- DL manuals

- Yamaha

- Boat

- WaveRunner GP1300R

- Service Manual

Yamaha WaveRunner GP1300R Service Manual

Summary of WaveRunner GP1300R

Page 1

Service manual gp1300r waverunner f1g-28197-1f-11 lit-18616-02-44 *lit186160244*.

Page 2: Notice

E notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical co...

Page 3: How to Use This Manual

E how to use this manual manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The informa- tion has been compiled to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assem...

Page 4

E important information in this service manual particularly important information is distinguished in the following ways. The safety alert symbol means attention! Become alert! Your safety is involved! Warning failure to follow warning instructions could result in severe injury or death to the machi...

Page 5

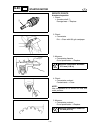

E how to use this manual 1 to help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section. 2 numbers are given in the order of the jobs in the exploded diagram. 3 symbols indicate parts to be lubricated or replaced (see “symbols”)...

Page 6: Gen

E a50001-1-4 symbols symbols 1 to 9 are designed to indicate the content of a chapter. 1 general information 2 specifications 3 periodic inspection and adjustment 4 fuel system 5 power unit 6 jet pump unit 7 electrical system 8 hull and hood 9 trouble analysis symbols 0 to e indicate specific data. ...

Page 7: Index

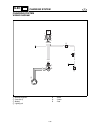

E index general information 1 gen info specifications 2 spec periodic inspection and adjustment 3 insp adj fuel system 4 fuel power unit 5 powr jet pump unit 6 jet pump electrical system 7 elec hull and hood 8 hull hood trouble analysis 9 trbl anls – + a30000-0

Page 8: Gen

E gen info 1 2 3 4 5 6 7 8 9 chapter 1 general information identification numbers ......................................................................... 1-1 primary l.D. Number ........................................................................... 1-1 engine serial number ......................

Page 9: Gen

1-1 e gen info identification numbers a60700-0* identification numbers primary l.D. Number the primary l.D. Number is stamped on a label 1 attached inside the engine compartment. Starting primary l.D. Number: f1g: 800301 1 engine serial number the engine serial number is stamped on a label 1 attache...

Page 10: Gen

1-2 e gen info safety while working safety while working to prevent and accident or injury and to ensure quality service, follow the safety proce- dures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flames. Ven...

Page 11: Gen

1-3 e gen info safety while working under normal conditions, the lubricants men- tioned in this manual should not harm or be hazardous to your skin. However, you should follow these precautions to minimize any risk when working with lubricants. 1. Maintain good standards of personal and industrial h...

Page 12: Gen

1-4 e gen info safety while working 3. Non-reusable parts always use new gaskets, seals, o-rings, oil seals, cotter pins, circlips, etc., when installing or assembling parts. Disassembly and assembly 1. Use compressed air to remove dust and dirt during disassembly. 2. Apply engine oil to the contact...

Page 13: Gen

1-5 e gen info special service tools special service tools using the special service tools recommended by yamaha will aid service and enable accu- rate assembly and tune-up. Improvisations and using improper tools can damage the equipment. Note: • for usa and canada, use the special ser- vice tools ...

Page 14: Gen

1-6 e gen info special service tools 9 peak volt meter adapter yu-39991 0 peak voltage adapter b 90890-03172 a spark gap tester ym-34487 b ignition tester 90890-06754 c lighting coil tester (3 pins) yb-06870 test harness smt250-3 (3 pins) 90890-06870 d air pressure sensor tester (3 pins) yb-06869 te...

Page 15: Gen

1-7 e gen info special service tools removal and installation 1 coupler wrench yw-06551 90890-06551 2 flywheel holder yw-06550 90890-06550 3 universal puller yb-06117 4 flywheel puller 90890-06521 5 drive shaft holder (impeller) yb-06151 drive shaft holder 5 (impeller) 90890-06519 6 slide hammer and...

Page 16: Gen

1-8 e gen info special service tools c outer race installer—forward gear (jet pump oil seal) yb-06085 d ball bearing attachment (jet pump oil seal) 90890-06634 e driver handle—large (intermediate shaft and jet pump) yb-06071 f driver rod ls (intermediate shaft and jet pump) 90890-06606 g drive shaft...

Page 17: Spec

E spec 1 2 3 4 5 6 7 8 9 chapter 2 specifications general specifications ....................................................................... 2-1 maintenance specifications ............................................................... 2-3 engine ....................................................

Page 18: Spec

2-1 e spec general specifications general specifications item unit model gp1300r model code hull f1g engine/jet 60t dimensions length mm (in) 2,930 (115.4) width mm (in) 1,150 (45.3) height mm (in) 1,020 (40.2) dry weight kg (lb) 297 (653) maximum capacity person/kg (lb) 2/160 (353) performance maxi...

Page 19: Spec

2-2 e spec *1 pump octane number = (motor octane number + research octane number)/2 *2 research octane number *3 yamalube 2-w has been developed for this watercraft and it is available at a yamaha dealer. Caution: use only yamalube 2-w oil. Using another oil can seriously damage the catalytic conver...

Page 20: Spec

2-3 e spec maintenance specifications maintenance specifications engine item unit model gp1300r cylinder head warpage limit mm (in) 0.05 (0.002) minimum compression pressure *1 kpa (kgf/cm 2 , psi) 640 (6.4, 91) cylinders bore size mm (in) 84.000–84.018 (3.3071–3.3078) taper limit mm (in) 0.080 (0.0...

Page 21: Spec

2-4 e spec maintenance specifications jet pump unit crankshaft assembly crank width a mm (in) 72.95–73.00 (2.872–2.874) deflection limit b mm (in) 0.05 (0.002) deflection limit c mm (in) 0.15 (0.006) big end side clearance d mm (in) 0.250–0.750 (0.0098–0.0295) maximum small end axial play e mm (in) ...

Page 22: Spec

2-5 e spec maintenance specifications hull and hood electrical item unit model gp1300r free play ypvs cable slack mm (in) 0.5–1.5 (0.02–0.06) throttle lever free play mm (in) 4–7 (0.16–0.28) item unit model gp1300r battery type fluid voltage, capacity v, ah 12, 19 specific gravity 1.28 ecm unit (b/r...

Page 23: Spec

2-6 e spec maintenance specifications ignition coil minimum spark gap mm (in) 10–11 (0.39–0.43) primary coil resistance (b/w – body) Ω 0.26–0.36 secondary coil resistance (b/w – spark plug lead terminal) k Ω 3.5–4.7 spark plug lead resistance #1 k Ω 6.1–14.3 #2 k Ω 4.5–10.9 #3 k Ω 3.3–8.2 rectifier/...

Page 24: Spec

2-7 e spec maintenance specifications *1 the figures are for reference only. Exhaust temperature sensor resistance at 300 °c (572 °f) k Ω 73–241 at 600 °c (1,112 °f) k Ω 0.86–1.58 at 900 °c (1,652 °f) Ω 64–90 cooling water temperature sensor resistance at 0 °c (32 °f) k Ω 24.0–37.1 at 100 °c (212 °f...

Page 25: Spec

2-8 e spec tightening torques tightening torques specified torques part to be tightened part name thread size q’ty tightening torques remarks n•m kgf•m ft•lb fuel system strap/fuel tank/oil tank – hull bolt m8 4 16 1.6 11 572 lt oil filler hose screw clamp — — 1 0.6 0.06 0.4 retainer/fuel pump modul...

Page 26: Spec

2-9 e spec tightening torques muffler stay 2 – crankcase bolt m10 2 39 3.9 28 271 lt muffler – muffler stay 2 bolt m10 1 39 3.9 28 271 lt exhaust temperature sensor — — 1 39 3.9 28 572 lt cooling water temperature sensor — — 1 20 2.0 14 572 lt muffler stay – catalytic converter housing 1st bolt m10 ...

Page 27: Spec

2-10 e spec tightening torques ground lead – cylinder head 1st bolt m6 1 3.8 0.38 2.7 2nd 7.6 0.76 5.5 exhaust chamber stay/ cylinder head – cylinder 1st bolt m8 2 15 1.5 11 572 lt 2nd 35 3.5 25 cylinder head – cylinder 1st bolt m8 16 22 2.2 16 572 lt 2nd 22 2.2 16 3rd 35 3.5 25 anode – cylinder hea...

Page 28: Spec

2-11 e spec tightening torques jet thrust nozzle – nozzle ring bolt m8 2 15 1.5 11 271 lt spout hose screw clamp — — 1 1.2 0.12 0.9 nozzle/impeller duct assembly – impeller housing 1 bolt m10 4 40 4.0 29 572 lt water inlet cover/water inlet strainer – impeller duct bolt m6 4 6.6 0.66 4.8 572 lt driv...

Page 29: Spec

2-12 e spec tightening torques steering cable locknut (jet thrust nozzle end) — — 1 6.5 0.65 4.7 steering cable – hull nut — 1 5.9 0.59 4.3 steering cable holder – bracket bolt m6 1 6.4 0.64 4.6 speed sensor lead – hull nut — 1 5.9 0.59 4.3 hinge assembly – hood bolt m6 2 12 1.2 8.7 visor – hood scr...

Page 30: Spec

2-13 e spec tightening torques electrical cover – electrical box tapping screw ø6 11 4.9 0.49 3.5 lead retainer – electrical box tapping screw ø6 2 4.9 0.49 3.5 positive battery lead – starter relay bolt m6 1 3.4 0.34 2.5 starter motor lead – starter relay bolt m6 1 3.4 0.34 2.5 rectifier/regulator ...

Page 31: Spec

2-14 e spec tightening torques general torque this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for spe- cial components or assemblies are provided in applicable sections of this manual. To avoid warpage, tighten multi...

