- DL manuals

- Yamaha

- Snowmobiles

- FX Nytro FX10MTRAX

- Owner's Manual

Yamaha FX Nytro FX10MTRAX Owner's Manual

Summary of FX Nytro FX10MTRAX

Page 1

Owner’s manual fx10x fx10rtx fx10rtrx fx10rtrax fx10mtx fx10mtrx fx10mtrax 8gl-28199-10 lit-12628-02-69.

Page 2

Esu10040 u8gl10e0.Book page 1 friday, may 18, 2007 3:17 pm.

Page 3: Introduction

Introduction esu10120 congratulations on your purchase of a yamaha snowmobile. This model is the result of yamaha’s vast experience in the produc- tion of fine sporting and touring snowmobiles. It represents the high degree of craftsmanship and reliability that have made yamaha a lead- er in these f...

Page 4

Important manual information esu10150 warning ews00010 please read and understand this manual completely before oper- ating the snowmobile. Note: ● yamaha continually seeks advancements in product design and quality. Therefore, while this manual contains the most current product information availabl...

Page 5: Contents

Contents safety information ............................ 1 location of the important labels ..... 4 description ........................................ 6 control functions .............................. 9 main switch .................................... 9 throttle lever ...............................

Page 6: Contents

Contents fittings and fasteners ................... 66 battery .......................................... 66 replacing a fuse .......................... 67 troubleshooting ............................. 69 storage ............................................ 72 specifications ...........................

Page 7: Safety Information

Safety information 1 esu10181 when you ride your snowmobile, you must know and use the following for your safety. Severe injury or death may result if you ignore any of the following. Before operating 1. Read the owner’s manual and all labels before operating this snowmobile. Be- come familiar with ...

Page 8: Safety Information

Safety information 2 ● fill the fuel tank outdoors with extreme care. Never remove the fuel cap in- doors. Never fill the fuel tank indoors. ● never refuel while smoking or in the vi- cinity of an open flame. ● make sure that the fuel tank cap is closed securely after refueling. Wipe up any spilled ...

Page 9: Safety Information

Safety information 3 begin decelerating early. The best brak- ing method on most surfaces is to release the throttle and apply the brake gently— not suddenly. Maintenance and storage 1. When laying the snowmobile on its side for maintenance, use a suitable stand to keep it level. 2. Do not leave the...

Page 10: Safety Information

Safety information 4 esu10211 location of the important labels please read the following labels carefully before operating this snowmobile. Note: maintain or replace safety and instruction labels, as necessary. U8gl10e0.Book page 4 friday, may 18, 2007 3:17 pm.

Page 11: Safety Information

Safety information 5 u8gl10e0.Book page 5 friday, may 18, 2007 3:17 pm.

Page 12: Description

Description 6 esu10260 1. Storage pouch 2. Tool kit 3. Coolant reservoir 4. Air filter 5. Battery 6. Main fuse 7. Oil filler cap 8. Fuse box 9. Strap (fx10mt / fx10mtr / fx10mtra) 10. Tail/brake light 11. Slide rail suspension 12. Drive track u8gl10e0.Book page 6 friday, may 18, 2007 3:17 pm.

Page 13: Description

Description 7 1. Brake lever 2. Parking brake lever 3. Grip/thumb warmer adjustment switch 4. Headlight beam switch 5. Engine stop switch 6. Throttle lever 7. Main switch 8. Shift lever (fx10 / fx10rtr / fx10rtra / fx10mtr / fx10mtra) 9. Auxiliary dc jack (fx10mt / fx10mtr / fx10mtra) 10. “reset” bu...

Page 14: Description

Description 8 note: ● the snowmobile you have purchased may differ slightly from those shown in the figures of this manual. ● design and specifications are subjected to change without notice. U8gl10e0.Book page 8 friday, may 18, 2007 3:17 pm.

