- DL manuals

- Yamaha

- Motorcycle

- WR450F

- Owner's Service Manual

Yamaha WR450F Owner's Service Manual

OWNER’S SERVICE MANUAL

MANUEL D’ATELIER DU

PROPRIETAIRE

WR450F

WR450FG

2GC-28199-70

PRINTED ON RECYCLED PAPER

2016

WR450F

WR450FG

2016

q

Read this manual carefully before operating this vehicle.

q

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

PRINTED IN JAPAN

2015.09—1.6 × 1

!

(E, F)

2GC-28199-70_cover.indd 1

2015/08/28 10:00:34

Summary of WR450F

Page 1

Owner’s service manual manuel d’atelier du proprietaire wr450f wr450fg 2gc-28199-70 printed on recycled paper 2016 wr450f wr450fg 2016 q read this manual carefully before operating this vehicle. Q il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Printed in japan...

Page 2

Q read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold. Q il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit être remis avec le véhicule en cas de vente de ce dernier. 2gc-28199-70_cover.I...

Page 3: Wr450Fg

Wr450fg 2015 2016 wr450f 2gc-28199-70-e0 owner’s service manual owner’s service manual read this manual carefully before operating this vehicle. Read this manual carefully before operating this vehicle..

Page 5

Eas2gc1002 wr450f wr450fg owner’s service manual ©2015 by yamaha motor co., ltd. First edition, august 2015 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed in japan..

Page 6

Eas2gc1003 introduction congratulations on your purchase of a yamaha wr series. This model is the culmination of yama- ha's vast experience in the production of pacesetting racing machines. It represents the highest grade of craftsmanship and reliability that have made yamaha a leader. This manual e...

Page 7

Eas2gc1005 safety information this machine is designed strictly for competition use, only on a closed course. It is illegal for this machine to be operated on any public street, road, or highway. Off-road use on public lands may also be illegal. Please check local regulations before riding. • this m...

Page 8

Eas2gc1006 how to use this manual in this manual, descriptions of installation, removal, disassembly, assembly, check, and adjustment procedures are laid out with the individual steps in sequential order. • the manual is divided into chapters and each chapter is divided into sections. The current se...

Page 9

Eas2gc1007 symbols the following symbols are used in this manual for easier understanding. Tip the following symbols are not relevant to every vehicle. Symbol definition symbol definition serviceable with engine mounted gear oil filling fluid molybdenum disulfide oil lubricant brake fluid special to...

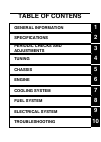

Page 11: Table of Contens

1 2 3 4 5 6 7 8 9 10 table of contens general information specifications periodic checks and adjustments tuning chassis engine cooling system fuel system electrical system troubleshooting.

Page 13

1 general information location of important labels ............................................................1-1 description ..................................................................................................1-4 identification ...........................................................

Page 14

Multi-function display .........................................................................1-21 description .........................................................................................1-21 basic mode .....................................................................................

Page 15

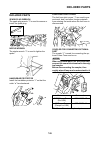

Location of important labels 1-1 eas2gc1008 location of important labels please read the following important labels carefully before operating this vehicle. Can 9,10,11 7,8 13 12 1,2,3 4,5,6.

Page 16

Location of important labels 1-2 eur.

Page 17

Location of important labels 1-3 aus, nzl, zaf.

Page 18

Description 1-4 eas2gc1009 description tip designs and specifications of the vehicle are subject to change without notice. Therefore, please note that the descriptions in this manual may be different from those for the vehicle you have pur- chased. 1. Clutch lever 12. Headlight 2. Multi-function dis...

Page 19

Identification 1-5 eas2gc1010 identification there are two significant reasons for knowing the serial number of your vehicle: 1. When ordering parts, you can give the num- ber to your yamaha dealer for positive iden- tification of the model you own. 2. If your vehicle is stolen, the authorities will...

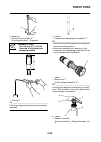

Page 20

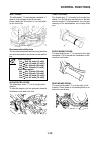

Included parts 1-6 eas2gc1014 included parts eas2gc1015 spark plug wrench the spark plug wrench “1” is used to remove or install the spark plug. Eas2gc1016 nipple wrench the nipple wrench “1” is used to tighten the spoke. Eas2gc1017 handlebar protector install the handlebar protector “1” so that the...

Page 21

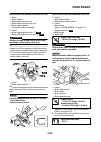

Important information 1-7 eas20180 important information eas2gc1020 preparation for removal and dis- assembly 1. Before the jobs, completely remove mud, dust, and the like in order to prevent the en- try of them into the inside during the jobs. • before cleaning with high-pressure water of washers, ...

Page 22

Important information 1-8 eas2gc1022 gaskets, oil seals and o-rings 1. When overhauling the engine, replace all gaskets and o-rings. All gasket surfaces, oil seal lips, and o-rings must be cleaned so that there may be no dust on them. 2. During assembly, always apply proper oil to bearings and prope...

Page 23

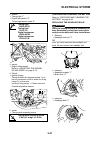

Basic service information 1-9 eas2gc1026 basic service information eas2gc1027 electrical system electrical parts handling eca notice never disconnect a battery lead while the engine is running; otherwise, the electrical components could be damaged. Eca notice when disconnecting the battery leads fro...

Page 24

Basic service information 1-10 eca notice handle electrical components with special care, and do not subject them to strong shocks. Eca notice electrical components are very sensitive to and can be damaged by static electricity. Therefore, never touch the terminals and be sure to keep the contacts c...

Page 25

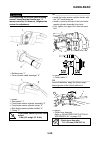

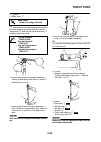

Basic service information 1-11 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector eca notice • when disconnecting a coupler, release the coupler lock, hold both sections of the coupler, and then disconnect t...

Page 26

Basic service information 1-12 4. Connect: • lead • coupler • connector tip • when connecting a coupler or connector, make sure that both terminals are connected securely. • make sure all connections are tight. 5. Check: • no continuity tip • if there is no continuity, clean the terminals. • when ch...

Page 27

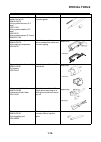

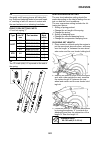

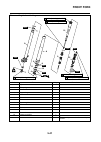

Special tools 1-13 eas2gc1028 special tools the following special tools are required for accurate and complete adjustment and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques. The shape and tool number used for the special...

Page 28

Special tools 1-14 radiator cap tester 90890-01325 mityvac cooling system tester kit yu-24460-a this tool is used to check the radiator and the radiator cap. Radiator cap tester adapter 90890-01352 pressure tester adapter yu-33984 this tool is used to check the radiator and the radiator cap. Steerin...

Page 29

Special tools 1-15 pocket tester 90890-03112 analog pocket tester yu-03112-c this tool is used to measure the voltage, current, and re- sistance of electrical compo- nents. Timing light 90890-03141 timing light yu-03141 this tool is used to measure the ignition timing. Pressure gauge 90890-03153 pre...

Page 30

Special tools 1-16 valve guide remover & in- staller set (ø5.5) 90890-04016 valve guide remover (5.5 mm) ym-01122 valve guide installer (5.5 mm) ym-04015 valve guide reamer (5.5 mm) 90890-01196 this tool is used to replace the valve guide. Valve spring compressor 90890-04019 valve spring compressor ...

Page 31

Special tools 1-17 valve spring compressor at- tachment 90890-04108 valve spring compressor adapter 22 mm ym-04108 this tool is used to discon- nect or connect the valve and the valve spring. Rotor puller 90890-04142 rotor puller ym-04142 this tool is used to remove the rotor. Crankcase separating t...

Page 32

Control functions 1-18 eas2gc1029 control functions eas2gc1030 indicator lights and warning lights fuel level warning light “ ” this warning light comes on when the fuel level drops below approximately 1.6 l (0.42 us gal, 0.35 imp.Gal). When this occurs, refuel as soon as possible. The electrical ci...

Page 33

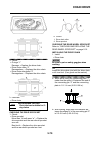

Control functions 1-19 eas2gc1034 shift pedal the shift pedal “1” has adopted a method of 1 down & 4 ups (press-down & kick-ups). Press it down for n (neutral) to 1st, and kick it up for 2nd to 5th. Recommended shift points the recommended shift points during accelera- tion and deceleration are show...

Page 34

Control functions 1-20 eas2gc1039 sidestand this sidestand “1” is used to support only the machine when standing or transporting it. Ewa warning • never apply additional force to the sides- tand. • hold up the sidestand before starting out. Eas2gc1040 starter knob/idle screw starting a cold engine r...

Page 35

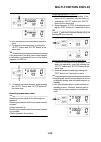

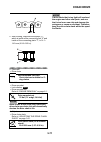

Multi-function display 1-21 eas2gc1042 multi-function display ewa warning be sure to stop the machine before making any setting changes to the multi-function display. The multi-function display is equipped with the following: basic mode: • speedometer • clock • two tripmeters (which shows the distan...

Page 36

Multi-function display 1-22 4. To end the setting, push the “rst” button for 2 seconds or more. Tip • in a 30-second absence of button operation, the setting will come to an end with the indi- cated time. • to reset the seconds, push the “slct1” but- ton or “slct2” button. Changing odometer and trip...

Page 37

Multi-function display 1-23 returning to basic mode from race mode tip it is possible to return to basic mode with tim- er measurement at a stop. 1. Check that the timer is not in operation. If the timer is in operation, stop the timer by push- ing the “slct1” button and “slct2” button at the same t...

Page 38

Multi-function display 1-24 3. Run the machine and start timer measure- ment. 4. To stop timer measurement, pushing the “slct1” button and “slct2” button at the same time. Tip if the machine is run while timer measurement is not made, no change will occur to the digit in tripmeter a (trip a). 5. To ...

Page 39

Multi-function display 1-25 correcting tripmeter a (trip a) 1. Change the travel distance display by push- ing the “slct1” button (plus) or “slct2” button (minus). A long push on the button will fast-forward the change. Tip change can be made any time while timer measurement is or is not being made..

