- DL manuals

- Xerox

- All in One Printer

- WorkCentre PE16

- Service Manual

Xerox WorkCentre PE16 Service Manual

Summary of WorkCentre PE16

Page 1

Service workcentre pe16 manual workcentre pe16 contents 1. Precautions 2. Reference information 3. Specifications 4. Summary of product 5. Disassembly and reassembly 6. Alignment and adjustments 7. Troubleshooting 8. Exploded views and parts list 9. Block diagram 10. Connection diagram 071-0871-00

Page 3: 1. Precautions

1 1 1-1 precautions service manual workcentre pe16 ju ly 2003 1. Precautions product terms caution: a personal injury hazard exists that may not be apparent. For example, a panel may cover the hazardous area. Danger: a personal injury hazard exists in the area where you see the sign. Symbols marked ...

Page 4: Laser Safety Statement

1-2 precautions service manual ju ly 2003 workcentre pe16 laser safety statement the printer is certified in the u.S. To conform to the requirements of dhhs 21 cfr, chapter 1 subchapter j for class 1(1) laser products, and elsewhere, it is certified as a class i laser product conforming to the requi...

Page 5: Power Safety Precautions

1-3 precautions service manual workcentre pe16 ju ly 2003 power safety precautions power source for 110 vac units, do not apply more than 140 volts rms between the supply conductors or between either supply conductor and ground. Use only the specified power cord and connector. For 220 vac units, do ...

Page 6

1-4 precautions service manual ju ly 2003 workcentre pe16 electrostatic discharge (esd) precautions some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by electrostatic discharge (esd). These components include integrated circuits (ics), large...

Page 7: Service Safety Summary

1-5 precautions service manual workcentre pe16 ju ly 2003 service safety summary general guidelines note the material presented here is intended as a safety reminder for qualified service personnel. Refer also to the preceding power safety precautions. Avoid servicing alone: do not perform internal ...

Page 8

1-6 precautions service manual ju ly 2003 workcentre pe16 servicing electrical components before starting any service procedure, switch off the product power and unplug the power cord from the wall outlet. If you must service the unit with power applied, be aware of the potential for electrical shoc...

Page 9

2 2 2-1 reference information service manual workcentre pe16 ju ly 2003 2. Reference information this chapter provides reference information for this service manual consist ing of the tool list, a list of acronyms and abbreviation s, an d examples of test patterns . 2.1 tool for troubleshooting the ...

Page 10

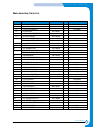

2-2 reference information service manual ju ly 2003 workcentre pe16 2.2 acronyms and abbreviations the table below explains the acronyms and abbreviations used in this service manual. The se are used throughout the text of this service manual. Please refer to the table. Ac alternating current adf au...

Page 11

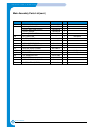

2-3 reference information service manual workcentre pe16 ju ly 2003 2.3 the sample test patterns the following test pattern s are the standard pattern s used to test the product in the factory. Cartridge life span and printing speed are measured with the pattern s shown below. (the picture in the ma...

Page 12

2-4 reference information service manual ju ly 2003 workcentre pe16 2.3.2 a4 2% pattern.

Page 13

2-5 reference information service manual workcentre pe16 ju ly 2003 2.3.3 a4 idc 5% pattern.

Page 14

2-6 reference information service manual ju ly 2003 workcentre pe16.

Page 15: 3. Specifications

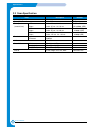

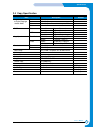

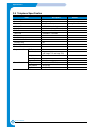

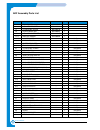

3 3 3-1 specifications service manual workcentre pe16 june 2003 3. Specifications specifications are correct at the time of printing. Product specifications are subject to change without notice. See below for product specifications. 3.1 general specifications items descriptions remarks major feature...

Page 16

3-2 specifications service manual june 2003 workcentre pe16 3.3 scan specification items descriptions remarks halftone(gray scale) 256 level scan method color ccd itu-t #1 chart scan speed adf letter : 25 sec, a4 : 28 sec text/mixed mode : (seconds/scan) platen letter : 25 sec, a4 : 28 sec b/w & 300...

Page 17

3-3 specifications service manual workcentre pe16 june 2003 3.4 copy specification items descriptions remarks copy quality selection text 600x300dpi or original image type auto 600x300dpi selection mode photo 600x600dpi for platen / 600x300dpi for adf other - fcot platen power save approx. 54 second...

Page 18

3-4 specifications service manual june 2003 workcentre pe16 3.5 telephone specification items descriptions remarks handset no on hook dial yes search yes (phone book) by using phone book button 1-touch dial 10ea (3*4 numeric key) auto dial 100 locations (using 3*4 buttons) tad i/f no tone/pulse sele...

