- DL manuals

- Yamaha

- Robotics

- RCX222

- User Manual

Yamaha RCX222 User Manual

Summary of RCX222

Page 1

Rcx 222 eur2153130 e99 ver. 1.30 userʼs manual yamaha 2-axis robot controller.

Page 3: Contents

Contents rcx222 user’s manual t-1 safety instructions 1. Safety information s-1 2. Signal words used in this manual s-2 3. Warning labels s-3 3.1 warning labels s-3 3.1.1 warning label messages on robot and controller s-3 3.1.2 supplied warning labels s-8 3.2 warning symbols s-9 4. Important precaut...

Page 4: Contents

Contents rcx222 user’s manual t-2 t-3 warranty introduction 1 before using the robot controller (be sure to read the following notes) 2 overview of the rcx series 3 chapter 1 using the robot safely 1. Operating environment 1-1 chapter 2 system overview 1. System overview 2-1 1.1 mainsystemconfigurat...

Page 5: Contents

T-2 contents rcx222 user’s manual t-3 4.1 connection example 3-7 4.2 power supply and ground terminals 3-8 4.3 ac power connector wiring 3-9 4.4 considering power capacity and generated heat amount 3-10 4.5 installing an external leakage breaker 3-11 4.6 installing a circuit protector 3-11 4.7 insta...

Page 6: Contents

Contents rcx222 user’s manual t-4 t-5 3.1 part names 4-3 3.2 main functions 4-3 3.3 connection to the robot controller 4-4 3.4 changing the rpb screen settings 4-5 4. Turning power on and off 4-6 5. Operation keys 4-8 5.1 rpb screen 4-8 5.2 operation key layout 4-9 5.3 basic key operation 4-10 5.4 f...

Page 7: Contents

T-4 contents rcx222 user’s manual t-5 9.9 break point 4-47 9.9.1 setting break points 4-48 9.9.2 deleting break points 4-49 9.10 executing a step 4-50 9.11 skipping a step 4-50 9.12 executing the next step 4-51 10. "program" mode 4-52 10.1 scrolling a program listing 4-53 10.2 program editing 4-54 1...

Page 8: Contents

Contents rcx222 user’s manual t-6 t-7 11.2.1 point data input and editing 4-89 11.2.1.1 restoring point data 4-90 11.2.2 point data input by teaching 4-91 11.2.3 point data input by direct teaching 4-93 11.2.4 point jump display 4-94 11.2.5 copying point data 4-95 11.2.6 erasing point data 4-97 11.2...

Page 9: Contents

T-6 contents rcx222 user’s manual t-7 11.10 executing the user function keys 4-154 12. "system" mode 4-155 12.1 parameters 4-157 12.1.1 parameter list 4-159 12.1.2 robot parameters 4-161 12.1.3 axis parameters 4-165 12.1.4 other parameters 4-185 12.1.5 parameters for option boards 4-201 12.1.5.1 opt...

Page 10: Contents

Contents rcx222 user’s manual t-8 t-9 12.6.2.2 saving files 4-269 12.6.2.3 initializing the files 4-270 13. "monitor" mode 4-271 14. "utility" mode 4-274 14.1 canceling emergency stop; motor power and servo on/off 4-276 14.1.1 canceling emergency stop 4-276 14.1.2 motor power and servo on/off 4-277 ...

Page 11: Contents

T-8 contents rcx222 user’s manual t-9 2. Ratings 5-22 3. Precautions 5-23 chapter 6 safety i/o interface 1. Safety i/o interface overview 6-1 1.1 power 6-1 1.2 connector i/o signals 6-2 1.3 connector terminal numbers 6-3 1.4 emergency stop input signal connections 6-4 1.5 dedicated input signal conn...

Page 12: Contents

Contents rcx222 user’s manual t-10 chapter 9 troubleshooting 1. Error messages 9-1 1.1 robot controller error messages 9-1 [ 0] warnings and messages 9-3 [ 1] warnings (error history entry) 9-5 [ 2] robot operating area errors 9-6 [ 3] program file operating errors 9-10 [ 4] data entry and edit erro...

Page 13: Contents

Contents 1. Safety information s-1 2. Signal words used in this manual s-2 3. Warning labels s-3 3.1 warning labels s-3 3.1.1 warning label messages on robot and controller s-3 3.1.2 supplied warning labels s-8 3.2 warning symbols s-9 4. Important precautions for each stage of the robot life cycle s...

Page 15: Safety Instructions

Safety instructions s-1 1. Safety information industrial robots are highly programmable, mechanical devices that provide a large degree of freedom when performing various manipulative tasks. To ensure safe and correct use of yamaha industrial robots and con- trollers*, carefully read and comply with...

Page 16: Safety Instructions

Safety instructions s-2 2. Signal words used in this manual this manual uses the following safety alert symbols and signal words to provide safety instructions that must be observed and to describe handling precautions, prohibited actions, and compulsory actions. Make sure you understand the meaning...

Page 17: Safety Instructions

Safety instructions s-3 3. Warning labels warninglabelsshownbelowareattachedtotherobotbodyandcontrollertoalerttheoperatortopotential hazards. To ensure correct use, read the warning labels and comply with the instructions. 3.1 warning labels w warning if warning labels are removed or difficult to se...

Page 18: Safety Instructions

Safety instructions s-4 warning label 3 (scara robots, cartesian robots, controllers*) ■ * some models w warning improper installation or operation may cause serious injury. Before installing or operating the robot, read the manual and instructions on the warning labels and understand the contents. ...

Page 19: Safety Instructions

Safety instructions s-5 warming label 6 (robot drivers rdv-x/rdv-p) ■ w warning • beforetouchingtheterminalsorconnectorsontheoutsideoftherobotdriver,turnoffthepowerandwaitfor 10 minutes or longer to prevent electrical shock. Otherwise, burn or electrical shock may result. • beforeusingtherobotdriver...

Page 20: Safety Instructions

Safety instructions s-6 warming label 8 (controllers rcx240, controllers rcx340) ■ w warning these are precautions for yamaha and distributors' service personnel. Customers must not attempt to open the covers. W warning wait at least 100 seconds after power-off before opening the covers. Instruction...

Page 21: Safety Instructions

Safety instructions s-7 warning label 11 (controller)* ■ * this label is attached to the front panel. C caution refer to the manual. 取扱説明書参照 read instruction manual instructions on this label thisindicatesimportantinformationthatyoumust knowandisdescribedinthemanual. Beforeusingthecontroller,besuret...

Page 22: Safety Instructions

Safety instructions s-8 3.1.2 supplied warning labels some warning labels are not affixed to robots but included in the packing box. These warning labels should be affixed to an easy-to-see location. Warning label is attached to the robot body. Warning label comes supplied with the robot and should ...

Page 23: Safety Instructions

Safety instructions s-9 3.2 warning symbols warningsymbolsshownbelowareindicatedontherobotsandcontrollerstoalerttheoperatortopotential hazards. To use the yamaha robot safely and correctly always follow the instructions and cautions indicated by the symbols. Electrical shock hazard symbol 1. W warni...

Page 24: Safety Instructions

Safety instructions s-10 4. Important precautions for each stage of the robot life cycle this section describes major precautions that must be observed when using robots and controllers. Be sure to carefully read and comply with all of these precautions even if there is no alert symbol shown. 4.1 pr...

Page 25: Safety Instructions

Safety instructions s-11 4.2 essential precautions for the linear conveyor module the linear conveyor module is a yamaha robot so safety measures must be followed and safety equipment must be installed just as required for other yamaha robots. This section describes essential precautions for handlin...

Page 26: Safety Instructions

Safety instructions s-12 4.3 design 4.3.1 precautions for robots restricting the robot moving speed 1. W warning restriction on the robot moving speed is not a safety-related function. To reduce the risk of collision between the robot and workers, the user must take the necessary protective measures...

Page 27: Safety Instructions

Safety instructions s-13 4.4 moving and installation 4.4.1 precautions for robots installation environment ■ do not use in strong magnetic fields 1. W warning donotusetherobotnearequipmentorinlocationsthatgeneratestrongmagneticfields.Therobotmaybreak down or malfunction if used in such locations. Do...

Page 28: Safety Instructions

Safety instructions s-14 wiring ■ protective measures against electrical shock 1. W warning always ground the robot to prevent electrical shock. Adjustment ■ adjustment that requires removing a cover 1. W warning adjustment by removing a cover require specialized technical knowledge and skills, and ...

Page 29: Safety Instructions

Safety instructions s-15 wiring ■ connection to robot controller 1. The controller parameters are preset at the factory before shipping to match the robot model. Check the specified robot and controller combination, and connect them in the correct combination. Since the software detects abnormal ope...

Page 30: Safety Instructions

Safety instructions s-16 4.5 safety measures 4.5.1 safety measures referring to warning labels and manual 1. W warning • beforestartinginstallationoroperationoftherobot,besuretoreadthewarninglabelsandthismanual,and comply with the instructions. • neverattemptanyrepair,partsreplacementandmodification...

Page 31: Safety Instructions

Safety instructions s-17 w warning • duringstartupormaintenancetasks,displayasign"workinprogress"ontheprogrammingboxand operation panel in order to prevent anyone other than the person for that task from mistakenly operating the start or selector switch. If needed, take other measures such as lockin...

Page 32: Safety Instructions

Safety instructions s-18 4.6 operation when operating a robot, ignoring safety measures and checks may lead to serious accidents. Always take the following safety measures and checks to ensure safe operation. W danger check the following points before starting robot operation. •nooneiswithintherobot...

Page 33: Safety Instructions

Safety instructions s-19 working inside safety enclosures 4. Before starting work within the safety enclosure, always confirm from outside the enclosure that each protective function is operating correctly (see the previous section 2.3). W danger never enter within the movement range while within th...

Page 34: Safety Instructions

Safety instructions s-20 4.6.2 automatic operation checkthefollowingpointswhenoperatingtherobotinautomode.Observetheinstructionsbelowincases where an error occurs during automatic operation. Automatic operation described here includes all operations inautomode. Checkpoints before starting automatic ...