Page 40

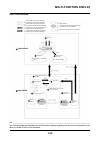

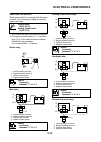

Multi-function display 1-26 eas2gc1047 function diagram tip the following diagram illustrates the multi-function display regarding the direction and operation con- dition involved in each of its functions. A short push on the button changes the operation in the arrowed direction. A short push on the...

Page 41

Multi-function display 1-27 a. A short push on the button changes the op- eration in the arrowed direction. B. A short push on the button changes the op- eration in both arrowed directions. C. A long push on the button changes the oper- ation in the arrowed direction. D. A long push on the button ch...

Page 42

Starting and break-in 1-28 eas2gc1048 starting and break-in eas2gc1049 fuel always use the recommended fuel as stated below. Also, be sure to use new gasoline the day of a race. Eca notice use only unleaded gasoline. The use of leaded gasoline will cause severe damage to the engine internal parts su...

Page 43

Starting and break-in 1-29 eca notice if the starter motor will not turn when the start switch is pushed, stop pushing it im- mediately in order to avoid placing extra load on the starter motor, and start the en- gine by using the kickstarter. Tip if the engine fails to start, push the engine stop s...

Page 44

Starting and break-in 1-30 eas2gc1053 starting a warm engine follow the same procedure as for starting a cold engine with the exception that the starter is not required when the engine is warm. Tip if it fails to start, fully open the throttle grip and give 10 to 20 slow kicks to clear the engine of...

Page 45

Maintenance after break-in 1-31 eas2gc1055 maintenance after break-in after a break-in, perform careful maintenance to get ready for the next practice or race. Refer to “pre-operation inspection and maintenance” on page 3-9. Eas2gc1056 major maintenance 1. For the engine • leaks around the engine ch...

Page 46

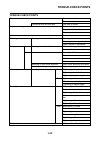

Torque-check points 1-32 eas2gc1057 torque-check points frame construction frame to rear frame frame to engine protector combined seat and fuel tank fuel tank to frame engine mounting frame to engine engine bracket to engine engine bracket to frame seat seat to frame steering steering stem to handle...

Page 47

Torque-check points 1-33 tip concerning the tightening torque, refer to “tightening torques” on page 2-12. Fuel system fuel pump to fuel tank fuel sender to fuel tank plastic cover tightening of front fender tightening of fork leg protector tightening of air scoop left cover to rear frame tightening...

Page 48

Motorcycle care and storage 1-34 eas2gc1058 motorcycle care and stor- age eas2gc1059 care while the open design of a motorcycle reveals the attractiveness of the technology, it also makes it more vulnerable. Rust and corrosion can develop even if high-quality components are used. A rusty exhaust pip...

Page 49

Motorcycle care and storage 1-35 2. Apply a corrosion protection spray on all metal, including chrome- and nickel-plated, surfaces to prevent corrosion. After cleaning 1. Dry the motorcycle with a chamois or an ab- sorbing cloth. 2. Immediately dry the drive chain and lubri- cate it to prevent it fr...

Page 50

Motorcycle care and storage 1-36 e. Remove the spark plug cap from the spark plug, and then install the spark plug and the spark plug cap. Warning! To prevent damage or injury from sparking, make sure to ground the spark plug electrodes while turning the engine over. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 51

2 specifications general specifications .........................................................................2-1 engine specifications .............................................................................2-2 chassis specifications ............................................................

Page 52

General specifications 2-1 eas2gc1061 general specifications model model 2gc1 (usa) 2gc2 (can) 2gc3 (eur) 2gc4, 2gc5 (aus) (nzl) (zaf) dimensions overall length 2165 mm (85.2 in) overall width 825 mm (32.5 in) overall height 1280 mm (50.4 in) seat height 965 mm (38.0 in) wheelbase 1465 mm (57.7 in) ...

Page 53

Engine specifications 2-2 eas2gc1062 engine specifications engine engine type liquid cooled 4-stroke, dohc displacement 449 cm 3 number of cylinders single cylinder bore stroke 97.0 60.8 mm (3.82 2.39 in) compression ratio 12.5:1 starting system electric starter and kickstarter fuel recommended fuel...

Page 54

Engine specifications 2-3 cylinder head combustion chamber volume 25.98–26.78 cm 3 (1.59–1.63 cu.In) warpage limit 0.05 mm (0.0020 in) camshaft drive system chain drive (left) camshaft cap inside diameter 22.000–22.021 mm (0.8661–0.8670 in) camshaft journal diameter 21.959–21.972 mm (0.8645–0.8650 i...

Page 55

Engine specifications 2-4 valve spring free length (intake) 40.76 mm (1.60 in) limit 38.72 mm (1.52 in) free length (exhaust) 36.94 mm (1.45 in) limit 35.09 mm (1.38 in) installed length (intake) 34.78 mm (1.37 in) installed length (exhaust) 30.83 mm (1.21 in) spring rate k1 (intake) 31.90 n/mm (3.2...

Page 56

Engine specifications 2-5 crankshaft crank assembly width 61.93–62.00 mm (2.438–2.441 in) runout limit 0.030 mm (0.0012 in) big end side clearance 0.150–0.450 mm (0.0059–0.0177 in) balancer balancer drive method gear clutch clutch type wet, multiple-disc clutch release method inner push, cam push cl...

Page 57

Engine specifications 2-6 fuel pump pump type electrical fuel injector model/quantity 1010/1 resistance 12 throttle body type/quantity 30ra-a05u/1 id mark 2gc1 00 fuel line pressure (at idle) 300.0–390.0 kpa (3.00–3.90 kgf/cm 2 , 43.5– 56.6 psi) throttle position sensor resistance 6.30 k output volt...

Page 58

Chassis specifications 2-7 eas2gc1063 chassis specifications chassis frame type semi double cradle caster angle 26.2 ° trail 114 mm (4.5 in) front wheel wheel type spoke wheel rim size 1.6 21 rim material aluminum wheel travel 310 mm (12.2 in) radial wheel runout limit 2.0 mm (0.08 in) lateral wheel...

Page 59

Chassis specifications 2-8 rear brake type hydraulic single disc brake operation right foot operation brake pedal position 5.0 mm (0.20 in) rear disc brake disc outside diameter thickness 245.0 4.0 mm (9.65 0.16 in) brake disc thickness limit 3.5 mm (0.14 in) brake disc runout limit (as measured on ...

Page 60

Chassis specifications 2-9 rear suspension type swingarm (link suspension) spring/shock absorber type coil spring/gas-hydraulic damper rear shock absorber assembly travel 126.0 mm (4.96 in) spring free length 275.0 mm (10.83 in) spring installed length 263.0 mm (10.35 in) spring rate k1 56.00 n/mm (...

Page 61

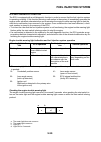

Electrical specifications 2-10 eas2gc1064 electrical specifications voltage system voltage 12 v ignition system ignition system tci advancer type digital ignition timing (b.T.D.C.) 10.0 ° at 2000 r/min engine control unit model/manufacturer 2gc0/yamaha (usa) (can) 2gc1/yamaha (eur) (aus) (nzl) (zaf)...

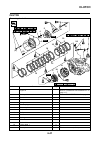

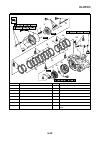

Page 62

Electrical specifications 2-11 starter motor power output 0.48 kw armature coil resistance 0.0117–0.0143 brush overall length 7.0 mm (0.28 in) limit 3.50 mm (0.14 in) brush spring force 3.92–5.88 n (400–600 gf, 14.11–21.17 oz) commutator diameter 17.6 mm (0.69 in) limit 16.6 mm (0.65 in) mica underc...

Page 63

Tightening torques 2-12 eas20320 tightening torques eas2gc1065 general tightening torque specifi- cations this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for spe- cial components or assemblies are provided for each c...

Page 64

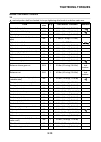

Tightening torques 2-13 eas2gc1066 engine tightening torques tip - marked portion shall be checked for torque tightening after break-in or before each race. Item thread size q’ty tightening torques remarks camshaft cap bolt m6 8 10 nm (1.0 m·kgf, 7.2 ft·lbf) cylinder head blind plug m12 1 28 nm (2.8...

Page 65

Tightening torques 2-14 throttle body joint clamp bolt m5 1 3.0 nm (0.30 m·kgf, 2.2 ft·lbf) air filter joint clamp bolt m4 1 3.5 nm (0.35 m·kgf, 2.5 ft·lbf) air filter case bolt m6 3 7 nm (0.7 m·kgf, 5.1 ft·lbf) air filter bolt m6 1 2.0 nm (0.20 m·kgf, 1.4 ft·lbf) air filter guide holder screw m5 8 ...

Page 66

Tightening torques 2-15 tip *1:cylinder head bolt first, tighten the cylinder head bolts to 30 nm (3.0 m·kgf, 22 ft·lbf) in the proper tightening sequence and remove them. Retighten the cylinder head bolts to 20 nm (2.0 m·kgf, 14 ft·lbf) in the proper tight- ening sequence, and then tighten the cyli...

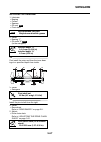

Page 67

Tightening torques 2-16 tip *2:exhaust pipe nut first temporarily tighten all nuts to 7 nm (0.7 m·kgf, 5.1 ft·lbf). Then retighten them to 10 nm (1.0 m·kgf, 7.2 ft·lbf). 1 4 2 3 x4 fwd.

Page 68

Tightening torques 2-17 eas2gc1067 chassis tightening torques tip - marked portion shall be checked for torque tightening after break-in or before each race. Item thread size q’ty tightening torques remarks outer tube and upper bracket bolt m8 4 21 nm (2.1 m·kgf, 15 ft·lbf) outer tube and lower brac...

Page 69

Tightening torques 2-18 front brake disc bolt m6 6 12 nm (1.2 m·kgf, 8.7 ft·lbf) rear brake disc bolt m6 6 14 nm (1.4 m·kgf, 10 ft·lbf) footrest bracket bolt m10 4 55 nm (5.5 m·kgf, 40 ft·lbf) sidestand bolt m10 1 25 nm (2.5 m·kgf, 18 ft·lbf) rear brake pedal bolt m8 1 26 nm (2.6 m·kgf, 19 ft·lbf) r...