Page 15: Control Functions

Control functions 9 esu10291 main switch the main switch controls the ignition and lighting systems. The various positions are described below. Off the ignition circuit is switched off. The key can be removed only in this position. On the ignition circuit is switched on. Start the starting circuit i...

Page 16: Control Functions

Control functions 10 ● be sure to use the specified spark plug and spark plug cap. Otherwise, the t.O.R.S. Will not work properly. If the throttle bodies or throttle cable malfunc- tions during operation, the t.O.R.S. Will oper- ate when the throttle lever is released. The t.O.R.S. Is designed to ov...

Page 17: Control Functions

Control functions 11 esu12720 speedometer unit the speedometer unit is equipped with the following: ● a digital speedometer (which shows the riding speed) ● an odometer (which shows the total dis- tance traveled) ● a tripmeter (which shows the distance trav- eled since it was last set to zero) ● an ...

Page 18: Control Functions

Control functions 12 and then push the “select” button for at least 10 seconds while the snowmobile is stopped. ● use the engine speed meter only when checking the snowmobile and performing basic maintenance. The engine speed meter should not be used while riding the snowmobile since the reading wil...

Page 19: Control Functions

Control functions 13 fuel meter the display segments of the fuel meter disap- pear towards “e” (empty) as the fuel level de- creases. When only one segment is left near “e”, the fuel level warning indicator and the warning light come on. If the fuel level warning indicator and the warning light come...

Page 20: Control Functions

Control functions 14 when this occurs, have a yamaha dealer in- spect the snowmobile as soon as possible. Esu10460 oil level warning indicator “ ” the oil level warning indicator and the warn- ing light come on when the engine oil level is low. If the oil level warning indicator and the warn- ing li...

Page 21: Control Functions

Control functions 15 warning ews00650 if the self-diagnosis warning indicator and warning light flash continuously, and an error code is displayed during operation, there may be some problem with an elec- trical circuit, couplers, etc. Note the error code, and then have a yamaha dealer inspect the s...

Page 22: Control Functions

Control functions 16 to raise the temperature to raise the grip warmer temperature, press the “ ” side of the switch. To raise the thumb warmer temperature, press the “ ” side of the switch. To lower the temperature continue to press the switch until the temper- ature level returns to the minimum le...

Page 23: Control Functions

Control functions 17 note: when the brake lever is operated, the brake light will illuminate. Caution: ecs00060 make sure that the brake lever end does not project out over the handlebar end. This will help prevent brake lever damage when the snowmobile is placed on its side for service. The brake l...

Page 24: Control Functions

Control functions 18 esu13030 shift lever (fx10 / fx10rtr / fx10rtra / fx10mtr / fx10mtra) the shift lever is used to put the snowmobile into forward or reverse. Before shifting, wait for the snowmobile to come to a complete stop with the engine idling. Pull the shift lever out, slide it to “fwd” or...

Page 25: Control Functions

Control functions 19 warning ews00090 ● do not drive the snowmobile with the shroud or covers unfastened or re- moved. ● keep your body and clothing away from rotating parts when servicing the snow- mobile with the shroud or covers re- moved. ● do not touch the hot muffler and engine during or immed...

Page 26: Control Functions

Control functions 20 to install the storage pouch place the storage pouch in the original posi- tion, and then hook the swivel hook onto the bracket. Note: when installing the storage pouch, make sure that the swivel hook is securely hooked onto the bracket. Storing the spare v-belt keep a spare v-b...

Page 27: Control Functions

Control functions 21 your yamaha engine has been designed to use regular unleaded gasoline with a pump octane number [(r+m)/2] of 86 or higher, or a research octane number of 91 or higher. Caution: ecs00080 ● oxygenated fuels (gasohol) containing a maximum 5% of ethanol can be used, although richer ...

Page 28: Control Functions

Control functions 22 esu12550 adjusting the front shock absorber air pressure (fx10rt / fx10rtr / fx10rtra) caution: ecs00700 the left and right shock absorber air pres- sure must be set to the same setting. Un- even settings can cause poor handling and loss of stability. This snowmobile is equipped...