Page 19

3-5 specifications service manual workcentre pe16 june 2003 3.6 fax specification items descriptions remarks compatibility itu-t g3 communication system pstn/pabx modem speed 33.6 kbps tx speed approx. 3 sec compression mh/mr/mmr/jpeg ecm yes resolution std 203 x 98 dpi fine 203 x 196 dpi s.Fine 300...

Page 20

3-6 specifications service manual june 2003 workcentre pe16 3.7 paper handling 3.8 software items descriptions remarks capacity main tray 250sheets (20lbs) bypass single sheet optional cassette no output capacity 150sheets/20lb, 1sheet/face up output control face down/face up paper size main tray cs...

Page 21

3-7 specifications service manual workcentre pe16 june 2003 3.9 consumables items descriptions remarks type single cartridge how to install front door open and front loading toner life initial 2,000 sheets idc 5% running 3,500 sheets character printing level sensor no toner count yes.

Page 22

3-8 specifications service manual june 2003 workcentre pe16.

Page 23: 4. Summary of Product

4-1 workcentre pe16 july 2003 summary of product service manual 4 4 4. Summary of product this chapter describes the functions and operating principals of the main components. 4.1 printer components 4.1.1 front view document guides document input tray document output tray control panel paper tray fr...

Page 24

4-2 summary of product workcentre pe16 july 2003 service manual 4.1.2 rear view ac power cord connector parallel connector power switch usb connector telephone line connector rear output slot (face up) rear cover.

Page 25

4-3 workcentre pe16 july 2003 summary of product service manual 1 4 6 5 3 2 4.1.3 control panel 1 c o p y 2 3 adjusts the brightness of the documents for the current copy job. Selects the document type for the current copy job. Allows you to use special copy features, such as clone, collation, auto ...

Page 26

4-4 summary of product workcentre pe16 july 2003 service manual 4 5 f a x 6 s a v e dials a number or enters alphanumeric characters. Adjusts the resolution of the documents for the current fax job. Allows you to send a fax to multiple destinations. Allows you to store frequently-dialed fax numbers ...

Page 27: 4.2 System Layout

4-5 workcentre pe16 july 2003 summary of product service manual 4.2 system layout 4.2.1 feeding section paper for the machine is supplied from a universal cassette or from the manual feeder, for single sheet feeding. The cassette contains a friction pad, to separate the paper and prevent multi-sheet...

Page 28

4-6 summary of product workcentre pe16 july 2003 service manual 4.2.4.5 safety relevant facts • protecting device when overheating - 1st protecting device: h/w cuts off when an overheat condition is detected. - 2nd protecting device: s/w cuts off when an overheat condition is detected. - 3rd protect...

Page 29

4-7 workcentre pe16 july 2003 summary of product service manual 4.2.6 lsu (laser scanner unit) the lsu is controlled by the video controller. It converts the received video data to pulsed laser light that is scanned onto the surface the opc drum using a rotating polygon mirror. This creates the late...

Page 30

4-8 summary of product workcentre pe16 july 2003 service manual 4.2.7 toner cartridge the xerographic process creates a visual image from the latent image. The toner cartridge contains the opc drum, developer, and toner components in one unit. The opc unit contains the opc drum and charging roller. ...

Page 31: 4.3 Main Pba

4-9 workcentre pe16 july 2003 summary of product service manual 4.3 main pba the main pba is the functional center of the product. It controls all basic machine operations including fax, scan, and printer operations, sensor detection, and power levels. U41 u74 osc3 u47 cn10 cn8 cn7 cn9 u118 u135 u11...

Page 32

4-10 summary of product workcentre pe16 july 2003 service manual 4.3.1 asic samsung’s s3c46q0x 16/32-bit risc micro controller is designed to provide a cost-effective, low power, small die size and high performance micro-controller solution for mfp. The s3c46q0x is developed using arm7tdmi core, 0.1...

Page 33

4-11 workcentre pe16 july 2003 summary of product service manual 4.3.4 sensor input circuit 1) paper empty sensor the paper empty sensor (photo interrupter) on the engine board notifies the cpu when the cassette is empty. The empty signal to the cpu sets the d0 bit in the cpu, which results in the c...

Page 34: 4.4 Smps & Hvps

4-12 summary of product workcentre pe16 july 2003 service manual 4.4 smps & hvps the smps supplies dc power to the system. The supply receives 110v/220v input, and outputs 5v, 12v, and 24v to supply the power to the main board and adf board. The hvps creates the high voltage for thv/mhv/supply/dev a...

Page 35

4-13 workcentre pe16 july 2003 summary of product service manual 4.4.1 hvps (high voltage power supply) 1) transfer high voltage (thv+) - function : voltage to transfer developed toner image on opc drum to paper. - output voltage : +1300v dc±20v - error : if thv (+) doesn't output, a ghost (same cha...

Page 36

4-14 summary of product workcentre pe16 july 2003 service manual 4.4.2 smps (switching mode power supply) this is the power source for the whole system. It is an independent module, so it can be used for common use. It is mounted at the bottom of the set. The module contains the smps, which supplies...