Page 32: Spec

2-15 e spec cable and hose routing cable and hose routing vent 20˚ k k l h-h i-i k-k m-m h h g g i i i i b d d a e-e d-d f-f 1 f g f f m m c e e j j g-g b c a j-j l 5 7 h 2 k f j h 7 7 h c a b 7 h i 1 1 d c b a 0 9 8 7 6 5 4 3 2 1 È É Ê Ë Ì Í Ì Î l e 1 fuel tank breather hose 2 cooling water pilot o...

Page 33: Spec

2-16 e spec cable and hose routing vent 20 ˚ k k l h-h i-i k-k m-m h h g g i i i i b d d a e-e d-d f-f 1 f g f f m m c e e j j g-g b c a j-j l 5 7 h 2 k f j h 7 7 h c a b 7 h i 1 1 d c b a 0 9 8 7 6 5 4 3 2 1 È É Ê Ë Ì Í Ì Î l e È align the parting line on the fuel filler neck with the lot mark on t...

Page 34: Spec

2-17 e spec cable and hose routing c d e f g h i j k 8 m l a n o 8 c d e b b f f b-b c f-f e d a 1 2 3 4 5 6 7 8 9 0 a b 7 a 5 p b 7 p Î Í È É Ê Ì Ë 1 buzzer lead 2 throttle cable 3 ypvs servomotor 4 ypvs cables 5 positive battery lead 6 battery breather hose 7 electrical bilge pump lead 8 steering ...

Page 35: Spec

2-18 e spec cable and hose routing c d e f g h i j k 8 m l a n o 8 c d e b b f f b-b c f-f e d a 1 2 3 4 5 6 7 8 9 0 a b 7 a 5 p b 7 p Î Í È É Ê Ì Ë È to cylinder #3 É to cylinder #2 Ê to cylinder #1 Ë cooling water temperature sensor Ì exhaust temperature sensor Í to positive battery terminal Î to ...

Page 36: Spec

2-19 e spec cable and hose routing b b a c-c c c 4 6 6 4 9 0 1 2 3 6 5 4 7 8 8 5 6 2 0 3 9 8 2 0 3 1 7 5 8 a 9 7 1 È a 1 bilge hose 1 2 bilge hose 2 3 steering cable 4 bilge hose 3 5 qsts cable 6 bilge hose 4 7 cooling water hose (cooling water inlet) 8 flushing hose 9 speed sensor lead 0 cooling wa...

Page 37: Spec

2-20 e spec cable and hose routing c b a c-c d b c È É Ê Ë Ì Í 3 4 1 Î Ï Ð Ñ Ò Ó d a 1 2 3 4 1 oil delivery hose #1 2 sub-wire harness 3 oil delivery hose #3 4 oil delivery hose #2 È pass the plastic tie through the holes of the rib on the fuel rail. É fasten oil delivery hoses #2 and #3 and the eng...

Page 38: Spec

2-21 e spec cable and hose routing c b a c-c d b c È É Ê Ë Ì Í 3 4 1 Î Ï Ð Ñ Ò Ó d a 1 2 3 4 Î push the corrugated tube toward the oil pump, and then tape it. Ï to oil tank Ð to check valve Ñ install the oil hoses into the hose holders so that the holders do not cover the check valve clips. Ò pass t...

Page 39: Spec

2-22 e spec cable and hose routing b d c 15˚ 15˚ b a d c 1 2 3 Ñ È a É Ê Ë Ï Î Î Ï Í Ì Ð Ô Ó Õ Ö × Ø Ù Ú Û Ï Ï Ò Ü 20˚ 1 cooling water hose (cooling water pilot outlet on port side) 2 fuel hose 3 oil return hose È to throttle lever É to cooling water pilot outlet on port side Ê when fastening the co...

Page 40: Spec

2-23 e spec cable and hose routing b d c 15˚ 15˚ b a d c 1 2 3 Ñ È a É Ê Ë Ï Î Î Ï Í Ì Ð Ô Ó Õ Ö × Ø Ù Ú Û Ï Ï Ò Ü 20˚ Ð contact the corrugated tube to the hose screw clamp (muffler assembly end). Ñ strongly pull the plastic tie. Ò after installing the ypvs servomotor, fasten the throttle cable. Ó f...

Page 41: Insp

E insp adj 1 2 3 4 5 6 7 8 9 chapter 3 periodic inspection and adjustment maintenance interval chart .............................................................. 3-1 periodic service ....................................................................................... 3-2 control system ...........

Page 42: Insp

3-1 e insp adj maintenance interval chart maintenance interval chart use the following chart as a guide to general maintenance. Adjust the maintenance intervals according to the operating conditions of the watercraft. *1 grease quantity: 33.0–35.0 cm 3 (1.11–1.18 oz) *2 grease quantity: 6.0–8.0 cm 3...

Page 43: Insp

3-2 e insp adj control system periodic service control system steering column inspection 1. Check: • steering column excessive play → replace the steering column. Refer to “steering column” in chapter 8. Checking steps: • move the handlebar up and down and back and forth. • check the excessive play ...

Page 44: Insp

3-3 e insp adj control system note: if the steering cable cannot be properly adjusted by the cable joint at the steering col- umn end, adjust the cable joint at the jet pump end so that the specified distance is obtained. Refer to “remote control cables and speed sensor lead” in chapter 8. Warning t...

Page 45: Insp

3-4 e insp adj control system qsts cable inspection and adjustment 1. Measure: • jet thrust nozzle set lengths a and b out of specification → adjust. Measurement steps: • set the control grip to the neutral posi- tion. • set the jet thrust nozzle in the center position. • measure jet thrust nozzle s...

Page 46: Insp

3-5 e insp adj control system note: if the qsts cable cannot be properly adjusted by the cable joint at the qsts converter end, adjust the cable joint at the jet pump end so that the same lengths are obtained. Refer to “remote control cables and speed sensor lead” in chapter 8. Trolling speed check ...

Page 47: Insp

3-6 e insp adj control system • check the exhaust passages. Refer to “muffler assembly” in chapter 5. Refer to “exhaust chamber assembly” in chapter 5. Refer to “exhaust manifold” in chapter 5. Refer to “exhaust system” in chap- ter 8. • measure the fuel pressure. Refer to “fuel pressure measurement...

Page 48: Insp

3-7 e insp adj fuel system fuel system warning when removing fuel system parts, wrap them in a cloth and take care that no fuel spills into the engine compartment. Fuel line inspection 1. Check: • fuel pump filter clog/contaminants → clean. Refer to “fuel tank and fuel pump module” in chapter 4. • f...

Page 49: Insp

3-8 e insp adj oil injection system oil injection system oil line inspection 1. Check: • oil filter contaminants → clean. Frays/tears → replace. • rubber seal cracks/wear → replace. • oil hoses • oil tank • oil filler cap cracks/damage → replace. • check valve malfunction → replace. Caution: do not ...

Page 50: Insp

3-9 e insp adj power unit power unit spark plug inspection 1. Check: • electrodes 1 damage/wear → replace. • insulator color 2 distinctly different color → check the condition of the engine. 2. Clean: • spark plug (using a spark plug cleaner or wire brush) color guide: medium-to-light tan color: nor...

Page 51: Insp

3-10 e insp adj power unit 4. Tighten: • spark plugs note: • before installing a spark plug, clean the gas- ket surface and spark plug surface. Also, it is suggested to apply a thin coat of anti-seize compound to the spark plug threads to pre- vent thread seizure. • if a torque wrench is not availab...

Page 52: Insp

3-11 e insp adj power unit 2. Measure: • ypvs cable slack a out of specification → adjust. Ypvs cable slack: 0.5–1.5 mm (0.02–0.06 in) 3. Adjust: • ypvs cables 1 and 2 adjustment steps: • loosen locknuts 1 and 2. • turn adjusters 3 and 4 in until there is slack in the cables. • align the hole a in t...

Page 53: Insp

3-12 e insp adj electrical electrical battery inspection warning • battery electrolyte is poisonous and dan- gerous, causing severe burns, etc. Elec- trolyte contains sulfuric acid. Avoid contact with skin, eyes or clothing. Antidotes external: flush with water. Internal: drink large quantities of w...

Page 54: Insp

3-13 e insp adj electrical 1. Remove: • battery bands • negative battery lead 1 • positive battery lead 2 • battery • battery breather hose 3 warning • when removing the battery, disconnect the negative lead first. • remove the battery to prevent acid loss before turning the watercraft on its side t...

Page 55: Insp

3-14 e insp adj electrical 3. Check: • specific gravity out of specification → charge. Specific gravity at 20 °c (68 °f): 1.28 charging current: 1.9 a × 10 h (68.4 kc) 4. Install: • filler caps caution: before installing the battery, rinse off any electrolyte from the battery box or battery and make...

Page 56: Insp

3-15 e insp adj jet pump unit jet pump unit impeller inspection 1. Check: • impeller 1 damage/wear → replace. Nicks/scratches → file or grind. 2. Measure: • impeller-to-housing clearance a out of specification → replace. Maximum impeller-to-housing clearance: 0.9 mm (0.035 in) measurement steps: • d...

Page 57: Insp

3-16 e insp adj bilge pump bilge pump bilge strainer inspection 1. Check: • bilge strainer contaminants → clean. Cracks/damage → replace. Checking steps: • remove the bilge strainer case 1 from the bilge strainer. • check the bilge strainer and bilge strainer case. • install the bilge strainer case....

Page 58: Insp

3-17 e insp adj general general drain plug inspection 1. Check: • drain plugs cracks/damage → replace. • o-rings cracks/wear → replace. • screw threads contaminants → clean. Lubrication points 1. Lubricate: • throttle cable (handlebar end) note: before lubricating the throttle cable, squeeze the thr...

