustments service manual 6-13 6.6 identify sale date this function confirms the date that the consumer bought the product and used the product for the first time. When the consumer first operates the system, it will start the scan and page counters. The time the system was first used...

Page 88

Alignment and adjustments 6-14 workcentre pe 120/120i 6.8 periodic defective image or abnormal printing if a mark or other printing defect occurs at regular intervals down the printed page it may be caused by a damaged or contaminated roller. Measure the repeating defect and refer to the table below...

Page 89: 6.9 Error Messages

Alignment and adjustments service manual 6-15 6.9 error messages the front panel displays the printer's status or error messages. Refer to the list below for an explanation of these messages and how to clear problems. Mp tray jam [door open] a paper jam has occurred in the bypass feeder or the media...

Page 90

Alignment and adjustments 6-16 workcentre pe 120/120i enter again unavailable item entered. Solution: enter the correct item again. Function impossible a combination of printer functions that can not be used at the same time. Solution: reduce the number of selected functions or use only one function...

Page 91

Alignment and adjustments service manual 6-17 no. Not available the user tried to delete the number for a delayed fax job. Solution: verify the number to be deleted and try again. Or delete the number after the delayed fax job is completed or deleted. [no paper] add paper the paper in the paper tray...

Page 92

Alignment and adjustments 6-18 workcentre pe 120/120i [incompatible] the remote machine did not have the requested feature, such as a sending a color fax. This message also occurs if the remote machine does not have enough memory space to complete the operation you are attempting. Solution: reconfir...

Page 93: 7.1 Paper Feed Problems

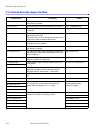

Troubleshooting service manual 7-1 7.1 paper feed problems 7.1.1 wrong print position 7.1.2 jam 0 7 troubleshooting printing begins at the wrong position on the paper. Possible cause solution 1. Defective feed sensor. A. Replace the defective acutator/sensor. Description: paper does not leave the tr...

Page 94

Troubleshooting 7-2 workcentre pe 120/120i 7.1.3 jam 1 7.1.4 jam 2 description: there is a paper jam in front of or inside the fuser. There is a paper jam stuck in the discharge roller and in the fuser, just after passing the feed actuator. Possible cause solution 1. Defective exit sensor/actuator. ...

Page 95

Troubleshooting service manual 7-3 7.2.5 multiple pick 7.2.6 paper rolled in the fuser 7.2.7 paper rolled in the opc drum description: multiple sheets of paper are picked from the tray at the same time. Possible cause solution 1. The paper guides are set incorrectly. 2. The paper has a rough surface...

Page 96

Troubleshooting 7-4 workcentre pe 120/120i 7.2.8 defective adf description: the adf does not operate correctly possible cause solution 1. The adf rubber or holder rubber are damaged or contaminated. 2. The adf document sensors (3 paper sensors) are not working correctly. A. Replace the contaminated ...

Page 97: 7.2 System Malfuction

Troubleshooting service manual 7-5 7.2 system malfuction 7.2.1 lcd display is defective 7.2.2 defective control panel keypad 7.2.3 fuser gear melted due to overheating, causing a paper jam description: strange characters are displayed on the lcd window and the control panel buttons do not work. Poss...

Page 98

Troubleshooting 7-6 workcentre pe 120/120i 7.2.4 paper empty error 7.2.5 paper empty error without indication 7.2.6 cover open 7.2.7 no error message when the cover is open description: paper empty is displayed even when paper is loaded in the tray. Possible cause sequence of repair actions 1. The p...

Page 99

Troubleshooting service manual 7-7 7.2.8 defective motor operation 7.2.9 no power 7.2.10 printed vertical lines become curved description: the main motor is faulty and paper does not feed into the printer, resulting in a jam0. Possible cause sequence of repair actions 1. The main motor harness or mo...

Page 100: 7.3 Print Quality Problems

Troubleshooting 7-8 workcentre pe 120/120i 7.3 print quality problems 7.3.1 wrong print position 7.3.2 vertical white lines 7.3.3 horizontal black band example possible cause sequence of repair actions printing begins with the paper in the wrong position. 1. Defective feed sensor. A. Replace the def...