Page 37

4-15 workcentre pe16 july 2003 summary of product service manual 6) feature - insulating resistance : over 50m Ω (at 500 vdc ) - insulating revisiting pressure : must be no problem within 1 min. (at 1500 vzc, 10 ma) - leaking voltage : under 3.5ma - running voltage : under 40 a peak (at 25°c, cold s...

Page 38: 4.5 Engine F/w

4-16 summary of product workcentre pe16 july 2003 service manual 4.5 engine f/w 4.5.1 feeding if feeding from the cassette, the pickup roller drive is controlled by the solenoid. The solenoid is switched on and off by contro signals from either the general output port or the external output port. If...

Page 39

4-17 workcentre pe16 july 2003 summary of product service manual 4.5.4 fusing the temperature of the heat roller’s surface is changed due to the resistance value of the thermistor. By converting the voltage value to a digital value, through the ad converter, the temperature is selected. The ac power...

Page 40: 4.6 Liu Pba

4-18 summary of product workcentre pe16 july 2003 service manual 4.6 liu pba liu board is a line interface unit, and it is a circuit for interfacing a telephone line with a modem. The circuit consists of matching transfer to conform to impedance of a receiving telephone line and a circuit to conform...

Page 41

5 5 5-1 disassembly and reassembly service manual workcentre pe16 july 2003 5. Disassembly and reassembly 5.1 general precautions on disassembly when you disassemble and reassemble compo- nents, you must use extreme caution. The close proximity of cables to moving parts makes proper routing essentia...

Page 42

5-2 disassembly and reassembly service manual july 2003 workcentre pe16 5.2 rear cover 1. Remove the four screws securing the rear cover. 2. Remove the rear cover from the frame ass'y and scanner ass'y. 3. Unlatch the (cover face up) securing the rear cover, as shown below.Then lift the (cover face ...

Page 43

5-3 disassembly and reassembly service manual workcentre pe16 july 2003 5.3 side cover (lh, rh) 1. Before you remove the side cover (lh, rh), you should remove: - rear cover (see page 5-2) 2. Unplug the speaker harness, as shown below. 3. Pull down and back on the lh and rh side covers and lift them...

Page 44

5-4 disassembly and reassembly service manual july 2003 workcentre pe16 5.4 front cover 1. Take out the cassette. 2. Open the front cover. 3. Unlatch the front cover securing the frame ass'y. Then remove the front cover, as shown below. Cassette front cover.

Page 45

5-5 disassembly and reassembly service manual workcentre pe16 july 2003 5.5 scanner ass'y 1. Before you remove the scanner ass'y, you should remove: - rear cover (see page 5-2) - side cover (lh, rh) (see page 5-3) 2. Remove the two screws securing the scanner ass'y, as shown below. 3. Unplug the fou...

Page 46

5-6 disassembly and reassembly service manual july 2003 workcentre pe16 6. Remove the three screws securing the scan ass’y. 7. Lift the ope unit out. Then unplug the two connec- tors from the ope unit and remove it. 8. Remove the four screws securing the scan upper. 9. Unlatch the scan upper securin...

Page 47

5-7 disassembly and reassembly service manual workcentre pe16 july 2003 10. Disconnect the ccd ass'y end of the ccd cable. 11. Push the belt holder and take out the belt, as shown below. 12. Pull up the ccd shaft and take out the scanner module. Ccd cable ccd shaft scanner module belt holder belt.

Page 48

5-8 disassembly and reassembly service manual july 2003 workcentre pe16 14. Remove the two screws and take out the motor bracket. 15. Unplug the one connector from the open sensor ass'y. 16. Unlatch the open sensor and remove it, as shown below. Open sensor motor bracket.

Page 49

5-9 disassembly and reassembly service manual workcentre pe16 july 2003 5.6 adf motor ass'y 1. Before you remove the adf motor ass'y, you should remove: - four screws securing the tray and remove the tray - two screws securing the adf ass'y - wiring harness from cover 2. Remove the adf ass'y. 3. Rem...

Page 50

5-10 disassembly and reassembly service manual july 2003 workcentre pe16 5.7 ope unit 1. Remove the seven screws securing the ope pba to the ope cover. 2. Remove the contact rubber from the ope cover. 3. Remove the key pad from the ope cover. Ope cover ope pba contact rubber key pad.

Page 51

5-11 disassembly and reassembly service manual workcentre pe16 july 2003 5.8 middle cover & exit roller 1. Before you remove the exit roller, you should remove: - rear cover (see page 5-2) - front cover ass’y (see page 5-4) - side cover (lh, rh) (see page 5-3) - scanner ass’y (see page 5-5) 2. Remov...

Page 52

5-12 disassembly and reassembly service manual july 2003 workcentre pe16 1. Before you remove the engine shield ass'y, you should remove: - rear cover (see page 5-2) - side cover(lh, rh) (see page 5-3) - scanner (see page 5-5) 2. Remove the two screws securing and unplug the fpc cable from the main ...