Page 59: Insp

3-18 e insp adj general 3. Lubricate: • qsts cables (pulley end) • ypvs cables recommended grease: yamaha marine grease, yamaha grease a (water-resistant grease) 4. Lubricate: • nozzle pivot shaft • steering cable (jet thrust nozzle end) • qsts cable (jet thrust nozzle end) recommended grease: yamah...

Page 60: Insp

3-19 e insp adj general 6. Fill: • intermediate housing note: using a grease gun, fill the intermediate hous- ing with the recommended grease through the grease nipples. Recommended grease: yamaha marine grease, yamaha grease a (water-resistant grease) grease quantity: 33.0–35.0 cm 3 (1.11–1.18 oz).

Page 61: Fuel

E fuel chapter 4 fuel system oil tank ........................................................................................................ 4-1 exploded diagram ............................................................................. 4-1 removal and installation chart ..........................

Page 62: Fuel

E fuel 1 2 3 4 5 6 7 8 9 oil pump...................................................................................................... 4-24 exploded diagram ........................................................................... 4-24 removal and installation chart .................................

Page 63: Fuel

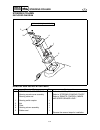

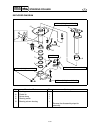

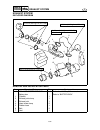

4-1 e fuel oil tank exploded diagram removal and installation chart step procedure/part name q’ty service points oil tank removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. Steering console cover assembly refer to “steering console cover” in chapter 8. 1 oil...

Page 64: Fuel

4-2 e fuel oil tank exploded diagram step procedure/part name q’ty service points 6 breather hose 1 7 oil hose 1 8 bolt 2 9 strap 2 10 oil tank 1 11 hose screw clamp 1 12 oil filler hose 1 13 oil level sensor 1 reverse the removal steps for installation..

Page 65: Fuel

4-3 e fuel oil tank service points oil line inspection 1. Check: • oil filter contaminants → clean. Frays/tears → replace. • rubber seal cracks/wear → replace. • oil hoses • oil filler cap cracks/damage → replace. • check valve faulty → replace. Oil level sensor inspection refer to “indication syste...

Page 66: Fuel

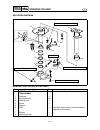

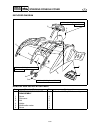

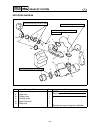

4-4 e fuel fuel tank and fuel pump module fuel tank and fuel pump module exploded diagram removal and installation chart step procedure/part name q’ty service points fuel tank removal follow the left “step” for removal. Oil tank refer to “oil tank.” 1 fuel tank breather hose 1 2 check valve 1 3 fuel...

Page 67: Fuel

4-5 e fuel fuel tank and fuel pump module exploded diagram step procedure/part name q’ty service points 6 cover 1 7 fuel hose 1 8 nut 9 9 retainer 1 10 fuel pump module 1 11 seal 1 12 fuel sender assembly 1 13 hose screw clamp 2 14 fuel filler hose 1 15 nut 1 16 fuel filler neck 1 1.3 n • m (0.13 kg...

Page 68: Fuel

4-6 e fuel fuel tank and fuel pump module exploded diagram step procedure/part name q’ty service points 17 rubber seal 1 18 fuel tank 1 19 bolt 2 20 strap 2 reverse the removal steps for installation. 1.3 n • m (0.13 kgf • m, 0.9 ft • ib) 8 × 18 mm 16 n • m (1.6 kgf • m, 11 ft • ib) 5.9 n • m (0.59 ...

Page 69: Fuel

4-7 e fuel fuel tank and fuel pump module service points fuel hose disconnection 1. Disconnect: • fuel hose refer to “fuel injection system.” fuel pump module removal 1. Remove: • nuts • retainer note: loosen the nuts in the sequence shown. 1 4 9 6 2 3 8 7 5 2. Remove: • fuel pump module 1 note: rem...

Page 70: Fuel

4-8 e fuel fuel tank and fuel pump module check valve inspection 1. Check: • check valve faulty → replace. Fuel pump filter inspection 1. Check: • fuel pump filter 1 clog/contaminants → wash the fuel pump filter in kerosene or gasoline. Checking steps: • connect a hose to end “a” of the check valve,...

Page 71: Fuel

4-9 e fuel intake duct and intake silencer exploded diagram removal and installation chart step procedure/part name q’ty service points intake duct and intake silencer removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly” in chapter 5. 1 intake sile...

Page 72: Fuel

4-10 e fuel intake duct and intake silencer exploded diagram step procedure/part name q’ty service points 6 bolt/collar/grommet 1/1/1 7 intake duct 1 reverse the removal steps for installation..

Page 73: Fuel

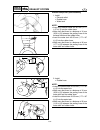

4-11 e fuel intake duct and intake silencer service points intake silencer installation 1. Install: • intake silencer pipe • intake silencer pipe screw clamps 1 • intake silencer • intake silencer screw clamp 2 note: set the screw clamps in the direction shown. 55˚ 2 1 1.

Page 74: Fuel

4-12 e fuel fuel injection system fuel injection system exploded diagram removal and installation chart step procedure/part name q’ty service points throttle bodies assembly removal follow the left “step” for removal. Intake silencer pipe refer to “intake duct and intake silencer.” 1 plastic tie 1 n...

Page 75: Fuel

4-13 e fuel fuel injection system exploded diagram step procedure/part name q’ty service points 4 plastic tie 1 note: fasten the sub-wire harness and oil delivery hoses together with the plastic tie. 5 cover 1 6 fuel hose 1 7 throttle bodies screw clamp 3 tighten the screw clamp until there is no cl...

Page 76: Fuel

4-14 e fuel fuel injection system exploded diagram removal and installation chart step procedure/part name q’ty service points intake silencer case and throttle bodies removal follow the left “step” for removal. 1 intake air temperature sensor coupler 1 2 intake silencer case screw clamp 3 tighten t...

Page 77: Fuel

4-15 e fuel fuel injection system exploded diagram removal and installation chart step procedure/part name q’ty service points intake silencer case disassembly follow the left “step” for disassembly. 1 intake air temperature sensor 1 2 tapping screw 13 3 intake silencer case cover 1 4 gasket 1 5 scr...

Page 78: Fuel

4-16 e fuel fuel injection system exploded diagram removal and installation chart step procedure/part name q’ty service points throttle bodies disassembly follow the left “step” for disassembly. 1 hose clamp 2 2 fuel hose 1 3 grommet 1 4 quick connector 1 5 sub-wire harness 1 6 bolt 3 7 fuel rail 1 ...

Page 79: Fuel

4-17 e fuel fuel injection system exploded diagram step procedure/part name q’ty service points 9 fuel injector 3 10 o-ring 3 11 throttle bodies 1 reverse the disassembly steps for assembly. 6 6 6 7 5 2 3 1 9 10 9 10 9 10 11 4 1 8.8 n • m (0.88 kgf • m, 6.4 ft • ib) 6 × 60 mm 8 a a a a a a not reusa...

Page 80: Fuel

4-18 e fuel fuel injection system service points hose clamp removal 1. Remove: • hose clamps caution: if the hose clamps are removed without cutting the crimp first, the fuel hose can be damaged. Hose clamp installation 1. Install: • hose clamps warning do not reuse the hose clamps, always replace t...

Page 81: Fuel

4-19 e fuel caution: • do not rotate the quick connector tab 1 past the stopper position a, otherwise the tab can be damaged. • when the fuel hoses are disconnected, quickly remove the retainer 2 from the quick connector, otherwise the retainer can be lost. 2. Disconnect the fuel hose 1 from the fue...

Page 82: Fuel

4-20 e fuel fuel injection system fuel injector inspection caution: the throttle bodies should not be disas- sembled unnecessarily. 1. Check: • fuel injector dirt/residue → clean. Damage → replace. 2. Measure: • fuel injector resistance out of specification → replace. 3. Check the operation of the f...

Page 83: Fuel

4-21 e fuel fuel injection system fuel hose installation (replacing with new fuel hose) 1. Install: • quick connector 1 note: to install the fuel hose, be sure to align the lot mark a on the fuel hose and the checker tab 2 on the quick connector with the crimped section b of the clamp. 2 1 a b 2. In...

Page 84: Fuel

4-22 e fuel fuel injection system fuel hose connection 1. Apply a thin coat of engine oil to the con- tact surfaces of the fuel pipe. 2. Insert the quick connector into the fuel pipe until you hear a “click.” 3. To check the connection of the quick con- nector, push and pull on the quick connec- tor...

Page 85: Fuel

4-23 e fuel fuel injection system 3. Start the engine and warm it up for several minutes. 4. Measure: • fuel pressure out of specification → replace the fuel pump module. 5. Remove: • fuel pressure gauge • fuel pressure gauge adapter note: to disconnect the fuel pressure gauge adapter, follow the pr...

Page 86: Fuel

4-24 e fuel oil pump oil pump exploded diagram removal and installation chart step procedure/part name q’ty service points oil pump removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly” in chapter 5. Intake duct refer to “intake duct and intake sile...

Page 87: Fuel

4-25 e fuel oil pump exploded diagram step procedure/part name q’ty service points 7 bolt 1 8 bleed hose stay 1 9 bolt 2 10 oil pump assembly 1 11 gasket 1 12 oil suction hose 1 13 oil return hose 1 reverse the removal steps for installation. 5 3 3 3 7 8 10 12 9 11 6 × 20 mm 13 4 6 6 × 12 mm 7.6 n •...

Page 88: Fuel

4-26 e fuel exploded diagram removal and installation chart step procedure/part name q’ty service points oil pump hoses and cable removal follow the left “step” for removal. 1 bleed hose 1 2 air bleed screw 1 3 gasket 1 4 bleed hose stay 1 5 oil delivery hose 3 6 oil delivery hose #1 1 7 oil deliver...