Page 35: Safety Instructions

Safety instructions s-21 use caution when releasing the z-axis (vertical axis) brake 3. W warning theverticalaxiswillslidedownwardwhenthebrakeisreleased,causingahazardoussituation.Takeadequate safety measures in consideration by taking the weight and shape into account. • beforereleasingthebrakeafte...

Page 36: Safety Instructions

Safety instructions s-22 4.7 inspection and maintenance always perform daily and periodic inspections and make a pre-operation check to ensure there are no prob- lems with the robot and related equipment. If a problem or abnormality is found, then promptly repair it or take other measures as necessa...

Page 37: Safety Instructions

Safety instructions s-23 4.7.2 precautions during service work precautions when removing a motor (cartesian robots and vertical mount single-axis robots) 1. W warning theverticalaxiswillslidedownwhenthemotorisremoved,causingahazardoussituation. • turnoffthecontrollerandplaceasupportundertheverticala...

Page 38: Safety Instructions

Safety instructions s-24 4.8 disposal whendisposingofrobotsandrelateditems,handlethemcarefullyasindustrialwastes.Usethecorrect disposal method in compliance with your local regulations, or entrust disposal to a licensed industrial waste disposal company. Disposal of lithium batteries 1. When disposi...

Page 39: Safety Instructions

Safety instructions s-25 5. Emergency action when a person is caught by robot if a person should get caught between the robot and a mechanical part such as the installation base, then release the axis. Emergency action ■ release the axis while referring to the following section in the manual for the...

Page 40: Safety Instructions

Safety instructions s-26 7. Using the robot safely 7.1 movement range when a tool or workpiece is attached to the robot manipulator tip, the actual movement range enlarges from the movement range of the robot itself (figure a) to include the areas taken up by movement of the tool and workpiece attac...

Page 41: Safety Instructions

Safety instructions s-27 7.2 robot protective functions protective functions for yamaha robots are described below. Overload detection 1. This function detects an overload applied to the motor and turns off the servo. If an overload error occurs, take the following measures to avoid such errors: 1. ...

Page 42: Safety Instructions

Safety instructions s-28 7.3 residual risk to ensure safe and correct use of yamaha robots and controllers, system integrators and/or end users imple- ment machinery safety design that conforms to iso12100. Residualrisksforyamaharobotsandcontrollersaredescribedinthedangerorwarninginstructions provid...

Page 44: Safety Instructions

Yamaha motor co., ltd. Im operations all rights reserved. No part of this publication may be reproduced in any form without the permission of yamaha motor co., ltd. Information furnished by yamaha in this manual is believed to be reliable. However, no responsibility is assumed for possible inaccurac...

Page 45: Arranty

W arranty ver.1.01_201209 warranty for information on the warranty period and terms, please contact our distributor where you purchased the product. This warranty does not cover any failure caused by: ■ 1. Installation, wiring, connection to other control devices, operating methods, inspection or ma...

Page 47: Introduction

1 introduction introduction our sincere thanks for your purchase of this yamaha robot controller. This manual explains how to install and operate the yamaha robot controller. Be sure to read this manual carefully as well as related manuals and comply with their instructions for using the yamaha robo...

Page 48

Before using the robot controller (be sure to read the following notes) 2 3 before using the robot controller (be sure to read the following notes) please be sure to perform the following tasks before using the robot controller. Failing to perform these tasks will require absolute reset for setting ...

Page 49: Over

2 3 over view of the rcx series overview of the rcx series the yamaha rcx series robot controllers were developed based on years of yamaha experience and proven achievements in robotics and electronics. These controllers are specifically designed to operate yamaha industrial robots efficiently and a...

Page 50: Memo

4 memo.

Page 51: Chapter 1

Chapter 1 using the robot safely contents 1. Operating environment 1-1.

Page 52: 1-1

1-1.

Page 53: 1-1

1-1 chapter 1 using the robot safel y 1. Operating environment operating temperature operatingtemperature 0°cto40°c the ambient temperature should be maintained within a range of 0 to 40°c in order to guarantee continuous operation of the robot controller that meets the initial specifications. If th...

Page 54: 1-2

1-2 chapter 1 using the robot safel y environments the controller is not designed to meet explosion-proof, dust-proof, and drip-proof specifications, and so do not use it in the following locations. If used in these locations, component corrosion, improper installation, or fire may result. 1)environ...

Page 55: Chapter 2

Chapter 2 system overview contents 1. System overview 2-1 1.1 main system configuration 2-1 1.2 rcx22 series axis definition 2-2 2. Part names and functions 2-3 2.1 rcx222 (maximum number of axes: 2) 2-3 2.2 rcx222hp (maximum number of axes: 2) 2-3 3. Control system 2-4 3.1 rcx222/rcx222hp 2-4 4. Op...

Page 56: 2-1

2-1.

Page 57: 2-1

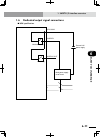

2-1 chapter 2 system over view 1. System overview 1. System overview the rcx22 series controllers are designed for use with a two-axis robot, mainly for assembly and pick-and-place applications. Applications also include various inspection instruments, sealers and spray equipment utilizing linear an...

Page 58: 2-2

2-2 chapter 2 system over view 2-3 1. System overview configuration 2: system for controlling two single-axis robots example: t9 + t9 ■ system for controlling two single-axis robots xm ym mot or rgen tem p acin n l l1 n1 safet y srv err rpb rob i/o sd/com rdy e-st op b/a bat rcx222 ext.E-st op pin11...

Page 59: 2-2

2-2 2-3 chapter 2 system over view 2. Part names and functions 2. Part names and functions 2.1 rcx222 (maximum number of axes: 2) ■ rcx222 front view xm ym motor rgen temp acin n l l1 n1 safety srv err rpb rob i/o sd/com rdy e-stop b/a bat rcx222 pin11-12 ext.E-stop op.1 op.2 ! 2.2 rcx222hp (maximum...

Page 60: 2-4

2-4 chapter 2 system over view 2-5 3. Control system 3. Control system the basic block diagram of the control system is shown below. 3.1 rcx222/rcx222hp ■ basic block diagram d.Power board assy cpu board assy driver2 board assy driver2 board assy fan op .Board op.Board cn3 cn4 ac200-230v regenerativ...

Page 61: 2-4

2-4 2-5 chapter 2 system over view 4. Optional devices 4. Optional devices 4.1 rpb programming box the rpb is a hand-held device used to perform all robot operations, including manual operations, program input and editing, teaching and parameter settings. Emergency stop button emergency stop button ...

Page 62: 2-6

2-6 chapter 2 system over view 5. Basic sequence from installation to operation the basic sequence from installation to actual operation is shown below. Refer to this sequence to use the rcx22 series safely, correctly and effectively. Before beginning the work, read this user's manual thoroughly. In...

Page 63: Chapter 3

Chapter 3 installation contents 1. Unpacking 3-1 1.1 packing box 3-1 1.2 unpacking 3-1 2. Installing the robot controller 3-2 2.1 installation conditions 3-2 2.2 installation methods 3-4 3. Connector names 3-6 4. Connecting to the power 3-7 4.1 connection example 3-7 4.2 power supply and ground term...

Page 64: 3-1

3-1 12.1 wiring methods 3-24 12.2 precautions for installation 3-26 12.3 methods of preventing malfunctions 3-26 13. Checking the robot controller operation 3-27 13.1 cable connection 3-27 13.2 operation check 3-28.

Page 65: 3-1

3-1 chapter 3 inst alla tion 1. Unpacking 1.1 packing box the robot controller is high precision equipment and is carefully packed in a cardboard box to avoid shocks and vibrations. If there is any serious damage or dents on the packing box, please notify your yamaha sales dealer without unpacking t...

Page 66: 3-2

3-2 chapter 3 inst alla tion 3-3 2. Installing the robot controller when installing, choose a proper place for your robot controller, taking into account your system layout, accessibility for maintenance, etc. 2.1 installation conditions c caution (1) whencarryingtherobotcontroller,useadollyorsimila...

Page 67: 3-2

3-2 3-3 chapter 3 inst alla tion ■ clearance for installing the controller xm ym motor rgen temp acin n l l1 n1 safety srv err rpb rob i/o sd/com rdy e-stop b/a bat rcx222 pin11-12 ext.E-stop op.1 op.2 ! 50mm or more 50mm or more 17mm or more 50mm or more when installing the robot controller, follow...

Page 68: 3-4

3-4 chapter 3 inst alla tion 3-5 2.2 installation methods there are three methods for installing the robot controller as explained below. 1)usingtherubberfeet(attachedasstandardparts) ■ using the rubber feet xm ym mot or rgen tem p acin n l l1 n1 safet y srv err rpb rob i/o sd/com rdy e-st op b/a ba...

Page 69: 3-4

3-4 3-5 chapter 3 inst alla tion 3)attachingthel-typebrackets(suppliedasstandardaccessories)totherear ■ attaching the l-type brackets to the rear xm ym mot or rgen tem p acin n l l1 n1 safet y srv err rpb rob i/o sd/com rdy e-st op b/a bat rcx222 ext.E-st op pin11-12 op.1 op.2 ! L-type bracket part ...

Page 70: 3-6

3-6 chapter 3 inst alla tion 3-7 3. Connector names connector names, locations and functions are shown below. ■ rcx connectors xm ym motor rgen temp acin n l l1 n1 safety srv err rpb rob i/o sd/com rdy e-stop b/a bat rcx222 pin11-12 ext.E-stop op.1 op.2 ! T com r rpb e safety q xm q ym y op.1 y op.2...

Page 71: 3-6

3-6 3-7 chapter 3 inst alla tion 4. Connecting to the power attach the power connector to the power cable and insert it into the "ac in" connector on the front panel of the controller as shown below. 4.1 connection example l n l1 n1 leakage breaker noise filter circuit protector circuit protector su...

