- DL manuals

- Yamaha

- Outboard Motor

- F4A

- Owner's Manual

Yamaha F4A Owner's Manual

Summary of F4A

Page 1

Q q q q read this manual carefully before operating this outboard motor. Owner’s manual f4a 68d-f8199-29-e0

Page 2

Emu25052 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold..

Page 3: Important Manual Information

Important manual information emu25105 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Table of Contents

Table of contents safety information............................. 1 outboard motor safety .................... 1 propeller............................................ 1 rotating parts.................................... 1 hot parts ........................................... 1 electric shock ..........

Page 5: Table of Contents

Table of contents engine shut-off cord (lanyard)......... 26 engine oil ........................................ 27 engine ............................................. 27 install cowling.................................. 27 filling fuel ...................................... 28 operating engine.......

Page 6: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36500 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 7: Safety Information

Safety information 2 death when inhaled. Symptoms include nau- sea, dizziness, and drowsiness. Keep cock- pit and cabin areas well ventilated. Avoid blocking exhaust outlets. Emu33780 modifications do not attempt to modify this outboard mo- tor. Modifications to your outboard motor may reduce safety...

Page 8: Safety Information

Safety information 3 operate defensively at safe speeds and keep a safe distance away from people, ob- jects, and other boats. ● do not follow directly behind other boats or waterskiers. ● avoid sharp turns or other maneuvers that make it hard for others to avoid you or un- derstand where you are go...

Page 9: General Information

4 general information emu25171 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 10: General Information

General information 5 1. C-tick label location zmu02651 1 zmu01697.

Page 11: General Information

General information 6 emu33520 read manuals and labels before operating or working on this motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33831 warning ...

Page 12: General Information

General information 7 emu35281 contents of labels the above warning labels mean as follows. 1 warning ewm01691 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01681 ● keep hands, hair, and clothing away from rotating...

Page 13: General Information

General information 8 sive. Shut off engine before refueling. Tighten tank cap and air vent screw when not in use..

Page 14: General Information

General information 9 emu35132 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard zmu05696 zmu05664 zmu05665 zmu05666.

Page 15: Specifications

10 specifications and requirements emu34520 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller install...

Page 16: Installation Requirements

Specifications and requirements 11 api se/sf/sg/sh/sj/sl recommended engine oil group 2*: sae 15w-40/20w-40/20w-50 api sh/sj/sl lubrication: wet sump engine oil quantity without replacement of oil filter (oil pan capacity): 0.5 l (0.53 us qt, 0.44 imp.Qt) recommended gear oil: hypoid gear oil sae#90...

Page 17: Start-In-Gear Protection

Specifications and requirements 12 that lets the engine run in the proper range for your maximum load but remember that you may need to reduce your throttle setting to stay within the recommended engine speed range when carrying lighter loads. For instructions on propeller removal and in- stallation...

Page 18: Muddy Or Acidic Water

Specifications and requirements 13 gasohol) gasoline whenever possible. Notice ecm01980 ● do not use leaded gasoline. Leaded gasoline can seriously damage the en- gine. ● avoid getting water and contaminants in the fuel tank. Contaminated fuel can cause poor performance or engine damage. Use only fr...

Page 19

Specifications and requirements 14 gines. See the label affixed to your engine for details. Emu25322 approval label of emission control certif- icate this label is attached to the bottom cowling. Existing technology; n/a emu25332 manufactured date label this label is attached to the clamp bracket or...

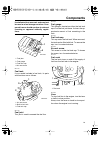

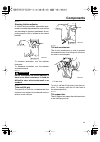

Page 20: Components

15 components emu2579j components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. F4a emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with this eng...

Page 21: Components

Components 16 its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to relevant licensing or approval authority regula- tions. Emu25821 fuel tank if your model included a fuel tank, its parts and functions are as follows. Emu25830 fuel joint...