Page 89: Fuel

4-27 e fuel oil pump service points oil pump inspection 1. Check: • oil pump contaminants → clean. Damage/wear → replace. • oil pump joint piece damage/wear → replace the oil pump. Oil hose inspection 1. Check: • oil hoses cracks/damage → replace. Caution: • if the oil delivery hoses and the oil suc...

Page 90: Fuel

4-28 e fuel oil pump oil pump lever position adjustment 1. Check: • oil pump lever position incorrect → adjust. Checking steps: • remove the intake duct. Refer to “intake duct and intake silencer.” • squeeze the throttle lever to fully open the throttle valve lever. • check that the gap of the oil p...

Page 91: Fuel

4-29 e fuel oil pump oil pump bleeding 1. Bleed: • oil pump bleeding steps: • place rags around the air bleed screw 1 to catch any oil that might spill. • fill the oil tank with the recommended oil. Note: if the oil pump is replaced or when the oil suction hose and oil delivery hoses are dis- connec...

Page 92: Powr

E powr chapter 5 power unit compression pressure measurement ............................................ 5-1 service points .................................................................................... 5-1 muffler assembly ........................................................................

Page 93: Powr

E powr 1 2 3 4 5 6 7 8 9 cylinder head.......................................................................................... 5-25 exploded diagram ........................................................................... 5-25 removal and installation chart ........................................

Page 94: Powr

5-1 e powr compression pressure measurement compression pressure measurement service points the following procedure applies to all of the cylinders. Note: insufficient compression pressure will result in a loss of performance. 1. Start the engine and warm it up until the engine temperature is 48 °c ...

Page 95: Powr

5-2 e powr compression pressure measurement 6. Measure: • compression pressure out of specification → refer to steps (b) and (c). 7. Install: • spark plugs minimum compression pressure (reference data): 640 kpa (6.4 kgf/cm 2 , 91 psi) measurement steps: a. With the throttle wide open, crank the engi...

Page 96: Powr

5-3 e powr muffler assembly muffler assembly exploded diagram removal and installation chart step procedure/part name q’ty service points muffler removal follow the left “step” for removal. Ypvs servomotor and ypvs servomotor bracket refer to “ypvs servomotor” in chapter 7. Battery box refer to “bat...

Page 97: Powr

5-4 e powr muffler assembly exploded diagram step procedure/part name q’ty service points 6 screw clamp/cooling water hose 1/1 È to cooling water pilot outlet (port) route the cooling hose under the exhaust chamber assembly. 7 screw clamp/cooling water hose 1/1 É to cooling water outlet (stern) cont...

Page 98: Powr

5-5 e powr muffler assembly exploded diagram step procedure/part name q’ty service points 8 outer exhaust joint screw clamp 2 slide the outer exhaust joint off. 9 inner exhaust joint screw clamp 2 10 exhaust joint screw clamp 1 11 water lock band 1 slide the water lock off. 12 nut 2 13 bolt 4 14 int...

Page 99: Powr

5-6 e powr muffler assembly exploded diagram step procedure/part name q’ty service points 16 bolt 2 17 bolt 1 18 bolt 1 19 bolt 1 20 muffler stay 2 1 21 muffler assembly 1 note: remove the cylinder head if it is difficult to remove the muffler assembly. 22 outer exhaust joint 1 23 inner exhaust join...

Page 100: Powr

5-7 e powr muffler assembly exploded diagram removal and installation chart step procedure/part name q’ty service points muffler disassembly follow the left “step” for disassembly. 1 exhaust temperature sensor 1 2 cooling water temperature sensor 1 3 bolt 2 4 muffler stay 1 5 dowel pin 1 6 bolt 6 7 ...

Page 101: Powr

5-8 e powr muffler assembly exploded diagram step procedure/part name q’ty service points 11 catalytic converter 1 12 gasket 1 13 pin 2 14 bolt 6 15 mixing joint 1 16 gasket 1 17 muffler 1 reverse the disassembly steps for assembly. Not reusable not reusable.

Page 102: Powr

5-9 e powr muffler assembly service points catalytic converter inspection 1. Check: • catalytic converter cracks/damage → replace. Muffler installation 1. Install: • inner exhaust joint • outer exhaust joint • muffler assembly • inner exhaust joint screw clamp • outer exhaust joint screw clamp note:...

Page 103: Powr

5-10 e powr exhaust chamber assembly exhaust chamber assembly exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust chamber assembly removal follow the left “step” for removal. Muffler assembly refer to “muffler assembly.” 1 screw clamp/cooling water ho...

Page 104: Powr

5-11 e powr exhaust chamber assembly exploded diagram step procedure/part name q’ty service points 8 screw clamp/cooling water hose 1/1 Ê from exhaust manifold 9 exhaust chamber assembly 1 note: before installing the exhaust chamber assembly, connect the cooling water hose and fasten it with the scr...

Page 105: Powr

5-12 e powr exhaust chamber assembly exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust chamber disassembly follow the left “step” for disassembly. 1 bolt 5 2 bolt 1 3 exhaust chamber joint 1 4 gasket 1 5 pin 2 6 exhaust chamber 1 reverse the disasse...

Page 106: Powr

5-13 e powr engine unit engine unit exploded diagram removal and installation chart step procedure/part name q’ty service points engine unit removal follow the left “step” for removal. Muffler assembly refer to “muffler assembly.” exhaust chamber assembly refer to “exhaust chamber assembly.” silence...

Page 107: Powr

5-14 e powr engine unit exploded diagram step procedure/part name q’ty service points 3 oil return hose 1 4 coupler 9 5 bolt/collar 1/1 6 coupling cover 1 7 bolt/washer 4/4 8 engine unit 1 9 shim — as required note: install shims in their original positions. Reverse the removal steps for installatio...

Page 108: Powr

5-15 e powr engine unit service points shim removal 1. Remove: • shims note: to ease reassembly and coupling alignment, remove the shims and organize them in their respective groups (e.G., front right, rear left) prior to removing the mounting bolts. Engine mount inspection 1. Check: • engine mounts...

Page 109: Powr

5-16 e powr exhaust manifold exhaust manifold exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust manifold removal follow the left “step” for removal. Engine unit refer to “engine unit.” 1 bolt 4 2 bolt 6 3 nut 2 4 exhaust manifold 1 5 gasket 1 6 pin ...

Page 110: Powr

5-17 e powr exhaust manifold exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust manifold disassembly follow the left “step” for disassembly. 1 screw clamp/cooling water hose 1/1 2 bolt 6 3 cooling water joint 1 4 o-ring 3 5 exhaust manifold 1 reverse...

Page 111: Powr

5-18 e powr reed valves reed valves exploded diagram removal and installation chart step procedure/part name q’ty service points reed valve removal follow the left “step” for removal. Throttle bodies assembly refer to “fuel injection system” in chapter 4. Oil delivery hoses refer to “oil pump” in ch...

Page 112: Powr

5-19 e powr reed valves exploded diagram step procedure/part name q’ty service points 7 balance plate 1 8 gasket 1 9 reed valve plate 1 10 reed valve assembly 3 11 screw 24 12 valve stopper 6 13 reed valve 6 reverse the removal steps for installation. Not reusable.

Page 113: Powr

5-20 e powr service points reed valve inspection 1. Check: • reed valves cracks/damage → replace. 2. Measure: • valve warpage a out of specification → replace. 3. Measure: • valve stopper height b out of specification → replace. Valve warpage limit: 1.5 mm (0.059 in) valve stopper height: 10.5–10.9 ...

Page 114: Powr

5-21 e powr ypvs ypvs exploded diagram removal and installation chart step procedure/part name q’ty service points ypvs removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly.” 1 bolt 12 2 ypvs valve cover 3 3 gasket 3 4 spacer 2 5 link joint/cover 2/...

Page 115: Powr

5-22 e powr ypvs exploded diagram step procedure/part name q’ty service points 8 bolt 3 note: for installation, align the hole a in the ypvs shaft with the bolt. 9 shaft 3 1 10 shaft 2 1 11 shaft 1 1 12 ypvs valve arm 3 13 bolt 3.

Page 116: Powr

5-23 e powr ypvs exploded diagram step procedure/part name q’ty service points 14 ypvs valve assembly 3 note: install the ypvs valves with the recess b facing toward the stern. 15 oil seal 6 note: if the ypvs shaft is removed, the oil seal must be replaced. Reverse the removal steps for installation...

Page 117: Powr

5-24 e powr ypvs service points ypvs valve inspection 1. Eliminate: • carbon deposits (using a rounded scraper 1) caution: do not use a sharp instrument to avoid damaging or scratching the surfaces. 1 2. Check: • ypvs valve assembly cracks/damage/wear → replace. Ypvs valve installation 1. Install: •...

Page 118: Powr

5-25 e powr cylinder head cylinder head exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder head removal follow the left “step” for removal. Muffler assembly refer to “muffler assembly.” 1 spark plug 3 2 bolt 1 3 ground lead 1 4 bolt 2 note: tighten ...

Page 119: Powr

5-26 e powr cylinder head exploded diagram step procedure/part name q’ty service points 7 cylinder head 1 8 gasket 1 9 screw clamp/cooling water hose 2/2 note: face the red mark a end of the cooling water hose toward the cylinder head cover, and then install the hose. 10 screw 2 11 anode 2 reverse t...

Page 120: Powr

5-27 e powr cylinder head service points cylinder head inspection 1. Eliminate: • carbon deposits (using a rounded scraper 1) caution: do not use a sharp instrument to avoid damaging or scratching the cylinder head or spark plug bore threads. 2. Check: • cylinder head water jacket corrosion/mineral ...