Page 72: 3-8

3-8 chapter 3 inst alla tion 3-9 4.2 power supply and ground terminals w warning • topreventelectricalshocksormalfunctionscausedbynoise, thegroundterminal(protectiveconductor) must be grounded properly. • topreventelectricalshocks,nevertouchtheacinterminals when power is supplied to the robot contro...

Page 73: 3-8

3-8 3-9 chapter 3 inst alla tion 4.3 ac power connector wiring l length of exposed wire lead strip the wire to expose 8 to 9 mm of bare lead. 8 to 9 mm l wiring insert the wire lead into the opening in the power connector in either of the following methods, and make sure the wire is securely attache...

Page 74: 3-10

3-10 chapter 3 inst alla tion 3-11 4.4 considering power capacity and generated heat amount the required power capacity and generated heat amount depend on the robot model and the number of axes to be controlled. C caution the power supply voltage for the robot controller must always be regulated wi...

Page 75: 3-10

3-10 3-11 chapter 3 inst alla tion 4.5 installing an external leakage breaker since the robot controller drives the motors by pwm control of igbt, leakage current flows at high frequencies. This might cause the external leakage breaker to malfunction. When installing an external leakage current brea...

Page 76: 3-12

3-12 chapter 3 inst alla tion 3-13 4.7 installing an electromagnetic contactor when controlling the power on/off operation of the robot controller using an external unit suchasaplc,anelectromagneticcontactorshouldbeinstalledontheacpowersupply line for the controller. Select an electromagnetic contac...

Page 77: 3-12

3-12 3-13 chapter 3 inst alla tion 4.9 installing a surge absorber userswhowishtoimproveimmunitytosurgenoisefromlightningstrikesshouldinstalla surge absorber. ■ dimensional outlines of recommended surge absorber manufacturer :soshinelectricco.,ltd. Typeno. :lt-c12g801ws status indicator φ4.3 +0.3 -0...

Page 78: 3-14

3-14 chapter 3 inst alla tion 3-15 5. Robot connections 5.1 connecting the robot cables connect the robot cables to the "xm", "ym" and "rob i/o" connectors on the front panel of the controller as shown below. The robot cable specifications depend on the robot model, so refer to each robot user's man...

Page 79: 3-14

3-14 3-15 chapter 3 inst alla tion 5. Robot connections 5.2 noise countermeasures the robot cables which are connected to the controller's xm and ym connectors are motor power cables, and these cables emit switching noise which occurs during motor control. This noise could cause malfunctions in sens...

Page 80: 3-16

3-16 chapter 3 inst alla tion 3-17 6. Connecting the rpb programming box as shown in the figure below, the rpb should be connected to the rpb connector on the front panel of the robot controller. If not connecting the rpb, plug a terminator (supplied as an accessory) into the rpb connector. C cautio...

Page 81: 3-16

3-16 3-17 chapter 3 inst alla tion 7. I/o connections the various input/output (i/o) signals from peripheral equipment can be connected to the robotcontroller.Eachi/oissetwithanumber,andthei/oconnectortobeuseddepends on that number. For more detailed information on inputs and outputs, see chapter 5,...

Page 82: 3-18

3-18 chapter 3 inst alla tion 3-19 8. Connecting a host computer as a standard feature, the robot controller has an rs-232c interface port for data communication with a host computer. Most computer models having an rs-232c port can be interfaced to the robot controller, by connecting the com connect...

Page 83: 3-18

3-18 3-19 chapter 3 inst alla tion 9. Connecting the absolute battery the absolute batteries shipped with the controller are unused, and the battery connectors are left disconnected to prevent discharge. After installing the controller, always be sure to connect the absolute batteries before connect...

Page 84: 3-20

3-20 chapter 3 inst alla tion 3-21 w warning • whenreplacingtheabsolutebatterywiththepowerturnedon,put the robot in the emergency stop status. • performtheworkaftercheckingthatthereisnoelectrical shockhazardintheperipheralunitsofthecontroller. • theabsolutebatteryreplacementintheservoonstatusis haza...

Page 85: 3-20

3-20 3-21 chapter 3 inst alla tion 10. Replacing the absolute battery the absolute battery will wear down and must be replaced as needed. For example, when problems with backing up data occur, replace the battery since the battery has reached the end of the service life. Though battery wear depends ...

Page 86: 3-22

3-22 chapter 3 inst alla tion 3-23 11. Connecting a regenerative unit whenaregenerativeunitisrequired,connectittothergenandtempconnectorson the front panel of the controller. The regenerative unit is attached to the right side of the controller prior to shipping. N note • thercx222mayrequirearegener...

Page 87: 3-22

3-22 3-23 chapter 3 inst alla tion ■ regenerative unit block diagram rcx222 rgen temp regenerative unit standard cable length: 300mm thermal sensor (normally closed) c caution (1) thegenerativeunitbecomeshotduringoperation.Donottouchitto avoid burns. Also do not install the generative unit near an o...

Page 88: 3-24

3-24 chapter 3 inst alla tion 3-25 12. Precautions for cable routing and installation 12.1 wiring methods various cables are used to connect the robot controller to peripheral devices. Follow the precautions below when making cable routing and connections to avoid malfunctions due to noise. C cautio...

Page 89: 3-24

3-24 3-25 chapter 3 inst alla tion refer to the drawing below when making the cable connections. ■ cable connection xm ym motor rgen temp acin n l l1 n1 safety srv err rpb rob i/o sd/com rdy e-stop b/a bat rcx222 pin11-12 ext.E-stop op.1 op.2 ! Dio cable safety cable power cable robot cable communic...

Page 90: 3-26

3-26 chapter 3 inst alla tion 3-27 12.2 precautions for installation this robot controller is not designed with an explosion-proof, dust-proof or drip-proof structure. Do not install it in the following locations or environments (1) where exposed to flammable gases or liquids. (2) where conductive d...

Page 91: 3-26

3-26 3-27 chapter 3 inst alla tion 13. Checking the robot controller operation this section explains how to check the controller operation using a special connector that comes with the controller and an applicable robot. Before beginning this check, finish making connections to the following items. ...

Page 92: 3-28

3-28 chapter 3 inst alla tion 13.2 operation check after connecting the robot and special connector (supplied) to the controller, turn on the power to the controller and check the following points. Normal operation •the"rdy"and"srv"ledlampsonthefrontpanelofthecontrollerlightup.The "err"ledlampisoff....

Page 93: Chapter 4

Chapter 4 operation contents 1. Operation overview 4-1 2. The rcx robot controller 4-2 2.1 part names 4-2 2.2 main functions 4-2 3. Rpbprogrammingbox 4-3 3.1 part names 4-3 3.2 main functions 4-3 3.3 connection to the robot controller 4-4 3.4 changing the rpb screen settings 4-5 4. Turning power on ...

Page 94

9. "auto" mode 4-30 9.1 automatic operation 4-33 9.2 stopping the program 4-34 9.3 resetting the program 4-35 9.4 switching task display 4-37 9.5 switching the program 4-38 9.6 changing the automatic movement speed 4-39 9.7 executing the point trace 4-40 9.7.1 ptp motion mode 4-42 9.7.2 arch motion ...

Page 95

10.3.4 copying a program 4-69 10.3.5 erasing a program 4-70 10.3.6 renaming a program 4-71 10.3.7 changing the program attribute 4-72 10.3.8 displaying object program information 4-73 10.3.9 creating a sample program automatically 4-74 10.4 compiling 4-76 10.5 line jump and character string search 4...

Page 96

11.5.2 editing the shift coordinate range 4-121 11.5.2.1 restoring a shift coordinate range 4-123 11.5.3 shift coordinate setting method 1 4-124 11.5.4 shift coordinate setting method 2 4-127 11.6 displaying, editing and setting hand definitions 4-130 11.6.1 editing hand definitions 4-133 11.6.1.1 r...

Page 97

12.5 self diagnosis 4-251 12.5.1 controller check 4-252 12.5.2 error history display 4-253 12.5.3 displaying the absolute battery condition 4-254 12.5.4 displaying the total operation time 4-255 12.5.5 system error details display 4-256 12.6 backup processes 4-257 12.6.1 sd memory card 4-258 12.6.1....

Page 98: 4-1

4-1.

Page 99: 4-1

4-1 chapter 4 opera tion 1. Operation overview the controller configuration and main functions are shown below. Set up the equipment as needed according to the operation to be performed. C caution theexternalcircuitconnectedtotherobotcontrollershouldbepreparedby the user. N note • refertochapter5for...

Page 100: 4-2

4-2 chapter 4 opera tion 4-3 2. The rcx robot controller 2.1 part names controller front panel ■ part names and layout xm ym motor rgen temp acin n l l1 n1 safety srv err rpb rob i/o sd/com rdy e-stop b/a bat rcx222 pin11-12 ext.E-stop op.1 op.2 ! Q ac in terminal y rpb connector u sd/com connector ...

Page 101: 4-2

4-2 4-3 chapter 4 opera tion 3. Rpb programming box the rpb programming box connects to the robot controller and is used to edit and execute robot programs. 3.1 part names ■ programming box y enable switch (rpb-e only) rear view t selector switch (rpb-e only) q display (liquid crystal screen) e emer...

Page 102: 4-4

4-4 chapter 4 opera tion 4-5 t selector switch (rpb-e only) thisswitchcanbeusedasneededbywiringtothesafetyconnectorbytheuser. The switch on/off function is disabled if not wired correctly. Y 3-position enable switch (rpb-e only) this switch is provided for safety. Pressing it to mid-position only al...

Page 103: 4-4

4-4 4-5 chapter 4 opera tion 3.4 changing the rpb screen settings the rpb screen contrast can be adjusted, and the key-press volume can be changed as needed. 1) turn on the power while holding down on the rpb. Therpbsettingscreen("adjust"mode)appears. ■ "adjust" mode for changing rpb screen settings...

Page 104: 4-6

4-6 chapter 4 opera tion 4-7 4. Turning power on and off this section explains how to turn power on and off, assuming that the external emergency stop circuit and other necessary units are connected according to the instructions in chapter 3, "installation", and also that the robot controller operat...