Page 22: Components

Components 17 emu25901 open the fuel cock has two open positions, one for selecting fuel flow from the built-in fuel tank, and one for an external tank. Fuel flows to the carburetor with the lever or knob in either open position. These are the normal running positions. Emu25911 tiller handle to chan...

Page 23: Components

Components 18 emu25941 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwise to decrease speed. Emu25961 throttle indicator the fuel consumption curve on the throttle indicator shows the relative amount of fuel consumed for each throt...

Page 24: Components

Components 19 emu25993 engine shut-off cord (lanyard) and clip the clip must be attached to the engine shut- off switch for the engine to run. The cord should be attached to a secure place on the operator’s clothing, or arm or leg. Should the operator fall overboard or leave the helm, the cord will ...

Page 25: Components

Components 20 emu26122 steering friction adjuster a friction device provides adjustable resis- tance to the steering mechanism, and can be set according to operator preference. An ad- justing screw or bolt is located on the swivel bracket. To increase resistance, turn the adjuster clockwise. To decr...

Page 26: Components

Components 21 notice ecm01660 do not use the tilt support bar when trailering the boat. The outboard motor could shake loose from the tilt support and fall. If the motor cannot be trailered in the normal running position, use an addi- tional support device to secure it in the tilt position. Emu26382...

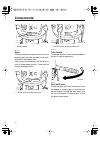

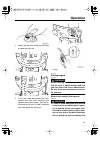

Page 27: Installation

22 installation emu26902 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Prop- er mounting depends in part on experience and the specific boat and motor combinatio...

Page 28: Installation

Installation 23 notice ecm01630 ● during water testing, check the buoy- ancy of the boat, at rest, with its maxi- mum load. Check that the static water level on the exhaust housing is low enough to prevent water entry into the power head when water rises due to waves when the outboard is not run- ni...

Page 29: Installation

Installation 24 3. Secure the clamp bracket to the transom using the bolts provided with the out- board (if packed). For details, consult your yamaha dealer. Warning! Avoid using bolts, nuts or washers other than those contained in the engine packaging. If used, they must be of at least the same qua...

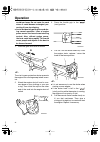

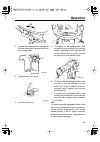

Page 30: Operation

25 operation emu36380 first-time operation emu36390 fill engine oil the engine is shipped from the factory with- out engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. No- tice: check that the engine is filled with oil before first-time operation to avoid s...

Page 31: Operation

Operation 26 heating and serious engine damage can occur. Emu36560 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/ 3 as an emergency reserve. With the boat level on a trailer or in the water, ch...

Page 32: Operation

Operation 27 emu27165 engine oil 1. Put the outboard motor in an upright po- sition (not tilted). Notice: if the motor is not level, the oil level indicated on the dipstick may not be accurate. [ecm01790] 2. Remove the top cowling. 3. Remove oil dipstick and wipe it clean. 4. Insert the dipstick and...

Page 33: Operation

Operation 28 shown. Notice: if the cowling is not installed correctly, water spray under the cowling can damage the engine, or the cowling can blow off at high speeds. [ecm01990] after installing, check the fitting of the top cowling by pushing it with both hands. If the top cowling is loose, have i...

Page 34: Operation

Operation 29 creases. Tip: the upper fuel level mark is indicated on the built-in fuel tank. 8. Tighten the filler cap securely. 9. Wipe up any spilled gasoline immediate- ly with dry rags. Dispose rags properly. According to local laws or regulations. Emu27451 operating engine emu27473 feeding fuel...

Page 35: Operation

Operation 30 2. Select the fuel tank using the fuel cock or open the fuel cock. 3. If you are using an external fuel tank, connect the fuel joints securely and squeeze the primer pump, with the ar- row pointing up, until you feel it become firm (if equipped the fuel joint). Emu27492 starting engine ...

Page 36: Operation

Operation 31 could tear loose. Do not route the cord where it could become entangled, pre- venting it from functioning. ● avoid accidentally pulling the cord dur- ing normal operation. Loss of engine power means the loss of most steering control. Also, without engine power, the boat could slow rapid...