Page 121: Powr

5-28 e powr cylinders cylinders exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder removal follow the left “step” for removal. Ypvs refer to “ypvs.” cylinder head refer to “cylinder head.” 1 engine temperature sensor 1 2 bolt 12 note: tighten the bo...

Page 122: Powr

5-29 e powr cylinders exploded diagram step procedure/part name q’ty service points 4 cylinder gasket 3 5 pin 6 reverse the removal steps for installation. Not reusable.

Page 123: Powr

5-30 e powr cylinders service points cylinder inspection 1. Eliminate: • carbon deposits (using a rounded scraper 1) 2. Check: • cylinder water jacket corrosion/mineral deposits → clean or replace. • cylinder inner surface score marks → replace. 3. Measure: • cylinder bore “d” (using a cylinder gaug...

Page 124: Powr

5-31 e powr pistons pistons exploded diagram removal and installation chart step procedure/part name q’ty service points piston removal follow the left “step” for removal. Cylinders refer to “cylinders.” 1 piston pin clip 2 caution: do not align the open end of the clip with the piston pin slot a. 2...

Page 125: Powr

5-32 e powr pistons exploded diagram step procedure/part name q’ty service points 5 bearing 1 6 piston ring 2 caution: align each end gap with its respective locating pin. Reverse the removal steps for installation..

Page 126: Powr

5-33 e powr pistons service points piston pin clip removal and installation 1. Remove and install: • piston pin clip note: before removing or installing the piston pin clip, cover the crankcase opening with a clean rag to prevent the piston pin clip from falling into the crankcase. Piston inspection...

Page 127: Powr

5-34 e powr pistons 4. Calculate: • piston-to-cylinder clearance out of specification → replace the pis- ton, piston rings, and cylinder as a set. Cylinder and piston combination select the appropriate piston to match the cyl- inder size from the table as follows. Note: new cylinder bore size = 84.0...

Page 128: Powr

5-35 e powr pistons 2. Measure: • end gap (using a thickness gauge 1) out of specification → replace the pis- ton rings as a set. Note: push the piston ring into the cylinder with the piston crown. End gap: 0.45–0.60 mm (0.018–0.024 in) piston pin and bearing inspection 1. Check: • piston pins • bea...

Page 129: Powr

5-36 e powr pistons 4. Check: • piston-pin-to-small-end-bearing-to- connecting-rod free play (at the small end of the connecting rod as shown) free play/wear at the small end → replace the piston pin, connecting rod, small end bearing, or all parts. Piston installation 1. Install: • top ring • 2nd r...

Page 130: Powr

5-37 e powr generator and starter motor generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator cover removal follow the left “step” for removal. Oil pump refer to “oil pump” in chapter 4. 1 bolt 1 2 bolt 7 note: do not apply...

Page 131: Powr

5-38 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 8 pin 2 9 bolt 2 10 bolt 2 11 exhaust chamber bracket 1 reverse the removal steps for installation..

Page 132: Powr

5-39 e powr generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points stator coil and pickup coil removal follow the left “step” for removal. 1 plastic tie 1 2 bolt/washer 3/3 note: these washers hold the pickup coil leads. Be sure not t...

Page 133: Powr

5-40 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 8 ground lead 2 9 bolt 3 10 lighting coil 1 reverse the removal steps for installation. 4.9 n • m (0.49 kgf • m, 3.5 ft • ib) 5 × 14 mm 14 n • m (1.4 kgf • m, 10 ft • ib) 6 × 35 mm 14 n • m (1.4 kgf...

Page 134: Powr

5-41 e powr generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator rotor and starter motor removal follow the left “step” for removal. 1 drive coupling 1 2 flywheel magneto bolt 1 3 flywheel magneto 1 note: degrease the flyw...

Page 135: Powr

5-42 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 7 negative battery lead 1 8 nut/washer 1/1 9 starter motor lead 1 10 starter motor 1 reverse the removal steps for installation..

Page 136: Powr

5-43 e powr generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points starter clutch disassembly follow the left “step” for disassembly. 1 clip 1 2 clip stopper 1 3 spring seat 1 4 spring 1 5 washer 1 6 idle gear 1 7 circlip 1 8 plate 1 ...

Page 137: Powr

5-44 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 9 weight 3 10 spring ring 1 note: install the spring ring after installing the weights, plate, and circlip. 11 pinion gear 1 reverse the disassembly steps for assembly..

Page 138: Powr

5-45 e powr generator and starter motor service points drive coupling removal and installation 1. Remove: • drive coupling note: install the drive coupling with the same special service tools that were used for removal. Coupler wrench: yw-06551/90890-06551 flywheel holder: yw-06550/90890-06550 t r ....

Page 139: Powr

5-46 e powr generator and starter motor 2. Remove: • generator rotor È for usa and canada É for worldwide caution: to prevent damage to the engine or special service tools, screw in the flywheel puller set bolts evenly and completely so that the puller plate is parallel to the generator rotor. Unive...

Page 140: Powr

5-47 e powr crankcase crankcase exploded diagram removal and installation chart step procedure/part name q’ty service points crankcase disassembly follow the left “step” for disassembly. Pistons refer to “pistons.” generator cover and starter motor refer to “generator and starter motor.” 1 bolt 6 2 ...

Page 141: Powr

5-48 e powr crankcase exploded diagram step procedure/part name q’ty service points 8 lower crankcase 1 9 pin 2 10 crankshaft assembly 1 11 upper crankcase 1 reverse the disassembly steps for assembly..

Page 142: Powr

5-49 e powr crankcase service points crankcase inspection 1. Check: • mating surfaces scratches → replace the crankcase. • crankcase cracks/damage → replace. Crankcase installation 1. Apply: • gasket maker (to the crankcase mating surfaces) note: before applying gasket maker, clean the crankcase mat...

Page 143: Powr

5-50 e powr crankshaft crankshaft exploded diagram removal and installation chart step procedure/part name q’ty service points crankshaft removal follow the left “step” for removal. Crankcase refer to “crankcase.” 1 oil seal 1 2 bearing 1 3 oil seal 1 1 4 oil seal 2 1 5 crankshaft assembly 1 caution...

Page 144: Powr

5-51 e powr crankshaft service points crankshaft inspection 1. Measure: • crank width a out of specification → replace the crankshaft. Crank width: 72.95–73.00 mm (2.872–2.874 in) 2. Measure: • deflection b (using a dial gauge) out of specification → replace. Maximum deflection: b 0.05 mm (0.002 in)...

Page 145: Powr

5-52 e powr crankshaft 5. Check: • bearings damage/pitting → replace. Note: • before checking bearings, thoroughly clean them. • immediately after checking the bearings, lubricate them to prevent rust. 6. Check: • oil seals damage/wear → replace..

Page 146: Jet

E jet pump 1 2 3 4 5 6 7 8 9 chapter 6 jet pump unit jet pump unit.............................................................................................. 6-1 exploded diagram ............................................................................. 6-1 removal and installation chart ........

Page 147: Jet

6-1 e jet pump jet pump unit jet pump unit exploded diagram removal and installation chart step procedure/part name q’ty service points jet pump unit removal follow the left “step” for removal. 1 bolt 2 2 bolt 2 3 intake grate 1 4 bolt 4 5 intake duct 1 6 felt seal 1 7 screw 4 8 speed sensor 1 note:...

Page 148: Jet

6-2 e jet pump jet pump unit exploded diagram step procedure/part name q’ty service points 9 bolt 4 10 ride plate 1 11 qsts cable joint 1 12 plastic tie/bilge hose 5 1/1 13 nut/washer 1/2 14 steering cable joint 1 15 screw clamp/spout hose 1/1 16 bolt 1 17 bolt 4.

Page 149: Jet

6-3 e jet pump jet pump unit exploded diagram step procedure/part name q’ty service points 18 jet pump unit assembly 1 note: clean the mating surfaces before applying yamabond no. 4. 19 dowel pin 2 20 impeller housing 2 1 21 dowel pin 2 reverse the removal steps for installation..

Page 150: Jet

6-4 e jet pump jet pump unit exploded diagram removal and installation chart step procedure/part name q’ty service points speed sensor disassembly follow the left “step” for disassembly. 1 paddle wheel set 1 2 speed sensor 1 reverse the disassembly steps for assembly. Fwd 1 2 not reusable.

Page 151: Jet

6-5 e jet pump jet thrust nozzle and nozzle ring jet thrust nozzle and nozzle ring exploded diagram removal and installation chart step procedure/part name q’ty service points jet thrust nozzle and nozzle ring removal follow the left “step” for removal. Jet pump unit refer to “jet pump unit.” 1 bolt...

Page 152: Jet

6-6 e jet pump impeller duct and impeller housing 1 impeller duct and impeller housing 1 exploded diagram removal and installation chart step procedure/part name q’ty service points impeller duct and impeller housing 1 removal follow the left “step” for removal. Nozzle ring refer to “jet thrust nozz...

Page 153: Jet

6-7 e jet pump impeller duct and impeller housing 1 exploded diagram step procedure/part name q’ty service points 7 bolt 4 8 water inlet cover 1 9 seal 1 10 water inlet strainer 1 11 seal 1 reverse the removal steps for installation..

Page 154: Jet

6-8 e jet pump impeller duct and drive shaft impeller duct and drive shaft exploded diagram removal and installation chart *1 epnoc grease ap #0 step procedure/part name q’ty service points impeller duct and drive shaft disassembly follow the left “step” for disassembly. 1 impeller 1 left-hand threa...

Page 155: Jet

6-9 e jet pump impeller duct and drive shaft exploded diagram *1 epnoc grease ap #0 step procedure/part name q’ty service points 8 drive shaft 1 9 rear bearing 1 10 spacer 1 11 front bearing 1 12 oil seal 1 13 oil seal 1 14 impeller duct 1 reverse the disassembly steps for assembly. Not reusable not...