Page 53

5-13 disassembly and reassembly service manual workcentre pe16 july 2003 1. Before you remove the main pba, you should remove: - engine shield ass’y(see page 5-12) 2. Unplug the one connector and remove the five screws securing the main pba. Then lift the main pba out, as shown. Main pba 5.10 main p...

Page 54

5-14 disassembly and reassembly service manual july 2003 workcentre pe16 5.11 smps 1. Before you remove the smps, you should remove: - engine shield ass’y(see page 5-12) 2. Remove the three screws securing the inlet bracket and remove it 3. Unplug the one connector and remove the one screw securing ...

Page 55

5-15 disassembly and reassembly service manual workcentre pe16 july 2003 5.12 fuser ass'y 1. Before you remove the fuser ass'y, you should remove: - rear cover (see page 5-2) 2. Unplug the two connectors from the main pba and smps, as shown below. Then remove the four screws securing the fuser ass'y...

Page 56

5-16 disassembly and reassembly service manual july 2003 workcentre pe16 thermister harness thermister 7. Unwrap the thermister harness, as shown below. 8. Remove the one screw securing the thermister and remove it, as shown below..

Page 57

5.13 fan 1. Before you remove the fan, you should remove: - rear cover (see page 5-2) - side cover (rh) (see page 5-3) 2. Unplug the connector from the smps and remove the one screw. Then take out the fan. Dc fan 5-17 disassembly and reassembly service manual workcentre pe16 july 2003.

Page 58

5-18 disassembly and reassembly service manual july 2003 workcentre pe16 1. Before you remove the lsu, you should remove: - rear cover (see page 5-2) - side cover (lh, rh) (see page 5-3) - scanner ass’y (see page 5-5) - front cover (see page 5-4) - middle cover (see page 5-11) 2. Unplug the two conn...

Page 59

5-19 disassembly and reassembly service manual workcentre pe16 july 2003 1. Before you remove the transfer ass'y, you should remove: - rear cover (see page 5-2) - side cover (lh, rh) (see page 5-3) - scanner ass’y (see page 5-5) - front cover (see page 5-4) - middle cover (see page 5-11) - lsu (see ...

Page 60

5-20 disassembly and reassembly service manual july 2003 workcentre pe16 5.17 feed ass'y 1. Before you remove the feed ass'y, you should remove: - rear cover (see page 5-2) - side cover (lh, rh) (see page 5-3) - scanner ass’y (see page 5-5) - front cover (see page 5-4) - middle cover (see page 5-11)...

Page 61

5-21 disassembly and reassembly service manual workcentre pe16 july 2003 6. Remove the feed gear1 ass'y. 7. Pull up the feed roller and feed roller1. Feed gear1 ass’y feed roller1 feed roller.

Page 62

5-22 disassembly and reassembly service manual july 2003 workcentre pe16 5.18 pick-up ass'y & solenoid 1. Before you remove the pick-up ass'y, you should remove: - rear cover (see page 5-2) - side cover (lh, rh) (see page 5-3) - front cover (see page 5-4) - scanner ass’y (see page 5-5) - middle cove...

Page 63: 6.1 Paper Path

6 6 6-1 alignment & a d j u s t m e n t s service manual workcentre pe16 june 2003 6. Alignment and adjustments this chapter describes the main functions for service, such as the product maintenance method, the test output related to maintenance and repair, dcu using method, jam removing method, and...

Page 64

6-2 alignment & a d j u s t m e n t s service manual july2003 workcentrepe16 6.1.1 copy & scan document path 6.1.2 printer paper path 1) after receiving a print job, the printer feeds the paper from the cassette or manual feeder. 2) the fed paper passes the paper feeding sensor. (jam 0 occurs if the...

Page 65: 6.2 Clearing Paper Jams

6-3 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.2 clearing paper jams occasionally, paper can be jammed during a print job. Some of the causes include: • the tray is loaded improperly or overfilled. • the tray has been pulled out during a print job. • the front cover...

Page 66

6-4 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.2.1 clearing document jams if a document jams while it is feeding through the adf (automatic document feeder),“document jam ” appears on the display. 6.2.1.1 input misfeed 1) open the adf top cover. 2) pull the document...

Page 67

1) open the document cover. 2) turn the release knob so that you can easily remove the misfed document. Remove the document from the adf or the feed area by carefully pulling it towards the right by using both hands. 3) close the document cover. Then load the documents back into the adf. 6-5 alignme...

Page 68

6-6 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.2.2 clearing paper jams if paper jams occur, “paper jam ” appears on the display. Refer to the table below to locate and clear the paper jam. Paper jam 0 : in the paper feed area paper jam 2 : in the paper exit area pap...

Page 69

6-7 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.2.2.2 jam 2 (in the paper exit area) 1) open and close the front cover. The jammed paper automatically exits the machine. If the paper does not exit, continue to step 2. 2) gently pull the paper out of the front output ...