Page 70

Tightening torques 2-19 drive chain tensioner bolt (lower side) m8 1 16 nm (1.6 m·kgf, 12 ft·lbf) drive chain support bolt m6 1 7 nm (0.7 m·kgf, 5.1 ft·lbf) drive chain support nut m6 2 7 nm (0.7 m·kgf, 5.1 ft·lbf) drive chain guide bolt m5 3 4.0 nm (0.40 m·kgf, 2.9 ft·lbf) rear frame and left cover...

Page 71

Tightening torques 2-20 tip lower ring nut 1. First, tighten the lower ring nut approximately 38 nm (3.8 m·kgf, 27 ft·lbf) by using the steering nut wrench, then loosen the lower ring nut one turn. 2. Retighten the lower ring nut 7 nm (0.7 m·kgf, 5.1 ft·lbf). Starter relay and starter motor lead bol...

Page 72

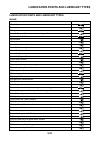

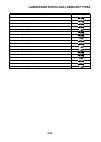

Lubrication points and lubricant types 2-21 eas2gc1068 lubrication points and lubricant types eas2gc1069 engine lubrication point lubricant types oil seal lips bearing o-ring camshaft cap bolt threads and contacting surface cylinder head bolt threads, seats, washers valve stems valve stem ends valve...

Page 73

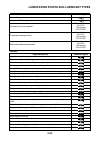

Lubrication points and lubricant types 2-22 eas2gc1070 chassis starter idle gear inner surface, thrust surfaces starter clutch drive gear inner surface, thrust surfaces cylinder head cover gasket yamaha bond no.1215 (three bond no.1215®) crankcase mating surface yamaha bond no.1215 (three bond no.12...

Page 74

Lubrication points and lubricant types 2-23 clutch lever sliding surface and bolt outer surface clutch lever adjuster rubber lip clutch cable end (clutch lever side) tube guide (throttle grip) inner surface and throttle cable end front brake caliper piston front brake caliper piston seal front brake...

Page 75

Lubrication points and lubricant types 2-24 eas2gc1071.

Page 76

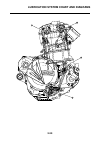

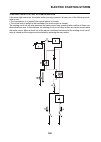

Lubrication system chart and diagrams 2-25 lubrication system chart and diagrams eas2gc1072 lubrication diagrams.

Page 77

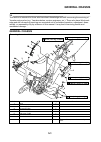

Lubrication system chart and diagrams 2-26 1. Intake camshaft 2. Exhaust camshaft 3. Piston 4. Oil nozzle 5. Oil filter element 6. Oil pump 7. Oil strainer 8. Crankshaft 9. Drive axle 10. Main axle.

Page 78

Lubrication system chart and diagrams 2-27.

Page 79

Lubrication system chart and diagrams 2-28 1. Connecting rod 2. Crankshaft 3. Main axle 4. Oil strainer 5. Drive axle.

Page 80

Lubrication system chart and diagrams 2-29.

Page 81

Lubrication system chart and diagrams 2-30 1. Exhaust camshaft 2. Intake camshaft 3. Oil filter element 4. Oil pump.

Page 82

Lubrication system chart and diagrams 2-31.

Page 83

Lubrication system chart and diagrams 2-32 1. Camshaft 2. Oil pressure check bolt 3. Oil filter element 4. Oil pump.

Page 84

Cable routing diagram 2-33 eas2gc1073 cable routing diagram.

Page 85

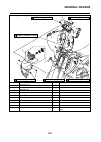

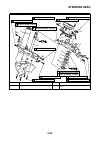

Cable routing diagram 2-34 1. Clutch cable 2. Throttle cable (return) 3. Throttle cable (pull) 4. Engine stop switch lead 5. Coupler for connecting optional part 6. Engine stop switch coupler 7. Rectifier/regulator coupler 8. Ac magneto lead 9. Starter knob/idle screw 10. Engine ground sub-lead 11. ...

Page 86

Cable routing diagram 2-35.

Page 87

Cable routing diagram 2-36 1. Clamp 2. Throttle position sensor lead 3. Joint coupler 4. Intake air temperature sensor lead 5. Intake air pressure sensor lead 6. Wire harness 7. Injector lead 8. Injector coupler 9. Throttle body 10. Cylinder head breather hose 11. Engine ground sub-lead 12. Plate 13...

Page 88

Cable routing diagram 2-37.

Page 89

Cable routing diagram 2-38 1. Cable guide 2. Speed sensor lead 3. Joint coupler 4. Ground lead 5. Throttle position sensor lead 6. Throttle position sensor coupler 7. Radiator breather hose 8. Radiator hose 9. Fuel hose 10. Coolant temperature sensor coupler 11. Radiator fan motor lead 12. Intake ai...

Page 90

Cable routing diagram 2-39.

Page 91

Cable routing diagram 2-40 1. Battery negative lead 2. Fuel hose 3. Fuel pump coupler 4. Fuel pump lead 5. Resistor 6. Resistor coupler 7. Battery positive lead 8. Lean angle sensor 9. Starter motor lead 10. Radiator fan motor relay (blue tape) 11. Main relay (red tape) 12. Wire harness 13. Ground l...

Page 92

Cable routing diagram 2-41.

Page 93

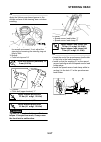

Cable routing diagram 2-42 1. Clutch switch lead 2. Engine stop switch lead 3. Clutch cable 4. Brake hose guide 5. Headlight lead 6. Speed sensor lead 7. Indicator light coupler 8. Meter assembly optional switch coupler 9. Meter assembly coupler 10. Speed sensor coupler 11. Start switch lead 12. Pla...

Page 94

Cable routing diagram 2-43.

Page 95

Cable routing diagram 2-44 1. Brake master cylinder 2. Brake hose holder 3. Brake hoses a. While installing the brake hose, direct a bend in its pipe portion as shown, and bring it into contact with the projection on the brake caliper. B. Pass the brake hose into the brake hose holders. C. If the br...

Page 96

Cable routing diagram 2-45.

Page 97

3 periodic checks and adjustments periodic maintenance .............................................................................3-1 introduction ........................................................................................3-1 periodic maintenance chart for the emission control system ...

Page 98

Adjusting the rear shock absorber assembly...................3-34 checking the tires...........................................................................3-36 checking and tightening the spokes.......................................3-36 checking the wheels .........................................

Page 99

Periodic maintenance 3-1 eas2gc1074 periodic maintenance eas2gc1075 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and ...

Page 100

Periodic maintenance 3-2 eas2gc1077 general maintenance and lubrication chart no. Item checks and maintenance jobs initial odometer read- ings 600 mi (1000 km) or 1 month 1800 mi (3000 km) or 3 months 3000 mi (5000 km) or 6 months 1 clutch • check operation. • adjust or replace cable. 2 * cooling sy...

Page 101

Periodic maintenance 3-3 tip • the air filter needs more frequent service if you are riding in unusually wet or dusty areas. • hydraulic brake service • after disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reservoir...

Page 102

Periodic maintenance 3-4 eas2gc1078 maintenance intervals for competition use tip • the following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as weather, terrain, geographical location, and individual usage will alter the re- quired maintena...

Page 103

Periodic maintenance 3-5 piston pin inspect replace cylinder head inspect carbon deposits and eliminate them. Inspect and clean change gasket. Cylinder inspect and clean inspect score marks. Inspect wear. Replace clutch inspect and adjust inspect housing, friction plate, clutch plate and spring. Rep...

Page 104

Periodic maintenance 3-6 cooling system check coolant lev- el and leakage check radiator cap operation replace coolant every two years inspect hoses outside nuts and bolts retighten refer to “starting and break-in” on page 1-28. Air filter clean and lubri- cate use yamaha foam air filter oil or othe...

Page 105

Periodic maintenance 3-7 brakes adjust lever posi- tion and pedal height lubricate pivot point check brake disc surface check fluid level and leakage retighten brake disc bolts, caliper bolts, master cylin- der bolts and union bolts replace pads replace brake flu- id every one year front forks inspe...

Page 106

Periodic maintenance 3-8 swingarm inspect, lube and retighten molybdenum disulfide grease relay arm, con- necting rod inspect, lube and retighten molybdenum disulfide grease sidestand lubricate lithium-soap-based grease steering head inspect free play and retighten clean and lube lithium-soap-based ...

Page 107

Pre-operation inspection and maintenance 3-9 eas2gc1079 pre-operation inspection and maintenance before riding for break-in operation, practice or a race, make sure the machine is in good operating condition. Before using this machine, check the following points. Eas2gc1080 general inspection and ma...

Page 108

Engine 3-10 eas2gc1081 engine eas2gc1082 checking the coolant level ewa warning if coolant seems hot, do not remove the ra- diator cap. 1. Stand the vehicle upright on a level surface. 2. Remove: • radiator cap “1” 3. Check: • coolant level maximum level “a” or below add coolant up to the maximum le...

Page 109

Engine 3-11 3. Remove: • radiator cap slowly loosen the radiator cap to drain cool- ant. Tip when the radiator cap is loosened, coolant will gush out transversely; therefore, bring the con- tainer near to the outlet. 4. Thoroughly flush the cooling system with clean tap water. 5. Install: • copper w...

Page 110

Engine 3-12 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2gc1087 checking the coolant circulatory system for leaks 1. Check: • coolant level 2. Install: • radiator cap tester “1” • adapter “2” 3. Activate the tester to apply the test pressure. Eca notice • do not apply such a high pressure as ex- ceeds the t...

Page 111

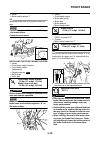

Engine 3-13 2. Adjust: • clutch lever free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ handlebar side a. Turn the adjuster “1” in direction “a” or “b” until the specified clutch lever free play is ob- tained. Tip if the clutch lever free play cannot be obtained on the handlebar side, use the adjuster on t...