Page 101

Troubleshooting service manual 7-9 7.3.4 black/white spot 7.3.5 light image example possible cause sequence of repair actions dark or blurry spots are randomly spread on the page, or white spots are randomly on the page. 1. If dark or blurry black spots appear, the rollers in the developer may be co...

Page 102

Troubleshooting 7-10 workcentre pe 120/120i 7.3.6 dark image or completely black print 7.3.7 uneven density example possible cause sequence of repair actions the printed image is dark or the page is entirely black. 1. Charge voltage fault due to bad contact between the toner cartridge and printer co...

Page 103

Troubleshooting service manual 7-11 7.3.8 background contamination 7.3.9 ghosting 1 example possible cause sequence of repair actions light or dark background contamination appears all over the paper. 1. Using unsupported media. 2. Printing large quantities of low coverage (2%) pages or not using th...

Page 104

Troubleshooting 7-12 workcentre pe 120/120i 7.3.10 ghosting 2 7.3.11 ghosting 3 example possible cause sequence of repair actions ghosting appears at 75.5 mm on the whole print. 1. Bad contacts caused by contamination from toner particles between the high voltage terminals, the printer, and the elec...

Page 105

Troubleshooting service manual 7-13 7.3.12 ghosting 4 7.3.13 contamination on the front of the page 7.3.14 contamination on the back of the page example possible cause sequence of repair actions white ghosting occurs every 32 mm on a black image. 1. The life of the toner cartridge may be expired. 2....

Page 106

Troubleshooting 7-14 workcentre pe 120/120i 7.1.15 blank page is printed 1 7.3.16 blank page is printed 2 example possible cause sequence of repair actions the printed page is blank. 1. Bad ground contacts in the opc and/or toner cartridge. A. Clean the ground terminals on the toner cartridge and in...

Page 107: 7.4 Fax and Phone Problems

Troubleshooting service manual 7-15 7.4 fax and phone problems 7.4.1 no dial tone 7.4.2 defective mf dial description: there is no dial tone when the on-hook dial button is pressed possible cause sequence of repair actions 1. The telephone line cord is incorrectly connected. 2. The speaker may not b...

Page 108

Troubleshooting 7-16 workcentre pe 120/120i 7.4.3 defective fax forward/receive 7.4.4 defective fax forward 7.4.5 defective fax receive 1 7.4.6 defective fax receive 2 description: fax forward/receive is not working. Possible cause sequence of repair actions 1. Check that you can hear a dial tone by...

Page 109

Troubleshooting service manual 7-17 7.4.7 defective fax receive 3 7.4.8 defective fax receive 4 7.4.9 defective automatic receiving description: the phone is ringing continuosly, but the system will not answer the call. Possible cause sequence of repair actions 1. Verify receive mode is set to fax m...

Page 110: 7.5 Copy Problems

Troubleshooting 7-18 workcentre pe 120/120i 7.5 copy problems 7.5.1 white copies 7.5.2 black copies 7.5.3 abnormal noise 7.5.4 defective image quality description: a blank page prints out when copying. Possible cause sequence of repair actions 1. The scanner cover is open. 2. Shade profile is incorr...

Page 111: 7.6 Scanning Problems

Troubleshooting service manual 7-19 7.6 scanning problems 7.6.1 pc scanning problems 7.6.2 poor quality output of pc scanned images description: unable to scan using a pc. Possible cause sequence of repair actions 1. Faulty cable communication between the system and computer. 2. Driver is inproperly...

Page 112

Troubleshooting 7-20 workcentre pe 120/120i 7.7 toner cartridge servicing use only xerox toner cartridges in the printer. Non-xerox toner or third party toner refills are not guaranteed to work with this printer and can cause malfunctions, print-quality problems, and jamming to occur. 7.7.1 precauti...

Page 113: 7.9 Software Problems

Troubleshooting service manual 7-21 7.9 software problems 7.9.1 the printer is not responding to the print command the printer is on, but not operating in print mode. 1. Run self-test mode using the menu buttons, press menu, enter, enter: a. If the test print works, there are no hardware problems wi...