Page 70

6-8 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.2.2.3 jam1 (in the fuser area of around the toner cartridge area) note : the fuser area is hot. Be careful when removing paper from the machine. 1) open the front cover and remove the toner cartridge. 2) remove the jamm...

Page 71

6-9 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.2.2.4 bypass jam (in the bypass tray) “bypass jam ” appears on the display when the machine does not detect paper in the bypass tray due to no paper or improper paper loading when you try to print using the bypass tray....

Page 72

6-10 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 1.Paper setting paper tray paper size 2.Copy setup change default timeout 3.Fax setup receive mode ring to answer contrast redial term redials msg confirm. Auto report auto reduction discard size 4.Fax feature delay fax ...

Page 73: 6.4 Tech Mode

6-11 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.4 tech mode 6.4.1 how to enter tech mode in service (tech) mode, the technician can check the machine and perform various tests to isolate the cause of a malfunction. While in tech mode, the machine still performs all ...

Page 74

6-12 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.4.3 data setup send level you can set the level of the transmission signal. Typically, the tx level should be under -12 dbm. Caution : the send fax level is set for optimum performance when shipped from the factory. Ne...

Page 75

6-13 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 flash upgrade the firmware upgrade function and has two methods, local and remote. (1) local machine • rcp (remote control panel) mode this method is for parallel port or usb port. Connect to pc and activate rcp (remote ...

Page 76

6-14 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.4.4 machine test switch test use this feature to test all keys on the operation control panel. The result is displayed on the lcd window each time you press a key. Modem test use this feature to hear various transmissi...

Page 77

6-15 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.4.5 report protocol list this list shows the sequence of the ccitt group 3 t.30 protocol during the most recent sending or receiving operation. Use this list to check for send and receive errors. If a communication err...

Page 78: 6.5 Engine Test Mode

6-16 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.5 engine test mode the engine tests mode supplies useful functions to check the condition of the engine. It tests the condition of each device and displays the result of the test on the lcd. It is classified into 5 fun...

Page 79: 6.6 Identify Sale Date

6-17 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.6 identify sale date this function confirms the date the consumer bought the product and used it for the first time. When the consumer first operates the machine, it will start a scan and page count. The time the machi...

Page 80

6-18 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.7 consumables and replacement parts the cycle periods listed below are a general guideline for maintenance. The example list is for an average usage of 50 transmitted and received documents per day. Environmental condi...

Page 81

6-19 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 6.8 abnormal image printing and defective roller if abnormal image prints periodically, check the parts shown below. No roller abnormal image period kind of abnormal image 1 opc drum 75.5mm white spot, black spot 2 charg...

Page 82: 6.9 Error Messages

6-20 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16 6.9 error messages the display on the front panel shows printer status and error messages. Refer to the following material for explanations of the messages and possible solutions to the problems. The messages are listed ...

Page 83

6-21 alignment & a d j u s t m e n t s service manual workcentre pe16 july 2003 no answer meaning : the remote machine did not answer after all the redial attempts. Solution : try again. Make sure the remote machine is ok. No cartridge meaning : the machine has detected that no toner cartridge is in...

Page 84

6-22 alignment & a d j u s t m e n t s service manual july 2003 workcentre pe16.

Page 85: 7. Troubleshooting

7 7 7-1 workcentre pe16 troubleshooting service manual ju ly 2003 7. Troubleshooting 7.1 paper feeding problems 7.1.1 wrong print position • description printing begins when the paper is in the wrong position. Check and cause solution a defective feed sensor actuator can cause incorrect tim- ing. Re...

Page 86

7-2 troubleshooting workcentre pe16 service manual ju ly 2003 7.1.4 jam 2 • description 1. Paper exits the printer but jam 2 occurs . 2. Paper is stuck in the fuser roller . Ptl p i c k /r pr cr dr sr tr fr empty sensor opc l s u fuser toner cartridge exit sensor feed sensor mp sensor check and caus...

Page 87

7-3 workcentre pe16 troubleshooting service manual ju ly 2003 7.1.5 multi-feeding • description multiple sheets of paper are fed at once. Check and cause solution 1. Solenoid malfunction(the solenoid does not work properly): perform engine test mode : diagnostic mode code 0. 2. Friction-pad is conta...

Page 88

7-4 troubleshooting workcentre pe16 service manual ju ly 2003 7.1.7 paper rolled in the opc • description paper is rolled up in the opc. Check and cause solution 1. Paper is out of specification. 2. Paper is curled. 1. Use recommend paper. 2. How to remove the rolled paper in the opc. • remove the p...

Page 89

7-5 workcentre pe16 troubleshooting service manual ju ly 2003 7.2. Printing problems (malfunction) 7.2.1 defective operation (lcd window ) display • description strange characters are displayed on the ope panel and buttons do not operate. Check and cause solution 1. Clear the memory.(see page 6.5.3)...