Page 37: Operation

Operation 32 6. After the engine starts, slowly return the manual starter handle to its original po- sition before releasing it. 7. Slowly return the throttle grip to the fully closed position. Tip: ● when the engine is cold, it needs to be warmed up. For further information, see page 32. ● if the e...

Page 38: Operation

Operation 33 tip: ● if the choke knob is left pulled out after the engine starts, the engine will stall. ● in temperatures of -5°c or less, leave the choke knob pulled out fully for approxi- mately 30 seconds after starting. Emu36530 checks after engine warm-up emu36540 shifting while tightly moored...

Page 39: Operation

Operation 34 tip: the outboard motor can turn 360° in its bracket (full-pivot system). The boat can also be backed up by simply turning the outboard motor around 180° with the steering handle facing toward you. Emu31742 stopping boat warning ewm01510 ● do not use the reverse function to slow down or...

Page 40: Operation

Operation 35 tip: if the outboard motor is equipped with an en- gine shut-off cord, the engine can also be stopped by pulling the cord and removing the clip from the engine shut-off switch. Emu27862 trimming outboard motor warning ewm00740 excessive trim for the operating condi- tions (either trim u...

Page 41: Operation

Operation 36 3. Reposition the rod in the desired hole. To raise the bow (“trim-out”), move the rod away from the transom. To lower the bow (“trim-in”), move the rod to- ward the transom. Make test runs with the trim set to different angles to find the position that works best for your boat and oper...

Page 42: Operation

Operation 37 ating with excessive trim-in at higher speeds also makes the boat unstable. Resistance at the bow is greatly increased, heightening the danger of “bow steering” and making opera- tion difficult and dangerous. Tip: depending on the type of boat, the outboard motor trim angle may have lit...

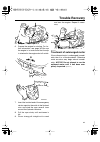

Page 43: Operation

Operation 38 2. Tighten the steering friction adjuster by turning it clockwise to prevent the motor from turning freely. 3. Tighten the air vent screw. 4. Close the fuel cock. 5. Tilt support bar equipped models: hold the rear of the top cowling or the carrying handle (if equipped) with one hand and...

Page 44: Operation

Operation 39 emu28033 procedure for tilting down (manual tilt models) 1. Slightly tilt the outboard motor up. 2. If equipped with the tilt support bar: slowly tilt the outboard motor down while pulling the tilt support bar lever up. 3. If equipped with the tilt support knob: pull the knob out, and t...

Page 45: Operation

Operation 40 emu28102 procedure 1. Place the gear shift lever in neutral and face the outboard motor forward. 2. Slightly tilt the outboard motor up until the tilt support bar automatically turns to the lock position to support the engine. The outboard motor is equipped with 2 or 3 positions for sha...

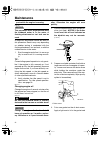

Page 46: Maintenance

41 maintenance emu28226 transporting and storing outboard motor warning ewm00692 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. Thi...

Page 47: Maintenance

Maintenance 42 tip: place a towel or something similar under the outboard motor to protect it from damage. Emu35970 storing outboard motor when storing your yamaha outboard motor for prolonged periods of time (2 months or longer), several important procedures must be performed to prevent excessive d...

Page 48: Maintenance

Maintenance 43 tip: dispose of old gasoline according to local regulations. 4. Remove the engine top cowling and fog- ging hole cap. 5. Install the outboard motor on the test tank. 6. Fill the tank with fresh water to above the level of the anti-cavitation plate. No- tice: if the fresh water level i...

Page 49: Maintenance

Maintenance 44 15. Remove the outboard motor from the test tank. 16. Install the top cowling and fogging hole cap. 17. Drain the cooling water completely out of the motor. Clean the body thoroughly. Tip: store the fuel tank in a dry, well-ventilated place, not in direct sunlight. Emu28402 lubricatio...