Page 105: 4-6

4-6 4-7 chapter 4 opera tion 4) if return-to-origin is incomplete, eliminate the problem and perform absolute reset. Then start the robot operation. Refer to "11.8 absolute reset" in this chapter for how to perform absolute reset. ■ "manual" mode screen manual –––––––––––––––––––––––––––––––––––––––...

Page 106: 4-8

4-8 chapter 4 opera tion 4-9 5. Operation keys 5.1 rpb screen the rpb screen display is composed of 4 areas as shown below. ■ rpb screen example program >edit '***** test1 program ***** 2 ' 3 do2(0)=0 4 wait di3(4,3,2)=3 5 move p,p0 select copy cut paste bs 1st line 2nd line 3rd line 4th line 5th li...

Page 107: 4-8

4-8 4-9 chapter 4 opera tion 5.2 operation key layout the operation keys are covered with a plastic sheet to prevent dust. There are 3 main kinds of keys. 1) function keys 2) control keys 3) data keys ■ sheet key layout function key data key control key 5. Operation keys.

Page 108: 4-10

4-10 chapter 4 opera tion 4-11 5.3 basic key operation 1)eachoperationkeyhas3differentfunctionsasshownbelow. Use or as needed to enable various functions. ■ key configuration shift 1 shift 2 shift 3 2) there are 3 ways (shift 1 to shift 3) to use each operation key. Shift example of key input input ...

Page 109: 4-10

4-10 4-11 chapter 4 opera tion 5.4 function keys to operate the rpb, select the menus by pressing the function keys. Therelationofthefunctionkeystotheirmenusin"manual"modeisshownbelow. Function key selected menu (f1) point (f2) pallet (f4) vel+ (f5) vel- + (f6) shift + (f7) hand + (f8) unitchg + (f9...

Page 110: 4-12

4-12 chapter 4 opera tion 4-13 relation of function keys to menus ■ function keys and menus manual 50%[mg][s0h0j] current position point pallet vel+ vel- ↓ ↓ ↓ ↓ ↓ [f1] [f2] [f3] [f4] [f5] ∧ shift hand unitchg vel++ vel— ↓ ↓ ↓ ↓ ↓ [f6] [f7] [f8] [f9] [f10] ...Upper ∨ abs.Rst coordi ↓ ↓ ↓ ↓ ↓ [f11] [...

Page 111: 4-12

4-12 4-13 chapter 4 opera tion 5.5 control keys thereare6kindsofcontrolkeys:(1)modeselectionkeys,(2)extendedfunctionkeys, (3)cursorkeys,(4)pagekeys,(5)editkeys,(6)jogkeys. The functions of each key are explained below. (1) mode selection keys : displays the mode menu (highest hierarchy). : selects t...

Page 112: 4-14

4-14 chapter 4 opera tion 4-15 (5) edit keys these keys are enabled when the editing cursor is displayed. : toggles between "insert" and "overwrite" modes. The cursor "_" appears in "overwrite" mode and " ■ " appears in "insert" mode. : deletes one character at the cursor position. : inserts one lin...

Page 113: 4-14

4-14 4-15 chapter 4 opera tion 5.6 data keys the data keys are used for data input, programming and data editing. There are 2 kinds of data keys. (1) alphanumeric keys to :entersnumbers. To :entersalphabeticcharacters. : inserts spaces. (2) symbol keys 5.7 other keys (1) enter key : pressingthiskeye...

Page 114: 4-16

4-16 chapter 4 opera tion 4-17 6. Emergency stop if for some reason you want to stop the robot immediately during operation, press the emergency stop button on the rpb. Pressing the emergency stop button cuts off power to the robot to stop operation. A message appears on the rpb screen as shown belo...

Page 115: 4-16

4-16 4-17 chapter 4 opera tion 6.1 emergency stop reset to return to normal operation after emergency stop, emergency stop must be reset. N note • emergency stop can also be triggered by an emergency stop input from thesafetyi/ointerface.Tocancelthisemergencystop,refertochapter6. • originpositionsar...

Page 116: 4-18

4-18 chapter 4 opera tion 4-19 4) press (motor). The following screen appears. ■ "utility>motor" mode (1) utility>motor motor power: off d1=m1: brake d5=m5: no axis d2=m2: brake d6=m6: no axis d3=m3: no axis d4=m4: no axis on off 5) press (on) to turn on the motor power. At the same time, the servom...

Page 117: 4-18

4-18 4-19 chapter 4 opera tion 6. Emergency stop 6.2 overload error reset in order to restore (enable) robot operation following a "17.4: overload" error occurrence, the overload cause must be identified and corrected, and then the error status must be reset. N notes • anemergencystopstatusisestabli...

Page 118: 4-20

4-20 chapter 4 opera tion 4-21 6. Emergency stop press the key at this time to return to the original mode with the motor power off. Continue with the following steps to turn the motor power on. 4) press the (motor) key. The following screen is then displayed. ■ motor power on (1) utility>motor moto...

Page 119: 4-20

4-20 4-21 chapter 4 opera tion 7. Mode configuration the robot operation mode consists of the following modes. “service” mode basic operation modes “auto” mode “manual” mode “program” mode “system” mode “di/do monitor” mode “utility” mode "service"modecanbeusedonlywhen"safe"modeisenabled. 7.1 basic ...

Page 120: 4-22

4-22 chapter 4 opera tion 4-23 c caution the"system"modeisusedtoselectthe"service"modefunctions.(referto '12.3.2settingthe"service"mode'inthischapter.) (2) "auto" mode select this mode to execute robot programs. Robot programs can be executed only in this mode. Operable tasks in this mode differ dep...

Page 121: 4-22

4-22 4-23 chapter 4 opera tion 7.3 mode hierarchy robot operation is mainly performed by pressing the function keys to select the desired mode from the menu. (refer to the "mode hierarchy diagram" described later.) whenthecontrolleristurnedon,the"manual"modemenufirstappearsonthescreen. Pressing disp...

Page 122: 4-24

4-24 chapter 4 opera tion 4-25 functions are switched with the and shift keys. The menu display changes while this shift key is pressed. ■ shift keys ■ function switching reset task dir vel+ vel- ↓ ↓ ↓ ↓ [f1] ↓ [f2] [f3] [f4] [f5] ∧ point direct break vel++ vel-- ↓ ↓ ↓ ↓ ↓ [f6] [f7] [f8] [f9] [f10] ...

Page 123: 4-24

4-24 4-25 chapter 4 opera tion n note • whenthedataisbeingeditedsuchasin"edit"mode, is inoperative. After pressing to return the mode hierarchy, press . • fromhereinthisuser'smanualthemodehierarchystatusisstatedinthe order as shown below. First(highest)hierarchy>secondhierarchy>thirdhierarchy>fourth...

Page 124: 4-26

4-26 chapter 4 opera tion 4-27 ■ mode hierarchy diagram f1 auto f1 edit f2 teach f3 jump f4 vel+ f5 vel- f6 copy f7 erase f8 unitchg f9 vel++ f10 vel-- f11 find f12 find+ f13 find- f1 undo f3 jump f1 point f1 edit f2 teach f3 jump f4 vel+ f5 vel- f6 copy f7 erase f8 unitchg f9 vel++ f10 vel-- f11 tr...

Page 125: 4-26

4-26 4-27 chapter 4 opera tion f1 edit f4 vel+ f5 vel- f6 method1 f8 unitchg f9 vel++ f10 vel-- f1 m1 f2 m2 (f3 m3) (f4 m4) (f5 m5) (f6 m6) f11 all f1 4points f2 3points f5 simple f4 vel+ f5 vel- f8 unitchg f9 vel++ f10 vel-- f4 vel+ f5 vel- f8 unitchg f9 vel++ f10 vel-- f4 vel+ f5 vel- f8 unitchg f...

Page 126: 4-28

4-28 chapter 4 opera tion 4-29 8. "service" mode 8. "service" mode "service"modecanbeusedonlywhen"safe"modeisenabled. Use"service"modetoperformsafemaintenanceworkwiththerpbwhilewithinthe safetyenclosureoftherobotsystem.Thismodecanbeselectedbyturningdi02("service" mode input) off. C caution • use"sys...

Page 127: 4-28

4-28 4-29 chapter 4 opera tion 8. "service" mode 8.4 limits on robot moving speed robot operation from within the safety enclosure of the robot system is mainly for teaching and maintenance for the robot. Therefore,robotmovingspeedinservicemodeislimitedto3%ofthemaximumspeed so that the robot will mo...

Page 128: 4-30

4-30 chapter 4 opera tion 4-31 9. "auto" mode 9. "auto" mode "auto"modeexecutesrobotlanguageprogramsandrelatedtasks. Theinitial"auto"modescreenisshownbelow. ■ "auto" mode auto [t1] 100% s@ ————————————————————————————————————— 1 ’***** test1 program ***** 2 start *subtask,t2 3 do2(0)=0 4 wait di3(4,...

Page 129: 4-30

4-30 4-31 chapter 4 opera tion 9. "auto" mode i pointer display the program line number to be executed next is shown highlighted in the program listing. O guideline the contents assigned to function keys are shown highlighted. A message on what to do next also appears here in some operation steps. U...

Page 130: 4-32

4-32 chapter 4 opera tion 4-33 9. "auto" mode validkeysandsubmenudescriptionsin"auto"modeareshownbelow. Valid keys menu function cursorkey ( ↑/↓) scrollstheprogramlisting. Pagekey ( 〈〈 / 〈〈 ) switchestootherscreens. F1 reset resetstheprogram. F2 task changestheprogramlistingaccordingtoeachtask. F3 d...

Page 131: 4-32

4-32 4-33 chapter 4 opera tion 9. "auto" mode 9.1 automatic operation program commands are executed continuously during automatic operation. Before starting automatic operation, make sure that return-to-origin, program debugging, i/o signal connections and point data teaching have already been compl...

Page 132: 4-34

4-34 chapter 4 opera tion 4-35 9. "auto" mode the following keys are enabled during automatic operation. Valid keys menu function f9 vel++ increasesautomaticmovementspeedfortheselected robotgroupin5%increments. F10 vel-- decreasesautomaticmovementspeedfortheselected robotgroupin5%decrements. Robot (...