Page 90

7-6 troubleshooting workcentre pe16 service manual ju ly 2003 7.2.3 not functioning of the fuser gear due to melting away • description the fuser gear melts and breaks. Check and cause solution 1. Check the heat lamp. 1. Replace the fuser. 2. Replace the main pba. 3. Replace the smps. 7.2.4 paper em...

Page 91

7-7 workcentre pe16 troubleshooting service manual ju ly 2003 7.2.6 door open • description the error lamp is on even when the print door is closed. Check and cause solution 1. The hook lever in the front cover may be defective. 2. Check the connector(cn1) and circuit of the cover switch department ...

Page 92

7-8 troubleshooting workcentre pe16 service manual ju ly 2003 7.2.8 defective motor operation • description main motor is not driving when printing, and paper does not feed into the printer, resulting 'jam 0'. Check and cause solution 1. Motor harness may be defective. 2. Perform engine test mode di...

Page 93

7-9 workcentre pe16 troubleshooting service manual ju ly 2003 7.2.10 vertical line getting curved • description when printing, vertical line gets curved. Check and cause solution 1. If the supply of +24v is unstable in the main control board linking with lsu, check drive by engine test mode : diagno...

Page 94

7-10 troubleshooting workcentre pe16 service manual ju ly 2003 7.3.1 vertical black line and band • description 1. Straight thin black vertical line occurs in the printing. 2. Dark black vertical band occur s in the printing. Digital printer digital printer digital printer digital printer digital pr...

Page 95

7.3.3 horizontal black band • description 1. Dark or blurry horizontal stripes occur in the printing periodically. (they may not occur periodically.) digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Bad contact of the voltage terminals to de...

Page 96

7-12 troubleshooting workcentre pe16 service manual ju ly 2003 7.3.5 light image • description the printed image is light, with no ghost. Digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Develop er roller is stained when the toner is almost ...

Page 97

7-13 workcentre pe16 troubleshooting service manual ju ly 2003 7.3.7 uneven density • description print density is uneven between left and right. Check and cause solution 1. The pressure force on the left and right springs of the transfer roller is not even, the springs are damaged, the transfer rol...

Page 98: Digital Printer

7-14 troubleshooting workcentre pe16 service manual ju ly 2003 7.3.9 ghost (1) • description ghost occurs at 75.5 mm intervals of the opc drum in the whole printing. Digital printer digital printer digital printer digital printer digital printer digital printer 75.5 mm check and cause solution 1. Ba...

Page 99: Digital Printer

7-15 workcentre pe16 troubleshooting service manual ju ly 2003 7.3.11 ghost (3) • description white ghost occurs in the black image printing at 32 mm intervals. Digital printer digital printer digital printer digital printer digital printer digital printer 32 mm check and cause solution 1. The life ...

Page 100

7-16 troubleshooting workcentre pe16 service manual ju ly 2003 7.3.14 stains on back of the page • description the back of the page is stained at 56.1 mm intervals. Digital digital pri digital printer digital printer digital printer check and cause solution 1. Transfer roller is contaminated. 2. Pre...

Page 101

7-17 workcentre pe16 troubleshooting service manual ju ly 2003 7.4.1 no dial tone • description while on-hook button is pressed, there is no dial tone. 7.4 fax & phone problems check and cause solution 1. Check if the telephone line cord is connected to tel line correctly. 2. Check if it makes click...

Page 102

7-18 troubleshooting workcentre pe16 service manual ju ly 2003 7.4.3 defective fax send/receive • description the fax send/receive is not functioning. Check and cause solution 1. Check if you can get a dial tone by pressing ohd. 2. Check if you can hear a receive tone while modem testing in the tech...

Page 103

7-19 workcentre pe16 troubleshooting service manual ju ly 2003 7.4.5 defective fax receive (1) • description send is functioning, but receive is not functioning or the received data are broken. Check and cause solution 1. Check if there is noise when pressing on-hook dial. 2. Check the receive condi...

Page 104

7-20 troubleshooting workcentre pe16 service manual ju ly 2003 7.4.8 defective fax receive (4) • description the received data is reduced by more than 50% in the printing. 7.4.9 defective automatic receiving • description the automatic receiving function is not working. Check and cause solution chec...

Page 105

7-21 workcentre pe16 troubleshooting service manual ju ly 2003 7.5.1 white copy • description blank page is printed out when copy ing . 7.5 copy problems check and cause solution 1. Ensure that the scan-cover is closed . 2. Check shading profile. 3. Check white/black reference voltage in the main pb...

Page 106

7-22 troubleshooting workcentre pe16 service manual ju ly 2003 7.5.3 abnormal noise • description there is noise when copy ing . Check and cause solution 1. Check the scanner motor and for any mechanical damage . 2. Check the motor driver in driver pba. 7.5.4 defective image quality • description th...

Page 107

7-23 workcentre pe16 troubleshooting service manual ju ly 2003 7.6.1 defective pc scan • description the pc scan is not functioning at all. 7.6 scanning problems check and cause solution 1. Check the cable (usb or parallel) 2. Check if the driver is installed properly. 3. Check if copy function oper...