Page 29: Control Functions

Control functions 23 4. Install the hose connector of the shock absorber pump onto the air valve of the shock absorber and tighten it approxi- mately six turns until the pressure regis- ters on the pump gauge. Caution: ecs00720 do not overtighten the connector onto the air valve as this will damage ...

Page 30: Control Functions

Control functions 24 caution: ecs00730 do not exceed 1,034 kpa (10.3 kgf/cm², 150 psi). 7. Install the air valve cap. Note: if the front suspension bottoms too easily or rolls too much during cornering, increase the air pressure by 34 kpa (0.3 kgf/cm², 5 psi). If the suspension is too firm and you w...

Page 31: Control Functions

Control functions 25 esu10930 adjusting the rear suspension spring preload the spring preload can be adjusted by turning the spring preload adjusting ring on the center shock absorber and the spring preload adjust- er on the rear shock absorber. Fx10mt / fx10mtr / fx10mtra fx10 / fx10rt / fx10rtr / ...

Page 32: Control Functions

Control functions 26 esu12751 adjusting the rear suspension damp- ing force (fx10 / fx10rt / fx10rtr / fx10rtra) fx10 the compression damping force can be ad- justed by turning the adjusting screw. To increase the compression damping force, turn the adjusting screw in direction (a). To decrease the ...

Page 33: Control Functions

Control functions 27 to increase the rebound damping force, turn the adjusting dial in direction (a). To decrease the rebound damping force, turn the adjusting dial in direction (b). Caution: ecs00790 ● do not continue to turn the adjusting screw or dial in direction (a) after it stops. The shock ab...

Page 34: Control Functions

Control functions 28 warning ews00170 never adjust the control rods beyond the maximum range indicated on the rods with red paint. 3. Tighten the locknut while holding the con- trol rod adjusting nut in place. Caution: ecs00800 the left and right adjusting nuts must be set to the same position. Unev...

Page 35: Pre-Operation Checks

Pre-operation checks 29 esu11070 the condition of a snowmobile is the owner’s responsibility. Vital components can start to de- teriorate quickly and unexpectedly, even if the snowmobile remains unused (for example, as a result of exposure to the elements). Any damage or fluid leakage could have ser...

Page 36: Pre-Operation Checks

Pre-operation checks 30 tool kit and recommended equipment • check for proper placement. 43 shroud and covers • make sure that the shroud and covers are securely fastened. 18 skis and ski runners • check for wear and damage. • if necessary, have yamaha dealer replace skis or ski runners. 60 drive tr...

Page 37: Operation

Operation 31 esu11300 starting the engine warning ews00200 ● be sure to check the “safety infor- mation” section carefully before start- ing the engine. ● make sure that the parking brake is ap- plied. Note: make sure that the engine stop switch is in the on position. The starter motor cannot be ope...

Page 38: Operation

Operation 32 500 km (300 mi) and beyond the snowmobile can now be operated nor- mally. Caution: ecs00340 ● after 800 km (500 mi) of operation, the engine oil must be changed and the oil filter cartridge replaced. ● if any engine trouble should occur dur- ing the engine break-in period, immedi- ately...

Page 39: Operation

Operation 33 warning ews00220 ● many surfaces such as ice and hard- packed snow require much longer stop- ping distances. Be alert, plan ahead, and begin decelerating early. ● improper use of the brake can cause the drive track to lose traction, reduce con- trol, and increase the possibility of an a...

Page 40: Operation

Operation 34 snowmobile from the uphill side. Restart the engine, release the parking brake, and de- scend the hill. Warning ews00230 side hills and steep slopes are not recom- mended for a novice snowmobiler. Riding downhill when riding downhill, keep speed to a mini- mum. It is important to apply ...