Page 114: 7.9 Networking Problems

Troubleshooting 7-22 workcentre pe 120/120i 7.8.3 spool error simultaneous peripheral operations online (spool) is the process windows uses to manage print jobs. Jobs are processed and then stored on the hard disk until the printer is ready to accept them. 1. Insufficient space on the hard disk in t...

Page 115: Contents

Parts list service manual 8-1 contents ■ 8.1 main assembly ■ 8.2 main drive assembly ■ 8.3 adf assembly ■ 8.4 control panel ope assembly ■ 8.5 scanner assembly ■ 8.6 middle cover assembly ■ 8.7 frame assembly ■ 8.8 fuser unit assembly ■ 8.9 mp assembly ■ 8.10 tray 1 (cassette) unit assembly ■ 8.11 t...

Page 116: 8.1 Main Assembly

Parts list 8-2 workcentre pe 120/120i 8.1 main assembly 2 27 3 16 4 4-1 5 8 7 1-1 toner cartridge 21 22 scf 20 19 19-1 19-2 19-3 19-4 17-1 17 17-2 26 1 18 15 1-2 1-4 0 22-4 22-7 22-8 22-10 22-9 22-5 22-13 22-6 22-1 22-2 22-3 22-1 1 22-12 21-1 21-2 21-3 21-4 14 23 23-1 23-2 1-3 6 24 13 12 11 10

Page 117

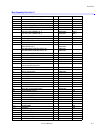

Parts list service manual 8-3 main assembly parts list 8.1 no. Part name and (part description) qty part number remark 0 workcentre pe120/120i system 1 n/s 1 ela hou-scan 1 n/s 1-1 ela hou-adf 1 002n02331 1-2 ela hou-ope (xerox control panel) 1 002n02332 1-3 cover-m-ope front 1 n/s 1-4 ela hou plate...

Page 118

Parts list 8-4 workcentre pe 120/120i 22-4 tray m exit mp 1 n/s 22-5 adjust m mp l 1 n/s 22-6 adjust m mp r 1 n/s 22-7 tray m cover mp 1 n/s 22-8 gear pinion 1 n/s 22-9 tray m case mp 1 n/s 22-10 tray m link mp 2 n/s 22-11 spring cis (2) 1 n/s 22-12 screw taptite 2 n/s 22-13 screw taptite 1 n/s 23 m...

Page 119: 8.2 Main Drive Assembly

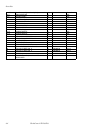

Parts list service manual 8-5 8.2 main drive assembly main drive unit assembly parts list 8.2 no. Part name and (part description) qty part number remark 0 ela unit- drive 1 n/s 1 bracket-gear main 1 n/s 2 gear-rdcn 53/26 1 n/s 3 gear-rdcn 113/33 1 n/s 4 gear-rdcn 57/18 2 n/s 5 washer-plain 2 n/s 6 ...

Page 120: 8.3 Adf Assembly

Parts list 8-6 workcentre pe 120/120i 8.3 adf assembly 1 5 6 4 adf ass'y 5-1 6-1 6-2 6-3 1-2 1-1 1-2-1 1-2-4 1-2-2 1-2-3 2 0 2-1 2-2 2-16 2-3 2-6 2-7 2-9 2-13 2-12 2-17 2-18 2-5 2-8 2-15 2-15 2-4 2-10 2-20 2-20 2-21 2-14 2-19 2-22 2-22 2-19 5-2 5-2 5-3 3 3-1 3-20 3-21 3-13 3-16 3-18 3-9 3-15 3-10 3-...

Page 121

Parts list service manual 8-7 4-1 4-3-1 4-3 4-3-2 4-3-4 4-3-3 4-3-5 4-8 4-6 4-4 4-5 4-4 4-9 4-2 s 4-7 4-7 s.

Page 122

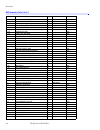

Parts list 8-8 workcentre pe 120/120i adf assembly parts list 8.3 no. Part name and (part description) qty part number remark 0 ela hou adf - system 1 n/s 1 mea unit adf upper 1 022n02094 1 -1 cover adf upper 1 n/s 1-2 mea unit holder adf 1 019n00809 1-2-1 rmo adf rubber 1 019n00566 1-2-2 holder pad...