Page 108

7-24 troubleshooting workcentre pe16 service manual ju ly 2003 7.7 toner cartridge service this product should only be used with xerox toner cartridges specified in this document and the user manual . 7.7.1 precautions on safe-keeping of toner cartridge exposure to direct light for more than a few m...

Page 109

7-25 workcentre pe16 troubleshooting service manual ju ly 2003 7.7.3 signs and measures at poor toner cartridge fault signs cause & check solution light image and partially blank image (the life is ended.) toner contamination • the printed image is light or unclean and untidy. • some part of the ima...

Page 110

7-26 troubleshooting workcentre pe16 service manual ju ly 2003 fault signs cause & check solution white / black spot • light or dark black dots on the image occur periodically. • white spots occur in the image period- ically. 1. If light or dark black dots occur periodically , it is because the deve...

Page 111

7-27 workcentre pe16 troubleshooting service manual ju ly 2003 fault signs cause & check solution ghost & image contamination • the printed image is too light or dark, or partially contami- nated black. • totally contaminat- ed black. (black image print- ed out) • the density of print- outs is too d...

Page 112

7-28 troubleshooting service manual july 2003 workcentre pe16.

Page 113

8 8 8-1 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 8. Exploded views and parts list 8.1 main assembly exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page(8-2) 8.2 rx drive ass’y exploded view . . . . . . . . . . . . . . . . . ....

Page 114: 8.1 Main Assembly

8-2 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.1 main assembly 13 2 15 21 3 16 4 5 7 19 23 8 18 27 10 10-1 10-2 10-3 1-2 29 10-4 10-5 10-6 11 20 12 12-1 12-2 12-3 14 24 25 25-2 25-2 25-1 14-1 14-2 17-2 17-1 17-3 17 1 1-1 1-4 1-3 0 22 9 26 28.

Page 115

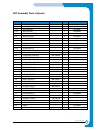

8-3 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 main assembly parts list no. Description part number q’ty remark 0 workcentre pe16 1 ela hou-unit scan 500 n 00105 1 1-1 cover-lcd window * 1 not spared 1-2 ela hou-adf 101 n 01337 1 1-3 as-ela hou-ope(xerox) 101 n 01338 ...

Page 116

8-4 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 main assembly parts list(cont.) no. Description part number q’ty remark 18 cbf signal-liu 140 n 62744 1 19 pba-liu_usa/canada 140 n 62758 1 pba-liu_western europe 140 n 62745 1 pba-liu_russia 140 n 62759 1 pba-liu_south a...

Page 117: 8.2 Rx Drive Assembly

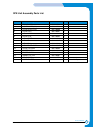

8.2 rx drive assembly 0 1 2 3 4 4 5 6 7 8 9 10 5 rx drive assembly parts list no. Description part number q’ty remark 0 ela unit-rx drive 126 n 00211 1 1 bracket-p-gear 1400 * 1 not spared 2 gear-rdcn 53/26 * 1 not spared 3 gear-rdcn 113/33 * 1 not spared 4 gear-rdcn 57/18 * 2 not spared 5 washer-pl...

Page 118: 8.3 Adf Assembly

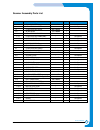

8-6 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.3 adf assembly 1 5 6 0 4 5-1 6-1 6-4 6-2 6-3 1-2 1-3 1-1 1-3-1 1-3-4 1-3-2 1-3-3 2 2-1 2-2 2-16 2-3 2-11 2-6 2-7 2-9 2-13 2-12 2-17 2-18 2-5 2-8 2-15 2-15 2-4 2-10 2-19 2-11 2-19 2-11 2-14 5-2 5-2 3 3-1 3-13 3-20 3-13 3...

Page 119

4 4-1 4-3-1 4-3 4-3-2 4-3-4 4-3-3 4-3-5 4-8 4-9 4-4 4-5 4-4 4-6 4-2 s 4-7 4-7 s 8-7 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003.

Page 120

8-8 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 adf assembly parts list no. Description part number q’ty remark 0 ela hou-adf 101 n 01337 1 1 mea unit-adf upper 500 n 00106 1 1-1 cover-m-adf upper 002 n 02195 1 1-2 roller-m-adf idle 022 n 02012 1 1-3 mea unit-holder ad...

Page 121

8-9 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 adf assembly parts list(cont.) no. Description part number q’ty remark 3-9 gear-swing 31/20 adf * 1 not spared 3-10 link-m-swing adf * 1 not spared 3-11 gear-58/25 adf * 1 not spared 3-12 impeller-adf * 1 not spared 3-13 ...

Page 122: 8.4 Ope Unit Assembly

8-10 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.4 ope unit assembly 0 1 2 3 4 5 6 7 8 9 10 11 12 13 15.