Page 156: Jet

6-10 e jet pump impeller duct and drive shaft service points drive shaft removal 1. Remove: • impeller note: the impeller has left-hand threads. Turn the impeller clockwise to loosen it. 2. Remove: • nut 1 3. Remove: • drive shaft 1 note: remove the drive shaft using a press. Drive shaft holder: yb-...

Page 157: Jet

6-11 e jet pump impeller duct and drive shaft 5. Remove: • front bearing note: remove the front bearing using a press. Driver handle—large: yb-06071 driver rod l3: 90890-06652 bearing housing needle bearing remover: yb-06112 needle bearing attachment: 90890-06614 6. Remove: • oil seal note: remove t...

Page 158: Jet

6-12 e jet pump impeller duct and drive shaft drive shaft installation 1. Install: • oil seals driver handle—large: yb-06071 driver rod ls: 90890-06606 outer race installer—forward gear: yb-06085 ball bearing attachment: 90890-06634 distance a: 14.2 ± 0.2 mm (0.56 ± 0.01 in) distance b: 4.7 ± 0.2 mm...

Page 159: Jet

6-13 e jet pump impeller duct and drive shaft 5. Install: • rear bearing note: • press the bearing inner/outer race at the same time holding the drive shaft and impel- ler duct. • if a bearing inner/outer race attachment is not available, use a washer or pipe with an outer diameter of 47–50 mm (1.85...

Page 160: Jet

6-14 e jet pump transom plate and hoses transom plate and hoses exploded diagram removal and installation chart step procedure/part name q’ty service points transom plate and hose removal follow the left “step” for removal. Exhaust system refer to “exhaust system” in chapter 8. Jet pump unit assembl...

Page 161: Jet

6-15 e jet pump transom plate and hoses exploded diagram step procedure/part name q’ty service points 6 bilge hose 4 1 7 band 1 8 electric bilge pump assembly 1 9 hose clamp 1 10 bilge hose 3 1 11 bilge strainer 1 12 nut/washer 4/4 13 transom plate 1 14 plastic tie/bilge hose 5 1/1 reverse the remov...

Page 162: Jet

6-16 e jet pump transom plate and hoses service points bilge strainer inspection refer to “jet pump unit” in chapter 3. Electric bilge pump inspection refer to “bilge pump” in chapter 3. Refer to “electric bilge pump” in chapter 7. Bilge hose inspection 1. Check: • bilge hoses cracks/damage/wear → r...

Page 163: Jet

6-17 e jet pump bearing housing bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. 1 rubber coupling 1 2 bolt 3 3 intermediate housin...

Page 164: Jet

6-18 e jet pump bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing disassembly follow the left “step” for disassembly. 1 grease hose 1 2 grease nipple 1 3 grease nipple stay 1 4 nipple 2 5 driven coupling 1 6 washer 1 7 interm...

Page 165: Jet

6-19 e jet pump bearing housing exploded diagram step procedure/part name q’ty service points 9 oil seal 1 10 oil seal 1 11 oil seal 1 12 circlip 1 13 bearing 1 14 circlip 1 reverse the disassembly steps for assembly. Not reusable not reusable not reusable not reusable.

Page 166: Jet

6-20 e jet pump bearing housing service points driven coupling removal and installation 1. Remove and install: • driven coupling note: install the driven coupling with the same spe- cial service tools that were used for removal. T r . . Driven coupling: 36 n • m (3.6 kgf • m, 25 ft • lb) loctite 572...

Page 167: Jet

6-21 e jet pump bearing housing bearing removal 1. Remove: • bearing note: • install the bearing with the same special ser- vice tools that were used for removal. • support the intermediate housing with steel blocks 1 and remove the bearing using a press. Bearing, intermediate drive shaft, and greas...

Page 168: Jet

6-22 e jet pump bearing housing 2. Install: • bearing note: support the intermediate housing with steel blocks 1 and install the bearing using a press. Oil seal installation 1. Install: • oil seal note: before installing the oil seal, lubricate the clip groove with water-resistant grease. 2. Install...

Page 169: Jet

6-23 e jet pump bearing housing 3. Install: • oil seal 1 [8 mm (0.31 in)] • oil seal 2 [10 mm (0.39 in)] distance a: 10.3–10.7 mm (0.41–0.42 in) distance b: 1.6–2.0 mm (0.06–0.08 in) b a 2 1 intermediate housing installation 1. Install: • intermediate housing • shim(s) • bolts note: install shims in...

Page 170: Elec

E – + elec 1 2 3 4 5 6 7 8 9 chapter 7 electrical system electrical components........................................................................ 7-1 electrical box.......................................................................................... 7-2 exploded diagram ......................

Page 171: Elec

E – + elec fuel control system ........................................................................... 7-23 wiring diagram ................................................................................. 7-23 fuel pump ...............................................................................

Page 172: Elec

E – + elec ypvs servomotor................................................................................... 7-39 exploded diagram ........................................................................... 7-39 removal and installation chart .............................................. 7-39 serv...

Page 173: Elec

7-1 e – + elec electrical components electrical components 2 3 4 5 6 7 8 9 0 b 1 8 a 8 c n m l j e f g d h i k o p q 1 slant detection switch 2 fuel pump 3 atmospheric pressure sensor 4 multifunction meter 5 steering switch 6 intake air temperature sensor 7 throttle position sensor 8 fuel injectors ...

Page 174: Elec

7-2 e – + elec electrical box electrical box exploded diagram removal and installation chart step procedure/part name q’ty service points electrical box disassembly follow the left “step” for disassembly. 1 plastic tie 6 2 tapping screw 11 3 cover 1 4 gasket 1 5 tapping screw 2 6 lead holder 1 7 bol...

Page 175: Elec

7-3 e – + elec electrical box exploded diagram step procedure/part name q’ty service points 10 bolt 1 11 starter relay 1 12 tapping screw 1 13 fuse holder stay 1 14 tapping screw 1 15 main and fuel pump relay 1 16 tapping screw 2 17 rectifier/regulator 1 18 tapping screw 2 19 coupler bracket 1 20 bo...

Page 176: Elec

7-4 e – + elec electrical box exploded diagram step procedure/part name q’ty service points 21 tapping screw 6 22 ignition coil #1 1 23 ignition coil #1 lead 1 24 ignition coil #2 1 25 ignition coil #2 lead 1 26 ignition coil #3 1 27 ignition coil #3 lead 1 28 spark plug lead #1/cap 1/1 29 spark plu...

Page 177: Elec

7-5 e – + elec electrical box exploded diagram step procedure/part name q’ty service points 32 fuse (20 a) 1 33 tapping screw 2 34 wire harness 1 reverse the disassembly steps for assembly. 3.9 n • m (0.39 kgf • m, 2.8 ft • ib) 6 × 30 mm 4.9 n • m (0.49 kgf • m, 3.5 ft • ib) 6 × 25 mm 3.4 n • m (0.3...

Page 178: Elec

7-6 e – + elec electrical box a a 1 2 a 3 b b 3 2 1 r br br b b b b b b b b 7.6 n • m (0.76 kgf • m, 5.5 ft • ib) 6 × 16 mm 3.9 n • m (0.39 kgf • m, 2.8 ft • ib) 6 × 25 mm 3.4 n • m (0.34 kgf • m, 2.5 ft • ib) 6 × 16 mm 7.6 n • m (0.76 kgf • m, 5.5 ft • ib) 6 × 16 mm 3.9 n • m (0.39 kgf • m, 2.8 ft ...

Page 179: Elec

7-7 e – + elec ecm and slant detection switch ecm and slant detection switch exploded diagram removal and installation chart step procedure/part name q’ty service points ecm and slant detection switch removal follow the left “step” for removal. 1 nut/washer 2/2 2 ecm 1 3 ecm coupler 1 4 nut/washer 2...

Page 180: Elec

7-8 e – + elec electrical analysis electrical analysis inspection caution: • all measuring instruments should be han- dled with special care. Damaged or mis- handled instruments will not measure properly. • on instruments powered by dry batteries, check the battery voltage periodically and replace t...

Page 181: Elec

7-9 e – + elec electrical analysis low resistance measurement note: • when measuring a resistance of 10 Ω or less with the digital tester, the correct measure- ment cannot be obtained because of the tester’s internal resistance. • to obtain the correct value, subtract the internal resistance from th...

Page 182: Elec

7-10 e – + elec electrical analysis peak voltage adapter note: • throughout this chapter the part number of the peak voltage adapters have been omit- ted. Refer to the following part numbers. • the peak voltage adapter should be used with the digital tester. • when measuring the peak voltage, connec...

Page 183: Elec

7-11 e – + elec ignition system ignition system wiring diagram free push b w free push br br free push w b r br 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 b/r o r/y l/b b p/g p b b/y b/w 19 : 20 : 27 : 28 : 29 : 30 : 31 : 33 : 34 : 35 : y w b/y b/...

Page 184: Elec

7-12 e – + elec ignition system wiring diagram free push b w free push br br free push w b r br 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 b/r o r/y l/b b p/g p b b/y b/w 19 : 20 : 27 : 28 : 29 : 30 : 31 : 33 : 34 : 35 : y w b/y b/g b/o b/l o w/y ...

Page 185: Elec

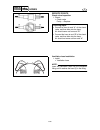

7-13 e – + elec ignition system ignition spark gap warning • when checking the spark gap, do not touch any of the connections of the spark gap tester lead wires. • when performing the spark gap test, take special care not to let sparks leak out of the removed spark plug cap. • when performing the sp...

Page 186: Elec

7-14 e – + elec ignition system ignition system peak voltage warning when checking the electrical components, do not touch any of the connections of the digital tester lead wires. Note: • if there is no spark, or the spark is weak, continue with the ignition system test. • if a good spark is obtaine...