Page 112

Engine 3-14 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2gc1090 lubricating the throttle cable 1. Remove: • cover (throttle cable cap) “1” • cover (grip cap) “2” • throttle grip cap “3” 2. Lubricate: • throttle cable end “a” 3. Install: • throttle grip cap • screw (throttle grip cap) 4. Install: • cover (gr...

Page 113

Engine 3-15 notice do not twist the element when squeezing the element. 4. Check: • air filter element damage replace. 5. Yamaha foam air filter oil or other quality foam air filter oil. Tip squeeze out the excess oil. Element should be wet but not dripping. 6. Install: • air filter guide “1” (to th...

Page 114

Engine 3-16 3. Check: • tightening torques 4. Install: • exhaust pipe protector eas2gc1095 checking the fuel line 1. Remove: • seat • side cover (left/right) • air scoop (left/right) refer to “general chassis” on page 5- 1. • fuel tank refer to “fuel tank” on page 8-1. 2. Check: • fuel hose “1” crac...

Page 115

Engine 3-17 notice • since engine oil also lubricates the clutch, the wrong oil types or additives could cause clutch slippage. Therefore, do not add any chemical additives. • do not allow foreign material to enter the crankcase. Eas2gc1097 changing the engine oil stand the vehicle upright on a leve...

Page 116

Engine 3-18 c. Replace the o-ring “2”. D. Install the oil strainer. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 6. Install: • gasket • drain bolt 7. Pour the specified amount of engine oil into the oil filler cap hole. 8. Install: • oil filler cap 9. Check: • oil level refer to “checking the engine oil level” ...

Page 117

Engine 3-19 eas2gc1098 adjusting the engine idling speed tip • because the air pressure is lower at high alti- tudes, the air-fuel mixture will become richer. If the idling speed is low, turn the starter knob/ idle screw a few clicks counterclockwise to in- crease the speed before the adjustment. • ...

Page 118

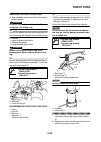

Engine 3-20 eas2gc1099 adjusting the valve clearance tip • this section is intended for those who have basic knowledge and skill concerning the ser- vicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowledge and skill concerning ser- vicing are requ...

Page 119

Engine 3-21 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Adjust: • valve clearance ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the camshaft (intake and exhaust). Refer to “camshaft” on page 6-11. B. Remove the valve lifter “2” and the adjusting pad “3” with a valve lapper “1”. Tip • place a cloth in the timin...

Page 120

Engine 3-22 e. Install the new adjusting pads “4” and the valve lifters “5”. Eca notice do not twist adjusting pads and valve lifters forcibly during installation. Tip • apply the engine oil on the valve lifters. • apply molybdenum disulfide oil to the valve stem ends. • check that the valve lifters...

Page 121

Engine 3-23 intake example: valve clearance (cold) 0.13–0.20 mm (0.0051–0.0079 in) installed is 175 measured clearance 0.27 mm (0.0106 in) replace 175 pad with 185 pad pad no.175 = 1.75 mm (0.0689 in) pad no.185 = 1.85 mm (0.0728 in) 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 20...

Page 122

Engine 3-24 exhaust example: valve clearance (cold) 0.18–0.25 mm (0.0071–0.0098 in) installed is 175 measured clearance 0.32 mm (0.0126 in) replace 175 pad with 185 pad pad no.175 = 1.75 mm (0.0689 in) pad no.185 = 1.85 mm (0.0728 in) eas2gc1100 cleaning the spark arrester refer to “cleaning the spa...

Page 123

Chassis 3-25 eas2gc1101 chassis eas2gc1102 bleeding the brake system ewa warning bleed the brake system whenever: • the system is disassembled. • a brake hose is loosened, disconnected, or replaced. • the brake fluid level is very low. • brake operation is faulty. 1. Remove: • brake master cylinder ...

Page 124

Chassis 3-26 eas2gc1103 checking the brake hose 1. Check: • brake hose “1” cracks/damage/wear replace. 2. Check: • brake hose clamp loose connection tighten the clamp bolt. 3. Stand the vehicle upright and apply the front brake and the rear brake several times. 4. Check: • brake hoses brake fluid le...

Page 125

Chassis 3-27 eas2gc1105 adjusting the rear brake 1. Check: • brake pedal position “a” (distance from the top of the rider footrest to the top of the brake pedal) out of specification regulate. 2. Adjust: • brake pedal position ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Loosen the locknut “1”. B. Turn the a...

Page 126

Chassis 3-28 c. Remove the brake caliper “3” from the front fork. D. Remove the pad pin and brake pads “4”. E. Connect the plastic hose “5” to the bleed screw “6” and place a container under the end of the plastic hose. F. Loosen the bleed screw and push the brake caliper piston in. Ewa warning do n...

Page 127

Chassis 3-29 eas2gc1107 checking the rear brake pads 1. Measure: • brake pad thickness “a” out of specification replace as a set. Tip the pads worn up to the indicator “b” grooves mean that the brake pad thickness limit is reached. 2. Replace: • brake pads ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove ...

Page 128

Chassis 3-30 i. Install the brake caliper “12” and the rear wheel “13”. Refer to “rear wheel” on page 5-9. J. Tighten the pad pin “14”. K. Install the pad pin plug “15” and the protector “16”. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Check: • brake fluid level refer to “checking the brake fluid level” on...

Page 129

Chassis 3-31 • when refilling, be careful that water does not enter the brake fluid reservoir. Water will significantly lower the boiling point of the brake fluid and could cause vapor lock. Eca notice brake fluid may damage painted surfaces and plastic parts. Therefore, always clean up any spilt br...

Page 130

Chassis 3-32 3. Hold the vehicle upright and apply the front brake. 4. Check: • front fork operation push down hard on the handlebar several times and check if the front fork rebounds smoothly. Unsmooth operation correct or replace. Refer to “front fork” on page 5-40. Eas2gc1112 checking the front f...

Page 131

Chassis 3-33 3. Tighten: • air bleed screw eas2gc1115 adjusting the front fork legs ewa warning • always adjust the left and right front forks evenly. If this is not done, the vehicle may have poor stability. • securely support the vehicle so that there is no danger of it falling over. Rebound dampi...

Page 132

Chassis 3-34 eas2gc1116 checking the swingarm operation 1. Check: • swingarm smooth action • swingarm free play refer to “swingarm” on page 5-65. Eas2gc1117 checking the rear suspension 1. Stand the vehicle upright on a level surface. Ewa warning securely support the vehicle so that there is no dang...

Page 133

Chassis 3-35 tip • be sure to remove all dirt and mud from around the locknut and adjusting ring before adjustment. • the length of the spring (installed) changes 1.5 mm (0.06 in) per turn of the adjusting ring. E. Tighten the locknut. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Install: • rear frame refer ...

Page 134

Chassis 3-36 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ compression damping (for slow compres- sion damping) eca notice do not turn the adjuster forcibly beyond its adjusting range. 1. Adjust: • compression damping (for slow compres- sion damping) ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the adjuster “1” in t...

Page 135

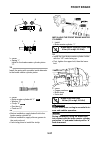

Chassis 3-37 2. Tighten: • spokes use a spoke nipple wrench “1” for tighten- ing. Tip • do not give a half turn (180 °) or more for one tightening. • make sure that tightening after a break-in is done until the initial looseness in nipples dis- appears. • make sure that tightening is done in stages,...

Page 136

Chassis 3-38 c. Turn the front fork to the right and left a few times, and make sure that the steering ro- tates smoothly. If it does not turn smoothly, remove the lower bracket and check the up- per and lower bearings. Refer to “steering head” on page 5-53. D. Loosen the ring nut fully turn and the...

Page 137

Chassis 3-39 eas2gc1127 lubricating the drive chain the drive chain consists of many interacting parts. If the drive chain is not maintained prop- erly, it will wear out quickly. Therefore, the drive chain should be serviced, especially when the vehicle is used in dusty areas. This vehicle has a dri...

Page 138

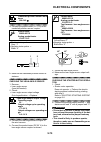

Electrical system 3-40 eas2gc1130 electrical system eas2gc1131 checking the spark plug 1. Remove: • seat • air scoop (left/right) refer to “general chassis” on page 5- 1. • fuel tank “1” refer to “fuel tank” on page 8-1. Eca notice do not use too much force to pull the hose. Tip remove the fuel tank...

Page 139

Electrical system 3-41 2. Attach: • timing light “1” • digital tachometer “2” to the high tension code “3”. 3. Adjust: • engine idling speed refer to “adjusting the engine idling speed” on page 3-19. 4. Check: • ignition timing check whether the alignment mark “a” on the left crankcase cover is with...

Page 140

Electrical system 3-42 4. Install: • headlight bulb fasten the new headlight bulb with the headlight bulb holder. Eca notice avoid touching the glass part of the head- light bulb to keep it free from oil, otherwise the transparency of the glass, the life of the bulb and the luminous flux will be adv...

Page 141

4 tuning chassis ..........................................................................................................4-1 selection of the secondary reduction ratio (sprocket) ............................................................................................4-1 drive and rear wheel sp...

Page 142

Chassis 4-1 eas2gc1136 chassis eas2gc1137 selection of the secondary reduc- tion ratio (sprocket) reduction ratio> • it is generally said that the secondary gear ra- tio should be reduced for a longer straight por- tion of a speed course and should be increased for a course with many corners. Ac- tu...

Page 143

Chassis 4-2 • under a stony or a hard road condition, the tire pressure should be higher to prevent a flat tire. Eas2gc1140 front fork setting the front fork setting should be made depend- ing on the rider’s feeling of an actual run and the circuit conditions. The front fork setting includes the fol...

Page 144

Chassis 4-3 tip generally a stiff spring gives a stiff riding feel- ing. Rebound damping tends to become weak- er, resulting in lack of a sense of contact with the road surface or in a vibrating handlebar. Eas2gc1143 front fork setting parts • front fork spring “1” tip the i.D. Mark (slits) “a” is p...