Page 50: Maintenance

Maintenance 45 tor before operation. Maintenance, replacement, or repair of the emission control devices and sys- tems on models affixed with an emission control label may be performed by any marine engine repair establishment or in- dividual. All warranty repairs, however, including those to the em...

Page 51: Maintenance

Maintenance 46 emu34445 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 52: Maintenance

Maintenance 47 fuel line(low pres- sure) inspection or replace- ment as necessary fuel pump inspection or replace- ment as necessary fuel/oil leakage inspection gear oil replacement greasing points greasing impeller/water pump housing inspection or replace- ment as necessary impeller/water pump hous...

Page 53: Maintenance

Maintenance 48 emu34451 maintenance chart 2 item actions every 1000 hours guide exhaust/exhaust manifold inspection or replace- ment as necessary.

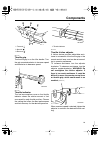

Page 54: Maintenance

Maintenance 49 emu28941 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f4a emu28955 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug can ind...

Page 55: Maintenance

Maintenance 50 other deposits are excessive, you should re- place the spark plug with another of the cor- rect type. 1. Remove the spark plug caps from the spark plugs. 2. Remove the spark plug. If electrode ero- sion becomes excessive, or if carbon and other deposits are excessive, you should repla...

Page 56: Maintenance

Maintenance 51 parts while the engine is running. Notice ecm00490 this procedure must be performed while the outboard motor is in the water. A flushing attachment or test tank can be used. A diagnostic tachometer should be used for this procedure. Results may vary depending on whether testing is con...

Page 57: Maintenance

Maintenance 52 install the drain screw. Tip: if a torque wrench is not available when you are installing the drain plug, finger tighten the bolt just until the gasket comes into contact with the surface of the drain hole. Then tight- en 1/4 - 1/2 turn. Have the drain plug torqued to the correct valu...

Page 58: Maintenance

Maintenance 53 checkpoints ● check each of the propeller blades for wear, erosion from cavitation or ventila- tion, or other damage. ● check the propeller shaft for damage. ● check the splines for wear or damage. ● check for fish line tangled around the pro- peller shaft. ● check the propeller shaft...

Page 59: Maintenance

Maintenance 54 4. Align the propeller nut with the propeller shaft hole. Insert a new cotter pin in the hole and bend the cotter pin ends. No- tice: do not reuse the cotter pin in- stalled. Otherwise the propeller can come off during operation. [ecm01890] tip: if the propeller nut does not align wit...

Page 60: Maintenance

Maintenance 55 gear oil drain screw hole. 6. Put a new gasket on the oil level plug. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Put a new gasket on the gear oil drain screw. Insert and tighten the gear oil drain screw. Emu29302 cleaning fuel...

Page 61: Maintenance

Maintenance 56 yamaha dealer for replacement of external anodes. Notice ecm00720 do not paint anodes, as this would render them ineffective. Tip: inspect ground leads attached to external anodes on equipped models. Consult a yamaha dealer for inspection and replace- ment of internal anodes attached ...

Page 62: Trouble Recovery

57 trouble recovery emu29427 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 63: Trouble Recovery

Trouble recovery 58 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 64: Trouble Recovery

Trouble recovery 59 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 65: Trouble Recovery

Trouble recovery 60 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

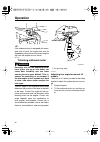

Page 66: Trouble Recovery

Trouble recovery 61 could result in an accident. ● attach the engine shut-off cord to a se- cure place on your clothing, or your arm or leg while operating the boat. ● do not attach the cord to clothing that could tear loose. Do not route the cord where it could become entangled, pre- venting it fro...

Page 67: Trouble Recovery

Trouble recovery 62 6. Prepare the engine for starting. For fur- ther information, see page 30. Be sure the engine is in neutral and that the clip is attached to the engine shut-off switch. 7. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope...

Page 68

Yamaha motor co., ltd. Printed in france april 2008–0.1 × 1 !.