Page 41: Operation

Operation 35 hard-packed snow it can be more difficult to negotiate on hard- packed snow as both the skis and drive track do not have as much traction as when the snowmobile is operated on fresh snow. Avoid rapid acceleration, turning, and braking. Operation on surfaces other than snow or ice operat...

Page 42: Operation

Operation 36 etc. If snow coverage is not sufficient, stay on trails to avoid impact damage to the drive track. Studded track in general, track life will be shortened when studs are installed. Drilling stud holes into the drive track will cut the internal fibers, which weakens the track. Avoid spinn...

Page 43: Operation

Operation 37 2. Press the throttle lever slowly to move the snowmobile. 3. Turn the handlebar in the desired direc- tion. 4. Squeeze the brake lever to stop the snowmobile. 5. Apply the parking brake by moving the parking brake lever to the left. Fx10 / fx10rtr / fx10rtra / fx10mtr / fx10mtra warnin...

Page 44: Operation

Operation 38 6. Apply the parking brake by moving the parking brake lever to the left. Esu11410 stopping the engine turn the main switch to the off position to stop the engine. Warning ews00330 ● push down the engine stop switch to stop the engine in an emergency. ● make sure that the key is removed...

Page 45: Periodic Maintenance

Periodic maintenance 39 esu11450 safety is an obligation of the owner. Periodic inspection, adjustment, and lubrication will keep your snowmobile in the safest and most efficient condition possible. The most important points of snowmobile inspection, adjustment, and lubrication are explained on the ...

Page 46: Periodic Maintenance

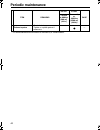

Periodic maintenance 40 * it is recommended that these items be serviced by a yamaha dealer. * exhaust system • check for leakage. • tighten or replace gasket if necessary. — item remarks initial every page 1 month or 800 km (500 mi) (40 hr) seasonally or 4000 km (2500 mi) (200 hr) u8gl10e0.Book pag...

Page 47: Periodic Maintenance

Periodic maintenance 41 esu11560 general maintenance and lubrication chart item remarks initial every page 1 month or 800 km (500 mi) (40 hr) seasonally or 4000 km (2500 mi) (200 hr) engine oil • change (warm engine before draining) 48 * engine oil filter car- tridge • replace. Every 20000 km (12000...

Page 48: Periodic Maintenance

Periodic maintenance 42 * it is recommended that these items be serviced by a yamaha dealer. Note: brake system: ● after disassembling the master cylinder or caliper cylinder, always change the brake fluid. Regularly check the brake fluid level and add fluid if necessary. ● replace the oil seals of ...

Page 49: Periodic Maintenance

Periodic maintenance 43 esu12770 tool kit the owner’s tool kit has the tools which are sufficient for most periodic maintenance and minor repairs. A torque wrench is also neces- sary to properly tighten nuts and bolts. Caution: ecs00760 before starting the engine, make sure that the storage pouch zi...

Page 50: Periodic Maintenance

Periodic maintenance 44 2. Loosen the fasteners, and then remove the side cover. To install a side cover 1. Place the side cover in the original posi- tion, and then tighten the fasteners. Note: be sure to insert the projection on the rear of the side cover into the hole in the fuel tank side cover ...

Page 51: Periodic Maintenance

Periodic maintenance 45 spark plugs are produced in several different thread lengths. The thread length or reach is the distance from the spark plug gasket seat to the end of the threaded portion. If the reach is too long, overheating and engine damage may result. If the reach is too short, spark pl...

Page 52: Periodic Maintenance

Periodic maintenance 46 warning ews00351 when checking the t.O.R.S.: ● make sure that the parking brake is ap- plied. ● make sure that the throttle lever moves smoothly. ● do not rev the engine to the point that the clutch engages, otherwise the snow- mobile could start moving, which could cause an ...

Page 53: Periodic Maintenance

Periodic maintenance 47 2. Remove the headlight unit stay quick fas- teners and disconnect the air tempera- ture sensor coupler. 3. Unhook the air filter case cover fasteners. 4. Lift the headlight unit and headlight unit stay, and then slide the air filter case cov- er toward the right side of the ...