Page 133: 4-34

4-34 4-35 chapter 4 opera tion 9. "auto" mode 9.3 resetting the program to restart a program stopped with from the beginning, reset the program. N note the output is also reset when the program is reset. However, the output will not be reset in the following cases: 1. “do cond. On pgm reset / rescdo...

Page 134: 4-36

4-36 chapter 4 opera tion 4-37 9. "auto" mode • when the program "_select" exists: 1) press (reset)in"auto"mode. Thefollowingmessageappearsontheguidelinewhen"_select"existsamong the programs. Press (yes)toresettheselectedprogrambyswitchingitto "_select",orpress (no) to just reset the current program...

Page 135: 4-36

4-36 4-37 chapter 4 opera tion 9. "auto" mode 9.4 switching task display when a program executing multiple tasks is stopped, the program listing for each task can be displayed. [procedure] 1) press during program execution to stop the program. 2) press to display the program listing. The pointer ind...

Page 136: 4-38

4-38 chapter 4 opera tion 4-39 9. "auto" mode 9.5 switching the program if the program displayed on the screen is not the one you want to execute, it can be switched to another program. N note the output is reset when the program is switched. However, the output will not be reset in the following ca...

Page 137: 4-38

4-38 4-39 chapter 4 opera tion 9. "auto" mode 9.6 changing the automatic movement speed automatic movement speed for the selected robot group can be set within the range of 1 to 100%. N note automatic movement speeds once set here are stored in the internal memory even when the power is turned off. ...

Page 138: 4-40

4-40 chapter 4 opera tion 4-41 9. "auto" mode 9.7 executing the point trace point data positions can be checked by actually moving the robot arm in the following modes. •ptpmotionmode •archmotionmode •linearinterpolationmotionmode(linearinterpolationmotionatthesubrobotis not supported in controller ...

Page 139: 4-40

4-40 4-41 chapter 4 opera tion 9. "auto" mode validkeysandsubmenudescriptionsin"auto>point"modeareshownbelow. Valid keys menu function cursorkey ( ↑/↓) switchesthepointnumberandscrollsthescreen. Pagekey ( 〈〈 / 〈〈 ) switchestootherscreens. F1 ptp/ arch/ linear switchesthetracemovementmode. F2 a.Pos s...

Page 140: 4-42

4-42 chapter 4 opera tion 4-43 9. "auto" mode 9.7.1 ptp motion mode [procedure] 1) press in"auto>point"modetodisplayascreenlikethatshownbelow,then press (ptp) to select the ptp motion mode. ■ point trace screen in ptp motion mode (1) auto >point 100% [mg][s0h0j] ————————————x———————y———————z———————r...

Page 141: 4-42

4-42 4-43 chapter 4 opera tion 9. "auto" mode 9.7.2 arch motion mode [procedure] 1) press in"auto>point"modetodisplayascreenlikethatshownbelow,then press (arch). ■ point trace screen in arch motion mode (1) auto >point 100% [mg][s0h0j] ————————————x———————y———————z———————r——— p3 = 150.50 64.53 p4 = ...

Page 142: 4-44

4-44 chapter 4 opera tion 4-45 9. "auto" mode n note enterthenumberofpulsesforthey-axis. 4)usethecursor( ↑/↓) keys to select the point number to be checked. 5) press to move the robot by arch motion to the specified point position. The trace speed is one fifth of the automatic movement speed. To sto...

Page 143: 4-44

4-44 4-45 chapter 4 opera tion 9. "auto" mode 9.7.3 linear interpolation motion mode [procedure] 1) press in"auto>point"modetodisplayascreenlikethatshownbelow,then press (linear). ■ point trace screen in linear interpolation motion mode (1) auto >point 100% [mg][s0h0j] ————————————x———————y———————z—...

Page 144: 4-46

4-46 chapter 4 opera tion 4-47 9. "auto" mode 9.8 direct command execution in"auto>direct"mode,onelineofthecommandstatementcanbeexecutedjustafter you have entered it. [procedure] 1) press (direct)in"auto"mode. Thescreenswitchesto"auto>direct"modeandthecursorappearsonthescreen. The prompt (>) also ap...

Page 145: 4-46

4-46 4-47 chapter 4 opera tion 9. "auto" mode 9.9 break point an ongoing program can be stopped if a break point is set in the program. This is useful when debugging the program. The program execution pauses on the line just prior to a break point. The program execution will restart from the break p...

Page 146: 4-48

4-48 chapter 4 opera tion 4-49 9. "auto" mode 9.9.1 setting break points to make program debugging easy, the program execution can be stopped on the line where a break point is set. [procedure] 1) press (break)in"auto"modetoswitchto"auto>break"mode. 2)usethecursorkeystoselectthelinenumberonwhichabre...

Page 147: 4-48

4-48 4-49 chapter 4 opera tion 9. "auto" mode 9.9.2 deleting break points break points can be deleted. Press (search)asneededtofindabreakpointthat was set. [procedure] 1)usethecursor( ↑/↓) keys to select the line number where the break point is set. 2) press (cancel). The " b " mark disappears and t...

Page 148: 4-50

4-50 chapter 4 opera tion 4-51 9. "auto" mode 9.10 executing a step w warning the robot may begin to move when step is executed. To avoid danger, do not enter the robot movement range. [procedure] 1) press (step)in"auto"mode. 2)eachtimethiskeyispressed,thecommandstatementofthehighlightedlinenumber i...

Page 149: 4-50

4-50 4-51 chapter 4 opera tion 9. "auto" mode 9.12 executing the next step w warning the robot may begin to move when next is executed. To avoid danger, do not enter the robot movement range. [procedure] 1) press (next)in"auto"mode. 2)eachtimethiskeyispressed,thecommandstatementofthehighlightedlinen...

Page 150: 4-52

4-52 chapter 4 opera tion 4-53 10. "program" mode 10. "program" mode robot language programs can be edited, deleted and managed in "program" mode. The initial "program" mode screen is shown below. When "program" mode is entered, the currently selected program appears on the screen. ■ "program" mode ...

Page 151: 4-52

4-52 4-53 chapter 4 opera tion 10. "program" mode valid keys and submenu descriptions in "program" mode are shown below. Valid keys menu function cursorkey ( ↑/↓) selectstheprogramandscrollsthescreen. Pagekey ( 〈〈 / 〈〈 ) switchesthepagedisplay. F1 edit editstheprogram. F3 dir displaystheprogramdata....

Page 152: 4-54

4-54 chapter 4 opera tion 4-55 10. "program" mode 10.2 program editing [procedure] 1) press (edit)in"program"mode. A cursor appears on the top line of a program listing as shown below, allowing program editing. 2)usethecursorkeystomovethecursortothepositiontobeeditedandentera program command with th...

Page 153: 4-54

4-54 4-55 chapter 4 opera tion 10. "program" mode validkeysandsubmenudescriptionsin"program>edit"modeareshownbelow. Valid keys menu function cursorkey ( ↑/↓) movesthecursorandscrollsthescreen. Pagekey ( 〈〈 / 〈〈 ) switchesthepagedisplay. Ins switchesbetweeninsertandovertypemodes. L.Ins insertsoneblan...

Page 154: 4-56

4-56 chapter 4 opera tion 4-57 10. "program" mode 10.2.1 cursor movement [procedure] 1) pressing the cursor ( ↑/↓)keysin"program>edit"modemovesthecursorupor down one line at a time. Pressing the cursor ( ←/→) keys moves the cursor right or left one character at a time. 2) pressing the page ( , , , )...

Page 155: 4-56

4-56 4-57 chapter 4 opera tion 10. "program" mode 10.2.2 insert/overwrite mode switching [procedure] 1) press in"program>edit"mode. The cursor changes to underline ( _ ) form, and the screen switches to insert mode. In insert mode, the input character is inserted just previous to the cursor position...

Page 156: 4-58

4-58 chapter 4 opera tion 4-59 10. "program" mode 10.2.3 inserting a line [procedure] pressing ( = + )in"program>edit"modeinsertsablanklineatthe line previous to the cursor position. ■ inserting a line program >edit 3 do2(0)=0 4 wait di3(4,3,2)=3 5 _ 6 move p,p0 ’origin 7 move p,p1 select copy cut p...

Page 157: 4-58

4-58 4-59 chapter 4 opera tion 10. "program" mode 10.2.6 user function key display userfunctionkeysmakeiteasiertoenterprograms. N note when using this function, it is necessary to make a program named "function" and then write command statements for registering functions. For information on how to r...

Page 158: 4-60

4-60 chapter 4 opera tion 4-61 10. "program" mode 10.2.7 quitting program editing press toquitprogrameditingin"program>edit"mode. 10.2.8 specifying the copy/cut lines [procedure] 1)in"program>edit"mode,movethecursortothelineyouwanttocopyorcut. 2) press (select)toselecttheline. 3)usethecursor( ↓) key...

Page 159: 4-60

4-60 4-61 chapter 4 opera tion 10. "program" mode 10.2.9 copying the selected lines [procedure] after selecting the lines in "10.2.8", press (copy). The data on the selected lines are copied into the buffer. The " c " marks then disappear. ■ copying the selected lines program >edit 1 ’***** test2 pr...

Page 160: 4-62

4-62 chapter 4 opera tion 4-63 10. "program" mode 10.2.11 pasting the data [procedure] when (paste)ispressedin"program>edit"mode,thedatastoredintothe buffer by copy/cut operation is inserted just before the cursor line. ■ pasting the data program >edit 1 ’***** test2 program ***** 2 ’ 3 do2(0)=0 4 w...

Page 161: 4-62

4-62 4-63 chapter 4 opera tion 10. "program" mode 10.2.13 line jump [procedure] 1)in"program>edit"mode,press (jump)toenter"program>edit>jump" mode. Themessage"enterlineno.>"appearsontheguideline. ■ line jump program >edit 1 ’***** test2 program ***** 2 goto *_’ 3 do2(0)=0 4 wait di3(4,3,2)=3 5 move ...