Page 145

Chassis 4-4 tip • if the machine is new and after it is broken in, the same set length of the spring may change because of the initial fatigue, etc. Of the spring. Therefore, be sure to make reevalua- tion. • if the standard figure cannot be achieved by adjusting the adjuster and changing the set le...

Page 146

Chassis 4-5 • spring preload adjusting positions tip for the spring preload adjustment, refer to “ad- justing the rear shock absorber assembly” on page 3-34. Spring preload adjusting positions minimum position in which the spring is turned in 1.5 mm (0.06 in) from its free length. Standard position ...

Page 147

Chassis 4-6 eas2gc1148 suspension setting (front fork) tip • if any of the following symptoms is experienced with the standard position as the base, make reset- ting by reference to the adjustment procedure given in the same chart. • before any change, set the rear shock absorber sunken length to th...

Page 148

Chassis 4-7 eas2gc1149 suspension setting (rear shock absorber) tip • if any of the following symptoms is experienced with the standard position as the base, make reset- ting by reference to the adjustment procedure given in the same chart. • adjust the rebound damping in 2-click increments or decre...

Page 149

Chassis 4-8 heavy and dragging rebound damping force turn adjuster counterclock- wise (about 2 clicks) to de- crease damping. Spring replace with soft spring. Poor road grip- ping rebound damping force turn adjuster counterclock- wise (about 2 clicks) to de- crease damping. Low compres- sion damping...

Page 150

Chassis 4-9.

Page 151

5 chassis general chassis ........................................................................................5-1 removing the left side cover.......................................................5-3 removing the seat ................................................................................

Page 152

Handlebar .................................................................................................5-33 removing the handlebar...............................................................5-35 checking the handlebar ...............................................................5-35 install...

Page 153

General chassis 5-1 eas2gc1150 tip this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowl- edge and skill concerning servicing are requested not to undertake ins...

Page 154

General chassis 5-2 removing the headlight assembly and multi-function meter order job/parts to remove q’ty remarks 1 headlight body 1 2 headlight coupler 1 disconnect. 3 headlight unit 1 4 speed sensor coupler 1 disconnect. 5 multi-function meter coupler 2 disconnect. 6 multi-function meter optiona...

Page 155

General chassis 5-3 eas2gc1152 removing the left side cover 1. Remove: • bolt (side cover) • side cover “1” tip draw the left side cover “1” backward to re- move it because its projection “a” is inserted in the rear frame. Eas2gc1153 removing the seat tip the fuel tank cap cover and the seat are cou...

Page 156

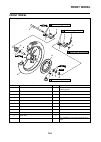

Front wheel 5-4 eas2gc1154 front wheel removing the front wheel order part name q’ty remarks use a suitable stand to raise the front wheel off the ground. 1 front wheel axle pinch bolt 4 loosen. 2 front wheel axle nut 1 3 front wheel axle 1 4 front wheel 1 5 speed sensor 1 6 collar 1 7 oil seal 1 8 ...

Page 157

Front wheel 5-5 eas2gc1155 removing the front wheel 1. Use a suitable stand to raise the front wheel off the ground. Ewa warning securely support the vehicle so that there is no danger of it falling over. 2. Remove: • front wheel eas2gc1156 checking the front wheel 1. Check: • front wheel axle roll ...

Page 158

Front wheel 5-6 eas2gc1157 disassembling the front wheel 1. Remove: • oil seals • bearings ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Clean the outside of the front wheel hub. B. Remove the oil seals “1” with a flat-head screwdriver. Tip to prevent damaging the wheel, place a rag “2” between the screwdrive...

Page 159

Front wheel 5-7 3. Install: • collar “1” tip apply the lithium-soap-based grease on the oil seal lip. 4. Install: • speed sensor “1” tip apply the lithium-soap-based grease on the oil seal lip of speed sensor. Make sure the two projections “a” in the wheel hub are meshed with the two slots “b” in th...

Page 160

Front wheel 5-8 1 1.

Page 161

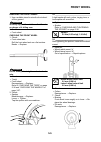

Rear wheel 5-9 eas2gc1160 rear wheel removing the rear wheel order part name q’ty remarks use a suitable stand to raise the rear wheel off the ground. 1 nut (rear wheel axle) 1 2 rear wheel axle 1 3 drive chain puller 2 4 rear wheel 1 5 collars 2 6 rear wheel sprocket 1 7 oil seals 2 8 circlip 1 9 b...

Page 162

Rear wheel 5-10 eas2gc1161 removing the rear wheel 1. Use a suitable stand to raise the rear wheel off the ground. Ewa warning securely support the vehicle so that there is no danger of it falling over. 2. Remove: • rear wheel axle nut “1” 3. Loosen: • locknut “2” 4. Tighten: • adjusting bolt “3” 5....

Page 163

Rear wheel 5-11 tip tighten the self-locking nuts in stages and in a crisscross pattern. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2gc1165 assembling the rear wheel 1. Install: • bearing (right side) “1” • circlip “2” • spacer “3” • bearing (left side) “4” • oil seals “5” tip • apply the lithium-soap-base...

Page 164

Rear wheel 5-12 tip install the brake disc “1” between the brake pads “2” correctly. 2. Install: • drive chain “1” tip push the rear wheel “2” forward and install the drive chain. 3. Install: • left drive chain puller “1” • rear wheel axle “2” tip • install the left drive chain puller, and insert th...

Page 165

Front brake 5-13 eas2gc1167 front brake removing the front brake caliper order part name q’ty remarks brake fluid drain. Refer to “bleeding the brake system” on page 3-25. 1 union bolt 1 2 copper washers 2 3 front brake hose 1 4 brake pad pin plug 1 5 brake pad pin 1 6 brake pads 2 7 brake pad sprin...

Page 166

Front brake 5-14 disassembling the front brake caliper order part name q’ty remarks 1 brake caliper piston 2 2 brake caliper piston dust seal 2 3 brake caliper piston seal 2 4 bleed screw 1 for assembly, reverse the disassemble pro- cedure. 1 2 3 4 s s bf bf t r . . S 6 nm (0.6 m kgf, 4.3 ft ibf).

Page 167

Front brake 5-15 removing the front brake master cylinder order part name q’ty remarks brake fluid drain. Refer to “bleeding the brake system” on page 3-25. 1 brake lever 1 2 union bolt 1 3 copper washers 2 4 front brake hose 1 5 brake master cylinder reservoir cap 1 6 brake master cylinder reservoi...

Page 168

Front brake 5-16 disassembling the front brake master cylinder order part name q’ty remarks 1 push rod 1 2 dust boot 1 3 circlip 1 4 washer 1 5 brake master cylinder kit 1 for assembly, reverse the disassemble pro- cedure. Bf 5 4 3 2 1 s new new.

Page 169

Front brake 5-17 eas2gc1168 introduction ewa warning if you need to disassemble the disc brake components, observe the following precau- tions. • never disassemble the brake components unless absolutely necessary. • if there is any problem with connections on the hydraulic brake system, perform the ...

Page 170

Front brake 5-18 b. Remove the brake caliper piston dust seal and the brake caliper piston seal. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2gc1172 checking the front brake caliper 1. Check: • brake caliper piston “1” rust/scratches/wear replace the brake caliper piston. • brake caliper cylinder “2” scratc...

Page 171

Front brake 5-19 3. Install: • brake caliper piston “1” tip apply the brake fluid on the piston outer sur- face. Eca notice • install the piston with its side “a” facing the brake caliper. • never force to insert. Eas2gc1175 installing the front brake caliper 1. Install: • front brake caliper bracke...

Page 172

Front brake 5-20 notice brake fluid may damage painted surfaces and plastic parts. Therefore, always clean up any spilt brake fluid immediately. 5. Bleed: • brake system refer to “bleeding the brake sys- tem” on page 3-25. 6. Check: • brake fluid level the minimum level mark or below add. Refer to “...

Page 173

Front brake 5-21 3. Install: • spring “1” install to the brake master cylinder piston “2”. Tip install the spring with a smaller inside diameter to the brake master cylinder piston. 4. Install: • brake master cylinder kit “1” • washer “2” • circlip “3” • dust boot “4” • push rod “5” tip • before ins...

Page 174

Front brake 5-22 tip turn the handlebar toward right and left to make sure that the brake hose does not touch other parts (e.G., wire harness, cables, leads). Adjust if necessary. 3. Pour brake fluid to the brake master cylinder reservoir up to the specified level. Ewa warning • use only the designa...

Page 175

Rear brake 5-23 eas2gc1180 rear brake removing the rear brake caliper order part name q’ty remarks brake fluid drain. Refer to “bleeding the brake system” on page 3-25. 1 protector 1 2 union bolt 1 3 copper washers 2 4 rear brake hose 1 5 brake pad pin plug 1 6 brake pad pin 1 7 rear brake pad assem...

Page 176

Rear brake 5-24 disassembling the rear brake caliper order part name q’ty remarks 1 brake caliper piston 1 2 brake caliper piston dust seal 1 3 brake caliper piston seal 1 4 bleed screw 1 for assembly, reverse the disassemble pro- cedure. 1 2 3 4 s bf t r . . 6 nm (0.6 m kgf, 4.3 ft ibf).

Page 177

Rear brake 5-25 removing the rear brake master cylinder order part name q’ty remarks brake fluid drain. Refer to “bleeding the brake system” on page 3-25. 1 union bolt 1 2 copper washers 2 3 brake hose 1 4 split pin 1 5 washer 1 6 pin 1 7 brake master cylinder reservoir cap 1 8 brake master cylinder...

Page 178

Rear brake 5-26 disassembling the rear brake master cylinder order part name q’ty remarks 1 dust boot 1 2 circlip 1 3 push rod 1 4 brake master cylinder kit 1 for assembly, reverse the disassemble pro- cedure. 4 3 2 1 bf s new new.

Page 179

Rear brake 5-27 eas2gc1181 introduction ewa warning if you need to disassemble the disc brake components, observe the following precau- tions. • never disassemble the brake components unless absolutely necessary. • if there is any problem with connections on the hydraulic brake system, perform the f...