Page 187: Elec

7-15 e – + elec ignition system 2. Measure: • pickup coil output peak voltage below specification → replace the pickup coil. Above specification → replace the ecm. Note: to crank the engine, connect the engine shut- off cord (lanyard) to the engine shut-off switch, and then press the start switch an...

Page 188: Elec

7-16 e – + elec 4. Measure: • rectifier/regulator output peak voltage below specification → replace the recti- fier/regulator. Note: • do not use the peak voltage adapter to mea- sure the output voltage. • disconnect the output lead of the tester har- ness. Battery refer to “electrical” in chapter 3...

Page 189: Elec

7-17 e – + elec ignition coil 1. Measure: • primary coil resistance out of specification → replace. Note: when measuring a resistance of 10 Ω or less with the digital tester, the correct measurement cannot be obtained because of the tester’s internal resistance. Refer to “low resistance measurement....

Page 190: Elec

7-18 e – + elec ignition system engine temperature sensor 1. Measure: • engine temperature sensor resistance (at the specified temperatures) out of specifications → replace. Engine temperature sensor resistance: 20 °c (68 °f): 54.2–69.0 k Ω 100 °c (212 °f): 3.12–3.48 k Ω measurement steps: • suspend...

Page 191: Elec

7-19 e – + elec ignition system cooling water temperature sensor 1. Measure: • cooling water temperature sensor resistance (at the specified temperatures) out of specifications → replace. Cooling water temperature sensor resistance: 0 °c (32 °f): 24.0–37.1 k Ω 100 °c (212 °f): 0.87–1.18 k Ω 200 °c (...

Page 192: Elec

7-20 e – + elec ignition system main and fuel pump relay 1. Check: • main and fuel pump relay continuity out of specification → replace. Checking steps: • connect the tester leads between main and fuel pump relay terminals 5, 6, and 7. • connect terminal 2 or 3 to the positive battery terminal. • co...

Page 193: Elec

7-21 e – + elec ignition system atmospheric pressure sensor 1. Measure: • atmospheric pressure sensor output voltage out of specification → replace. È: output voltage É: vacuum pressure note: while the yamaha diagnostic system is oper- ating, electric power is supplied to the atmo- spheric pressure ...

Page 194: Elec

7-22 e – + elec ignition system slant detection switch 1. Check: • slant detection switch continuity out of specification → replace. Position lead color blue/black (l/b) black/ orange (b/o) normal operation È overturned É up up È É.

Page 195: Elec

7-23 e – + elec fuel control system fuel control system wiring diagram 33 31 30 29 28 27 20 2 5 6 7 8 10 14 26 25 24 23 22 21 32 1 4 9 15 16 17 18 19 3 11 12 13 35 34 pu/y pu/b pu/r r/y l/b b p/g p b 24 : 25 : 26 : 27 : 28 : 29 : 30 : 31 : 33 : y b/y b/g b/o b/l o l/r o p 2 : 5 : 6 : 7 : 8 : 10 : 14...

Page 196: Elec

7-24 e – + elec fuel control system wiring diagram 33 31 30 29 28 27 20 2 5 6 7 8 10 14 26 25 24 23 22 21 32 1 4 9 15 16 17 18 19 3 11 12 13 35 34 pu/y pu/b pu/r r/y l/b b p/g p b 24 : 25 : 26 : 27 : 28 : 29 : 30 : 31 : 33 : y b/y b/g b/o b/l o l/r o p 2 : 5 : 6 : 7 : 8 : 10 : 14 : 20 : 23 : b/o b/o...

Page 197: Elec

7-25 e – + elec fuel control system fuel pump 1. Check: • fuel pump operating sound no sound → measure the fuel pressure. Refer to “fuel injection system” in chapter 4. Fuel sender 1. Measure: • fuel sender resistance out of specification → replace. Float position resistance ( Ω) a 133.5–136.5 b 5–7.

Page 198: Elec

7-26 e – + elec fuel control system fuel injector refer to “fuel injection system” in chapter 4. Engine temperature sensor refer to “ignition system.” intake air temperature sensor refer to “ignition system.” cooling water temperature sensor refer to “ignition system.” exhaust temperature sensor ref...

Page 199: Elec

7-27 e – + elec starting system starting system wiring diagram free push br br free push w b r br 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 y r/y b 2 : 27 : 33 : r br r br 1 2 3 4 5 6 7 8 y b b b b r/y r/y b b r/y r/y r/y r/y r/y r br b l/r y l r...

Page 200: Elec

7-28 e – + elec starting system battery refer to “electrical” in chapter 3. Wiring connections 1. Check: • wiring connections poor connections → properly connect. Fuses 1. Check: • fuses broken → replace. Note: the 20 a fuse is for the main relay, engine shut-off switch, and rectifier/regulator. The...

Page 201: Elec

7-29 e – + elec starting system starter relay 1. Check: • brown lead terminal • black lead terminal loose → tighten. 2. Check: • starter relay continuity out of specification → replace. Checking steps: • connect the tester leads between the starter relay terminals as shown. • connect the brown lead ...

Page 202: Elec

7-30 e – + elec starter motor starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points starter motor disassembly follow the left “step” for disassembly. Starter motor refer to “generator and starter motor” in chapter 5. 1 o-ring 1 2 bolt 2 3 starter ...

Page 203: Elec

7-31 e – + elec starter motor exploded diagram step procedure/part name q’ty service points 8 starter motor rear cover 1 9 o-ring 1 10 shim — as required thickness = 0.2 mm, 0.8 mm 11 armature assembly 1 12 nut/spring washer/washer 1/1/4 13 o-ring 1 14 brush holder 1 15 brush spring 4 16 bolt 1 17 b...

Page 204: Elec

7-32 e – + elec starter motor exploded diagram step procedure/part name q’ty service points 18 spacer 1 19 holder 1 20 starter motor yoke 1 reverse the disassembly steps for assembly..

Page 205: Elec

7-33 e – + elec starter motor service points armature inspection 1. Check: • armature shaft 1 damage/wear → replace. 1 2. Check: • commutator dirt → clean with 600 grit sandpaper. 3. Measure: • commutator diameter out of specification → replace. Minimum commutator diameter: 27.0 mm (1.06 in) 4. Chec...

Page 206: Elec

7-34 e – + elec starter motor 6. Check: • armature coil continuity out of specification → replace. Armature coil continuity: commutator segments 1 continuity segment – laminations 2 no continuity segment – armature shaft no continuity brush holder inspection 1. Measure: • brush length a out of speci...

Page 207: Elec

7-35 e – + elec charging system charging system wiring diagram b r b g g g g g g g g g g g g g g r b r r r r 1 2 3 4 1 rectifier/regulator 2 fuse (20 a) 3 battery 4 lighting coil b : black g : green r : red.

Page 208: Elec

7-36 e – + elec charging system fuse refer to “starting system.” battery refer to “electrical” in chapter 3. Lighting coil refer to “ignition system.” rectifier/regulator refer to “ignition system.”.

Page 209: Elec

7-37 e – + elec ypvs ypvs wiring diagram 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 l g p b b 21 : 22 : 23 : 29 : 33 : b/o o w/y w/b w/r 7 : 10 : 11 : 12 : 13 : b/o b/o b/o o o o b b b b b/o b/o b/o w/b w/r w/y b w/y w/r w/b b/o b r b g g g g g g ...

Page 210: Elec

7-38 e – + elec ypvs fuse refer to “starting system.” battery refer to “electrical” in chapter 3. Pickup coil refer to “ignition system.” lighting coil refer to “ignition system.” rectifier/regulator refer to “ignition system.”.

Page 211: Elec

7-39 e – + elec ypvs servomotor ypvs servomotor exploded diagram removal and installation chart step procedure/part name q’ty service points ypvs servomotor removal follow the left “step” for removal. 1 bolt 2 2 cable holder 1 3 ypvs servomotor coupler 1 4 nut/washer 2/2 5 ypvs servomotor 1 6 thrott...

Page 212: Elec

7-40 e – + elec ypvs servomotor exploded diagram step procedure/part name q’ty service points 8 cover 1 9 nut/washer 3/3 10 ypvs servomotor bracket 1 reverse the removal steps for installation..

Page 213: Elec

7-41 e – + elec ypvs servomotor service points ypvs cable removal and installation 1. Remove: • ypvs cables 1 and 2 note: • ypvs cable 2 is identifiable by its white paint mark a. • when installing the ypvs cable, make sure that the ypvs cable locknuts 3 are fully turned in. Removal steps: • remove ...

Page 214: Elec

7-42 e – + elec off throttle steering system off throttle steering system wiring diagram 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 g/b g/r g g/y r/y b p 15 : 16 : 17 : 18 : 27 : 29 : 31 : w/l b/o w/l o w/y w/b w/r 4 : 7 : 9 : 10 : 11 : 12 : 13 : ...

Page 215: Elec

7-43 e – + elec off throttle steering system steering switch 1. Check: • steering switch refer to “self-diagnosis” in chapter 9. Malfunction → check that the steering switch switches on and off when the handlebar is turned to the right and to the left using the “engine monitor” of the yamaha diagnos...

Page 216: Elec

7-44 e – + elec electric bilge pump electric bilge pump wiring diagram 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 y r/y 2 : 27 : 1 2 3 4 5 6 7 8 br r r/y r/y b b b r/y r/y r/y r/y r/y r br b l/r y l r/y y br b b r/y r/y b r/y r r b b b br b b b r ...

Page 217: Elec

7-45 e – + elec electric bilge pump electric bilge pump 1. Check: • electric bilge pump operation does not operate → replace. Fuse refer to “starting system.” battery refer to “electrical” in chapter 3. Main and fuel pump relay refer to “ignition system.” checking steps: • suspend the electric bilge...