Page 162: 4-64

4-64 chapter 4 opera tion 4-65 10. "program" mode 10.2.14 searching a character string [procedure] 1)in"program>edit"mode,press (find)toenter"program>edit>find" mode. The message "character string >" appears on the guideline. 2)enterthecharacterstringyouwanttosearchforandpress . A maximum of 20 char...

Page 163: 4-64

4-64 4-65 chapter 4 opera tion 10. "program" mode 10.3 directory when (dir) is pressed in "program" mode, information on each program appears as shown below. N note a maximum of 100 programs can be stored. ■ program information (1) program >dir > no. 1 test1 55 952 rw 2 * test2 50 907 rw 3 parts100 ...

Page 164: 4-66

4-66 chapter 4 opera tion 4-67 10. "program" mode contents of each item are shown below. Item description no. Indicatestheserialnumberoftheprogram.Thenumber oftheprogramwhichiscurrentlyselectedishighlighted (reversedbackground). Name indicatestheprogramname. The"*"mark(reversedbackground)showsthis p...

Page 165: 4-66

4-66 4-67 chapter 4 opera tion 10. "program" mode 10.3.1 cursor movement [procedure] to select the program, use the cursor ( ↑/↓) keys in "program>dir" mode. The pointer cursor moves to the selected program number. The program name is displayed at the right end on the system line (1st line). 10.3.2 ...

Page 166: 4-68

4-68 chapter 4 opera tion 4-69 10. "program" mode 10.3.3 directory information display [procedure] in "program>dir" mode, press (info) to enter "program>dir>info" mode. The following information on the selected program appears. ■ program information program >dir>info > source(use/sum) = 1316/364580 ...

Page 167: 4-68

4-68 4-69 chapter 4 opera tion 10. "program" mode 10.3.4 copying a program a program in the directory can be copied under a different name. N note program names can be up to 8 characters and consist of a combination of alphanumeric characters (0 to 9, a to z) and underscores ( _ ). [procedure] 1) in...

Page 168: 4-70

4-70 chapter 4 opera tion 4-71 10. "program" mode 10.3.5 erasing a program unnecessaryprogramsinthedirectorycanbeerased. C caution • programswithan"ro(readonly)"attributecannotbeerased.When these programs must be erased, change the attribute. • tochangetheprogramattribute,referto"10.3.7changingthepr...

Page 169: 4-70

4-70 4-71 chapter 4 opera tion 10. "program" mode 10.3.6 renaming a program to change the names of programs in the directory, proceed as follows. [procedure] 1) in "program>dir" mode, use the cursor ( ↑/↓) keys to select the program to be renamed. 2) press (rename)toenter"program>dir>rename"mode. Th...

Page 170: 4-72

4-72 chapter 4 opera tion 4-73 10. "program" mode 10.3.7 changing the program attribute editinganderasingtheprogramscanbeprohibitedbyspecifyingtheprogramattribute. Therearetwoprogramattributes:rwandro.Eachtimeachangeismadeaprogram attribute is alternately switched. 1. Rw (read or write) program cont...

Page 171: 4-72

4-72 4-73 chapter 4 opera tion 10. "program" mode 10.3.8 displaying object program information to display information on an executable object program, proceed as follows. [procedure] 1) press (object)toenter"program>dir>object"mode. 2) object information appears as shown below. ■ object program info...

Page 172: 4-74

4-74 chapter 4 opera tion 4-75 10. "program" mode 10.3.9 creating a sample program automatically this section explains the procedure of automatically creating a sample program for defininguserfunctionkeyswhichcanbeusedin"manual"and"program"modes. N note use caution when creating a sample program aut...

Page 173: 4-74

4-74 4-75 chapter 4 opera tion 10. "program" mode [sample program listing] ***sampleprogram **** '*you can change any statements * '*as you like. * '*willhelpyouin * '*manualandprogrammode. * '********************************************************* *m_f1:'do(20)alternate do(20)=~do(20) *m_f2:'do(2...

Page 174: 4-76

4-76 chapter 4 opera tion 4-77 10. "program" mode 10.4 compiling to compile the program and create an executable object program, follow the procedure below. The object program allows you to check input errors or bugs after program editing. N note even if the specified program is yet not compiled, it...

Page 175: 4-76

4-76 4-77 chapter 4 opera tion 10. "program" mode 10.5 line jump and character string search the (jump), (find), (find+) and (find-) keys can be used inthesamewayasin"program>edit"mode. Referto"10.2.13linejump"and"10.2.14searchingacharacterstring"earlierinthis chapter.) 10.6 registering user functio...

Page 176: 4-78

4-78 chapter 4 opera tion 4-79 10. "program" mode ■ registering "function" program (2) program >dir no. Rw/ro 1 test1 55 952 rw 2 *test2 50 907 rw 3 parts100 38 843 rw 4 function 1 1 rw new info name line byte 5) press (edit)toenter"program>edit"mode. A cursor appears on the first line. 6)enteracomm...

Page 177: 4-78

4-78 4-79 chapter 4 opera tion 10. "program" mode when registering function keys for i/o commands in "manual" mode n note • inone"function"program,functionsforprogrameditandi/ofunctions in "manual" mode can be used together and defined. • besidestheabovemethod,userfunctionscanalsobedefinedbythe next...

Page 178: 4-80

4-80 chapter 4 opera tion 4-81 10. "program" mode example) *m_f2:’moment .. Characterstring"moment"isassignedto . Do (20) =1 .......... Do (20) is turned on when is pressed. Do (20) =0 ........... Do (20) is turned off when is released. *m_f14:’alter ..... Characterstring"alter"isassignedto . Do (20...

Page 179: 4-80

4-80 4-81 chapter 4 opera tion 10. "program" mode 10.7 resetting an error in the selected program if an error "9.1 program destroyed" occurs in the selected program data, this function resets the error and allows you to continue editing. C caution this function resets an error, but does not restore ...

Page 180: 4-82

4-82 chapter 4 opera tion 4-83 11. "manual" mode 11. "manual" mode pointdataandshiftdatacoordinatescanbedefinedandeditedin"manual"mode. Theinitial"manual"modescreenisshownbelow. ■ "manual" mode o guideline manual 50%[mg][s0h0x] s@ ————————————————————————————————————— current position *mx= 0.00 *my=...

Page 181: 4-82

4-82 4-83 chapter 4 opera tion 11. "manual" mode i current position this shows the current position of the robot. When an "m" letter is followed by a number it indicates the position in "pulse" units (integer display) and when an "x" to "a" letter follows, it indicates "mm" units (decimal point disp...

Page 182: 4-84

4-84 chapter 4 opera tion 4-85 11. "manual" mode 11.1 manual movement in"manual"mode,youcanmanuallymovetherobotwiththejogkeysasexplained below. W warning therobotstartstomovewhenajogkeyispressed.Toavoid danger, do not enter the robot movement range. N note • fordetailsonthesoftlimits,referto"12.1.3a...

Page 183: 4-84

4-84 4-85 chapter 4 opera tion 11. "manual" mode if robot movement beyond the +/- soft limits is attempted with the jog keys, the error message "2.1: over soft limit" appears and the robot does not move. (2) when the current position is displayed in "mm" units: a letter "x" is displayed on the upper...

Page 184: 4-86

4-86 chapter 4 opera tion 4-87 11. "manual" mode 2. When return-to-origin is not complete c caution if return-to-origin is incomplete, the soft limits do not work correctly. N note if return-to-origin is incomplete, the current position always appears as "pulse" units when the controller is turned o...

Page 185: 4-86

4-86 4-87 chapter 4 opera tion 11. "manual" mode 11.2 displaying and editing point data press (point)in"manual"modetoenter"manual>point"mode.Thismode allows you to display and edit the point data. One point is made up of data from 6 axes (x, y, z, r, a, b). The rcx22 series uses only two axes (x, y)...

Page 186: 4-88

4-88 chapter 4 opera tion 4-89 11. "manual" mode validkeysandsubmenudescriptionsin"manual>point"modeareshownbelow. Valid keys menu function cursorkey ( ↑/↓) specifiesthepointdataandscrollsthescreen. Pagekey ( 〈〈 / 〈〈 ) switchestootherscreens. F1 edit enterspointdatawithkeys. F2 teach enterspointdata...

Page 187: 4-88

4-88 4-89 chapter 4 opera tion 11. "manual" mode 11.2.1 point data input and editing [procedure] 1)in"manual>point"mode,usethecursor( ↑/↓) keys to select the point to edit. 2) press (edit)toenter"manual>point>edit"mode. An edit cursor appears at the left end of the point line data that was selected....

Page 188: 4-90

4-90 chapter 4 opera tion 4-91 11. "manual" mode 4) press , cursor up/down ( ↑/↓) keys or page up/down ( , ) keys to finish the point data input. Press if you want to cancel the point data input. Validkeysandsubmenudescriptionsin"manual>point>edit"modeareshownbelow. Valid keys menu function cursorke...

Page 189: 4-90

4-90 4-91 chapter 4 opera tion 11. "manual" mode 11.2.2 point data input by teaching the current position of the robot can be obtained as point data by teaching. N note point data teaching cannot be performed when return-to-origin is incomplete. Perform point teaching after performing absolute reset...

Page 190: 4-92

4-92 chapter 4 opera tion 4-93 11. "manual" mode ■ point data teaching (2) manual >point 50% [mg][s0h0x] ————————————x———————y———————z———————r——— p7 = 100.00 250.00 p8 = 50.00 100.00 p9 = 122.62 -24.54 edit teach jump vel+ vel- comnt : [ ] [pos] 50.00 100.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 4...

Page 191: 4-92

4-92 4-93 chapter 4 opera tion 11. "manual" mode 11.2.3 point data input by direct teaching point data can also be obtained by direct teaching (moving the robot by hand to the target point while the robot servo is off). W warning whenyouperformdirectteaching,makesurethattheemergency stop button is p...