Page 123

Parts list service manual 8-9 3-17 cbr harness adf gnd 1 n/s 3-18 ring e 6 n/s 3-19 screw taptite 3 3-20 washer plain 1 n/s 3-21 spring etc 1 n/s 4 mea cover platen 1 4-1 cover m platen 4 in 1 1 002n02342 4-2 sheet white sponge 1 019n00810 4-3 mea tx stacker (adf feed tray assembly) 1 050n00452 4-3-...

Page 124

Parts list 8-10 workcentre pe 120/120i 8.4 control panel ope assembly 0 3 10 5 1 19 17 18 16 4 6 15 7 9 8 14 11 12 13 20 21 2.

Page 125

Parts list service manual 8-11 control panel (ope) assembly parts list 8.4 no. Part name and (part description) qty part number remark 0 ela hou ope 4 in 1 1 n/s 1 cover m ope 1 n/s 2 sheet overlay ope 4 in 1 english spanish brazilian portuguese french sheet overlay ope 5 in 1 english spanish brazil...

Page 126: 8.5 Scanner Assembly

Parts list 8-12 workcentre pe 120/120i 8.5 scanner assembly 0 1 1-4 1-5 1-5 1-1 1-2 1-3 1-3-1 1-3-2 1-3-4 1-3-3 2 2-14 2-1 2-5 2-2 2-3 2-15-1 2-15-4 2-15-3 2-15-8 2-15-2 2-15 2-15-5 2-15-7 2-15-6 ? 2-4 2-10 2-8 2-12 2-11 2-16 2-13 2-6 2-7 2-9.

Page 127

Parts list service manual 8-13 scanner assembly parts list 8.5 no. Part name and (part description) qty part number remark 0 ela hou platen 1 mea unit scan upper 1 1-1 cover m scan upper 1 002n02344 1-2 glass scan 1 118n00500 1-3 mea scan dummy (constant velocity (cvt) window assembly) 1 002n02354 1...

Page 128: 8.6 Middle Cover Assembly

Parts list 8-14 workcentre pe 120/120i 8.6 middle cover assembly middle cover assembly parts list 8.6 no. Part name and (part description) qty part number remark 0 ela hou cover middle 1 n/s 1 cover m middle 1 n/s 2 cover rear upper 1 n/s 3 pmo stacker rx 1 n/s 4 bush f/down 1 n/s 5 cbf harness ope ...

Page 129: 8.7 Frame Assembly

Parts list service manual 8-15 8.7 frame assembly 1 15 16 72 18 13 10 11 12 70 71 unit fuser 55 54 68 69 8 9 14 58 24 25 43 44 45 47 39 46 17 26 42 71 47-1 46-1 46-2 47-2 47-3 47-4 47-5 45-1 45-2 45-3 40 41 51 5 62 5 5 2 4 ela hou-frame 0 3 65 25 27 73 74 75 76 27-3 27-1 78 27-2 77 19-1 19-2 67 50 7...

Page 130

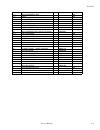

Parts list 8-16 workcentre pe 120/120i frame unit assembly parts list 8.7 no. Part name and (part description) qty part number remark 0 ela unit-frame 110v 1 002n02353 110v 0 ela unit-frame 220v 1 002n02352 220v 1 frame-base r2 1 n/s 2 guide-p-tr 1 038n00407 3 plate-p-saw 1 015n00500 4 guide-m-tr ri...

Page 131

Parts list service manual 8-17 43 solenoid-feed r2 1 121n01077 44 solenoid-hb (manual) 1 700n00094 45 mea unit-gear pickup 1 007n01271 45-1 gear-pick up b_r2 1 n/s 45-2 gear-pick up a_r2 1 n/s 45-3 spring-cs 1 n/s 46 mea unit-bracket feed 1 030n00690 46-1 bracket-feed r2 1 n/s 46-2 gear-z35 idle 1 n...