Page 218: Elec

7-46 e – + elec indication system indication system wiring diagram 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 o r/y b w/b b 20 : 27 : 29 : 32 : 33 : g y b/y b/o b/l 1 : 2 : 5 : 7 : 8 : b/y b/y b/y b w b b 1 2 3 4 5 6 7 8 r r b r r b b b r/y r/y b/...

Page 219: Elec

7-47 e – + elec indication system wiring diagram 19 35 34 33 31 30 29 28 27 20 2 3 5 6 7 8 10 11 12 13 14 32 26 25 24 23 22 21 1 4 9 15 16 17 18 o r/y b w/b b 20 : 27 : 29 : 32 : 33 : g y b/y b/o b/l 1 : 2 : 5 : 7 : 8 : b/y b/y b/y b w b b 1 2 3 4 5 6 7 8 r r b r r b b b r/y r/y b/o o g b/o b/l b/o ...

Page 220: Elec

7-48 e – + elec indication system fuse refer to “starting system.” battery refer to “electrical” in chapter 3. Engine temperature sensor refer to “ignition system.” cooling water temperature sensor refer to “ignition system.” exhaust temperature sensor refer to “ignition system.” main and fuel pump ...

Page 221: Elec

7-49 e – + elec indication system buzzer 1. Check: • buzzer buzzer does not sound → replace. Checking steps: • connect a 12 v battery to the buzzer cou- pler as shown. Positive battery terminal → red (r) terminal 1 negative battery terminal → black (b) terminal 2 multifunction meter multifunction me...

Page 222: Elec

7-50 e – + elec indication system display function 1. Check: • display function does not operate → replace the multi- function meter. R/w b/r b/y p b l b w r y y w b/y r/w l r p b l/r l/b r b b/r b l/b l/r b r 1 5 4 3 2 1 buzzer 2 speed sensor 3 ecm 4 oil level sensor 5 fuel sender b : black l : blu...

Page 223: Elec

7-51 e – + elec indication system speedometer display 1. Check: • speedometer display does not display → measure the speed sensor output voltage and pulses. 2. Measure: • speed sensor output voltage and pulses out of specification → replace the speed sensor. Within specification → replace the mul- t...

Page 224: Elec

7-52 e – + elec indication system hour meter display 1. Check: • hour meter display does not display → replace the multi- function meter. Voltage meter display 1. Check: • voltage meter display does not display → check the battery voltage using the “engine monitor” of the yamaha diagnostic system. I...

Page 225: Elec

7-53 e – + elec indication system engine overheat warning indicator 1. Check: • engine overheat warning indicator does not operate → replace the multi- function meter. Checking steps: • start the engine. • disconnect the cooling water tempera- ture sensor coupler 1. • check that the warning light co...

Page 226: Elec

7-54 e – + elec indication system check engine warning indicator 1. Check: • check engine warning indicator does not operate → replace the multi- function meter. Checking steps: • start the engine. • disconnect the coupler of a sensor (e.G., atmospheric pressure sensor) that nor- mally activates the...

Page 227: Hull

E hull hood chapter 8 hull and hood handlebar .................................................................................................. 8-1 exploded diagram ............................................................................. 8-1 removal and installation chart ........................

Page 228: Hull

E hull hood 1 2 3 4 5 6 7 8 9 hoses .......................................................................................................... 8-27 exploded diagram ........................................................................... 8-27 removal and installation chart ..........................

Page 229: Hull

8-1 e hull hood handlebar handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar cover removal follow the left “step” for removal. 1 screw 4 2 handlebar cover 1 3 screw 4 4 handlebar cover stay 1 5 plastic tie 1 6 throttle cable 1 7 bolt 4 8 ...

Page 230: Hull

8-2 e hull hood handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar removal follow the left “step” for removal. Qsts cable (to jet thrust nozzle) refer to “remote control cables and speed sensor lead.” 1 grommet 1 note: to ease installatio...

Page 231: Hull

8-3 e hull hood handlebar exploded diagram step procedure/part name q’ty service points 5 handlebar assembly 1 6 nut/washer 2/2 7 qsts converter 1 8 throttle cable 1 reverse the removal steps for installation..

Page 232: Hull

8-4 e hull hood handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar disassembly follow the left “step” for disassembly. 1 plastic tie 1 2 bolt 2 3 grip end 2 4 spacer 1 5 screw/spring washer/washer 1/1/1 6 qsts grip assembly 1 7 screw 2 8 ...

Page 233: Hull

8-5 e hull hood handlebar exploded diagram step procedure/part name q’ty service points 11 throttle lever assembly 1 12 handlebar grip 1 note: apply adhesive to the handlebar and the inner surface of the handlebar grip. 13 spacer 2 1 14 handlebar 1 reverse the disassembly steps for assembly..

Page 234: Hull

8-6 e hull hood handlebar service points handlebar inspection 1. Check: • handlebar bends/cracks/damage → replace. Handlebar switch inspection refer to “ignition system” and “start- ing system” in chapter 7. Handlebar assembly installation 1. Adjust: • qsts cable length a note: • before adjusting th...

Page 235: Hull

8-7 e hull hood handlebar 3. Install: • throttle cable note: fit the seal into the groove in the bracket. 4. Install: • plastic tie 1 note: after inserting the qsts cables and throttle cable into the grommet, fasten the end of grommet with the plastic tie. 5. Install: • handlebar cover 1 note: when ...

Page 236: Hull

8-8 e hull hood qsts grip qsts grip exploded diagram removal and installation chart step procedure/part name q’ty service points qsts grip disassembly follow the left “step” for disassembly. Qsts grip assembly refer to “handlebar.” 1 screw/washer 1/1 2 cover 1 3 ball 2 4 spring 2 5 qsts cable 1 1 6 ...

Page 237: Hull

8-9 e hull hood qsts grip exploded diagram step procedure/part name q’ty service points 7 screw/washer 2/2 8 collar 1 9 qsts shift lock lever 1 10 spring 1 11 spacer 1 12 qsts cable housing cover 1 13 qsts shift grip 1 reverse the disassembly steps for assembly..

Page 238: Hull

8-10 e hull hood qsts grip service points qsts cable inspection 1. Check: • qsts cables frays/kinks/rough movement → replace. Qsts grip inspection 1. Check: • qsts grip damage/wear → replace..

Page 239: Hull

8-11 e hull hood steering column steering column exploded diagram removal and installation chart step procedure/part name q’ty service points steering column removal follow the left “step” for removal. Steering console cover assembly refer to “steering console cover.” steering cable end refer to “re...

Page 240: Hull

8-12 e hull hood steering column exploded diagram removal and installation chart step procedure/part name q’ty service points steering column disassembly follow the left “step” for disassembly. 1 grommet 1 2 bolt/washer/nut 1/2/1 3 steering arm 1 4 screw 1 5 magnet 1 6 shim — install the same number...

Page 241: Hull

8-13 e hull hood steering column exploded diagram step procedure/part name q’ty service points 9 bushing 2 10 plastic tie 1 11 screw clamp 1 12 steering switch 1 13 steering column housing 1 reverse the disassembly steps for assembly. 2 9 11 7 6 3 2 1 13 8 9 12 10 4 5 16 n • m (1.6 kgf • m, 11 ft • ...

Page 242: Hull

8-14 e hull hood steering column service points steering column bushing inspection 1. Check: • bushings damage/wear → replace. 2. Check: • steering column refer to “control system” in chap- ter 3. Steering column assembly 1. Install: • steering switch 1 • screw clamp 2 • plastic tie 3 note: fasten t...

Page 243: Hull

8-15 e hull hood remote control cables and speed sensor lead remote control cables and speed sensor lead exploded diagram removal and installation chart step procedure/part name q’ty service points remote control cables and speed sensor lead removal follow the left “step” for removal. 1 speed sensor...

Page 244: Hull

8-16 e hull hood remote control cables and speed sensor lead exploded diagram step procedure/part name q’ty service points 10 seal 1 11 steering cable 1 12 nut 1 13 pin 1 14 qsts cable end 1 15 nut 1 16 seal 1 17 qsts cable 1 reverse the removal steps for installation..

Page 245: Hull

8-17 e hull hood remote control cables and speed sensor lead service points warning when routing the cables, do not grasp the cable by the outer crimped sheath or steel end. This could deform or loosen the cable end due to extreme angles and or pressure. Always hold the cables by the bracket or oute...

Page 246: Hull

8-18 e hull hood remote control cables and speed sensor lead qsts cable installation 1. Install: • qsts cable (jet pump end) warning the qsts cable must be screwed in a mini- mum of 8 mm (0.31 in). Qsts cable set length a (jet pump end): 12.0–14.0 mm (0.47–0.55 in) qsts cable stopper installation 1....

Page 247: Hull

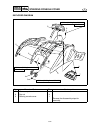

8-19 e hull hood hood hood exploded diagram removal and installation chart step procedure/part name q’ty service points hood removal follow the left “step” for removal. 1 bolt 2 2 screw 8 3 seal washer 8 4 visor 1 5 pop nut 8 6 bolt 2 7 hood lock 1 8 hood 1 10 9 1 11 2 3 5 8 4 6 7 5.4 n • m (0.54 kg...

Page 248: Hull

8-20 e hull hood exploded diagram step procedure/part name q’ty service points 9 nut 2 10 plate 1 11 hinge assembly 1 reverse the removal steps for installation. 10 9 1 11 2 3 5 8 4 6 7 5.4 n • m (0.54 kgf • m, 3.9 ft • ib) 6 × 14 mm 12 n • m (1.2 kgf • m, 8.7 ft • ib) 6 × 14 mm 5 × 20 mm 16 n • m (...

Page 249: Hull