Page 54: Periodic Maintenance

Periodic maintenance 48 esu11930 high-altitude settings operating at high altitude reduces the perfor- mance of a gasoline engine about 3% for ev- ery 305 m (1000 ft) of elevation. This is because there is less air as altitude increases. Less air means less oxygen available for combustion. Your snow...

Page 55: Periodic Maintenance

Periodic maintenance 49 2. Start the engine, warm it up for 10–15 minutes, and then turn it off. Note: ● the engine can also be warmed up by op- erating the snowmobile for 10–15 minutes. ● after operating the snowmobile, allow the engine to idle for at least 10 seconds before turning it off. 3. Remo...

Page 56: Periodic Maintenance

Periodic maintenance 50 7. Insert the dipstick into the oil filler hole, and then tighten the oil filler cap. 8. Connect the oil level gauge coupler. 9. Install the right side cover and the shroud. To change the engine oil (with or without oil fil- ter cartridge replacement) 1. Place the snowmobile ...

Page 57: Periodic Maintenance

Periodic maintenance 51 8. Place an oil pan under the engine to col- lect the used oil. 9. Remove the engine oil drain bolt to drain the oil from the crankcase. Note: ● a “ ” mark is stamped on the crankcase near the engine oil drain bolt. ● dispose of used oil according to local regu- lations. ● sk...

Page 58: Periodic Maintenance

Periodic maintenance 52 15. Start the engine, warm it up for several minutes, and then turn it off. 16. Add sufficient oil of the recommended type to raise it to the “h” level mark on the dipstick. (see above for the checking pro- cedure.) caution: ecs00461 ● when adding the engine oil, be careful n...

Page 59: Periodic Maintenance

Periodic maintenance 53 to check the coolant level check the coolant level in the coolant reser- voir when the engine is cold. If the coolant lev- el is below the “low” mark, add coolant until it reaches the “full” mark. (see the following section “replenishing the coolant” for more details.) cautio...

Page 60: Periodic Maintenance

Periodic maintenance 54 3. Start the engine and add coolant until the coolant level does not go down, and then stop the engine. 4. Fill the coolant reservoir with coolant until it reaches the “full” mark. 5. Install the coolant reservoir cap. 6. Check for any coolant leakage. 7. Install the shroud. ...

Page 61: Periodic Maintenance

Periodic maintenance 55 ● when installing the new v-belt, make sure that it is positioned properly. Other- wise, the v-belt clutch engagement speed will be changed and the snowmo- bile may move unexpectedly when the engine is started, which could cause an accident. ● have a yamaha dealer make this a...

Page 62: Periodic Maintenance

Periodic maintenance 56 5. Temporarily install the new v-belt on the secondary sheave assembly only, and then measure the v-belt position. Do not force the v-belt between the sheaves; the secondary sliding and fixed sheaves must touch each other. 6. If the v-belt position is incorrect, adjust it by ...

Page 63: Periodic Maintenance

Periodic maintenance 57 9. Rotate the secondary sliding sheave clockwise and push it so that it separates from the secondary fixed sheave. 10. Install the v-belt between the secondary sliding and fixed sheaves. 11. Install the drive guard, and then install the left side cover and the shroud. Esu1283...

Page 64: Periodic Maintenance

Periodic maintenance 58 caution: ecs00530 make sure that no foreign material enters the drive chain housing. 5. Install the dipstick. 6. Install the right side cover and the shroud. To adjust the chain tension 1. Remove the shroud and the right side cover. (see page 43 for removal proce- dures.) 2. ...

Page 65: Periodic Maintenance

Periodic maintenance 59 checking the parking brake pads check the parking brake pads for wear by measuring the thickness of the pads. If the parking brake pads reach the wear limit, ask a yamaha dealer to replace them. To adjust the parking brake as the parking brake pads wear, adjustment may be nec...