Page 192: 4-94

4-94 chapter 4 opera tion 4-95 11. "manual" mode 11.2.4 point jump display [procedure] 1) press (jump)in"manual>point"mode. Themessage"enterpointno.>"appearsontheguideline. ■ point jump (1) manual >point 50%[mg][s0h0x] ————————————x———————y———————z———————r——— p7 = 100.00 250.00 p8 = 50.00 100.00 p9 ...

Page 193: 4-94

4-94 4-95 chapter 4 opera tion 11. "manual" mode 11.2.5 copying point data point data can be copied under another point number. N note if a hand system flag is set in the point data, the hand system flag will also be copied. [procedure] 1) press (copy)in"manual>point"mode. The message "copy(####-###...

Page 194: 4-96

4-96 chapter 4 opera tion 4-97 11. "manual" mode ■ copying point data (2) manual >point 50% [mg][s0h0x] ————————————x———————y———————z———————r——— p30 = 100.00 250.00 p31 = 50.00 100.00 p32 = 122.62 -24.54 (30-34,50)copy ok? Yes no comnt : [ ] [pos] 50.00 100.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00...

Page 195: 4-96

4-96 4-97 chapter 4 opera tion 11. "manual" mode 11.2.6 erasing point data [procedure] 1) press (erase)in"manual>point"mode. Themessage"erase(####-####)>"appearsontheguideline. ■ erasing point data (1) manual >point 50% [mg][s0h0x] ————————————x———————y———————z———————r——— p30 = 100.00 250.00 p31 = 5...

Page 196: 4-98

4-98 chapter 4 opera tion 4-99 11. "manual" mode 11.2.7 point data trace point data positions can be checked by actually moving the robot. Referto"9.7executingthepointtrace"earlierinthischapterfordetails. N note • in"auto>point"mode,pressing (modify)returnsto "manual>point"modethatwasactivebeforetra...

Page 197: 4-98

4-98 4-99 chapter 4 opera tion 11. "manual" mode validkeysandsubmenudescriptionsin"manual>point"commentmodeareshown below. Valid keys menu function cursorkey ( ↑/↓) specifiespointdataorscrollsthescreenvertically. Pagekey ( 〈〈 / 〈〈 ) switchestootherscreens. F1 edit editspointcomments. F2 teach enters...

Page 198: 4-100

4-100 chapter 4 opera tion 4-101 11. "manual" mode 11.2.8.1 point comment input and editing n note • forpointcomments,itisadvisabletoenteracharacterstringthatiseasy to understand. • apointcommentcanbeupto15characters. [procedure] 1)in"manual>point>comment"mode,usethecursor( ↑/↓) keys to select the p...

Page 199: 4-100

4-100 4-101 chapter 4 opera tion 11. "manual" mode 11.2.8.3 jump to a point comment n note valid point numbers are from 0 to 9999. [procedure] 1) press (jump)in"manual>point>comment"mode. Themessage"enterpointno.>"appearsontheguideline. ■ jumping to a point comment display (1) manual >point>comment ...

Page 200: 4-102

4-102 chapter 4 opera tion 4-103 11. "manual" mode 2)use to , and to enter the point number range for the copy source and the point number for the copy destination in the following format, and press . "(copy start number) – (copy end number), (copy destination number)" for example, to copy the point...

Page 201: 4-102

4-102 4-103 chapter 4 opera tion 11. "manual" mode 11.2.8.5 erasing point comments point comments already entered can be deleted. N note valid point numbers are from 0 to 9999. [procedure] 1) press (erase)in"manual>point>comment"mode. Themessage"erase(####-####)>"appearsontheguideline. 2) use to and...

Page 202: 4-104

4-104 chapter 4 opera tion 4-105 11. "manual" mode 11.2.8.6 point comment search point comments already entered can be located. N note a point comment can be up to 15 characters. [procedure] 1) press (find)in"manual>point>comment"mode. The message "character string >" appears on the guideline. 2)ent...

Page 203: 4-104

4-104 4-105 chapter 4 opera tion 11. "manual" mode 11.2.9 point data error reset if an error "9.2 point data destroyed" occurs in the point data, this function resets the error and allows you to continue editing. C caution this function resets an error, but does not restore the point data. A problem...

Page 204: 4-106

4-106 chapter 4 opera tion 4-107 11. "manual" mode 11.3 displaying, editing and setting pallet definitions press (pallet)in"manual"modetoenter"manual>pallet"mode. This mode allows you to display, edit and set pallet definitions. A total of 20 pallets (definition numbers 0 to 19) can be defined to as...

Page 205: 4-106

4-106 4-107 chapter 4 opera tion 11. "manual" mode ■ pallet definition (2) manual >pallet 50%[mg][s0h0x] pl0 =set pl1 = pl2 =set pl3 = [pos] 400.00 0.00 0.00 0.00 edit method vel+ vel- palletdefinitionnumbersmarked"set"meanthattheyhavealreadybeendefined. Validkeysandsubmenudescriptionsin"manual>pall...

Page 206: 4-108

4-108 chapter 4 opera tion 4-109 11. "manual" mode 11.3.1 editing pallet definitions n note themaximumnumberofpointsperpalletis32767(=nx*ny*nz). [procedure] 1)in"manual>pallet"mode,selectthepalletnumberwiththecursor( ↑/↓) keys. 2) press (edit)toenter"manual>pallet>edit"mode. 3)usethecursor( ↑/↓) key...

Page 207: 4-108

4-108 4-109 chapter 4 opera tion 11. "manual" mode 11.3.1.1 point setting in pallet definition in"manual>pallet>edit"mode,ascreenlikethatshownbelowisdisplayed. N note • eachpalletisgeneratedwith5pointsforpalletdefinition. • these5pointsshouldbedefinedinorderfromp[1]top[5].See"11.3 displaying, editin...

Page 208: 4-110

4-110 chapter 4 opera tion 4-111 11. "manual" mode 11.3.1.1.1 editing the point in pallet definition n note • eachpalletisgenerated(outlined)with5points,soalwaysspecifythese 5 points for pallet definition. • pointdatainthepalletdefinitionmustbeenteredin"mm"units. • the5pointsshouldbedefinedinorderfr...

Page 209: 4-110

4-110 4-111 chapter 4 opera tion 11. "manual" mode 11.3.2 pallet definition by teaching n note pallets cannot be defined by teaching if return-to-origin is incomplete. Perform teaching after performing absolute reset. [procedure] 1)selectthepalletnumberin"manual>pallet"modewiththecursor( ↑/↓) keys. ...

Page 210: 4-112

4-112 chapter 4 opera tion 4-113 11. "manual" mode ■ pallet definition by teaching (2) manual >pallet>method 50%[mg][s0h0x] pallet no.=pl0 [xy] move arm to p[1] and press enter key vel+ vel– [pos] 50.00 100.00 0.00 0.00 5) perform teaching at p[2], p[3], p[4] and p[5] (only when "3-d" is selected) a...

Page 211: 4-112

4-112 4-113 chapter 4 opera tion 11. "manual" mode n note • eachpalletisgeneratedwith5pointsforpalletdefinition. • the5pointsshouldbedefinedinorderfromp[1]top[5].See"11.3 displaying, editing and setting pallet definitions". Validkeysandsubmenudescriptionsin"manual>pallet>method"modeareshown below. V...

Page 212: 4-114

4-114 chapter 4 opera tion 4-115 11. "manual" mode 11.3.3 copying a pallet definition n note • validpalletnumbersarefrom0to19. • palletdefinitioncannotbecopiedifthecurrentlyselectedpalletis undefined. [procedure] 1)selectthepalletnumberin"manual>pallet"withthecursor( ↑/↓) keys. 2) press (copy) and t...

Page 213: 4-114

4-114 4-115 chapter 4 opera tion 11. "manual" mode 11.3.4 deleting a pallet definition n note pallet definition cannot be deleted if the currently selected pallet is undefined. [procedure] 1)selectthepalletnumberin"manual>pallet"modewiththecursor( ↑/↓) keys. 2) press (erase). A confirmation message ...

Page 214: 4-116

4-116 chapter 4 opera tion 4-117 11. "manual" mode 11.4 changing the manual movement speed manual movement speed of the selected robot group can be set anywhere within the range from1to100%.Movementspeedin"manual"modeissetseparatelyfromthe"auto" modemovementspeed.One-fifthofthemaximumspeedin"auto"mo...

Page 215: 4-116

4-116 4-117 chapter 4 opera tion 11. "manual" mode 11.5 displaying, editing and setting shift coordinates press (shift)in"manual"modetoenter"manual>shift"mode. This mode allows you to display, edit and set shift coordinates. Shiftcoordinatescannotbeusedwithmultityperobots. N note shift coordinates c...

Page 216: 4-118

4-118 chapter 4 opera tion 4-119 11. "manual" mode when"manual>shift"modeisentered,ascreenlikethatshownbelowappears. The currently selected shift coordinate number is highlighted. ■ "manual>shift" mode manual >shift 50% [mg][s1h0x] ————————————x———————y———————z———————r——— s0 = 0.00 0.00 0.00 0.00 s1...

Page 217: 4-118

4-118 4-119 chapter 4 opera tion 11. "manual" mode 11.5.1 editing shift coordinates [procedure] 1)inthe"manual>shift"mode,selectashiftcoordinatenumberwiththecursor( ↑/↓) keys. 2) press (edit)toenter"manual>shift>edit"mode. 3)usethecursor( ←/→) key to move the cursor to the position you want to chang...

Page 218: 4-120

4-120 chapter 4 opera tion 4-121 11. "manual" mode 7) press toquiteditingandreturnto"manual>shift"mode. N note the shift coordinate data on which the cursor was positioned when returning to"manual>shift"modeisusedastheshiftcoordinatesforthecurrently selected robot group. Validkeysandsubmenudescripti...

Page 219: 4-120

4-120 4-121 chapter 4 opera tion 11. "manual" mode 11.5.2 editing the shift coordinate range by setting the shift coordinate range, the robot operating area can be restricted to the desired range on each shift coordinate. Moreover, setting the soft limit parameters allows you to specify the robot wo...