Page 180

Rear brake 5-28 eas2gc1183 removing the rear brake caliper tip before disassembling the brake caliper, drain the brake fluid from the entire brake system. 1. Remove: • union bolt • copper washers • brake hose tip put the end of the brake hose into a container and pump out the brake fluid. Eas2gc1184...

Page 181

Rear brake 5-29 eas2gc1187 installing the brake caliper piston 1. Clean: • brake caliper • brake caliper piston seal • brake caliper piston dust seal • brake caliper piston use brake fluid for cleaning. 2. Install: • brake caliper piston seals “1” • brake caliper piston dust seal “2” ewa warning alw...

Page 182

Rear brake 5-30 warning • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same type of brake fluid that is already in the system. Mixing brake flu- ids may result in a harmful chemical re...

Page 183

Rear brake 5-31 1. Wash the brake master cylinder and the brake master cylinder kit with brake fluid. 2. Install: • primary cylinder cup “1” • secondary cylinder cup “2” install to the brake master cylinder piston “3”. Ewa warning apply brake fluid to the cylinder cups and install them as shown. Wro...

Page 184

Rear brake 5-32 2. Pour brake fluid to the brake fluid reservoir up to the specified level. Ewa warning • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same type of brake fluid that is ...

Page 185

Handlebar 5-33 eas2gc1193 handlebar removing the handlebar order part name q’ty remarks 1 clutch cable 1 disconnect. 2 clutch switch 1 3 clutch lever holder 1 4 engine stop switch 1 5 brake master cylinder 1 6 throttle cable cap 1 7 throttle cable (pull) 1 disconnect. 8 throttle cable (return) 1 dis...

Page 186

Handlebar 5-34 15 handlebar lower holder 2 16 damper 4 for installation, reverse the removal proce- dure. Removing the handlebar order part name q’ty remarks.

Page 187

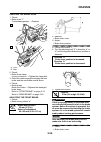

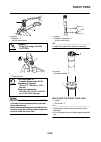

Handlebar 5-35 eas2gc1194 removing the handlebar 1. Stand the vehicle on a level surface. Ewa warning securely support the vehicle so that there is no danger of it falling over. 2. Remove: • clutch switch “1” tip press the projection, and remove it from the clutch lever assembly. 3. Remove: • handle...

Page 188

Handlebar 5-36 notice • first, tighten the bolts on the front side of the upper handlebar holder, and then on the rear side. • turn the handlebar all the way to the left and right. If there is any contact with the fuel tank, adjust the handlebar position. 3. Tighten: • lower handlebar holder nut 4. ...

Page 189

Handlebar 5-37 5. Install: • engine stop switch “1” • clutch lever “2” • clutch lever holder “3” • clamp “4” tip • the engine stop switch, the clutch lever, and the clutch lever holder should be installed ac- cording to the dimensions shown. • pass the engine stop switch lead through the middle of t...

Page 190

Handlebar 5-38 warning after tightening the throttle cable housing screws, check that the throttle grip “3” moves smoothly. If it does not, retighten the screws for adjustment. 10.Install: • rubber cover “1” • cover (throttle cable housings) “2” 11.Install: • start switch “1” • front brake master cy...

Page 191

Handlebar 5-39 14.Adjust: • throttle grip free play refer to “adjusting the throttle grip free play” on page 3-13. Throttle grip free play 3.0–6.0 mm (0.12–0.24 in).

Page 192

Front fork 5-40 eas2gc1197 front fork removing the front fork legs order part name q’ty remarks use a suitable stand to raise the front wheel off the ground. Front wheel refer to “front wheel” on page 5-4. Front brake caliper refer to “front brake” on page 5-13. 1 brake hose holder 2 2 protector 1 3...

Page 193

Front fork 5-41 disassembling the front fork leg order part name q’ty remarks 1 adjuster 1 2 fork spring 1 3 dust seal 1 4 stopper ring 1 5 inner tube 1 6 outer tube 1 7 piston metal 1 8 protector guide 1 9 slide metal 1 10 washer 1 11 oil seals 1 12 base valve 1 13 damper assembly 1 for assembly, r...

Page 194

Front fork 5-42 eas2gc1198 removing the front fork legs 1. Use a suitable stand to raise the front wheel off the ground. Ewa warning securely support the vehicle so that there is no danger of it falling over. Tip record the adjusting screw setting position be- fore loosening the adjuster and the bas...

Page 195

Front fork 5-43 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Remove: • base valve “1” (from the damper assembly) tip hold the damper assembly with the cap bolt ring wrench “2” and use the cap bolt wrench “3” to remove the base valve. Eas2gc1200 checking the front fork legs 1. Check: • inner tube surface “a” ...

Page 196

Front fork 5-44 5. Check: • base valve “1” wear/damage replace. Contamination clean. • o-rings “2” wear/damage replace. • base valve bushing “3” wear/damage replace. • spring “4” damage/fatigue replace the base valve. • air bleed screw “5” wear/damage replace. 6. Check: • contacting surface “a” wear...

Page 197

Front fork 5-45 4. Measure: • oil level (left and right) “a” out of specification regulate. 5. Tighten: • locknut “1” tip fully finger tighten the locknut onto the damper assembly. 6. Loosen: • compression damping force adjuster “1” tip • before loosening the damping force adjuster, record the setti...

Page 198

Front fork 5-46 9. Tighten: • base valve “1” tip hold the damper assembly with the cap bolt ring wrench “2” and use the cap bolt wrench “3” to tighten the base valve. 10.After filling, pump the damper assembly “1” slowly up and down more than 10 times to distribute the fork oil. 11.While protecting ...

Page 199

Front fork 5-47 tip • apply the lithium-soap-based grease on the dust seal lip and oil seal lip. • apply the fork oil on the inner tube. • when installing the oil seal, use vinyl seat “a” with fork oil applied to protect the oil seal lip. 15.Install: • inner tube bushing “1” tip install the inner tu...

Page 200

Front fork 5-48 19.Install: • oil seal clip “1” tip fit the oil seal clip correctly in the groove in the outer tube. 20.Install: • dust seal “1” tip apply lithium-soap-based grease on the inner tube. 21.Check: • inner tube smooth movement tightness/binding/rough spots repeat the steps 14 to 20. 22.M...

Page 201

Front fork 5-49 24.Install: • damper assembly “1” (to the inner tube “2”) eca notice allow the damper assembly to slide slowly down the inner tube until it contacts the bot- tom of the inner tube. Be careful not to dam- age the inner tube. 25.Loosen: • rebound damping force adjuster “1” tip • before...

Page 202

Front fork 5-50 29.Install: • adjuster “1” (to the inner tube) 30.Fill: • front fork leg eca notice • be sure to use the recommended oil. Other oils may have an adverse effect on front fork performance. • when disassembling and assembling the front fork leg, do not allow any foreign ma- terial to en...

Page 203

Front fork 5-51 2. Tighten: • damper assembly “1” tip use the cap bolt ring wrench “2” to tighten the damper assembly. 3. Adjust: • front fork top end “a” 4. Tighten: • pinch bolt (upper bracket) “1” • pinch bolt (lower bracket) “2” ewa warning tighten the lower bracket to specified torque. If torqu...

Page 204

Front fork 5-52 6. Install: • speed sensor lead “1” • plate 2 “2” (to the right front fork protector) tip install the plate 2 in the direction as shown. 7. Install: • protector “1” • bolt (protector) “2” 8. Adjust: • rebound damping force tip turn in the damping adjuster “1” finger-tight and then tu...

Page 205

Steering head 5-53 eas2gc1203 steering head removing the lower bracket order part name q’ty remarks refer to “checking and adjusting the steering head” on page 3-37. Use a suitable stand to raise the front wheel off the ground. Headlight assembly/multi-function meter/front fender refer to “general c...

Page 206

Steering head 5-54 for installation, reverse the removal proce- dure. Removing the lower bracket order part name q’ty remarks 2 4 5 7 3 (2) (2) (2) (2) (2) 1 6 8 9 10 ls ls t.R. 21 nm (2.1 m lbf) kgf, 15 ft t.R. 21 nm (2.1 m lbf) kgf, 15 ft t.R. 21 nm (2.1 m lbf) kgf, 15 ft t.R. 21 nm (2.1 m lbf) kg...

Page 207

Steering head 5-55 eas2gc1204 removing the lower bracket 1. Use a suitable stand to raise the front wheel off the ground. Ewa warning securely support the vehicle so that there is no danger of it falling over. 2. Remove: • rng nut “1” tip remove the ring nut with the steering nut wrench “2”. Ewa war...

Page 208

Steering head 5-56 tip apply the lithium-soap-based grease on the bearing and bearing race cover lip. 3. Install: • lower bracket “1” tip apply the lithium-soap-based grease on the bearing, the portion “a” and thread of the steer- ing stem. 4. Install: • steering ring nut “1” tip install the steerin...

Page 209

Steering head 5-57 tip apply the lithium-soap-based grease to the contact surface of the steering stem nut when installing. 9. After tightening the nut, check the steering for smooth movement. If not, adjust the steering by loosening the steering ring nut little by little. 10.Adjust: • front fork to...

Page 210

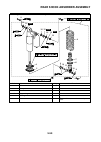

Rear shock absorber assembly 5-58 eas2gc1207 rear shock absorber assembly removing the rear shock absorber assembly order part name q’ty remarks seat refer to “general chassis” on page 5-1. Side cover (left / right) refer to “general chassis” on page 5-1. Air scoop (left / right) refer to “general c...

Page 211

Rear shock absorber assembly 5-59 12 collars 2 13 o-ring 2 14 dust seal 2 15 stopper ring 1 16 bearing 1 for installation, reverse the removal proce- dure. Removing the rear shock absorber assembly order part name q’ty remarks 2 12 16 15 14 13 12 14 4 5 7 6 8 3 9 9 10 10 11 1 new new 13 new ls ls m ...