Page 66: Periodic Maintenance

Periodic maintenance 60 checking the brake fluid level warning ews00460 be careful that water does not enter the master cylinder when refilling. Water will significantly lower the boiling point of the fluid and may result in vapor lock. If the brake fluid level goes down, consult a yamaha dealer. Ca...

Page 67: Periodic Maintenance

Periodic maintenance 61 caution: ecs00560 avoid scratching the skis when loading and unloading the snowmobile, when riding in areas with little or no snow, or on sharp edges such as concrete, curbs, etc. This will wear or damage the skis. To align the skis 1. Turn the handlebar so the skis face stra...

Page 68: Periodic Maintenance

Periodic maintenance 62 checking the drive track warning ews00490 do not operate the snowmobile if you find damage to the drive track, or if it has been maladjusted. Drive track damage or failure could result in loss of braking ability and snowmobile control, which could cause an accident. Check the...

Page 69: Periodic Maintenance

Periodic maintenance 63 1. Lift the rear of the snowmobile onto a suit- able stand to raise the drive track off the ground. 2. Loosen the rear axle nut. 3. Start the engine and rotate the drive track one or two turns. Stop the engine. 4. Check the drive track alignment with the slide runners. If the...

Page 70: Periodic Maintenance

Periodic maintenance 64 5. Adjust the drive track deflection to speci- fication. Caution: ecs00591 the right and left adjusting nuts should be turned an equal amount. 6. Recheck alignment and deflection. If nec- essary, repeat steps 3 to 5 until the prop- er adjustment is achieved. 7. Tighten the re...

Page 71: Periodic Maintenance

Periodic maintenance 65 warning ews00510 ● apply a dab of grease onto the cable end only. Do not grease the throttle cable be- cause it could become frozen, which could cause loss of control. ● be sure to have a yamaha dealer lubri- cate the front and rear suspensions. Esu12850 replacing a headlight...

Page 72: Periodic Maintenance

Periodic maintenance 66 5. Remove the bulb. 6. Install the new bulb, and then hook the bulb holder onto the headlight unit. Caution: ecs00620 keep oil and your hands away from the glass part of the bulb or its life and illumi- nation will be affected. If the glass is oil stained, thoroughly clean it...

Page 73: Periodic Maintenance

Periodic maintenance 67 warning ews00540 battery electrolyte is poisonous and dan- gerous. It contains sulfuric acid and can cause severe burns. Avoid contact with skin, eyes, or clothing. Antidote: ● external: flush with water. ● internal: drink large quantities of wa- ter or milk. Follow with milk...

Page 74: Periodic Maintenance

Periodic maintenance 68 4. Connect the negative battery lead. 5. Install the right side cover and the shroud. Note: if the fuse immediately blows again, ask a yamaha dealer to inspect the snowmobile. Specified fuses: main fuse: 40.0 a fuel injection system fuse: 10.0 a “head” (headlight) fuse: 20.0 ...

Page 75: Troubleshooting

Troubleshooting 69 esu12882 engine turns over but does not start 1. Fuel system no fuel supplied to combustion chamber ● no fuel in tank: supply fuel. ● clogged fuel line: clean fuel line. ● clogged injector: ask a yamaha dealer to inspect. Fuel supplied to combustion chamber ● flooded engine: crank...

Page 76: Troubleshooting

Troubleshooting 70 6. Connect the other end of the black (–) jumper cable to the negative (–) terminal of the discharged battery. Caution: ecs00670 do not reverse the connections! Make sure that all connections are secure and correct before attempting to start the en- gine. Any wrong connection coul...

Page 77: Troubleshooting

Troubleshooting 71 3. Loose or broken engine mount(s): ask a yamaha dealer to inspect. V-belt slips or becomes extremely hot 1. Oily or dirty v-belt or primary and second- ary sheave assembly surfaces: clean. 2. Problem with the driveline: see “v-belt twists” above. Engine does not upshift or downsh...