Page 132: 8.8 Fuser Unit Assembly

Parts list 8-18 workcentre pe 120/120i 8.8 fuser unit assembly 0 1 31 3 4 5 29 29 37 35 6 17 36 12 14 34 38 37 13 15 32 30 11 16 33 19 18 23 24 25 28 26 27 20 21 36 38 10 7 22 8 9.

Page 133

Parts list service manual 8-19 fuser assembly parts list 8.8 no. Part name and (part description) qty part number remark 0 ela hou-fuser 110v 1 126n002 14 110v 0 ela hou-fuser 220v 1 126n002 15 220v 1 cover-fuser r2 1 2 holder-plate claw r2 4 3 spring etc-claw 4 4 pmo-roller_exit 2 5 spring etc-fuse...

Page 134: 8.9 Mp Assembly

Parts list 8-20 workcentre pe 120/120i 8.9 mp assembly 0 11 18 24 31 10 2 12 15 29 16 17 13 19 27 6 7 14 26 14 23 28 23 1 30 20 9 3 21 25 25 19 5-2 4 5 5-1 5-3.

Page 135

Parts list service manual 8-21 mp assembly parts list 8.9 no. Part name and (part description) qty part number remark 0 ela unit-mp 1 022n02085 1 frame-17-mp 1 n/s 2 solenoid-mp 1 121n01078 3 cbf harness-mpf sen 1 n/s 4 bush-m-pick-up r 1 n/s 5 mea unit pick up mp 1 130n01366 5-1 housing-m-pick up2_...

Page 136

Parts list 8-22 workcentre pe 120/120i 8.10 tray 1 (cassette) unit assembly 0 1 2 3 4 16 6 7 6-4 6-3 6-2 6-1 5 5 10 11 15 12 13 14 8 17.

Page 137

Parts list service manual 8-23 tray 1 (cassette) unit assembly parts list 8.10 no. Part name and (part description) qty part number remark 0 mea unit-cassette, usa 1 1 frame-m-cassette 1 n/s 2 guide-m-extension large 1 n/s 3 guide-extension small 1 n/s 4 plate-p-knock_up 1 n/s 5 spring-cs 2 n/s 6 me...

Page 138

Parts list 8-24 workcentre pe 120/120i 8.11 tray 2 (scf - optional cassette) unit assembly 0 5 4 2 3 31 15 16 36 34 34 27 43 38 35 24 21 20 22 23 19 18 17 39 39-2 39-1 39-9 39-5 39-4 39-7 39-6 39-3 39-8 27 33 32 25 26 28 27 1 30 37 38 39-10 40 1-3 1-4 41 11 13 10 14 6 9 7 12 8 42 29 45.

Page 139

Parts list service manual 8-25 tray 2 (scf - optional cassette) assembly parts list 8.11 no. Part name and (part description) qty part number remark 0 ela hou-scf 1 1 cover-m-front scf r2 1 002n02347 2 cover-m-left scf 1 002n02348 3 cover-m-right scf 1 002n02349 4 cover-m-rear scf 1 002n02350 5 fram...

Page 140

Parts list 8-26 workcentre pe 120/120i xerox options and accessories 39-8 gear-idle 23 1 n/s 39-9 motor step(scf) 1 n/s 39-10 screw-machine 5 n/s 39-11 core-ferrite 1 n/s 39-12 cable tie 1 n/s 40 bush cable 1 n/s 42 mea cassette 1 n/s 43 mec brush antistatic .25 n/s 44 sheet brush 1 n/s 45 guide cam...

Page 141: Block Diagram

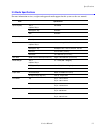

Block diagram service manual 9-1 9 block diagram.

Page 142

Block diagram 9-2 workcentre pe 120/120i.

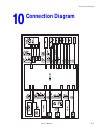

Page 143: Connection Diagram

Connection diagram service manual 10-1 10 connection diagram cn5 cn2 cn4 cn1 cn9 cn17 cn20 cn24 cn21 cn15 cn25 cn18 cn8 cn7 cn9 cn11 cn23 cn2 cn1 cn3.

Page 144

Connection diagram 10-2 workcentre pe 120/120i.

Page 145

071-0874-00