Page 212

Rear shock absorber assembly 5-60 disassembling the relay arm order part name q’ty remarks 1 relay arm 1 2 connecting arm 1 3 collars 3 4 oil seals 6 5 washers 8 6 bearing 6 for assembly, reverse the disassemble pro- cedure. 5 3 5 6 1 6 5 4 5 5 4 5 6 6 5 4 3 2 4 6 6 3 4 4 t.R. 80 nm (8.0 m lbf) kgf,...

Page 213

Rear shock absorber assembly 5-61 eas2gc1208 handling the rear shock absorber ewa warning this rear shock absorber contains highly compressed nitrogen gas. Before handling the rear shock absorber, read and make sure that you understand the following in- formation. The manufacturer cannot be held res...

Page 214

Rear shock absorber assembly 5-62 2. Remove: • upper bearing “1” tip remove the bearing by pressing its outer race. 3. Remove: • lower bearing “1” tip remove the bearing by pressing its outer race. Eas2gc1212 checking the rear shock absorber assembly 1. Check: • rear shock absorber rod bends/damage ...

Page 215

Rear shock absorber assembly 5-63 3. Install: • bearing “1” • oil seals “2” (to connecting arm “3”) eas2gc1215 installing the rear shock absorb- er assembly 1. Lubricate: • bearing (lower side) • dust seal • collars • bushing eca notice do not apply the grease to the bearing outer race because it wi...

Page 216

Rear shock absorber assembly 5-64 7. Tighten: • rear shock absorber assembly upper bolt • connecting arm bolt (frame side) • connecting arm bolt (relay arm side) • relay arm bolt (swingarm side) • rear shock absorber assembly lower bolt rear shock absorber assembly upper bolt 56 nm (5.6 m·kgf, 41 ft...

Page 217

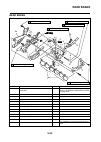

Swingarm 5-65 eas2gc1216 swingarm removing the swingarm order part name q’ty remarks use a suitable stand to raise the front wheel off the ground. Brake hose holder refer to “rear brake” on page 5-23. Rear brake caliper refer to “rear brake” on page 5-23. Bolt (brake pedal) drive chain 1 collars 2 2...

Page 218

Swingarm 5-66 eas2gc1217 removing the swingarm 1. Use a suitable stand to raise the rear wheel off the ground. Ewa warning securely support the vehicle so that there is no danger of it falling over. 2. Measure: • swingarm side play • swingarm vertical movement ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Mea...

Page 219

Swingarm 5-67 eas2gc1220 installing the swingarm 1. Lubricate: • bearing • collars • spacers • oil seal • pivot shaft 2. Install: • bearing “1” • oil seals “2” (to the swingarm) tip first install the outer and then the inner bear- ings to a specified depth from inside. 3. Install: • swingarm tip ins...

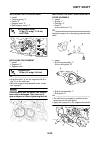

Page 220

Chain drive 5-68 eas2gc1221 chain drive removing the drive chain job order part name q’ty servicing information drive sprocket refer to “engine removal” on page 6-1. 1 drive chain 1 for installation, reverse the removal proce- dure. 1 t.R. 75 nm (7.5 m lbf) kgf, 54 ft t.R. 7 nm (0.7 m lbf) kgf, 5.1 ...

Page 221

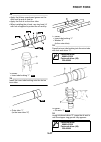

Chain drive 5-69 eas23420 removing the drive chain 1. Stand the vehicle on a level surface. Ewa warning securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • drive chain tip cut the drive...

Page 222

Chain drive 5-70 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 4. Check: • o-rings “1” damage replace the drive chain. • drive chain rollers “2” damage/wear replace the drive chain. • drive chain side plates “3” damage/wear replace the drive chain. 5. Lubricate: • drive chain eas2gc1222 checking the drive sprock...

Page 223

Chain drive 5-71 c. After riveting, make sure the space “c”, which is inside of the connecting link “3” and inside of the connecting plate “1”, is 14.1– 14.3 mm (0.56–0.65 in). ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 2. Lubricate: • drive chain 3. Install: • drive sprocket • lock washer • drive sprocket nu...

Page 224

Chain drive 5-72.

Page 225

6 engine engine removal .........................................................................................6-1 removing the silencer.....................................................................6-6 removing the exhaust pipe 2..........................................................6-6 ...

Page 226

Clutch .........................................................................................................6-41 removing the clutch ......................................................................6-44 checking the friction plates......................................................6-44 c...

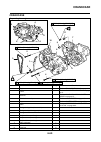

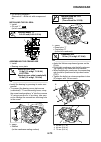

Page 227

Generator and starter clutch .......................................................6-63 removing the generator ..............................................................6-65 checking the starter clutch .....................................................6-65 installing the starter clutch ........

Page 228

Engine removal 6-1 eas2gc1225 tip this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowl- edge and skill concerning servicing are requested not to undertake insp...

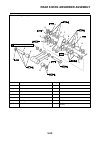

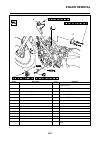

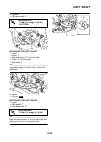

Page 229

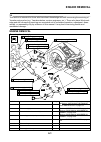

Engine removal 6-2 4 exhaust pipe 2 1 5 exhaust pipe 1 1 6 gaskets 3 7 exhaust pipe 1 protector 1 8 exhaust pipe 2 protector 1 9 silencer cap 1 10 spark arrester 1 for installation, reverse the removal proce- dure. Removing the exhaust pipe order part name q’ty remarks 10 5 9 2 6 1 6 6 3 8 4 7 (4) (...

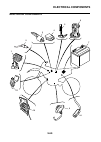

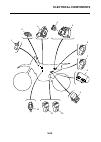

Page 230

Engine removal 6-3 removing the electronic parts order part name q’ty remarks use a suitable stand to raise the front wheel off the ground. Seat refer to “general chassis” on page 5-1. Side cover (left/right) refer to “general chassis” on page 5-1. Air scoop (left / right) refer to “general chassis”...

Page 231

Engine removal 6-4 removing the engine order part name q’ty remarks use a suitable stand to raise the front wheel off the ground. Seat refer to “general chassis” on page 5-1. Side cover (left/right) refer to “general chassis” on page 5-1. Air scoop (left / right) refer to “general chassis” on page 5...

Page 232

Engine removal 6-5 5 drive sprocket cover 1 6 drive chain guide 1 7 drive sprocket 1 8 upper engine bracket 2 9 lower engine bracket 2 10 pivot shaft 1 11 engine 1 for installation, reverse the removal proce- dure. Removing the engine order part name q’ty remarks new new ls m 8 8 7 6 11 4 5 new 1 10...

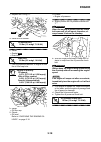

Page 233

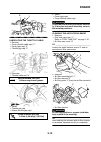

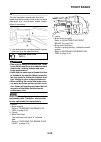

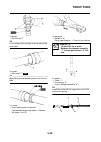

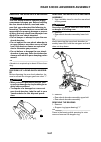

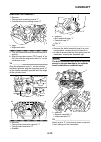

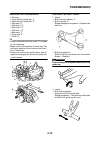

Engine removal 6-6 eas2gc1227 removing the silencer 1. Remove: • rear shock absorber assembly lower bolt “1” • connecting arm bolt (relay arm side) “2” • silencer “3” tip move the rear shock absorber to the left side of the chassis, and remove the silencer. Eas2gc1228 removing the exhaust pipe 2 1. ...

Page 234

Engine removal 6-7 eas2gc1230 removing the engine 1. Remove: • pivot shaft “1” tip if the pivot shaft is pulled all the way out, the swingarm will come loose. If possible, insert a shaft of similar diameter into the other side of the swingarm to support it. 2. Remove: • engine “1” from the right sid...

Page 235

Engine removal 6-8 5. Install: • spark arrester gasket • spark arrester insert the spark arrester into the muffler and align the bolt holes. • tail pipe gasket • spark arrester bolts 6. Install: • muffler cap tip first tighten the two screws “a” located horizon- tally apart, and then tighten the oth...

Page 236

Engine removal 6-9 eas2gc1234 installing the brake pedal 1. Install: • spring “1” • brake pedal “2” • o-rings “3” • bolt (brake pedal) “4” • clip “5” tip apply the lithium-soap-based grease on the bolt, o-rings and brake pedal bracket. Eas2gc1235 installing the drive sprocket 1. Install: • drive spr...

Page 237

Engine removal 6-10 2. Install: • clamp • exhaust pipe 2 “1” • bolt (exhaust pipe 2) “2” tip install and temporarily tighten the exhaust pipe 2 with its end positioned as shown with respect to the exhaust pipe 1. 3. Install: • clamp • silencer “1” • bolt (silencer) “2” tip install and temporarily ti...

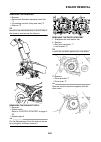

Page 238

Camshaft 6-11 eas2gc1237 camshaft removing the cylinder head cover order part name q’ty remarks seat refer to “general chassis” on page 5-1. Side cover (left/right) refer to “general chassis” on page 5-1. Air scoop (left / right) refer to “general chassis” on page 5-1. Fuel tank refer to “fuel tank”...

Page 239

Camshaft 6-12 removing the camshaft order part name q’ty remarks 1 timing mark accessing screw 1 2 crankshaft end accessing screw 1 3 timing chain tensioner cap bolt 1 4 timing chain tensioner 1 5 camshaft cap 2 6 clip 2 7 intake camshaft 1 8 exhaust camshaft 1 for installation, reverse the removal ...

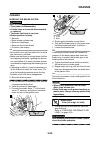

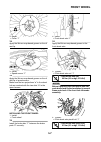

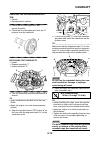

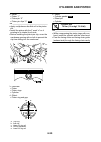

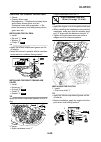

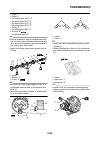

Page 240

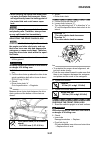

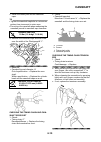

Camshaft 6-13 eas2gc1238 removing the camshaft 1. Remove: • timing mark accessing screw “1” • crankshaft end accessing screw “2” 2. Align: • alignment mark ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the crankshaft counterclockwise with a wrench. B. Align the top dead center (tdc) mark “a” on the rotor...