Page 220: 4-122

4-122 chapter 4 opera tion 4-123 11. "manual" mode 2) press (range)toenterthe"manual>shift>range"mode. A cursor for editing the shift coordinate range appears. ■ editing shift coordinate range (1) manual >shift>range 50% [mg][s1h0x] ————————————x———————y———————z———————r——— range of shift coorinate [...

Page 221: 4-122

4-122 4-123 chapter 4 opera tion 11. "manual" mode 6) to continue editing the shift coordinate range on the minus side, repeat steps 3) to 5). 7) press toquiteditingandreturnto"manual>shift"mode. N note theshiftcoordinatenumberselectedwhenreturningto"manual>shift" mode is used as the shift coordinat...

Page 222: 4-124

4-124 chapter 4 opera tion 4-125 11. "manual" mode 11.5.3 shift coordinate setting method 1 this method sets the shift coordinate data by performing teaching at two points and then entering the plus/minus direction of those two points. The first teach point 1 (1st p) becomes the shift coordinate ori...

Page 223: 4-124

4-124 4-125 chapter 4 opera tion 11. "manual" mode n note perform teaching carefully to obtain accurate points. Precise shift coordinates cannot be set if a point is inaccurate. 4) press , and the current position is then obtained as "1st p". (this value becomes the shift coordinate origin.) ■ shift...

Page 224: 4-126

4-126 chapter 4 opera tion 4-127 11. "manual" mode validkeysandsubmenudescriptionsin"manual>shift>method1"modeareshown below. Valid keys menu function f4 vel+ increasesmanualmovementspeedfortheselected robotgroupinsteps.(1 →5→20→50→100%) f5 vel- decreasesmanualmovementspeedfortheselected robotgroupi...

Page 225: 4-126

4-126 4-127 chapter 4 opera tion 11. "manual" mode 11.5.4 shift coordinate setting method 2 this method sets the shift coordinate data by performing teaching at two points and then entering the coordinate values of those two points. ■ shift coordinate setting method 2 (1) x x’ y y’ p1 p2 [procedure]...

Page 226: 4-128

4-128 chapter 4 opera tion 4-129 11. "manual" mode n note perform teaching carefully to obtain accurate points. Precise shift coordinates cannot be set if a point is inaccurate. 4) press to obtain the current position as "1st p". An edit cursor appears at the head of the "1st p" line. ■ shift coordi...

Page 227: 4-128

4-128 4-129 chapter 4 opera tion 11. "manual" mode 6) determine the teach point 2 with the same procedure as for point 1. N note the z-direction shift value is automatically obtained when point 1 is determined, so the z-axis data at point 2 is ignored. 7) when point 2 has been entered, the shift coo...

Page 228: 4-130

4-130 chapter 4 opera tion 4-131 11. "manual" mode 11.6 displaying, editing and setting hand definitions press (hand)in"manual"modetoenter"manual>hand"mode.Thismode allows you to display, edit and set hand definitions. However, the standard coordinates must be set when a scara robot is used. Refer t...

Page 229: 4-130

4-130 4-131 chapter 4 opera tion 11. "manual" mode when"manual>hand"modeisentered,ascreenlikethatshownbelowappears. The currently selected hand definition number is highlighted. ■ hand definition screen manual >hand 50% [mg][s0h1x] ————————————1———————2———————3———————4——— h0 = 0 0.00 0.00 h1 = 0.00 ...

Page 230: 4-132

4-132 chapter 4 opera tion 4-133 11. "manual" mode movement of each robot type and the parameter contents are shown below. Setting units for each parameter are shown in parentheses. Cartesian robots 1) hand attached to 2nd arm a. Robot movement •hand"n"movestoaspecifiedpoint. B. Parameter descriptio...

Page 231: 4-132

4-132 4-133 chapter 4 opera tion 11. "manual" mode 11.6.1 editing hand definitions [procedure] 1) press (edit)in"manual>hand"mode. 2)usethecursor( ↑/↓) keys to select the hand definition you want to edit. An edit cursor appears at the left end of the selected hand definition line. ■ hand editing scr...

Page 232: 4-134

4-134 chapter 4 opera tion 4-135 11. "manual" mode 7) press toquiteditingandreturnto"manual>hand"mode. N note the hand definition data with which the cursor was positioned when returningto"manual>hand"modeisusedasthecurrenthanddefinition. Validkeysandsubmenudescriptionsin"manual>hand>edit"modearesho...

Page 233: 4-134

4-134 4-135 chapter 4 opera tion 11. "manual" mode 11.6.2 hand definition setting method 1 by using this method, a hand attached to the 2nd arm can be set to the current hand definition. N note hand definition data is set by teaching the identical points that are used for hand working points and non...

Page 234: 4-136

4-136 chapter 4 opera tion 4-137 11. "manual" mode 5)usethejogkeystomovetherobotworkingpointtopoint2.(positionitaccurately.) 6) press to enter the teaching value. Thehanddefinitionsettingendsandthescreenreturnsto"manual>hand"mode. Validkeysandsubmenudescriptionsin"manual>hand>method1"modeareshown be...

Page 235: 4-136

4-136 4-137 chapter 4 opera tion 11. "manual" mode 11.7 changing the display units the units used to indicate the current position on the rpb screen can be switched to either "pulses" and "mm". If hand data for the r-axis is selected (hand definition is made), then "tool coordinate" mode can also be...

Page 236: 4-138

4-138 chapter 4 opera tion 4-139 11. "manual" mode 11.8 absolute reset absolute reset is an operation to find the origin position, when the position detector in the motor cannot identify the origin position (called "origin incomplete" from now on). Movement commands in robot language cannot be execu...

Page 237: 4-138

4-138 4-139 chapter 4 opera tion 11. "manual" mode 11.8.1 checking absolute reset check the status of absolute reset on each axis of the robot controller. [procedure] 1) press (rst.Abs)in"manual"modetoenter"manual>rst.Abs"mode. ■ checking absolute reset this screen shows the following information. M...

Page 238: 4-140

4-140 chapter 4 opera tion 4-141 11. "manual" mode 11.8.2 absolute reset on each axis this section explains how to perform absolute reset of each axis using the robot controller. The absolute reset method differs depending on the following settings for the "origin detection method" parameter. 1. Mar...

Page 239: 4-140

4-140 4-141 chapter 4 opera tion 11. "manual" mode key operations to move to a position where absolute reset is possible for instance, when the current axis position is q (machine reference: 82%): press (adj. +), and the axis moves to w and the machine reference will change to around 50%. (absolute ...

Page 240: 4-142

4-142 chapter 4 opera tion 4-143 11. "manual" mode [procedure] ■ absolute reset of each axis (mark method) (1) manual >rst.Abs 50% [mg] [sohoj] –––––––––––––––––––––––––––––––––––––––– press f.Key to get axis for absrst m1 = ng / mark m5= no axis m2 = ok / mark m6= no axis m3 = no axis no axis m4 = ...

Page 241: 4-142

4-142 4-143 chapter 4 opera tion 11. "manual" mode 2) in servo-on usethejogkeysor (adj.+) and (adj.-) to move the selected axis to a position where absolute reset is possible. Set so that the machine reference is within a range of 44 to 56%. W warning therobotstartstomovewhenajogkeyormovementkeyis p...

Page 242: 4-144

4-144 chapter 4 opera tion 4-145 11. "manual" mode ■ absolute reset of each axis (mark method) (4) manual >rst.Abs>m1 50% [mg] [sohoj] –––––––––––––––––––––––––––––––––––––––– align axes with mark,& press enter m1 = ng / 54% m5= no axis m2 = / m6= no axis m3 = m4 = ok 72% adj.+ adj.- vel+ vel- no ax...

Page 243: 4-144

4-144 4-145 chapter 4 opera tion 11. "manual" mode 2. When the stroke end or sensor method is used as the origin detection method when the selected axis uses the stroke end or sensor method, the servo must be turned on to perform return-to-origin. W warning the robot starts to move when absolute res...

Page 244: 4-146

4-146 chapter 4 opera tion 4-147 11. "manual" mode 2) after return-to-origin is complete, the machine reference of the selected axis is displayed. ■ absolute reset of each axis (stroke end / sensor method) (2) manual 50% [mg] [sohoj] –––––––––––––––––––––––––––––––––––––––– machine reference (%) m2 ...

Page 245: 4-146

4-146 4-147 chapter 4 opera tion 11. "manual" mode 11.8.3 absolute reset on all axes this section explains how to perform absolute reset on all axes of the robot controller. The sequence for performing absolute reset of the axes is given below. 1. First, perform absolute reset at the current positio...

Page 246: 4-148

4-148 chapter 4 opera tion 4-149 11. "manual" mode absolute reset position and "0" pulse position when absolute reset is performed at position a, the position b (machine reference 38%) is reset as the "0" pulse position. This means that the robot will move to the "0" pulse position after performing ...

Page 247: 4-148

4-148 4-149 chapter 4 opera tion 11. "manual" mode 1) press (all)in"manual>rst.Abs"modetoenter"absreset"modeforall axes. ■ absolute reset of all axes (mark method) (2) this screen shows the following information. Manual >rst.Abs>all 50% [mg] [sohoj] –––––––––––––––––––––––––––––––––––––––– align axe...

Page 248: 4-150

4-150 chapter 4 opera tion 4-151 11. "manual" mode ■ absolute reset of all axes (mark method) (3) manual >rst.Abs>all 50% [mg] [sohoj] –––––––––––––––––––––––––––––––––––––––– align axes with mark,& press enter m1 = ng / 50% m5= no axis m2 = m6= no axis no axis no axis m3 = m4 = ok / 72% adj.+ adj.-...

Page 249: 4-150

4-150 4-151 chapter 4 opera tion 11. "manual" mode 5) when absolute reset ends correctly on all axes using the mark method, a confirmation message appears on the guideline if axes using the stroke end or sensor methods are present. Press (yes)toperformabsoluteresetonaxesusingthestrokeendorsensor met...

Page 250: 4-152