Page 123

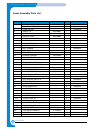

8-11 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 ope unit assembly parts list no. Description part number q’ty remark 0 ela hou-ope 101 n 01338 1 1 cover-m-ope(4in1) 002 n 02198 1 2 key-m-resolution 003 n 00890 1 3 key-m-copy 003 n 00891 1 4 key-m-scroll 003 n 00892 1 ...

Page 124: 8.5 Scanner Assembly

8-12 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.5 scanner assembly 0 1 1-1 1-2 1-3 1-3-1 1-3-2 1-3-3 1-3-4 2 2-1 2-2 2-3 2-5 2-6 2-7 2-14 2-8 2-9 2-11 2-10 2-16 2-12 2-13 2-4 2-15-1 2-15-4 2-15-3 2-15-2 2-15 2-15-5 2-15-7 2-15-6.

Page 125

8-13 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 scanner assembly parts list no. Description part number q’ty remark 0 ela hou-platen 101 n 01339 1 1 mea unit-scan upper * 1 not spared 1-1 cover-m-scan upper 002 n 02199 1 1-2 glass-scan 118 n 00500 1 1-3 mea unit-scan ...

Page 126: 8.6 Middle Cover Assembly

8-14 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.6 middle cover assembly 1 2 6 7 16 7 9 8 10 17 11 13 12 14 5 0 3 4 15 middle cover assembly parts list no. Description part number q’ty remark 0 mea unit-cover middle 101 n 01334 1 1 cover-m-middle * 1 not spared 2 pmo...

Page 127: 8.7 Frame Assembly

8-15 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 8.7 frame assembly 1 6 5 11 8 9 10 15 16 18 19 20 21 22 23 24 25 27 28 29 30 31 27-1 27-2 27-3 27-4 27-5 27-7 27-6 27-4 39 54 43 44 6 45 46 47 26 51 47-1 47-2 47-3 47-4 47-5 45-1 45-2 45-3 40 41 42 32 34 t ransfer roller...

Page 128

8-16 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 frame assembly parts list no. Description part number q’ty remark 0 ela hou-unit frame_110v 001 n 00407 1 110v ela hou-unit frame_220v 001 n 00408 1 220v 1 frame-m-base * 1 not spared 2 guide-p-tr 038 n 00407 1 3 plate-p...

Page 129

8-17 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 frame assembly parts list(cont.) no. Description part number q’ty remark 31 bush-m-tr l 016 n 00261 1 32 spring etc-tr l hawk * 1 not spared 33 roller-feed 022 n 01607 1 34 pmo-bushing_tr(l) 016 n 00254 1 35 ipr-p-ground...

Page 130: 8.8 Fuser Assembly

8-18 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.8 fuser assembly 0 1 2 35 3 4 5 32 32 6 33 7 8 9 10 12 13 14 15 16 17 18 19 20 21 31 25 26 27 30 28 34 29 22 23 24 11.

Page 131

8-19 e x p lo d e d view & pa rts list service manual workcentre pe16 june 2003 fuser assembly parts list no. Description part number q’ty remark 0 as-fuser 110v 126 n 00214 1 110v as-fuser 220v 126 n 00215 1 220v 1 cover-m-fuser * 1 not spared 2 holder-m-plate claw * 4 not spared 3 spring etc-claw ...

Page 132: 8.9 Cassette Assembly

8-20 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16 8.9 cassette assembly 0 1 2 3 4 5 5 18 6 7 8 9 10 11 15 16 18 12 13 14 17 18.

Page 133

Cassette assembly parts list no. Description part number q’ty remark 0 mea unit-cassette, usa 050 n 00427 1 1 frame-m_cassette * 1 not spared 2 pmo-extension large * 1 not spared 3 pmo-extension small * 1 not spared 4 plate-p-knock_up * 1 not spared 5 spring-cs * 2 not spared 6 holder-m-pad * 1 not ...

Page 134

8-22 e x p lo d e d view & pa rts list service manual june 2003 workcentre pe16.

Page 135: 9. Block Diagram

9 9 9-1 block diagram service manual workcentre pe16 june 2003 9. Block diagram us b 1. 1 ieee 12 84 modem 336.Kbps audio p a r t modem afe s3c46q0x arm9tdmi geu p1284 usb 1.1 1 tu i/o i/f dmac pvc uar tx2 memor y i/f cache (4k) image processor reset fl a s h me m o r y (1 m b ) sd r a m (8 m b ) ex...

Page 136

9-2 b l o c k d i a g r a m service manual june 2003 workcentre pe16.

Page 137: 10. Connection Diagram

1 1 0 0 10-1 connection diagram service manual workcentre pe16 june 2003 10. Connection diagram main mo to r dc f a n mp s e n s o r micro switch ex it se n s o r p_ em p t y se n s o r f e ed se n s o r main pba liu pba ope pba smps / hvps pba connect oin pba 1. Hot 2. Neutral 11 0v fo r u s a 22 0...

Page 138

10-2 c o n n e c t i o n d i a g r a m service manual june 2003 workcentre pe16.