Page 241

Camshaft 6-14 eas2gc1239 checking the camshaft 1. Check: • camshaft lobes blue discoloration/pitting/scratches re- place the camshaft. 2. Measure: • camshaft lobe dimensions “a” and “b” out of specification replace the cam- shaft. 3. Measure: • camshaft runout out of specification replace. 4. Measur...

Page 242

Camshaft 6-15 c. Install the dowel pins and the camshaft caps. Tip • tighten the camshaft cap bolts in a crisscross pattern from innermost to outer caps. • do not turn the camshaft when measuring the camshaft journal-to-camshaft cap clearance. D. Remove the camshaft caps and then mea- sure the width...

Page 243

Camshaft 6-16 eas2gc1242 checking the decompression sys- tem 1. Check: • decompression system ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Check that the decompressor cam “1” moves smoothly. B. Check that the decompressor lever pin “2” projects from the camshaft. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2gc1243 i...

Page 244

Camshaft 6-17 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 2. Install: • timing chain tensioner ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. While pressing the tensioner rod lightly with your fingers, use a thin screwdriver to wind the tensioner rod up fully clockwise. B. With the tensioner rod fully wound and the chain...

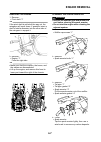

Page 245

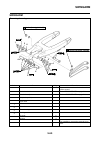

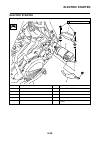

Cylinder head 6-18 eas2gc1244 cylinder head removing the cylinder head order part name q’ty remarks refer to “installing the cylinder head” on page 6-21. Seat refer to “general chassis” on page 5-1. Side cover (left/right) refer to “general chassis” on page 5-1. Air scoop (left / right) refer to “ge...

Page 246

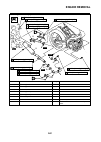

Cylinder head 6-19 5 cylinder head gasket 1 6 timing chain guide (intake side) 1 7 oil check bolt 2 8 oil passage plug 1 for installation, reverse the removal proce- dure. Removing the cylinder head order part name q’ty remarks 8 6 7 7 10 nm (1.0 m kgf, 7.2 ft ibf) t.R. 10 nm (1.0 m kgf, 7.2 ft ibf)...

Page 247

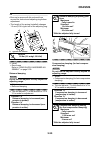

Cylinder head 6-20 eas2gc1245 removing the cylinder head 1. Remove: • cylinder head bolts tip • loosen the bolts in the proper sequence as shown. • loosen each bolt 1/2 of a turn at a time. After fully loosening all the bolts, remove them. • m6 35 mm (1.38 in): “1” – “2” • m10 149 mm (5.87 in): “3” ...

Page 248

Cylinder head 6-21 eas2gc1248 installing the cylinder head 1. Install: • timing chain guide (intake side) “1” • dowel pins “2” • cylinder head gasket • dowel head “4” tip while pulling up the timing chain, install the tim- ing chain guide (intake side) and the cylinder head. 2. Install: • washer “1”...

Page 249

Cylinder head 6-22 i. Retighten the cylinder head mounting bolts 150° in the proper tightening sequence. Tip tighten the bolts in two steps (90° and 60°) to reach the specified angle in the proper tighten- ing sequence. J. Tighten the bolts to the specified torque. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ b...

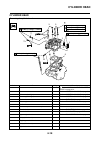

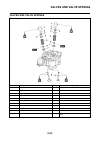

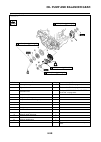

Page 250

Valves and valve springs 6-23 eas2gc1249 valves and valve springs removing the valves and valve springs order part name q’ty remarks cylinder head refer to “cylinder head” on page 6-18. 1 valve lifter 4 2 adjusting pad 4 3 valve cotter 8 4 valve spring retainer 4 5 valve spring 4 6 valve stem seal 4...

Page 251

Valves and valve springs 6-24 eas2gc1250 removing the valves tip before removing the internal parts of the cylin- der head (e.G., valves, valve springs, valve seats), make sure that the valves are properly sealed. 1. Remove: • valve lifter “1” • adjusting pad “2” tip • place a cloth in the timing ch...

Page 252

Valves and valve springs 6-25 4. Remove: • valve spring retainer “1” • valve spring “2” • valve “3” • valve stem seal “4” • valve spring seat “5” tip identify the position of each part very carefully so that it can be reinstalled in its original place. Eas2gc1251 checking the valves and valve guides...

Page 253

Valves and valve springs 6-26 c. After installing the valve guide, expand the hole in the valve guide with the valve guide reamer “3” to obtain the proper valve-stem- to-valve-guide clearance. Tip after replacing the valve guide, reface the valve seat. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Eliminate: ...

Page 254

Valves and valve springs 6-27 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Apply mechanic’s blueing dye (dykem) “b” onto the valve face. B. Install the valve into the cylinder head. C. Press the valve through the valve guide and onto the valve seat to make a clear impres- sion. D. Measure the valve seat cont...

Page 255

Valves and valve springs 6-28 g. Apply mechanic’s blueing dye (dykem) “b” onto the valve face. H. Install the valve into the cylinder head. I. Press the valve through the valve guide and onto the valve seat to make a clear impres- sion. J. Measure the valve seat contact width “c” again. If the valve...

Page 256

Valves and valve springs 6-29 eas2gc1254 checking the valve lifters 1. Check: • valve lifter damage/scratches replace the valve lift- ers and cylinder head. Eas2gc1255 installing the valves 1. Clean: • valve stem end 2. Lubricate: • valve stem “1” • valve stem seal “2” 3. Install: • spring seat “1” ...

Page 257

Valves and valve springs 6-30 5. To fasten the valve cotters onto the valve stem, lightly tap the valve tip with a soft-face hammer. Eca notice hitting the valve tip with excessive force could damage the valve. 6. Lubricate: • adjusting pad “1” • valve lifter “2” 7. Install: • adjusting pad • valve ...

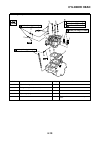

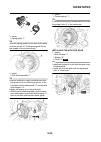

Page 258

Cylinder and piston 6-31 eas2gc1256 cylinder and piston removing the cylinder and piston order part name q’ty remarks cylinder head refer to “cylinder head” on page 6-18. 1 cylinder body 1 2 gaskets 1 3 dowel pin 2 4 piston pin clip 2 5 piston pin 1 6 piston 1 7 piston ring set 1 for installation, r...

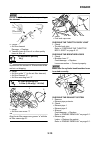

Page 259

Cylinder and piston 6-32 eas2gc1257 removing the piston 1. Remove: • piston pin clips “1” • piston pin “2” • piston “3” eca13810 notice do not use a hammer to drive the piston pin out. Tip • before removing the piston pin clip, cover the crankcase opening with a cloth to prevent the piston pin clip ...

Page 260

Cylinder and piston 6-33 b. If out of specification, rebore or replace the cylinder, and replace the piston and the pis- ton rings as a set. C. Measure the piston outside diameter “a” at the measuring point (from piston skirt bot- tom) “b” with the micrometer. D. If out of specification, replace the...

Page 261

Cylinder and piston 6-34 3. Measure: • piston ring end gap out of specification replace the piston ring. Tip the oil ring expander’s end gap cannot be measured. If the oil ring rail’s gap is excessive, replace all three oil rings. Eas2gc1260 checking the piston pin 1. Check: • piston pin blue discol...

Page 262

Cylinder and piston 6-35 2. Install: • piston “1” • piston pin “2” • piston pin clips “3” tip • apply molybdenum disulfide oil to the piston pin. • install the piston with the f mark “a” on it pointing to its intake (front) side. • before installing the piston pin clip, cover the crankcase opening w...

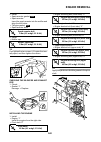

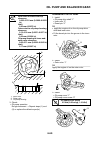

Page 263

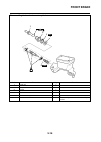

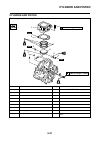

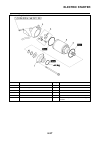

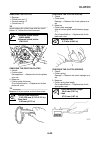

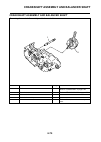

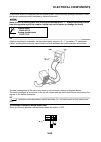

Electric starter 6-36 eas2gc1262 electric starter removing the starter motor order job/parts to remove q’ty remarks exhaust pipe refer to “engine removal” on page 6-1. 1 starter motor cover 1 2 starter motor lead 1 3 starter motor 1 for assembly, reverse the disassemble pro- cedure. 1 12 nm (1.2 m k...

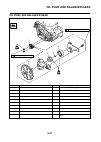

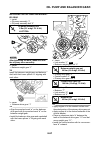

Page 264

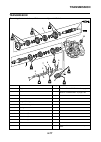

Electric starter 6-37 disassembling the starter motor order job/parts to remove q’ty remarks 1 starter motor front cover 1 2 starter motor yoke 1 3 armature assembly 1 4 starter motor rear cover 1 5 brush set 2 for assembly, reverse the disassembly pro- cedure..

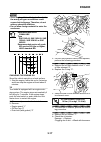

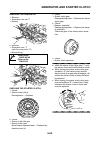

Page 265

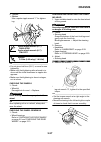

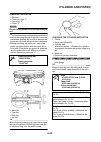

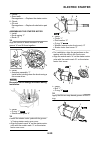

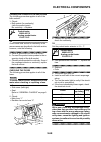

Electric starter 6-38 eas2gc1263 checking the starter motor 1. Check: • commutator dirt clean with 600 grit sandpaper. 2. Measure: • commutator diameter “a” out of specification replace the starter motor. 3. Measure: • mica undercut “a” out of specification scrape the mica to the proper measurement ...

Page 266

Electric starter 6-39 7. Check: • gear teeth damage/wear replace the starter motor. 8. Check: • oil seal damage/wear replace the defective part (s). Eas2gc1264 assembling the starter motor 1. Install: • brush spring “1” • brush “2” tip align the corner of brush terminal “a” with groove “b” and fit t...

Page 267