Page 78: Storage

Storage 72 esu12430 long-term storage requires some preventive procedures to guard against deterioration. Cleaning thoroughly clean the snowmobile, inside and out, to remove the corrosive salts and acids that can accumulate. Use yamaha mud, grease, and engine cleaner, or an equivalent product, to lo...

Page 79: Storage

Storage 73 ● to charge a sealed-type (mf) battery, a special (constant-voltage) battery charger is required. Using a convention- al battery charger will damage the bat- tery. If you do not have access to a sealed-type (mf) battery charger, have a yamaha dealer charge your battery. ● do not charge th...

Page 80: Specifications

Specifications 74 esu12462 dimensions: overall length: fx10 2815 mm (110.8 in) fx10mt 3240 mm (127.6 in) fx10mtr 3240 mm (127.6 in) fx10mtra 3240 mm (127.6 in) fx10rt 2815 mm (110.8 in) fx10rtr 2815 mm (110.8 in) fx10rtra 2815 mm (110.8 in) overall width: fx10 1205 mm (47.4 in) fx10mt 1225 mm (48.2 ...

Page 81: Specifications

Specifications 75 number of teeth: fx10 9 fx10mt 7 fx10mtr 7 fx10mtra 7 fx10rt 9 fx10rtr 9 fx10rtra 9 transmission: clutch type: automatic centrifugal engagement ratio range: 3.80–1.00 :1 sheave distance: 267.0–270.0 mm (10.51–10.63 in) sheave offset: 13.5–16.5 mm (0.53–0.65 in) engagement speed (su...

Page 82: Specifications

Specifications 76 warning light: led low coolant temperature indicator light: led u8gl10e0.Book page 76 friday, may 18, 2007 3:17 pm.

Page 83: Consumer Information

Consumer information 77 esu12480 identification number records record the frame serial number, engine serial number (primary id), and key identification number in the spaces provided for assistance when ordering spare parts from a yamaha dealer. Also, record and keep the id numbers in a separate pla...

Page 84: Consumer Information

Consumer information 78 esu12500 yamaha motor corporation, u.S.A. Snowmobile limit- ed warranty yamaha motor corporation, u.S.A. Hereby warrants that new yamaha snowmobiles purchased from an autho- rized yamaha snowmobile dealer in the continental united states will be free from defects in material ...

Page 85: Consumer Information

Consumer information 79 yamaha motor corporation, u.S.A. Makes no other warranty of any kind, expressed or implied. All implied war- ranties of merchantability and fit- ness for a particular purpose which exceed the obligations and time lim- its stated in this warranty are hereby disclaimed by yamah...

Page 86: Consumer Information

Consumer information 80 q. What responsibility does my dealer have under this warranty? A. Each yamaha snowmobile dealer is expected to: 1. Completely set up every new machine before sale. 2. Explain the operation, maintenance, and warranty requirements to your satisfaction at the time of sale, and ...

Page 87: Consumer Information

Consumer information 81 esu12510 yamaha extended service (y.E.S.) u8gl10e0.Book page 81 friday, may 18, 2007 3:17 pm.

Page 88: Index

Index a air filter, checking..................................... 46 auxiliary dc jack (fx10mt / fx10mtr / fx10mtra) .... 16 b battery...................................................... 66 brake and parking brake .......................... 58 brake lever .............................................

Page 89: Index

Index strap (fx10mt / fx10mtr / fx10mtra) .... 36 suspension .............................................. 21 t throttle cable free play, adjusting ............ 45 throttle lever .............................................. 9 throttle override system (t.O.R.S.) ........... 9 throttle override sys...

Page 90

A5-tate_blank.Fm page 1 friday, may 16, 2003 9:00 am.

Page 91

A5-tate_blank.Fm page 1 friday, may 16, 2003 9:00 am.

Page 92

Yamaha motor co., ltd. Printed on recycled paper printed in japan 2007.05-2.9 ×1 cr.