- DL manuals

- ABB

- Power Supply

- ACS550-01

- User Manual

ABB ACS550-01 User Manual

Summary of ACS550-01

Page 1

Drive it low voltage ac drives user’s manual acs550-01 drives (0.75 … 110 kw) acs550-u1 drives (1 … 150 hp).

Page 2

2 acs550 user’s manual acs550 drive manuals the industrial it wordmark and product names in the form drive it are registered or pending trademarks of abb. Canopen is a registered trademark of can in automation e.V. Controlnet is a registered trademark of controlnet international. Devicenet is a regi...

Page 3: Safety

Acs550 user’s manual 3 safety safety warning! The acs550 adjustable speed ac drive should only be installed by a qualified electrician. Warning! Even when the motor is stopped, dangerous voltage is present at the power circuit terminals u1, v1, w1 and u2, v2, w2 and, depending on the frame size, udc...

Page 4

4 acs550 user’s manual safety use of warnings and notes there are two types of safety instructions throughout this manual: • notes draw attention to a particular condition or fact, or give information on a subject. • warnings caution you about conditions which can result in serious injury or death a...

Page 5: Table of Contents

Acs550 user’s manual 5 table of contents table of contents safety use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 table of contents installation installation flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

6 acs550 user’s manual table of contents maintenance maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211 heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211 main fan replace...

Page 7: Installation

Acs550 user’s manual 7 installation installation study these installation instructions carefully before proceeding. Failure to observe the warnings and instructions may cause a malfunction or personal hazard. Warning! Before you begin read "safety" on page 3. Installation flow chart the installation...

Page 8

8 acs550 user’s manual installation preparing for installation lifting the drive lift the drive only by the metal chassis. Unpack the drive 1. Unpack the drive. 2. Check for any damage and notify the shipper immediately if damaged components are found. 3. Check the contents against the order and the...

Page 9

Acs550 user’s manual 9 installation type code use the following chart to interpret the type code found on either label. Ratings and frame size the chart in "ratings" on page 215 lists technical specifications, and identifies the drive’s frame size – significant, since some instructions in this docum...

Page 10

10 acs550 user’s manual installation • for installations involving acs550-u1, frame sizes r5 or r6 and ip 54 / ul type 12 enclosures: a punch for creating conduit mounting holes. • for installations involving acs550-u1, frame size r6: the appropriate crimping tool for power cable lugs. See "power te...

Page 11

Acs550 user’s manual 11 installation installing the drive warning! Before installing the acs550, ensure the input power supply to the drive is off. Prepare the mounting location the acs550 should only be mounted where all of the requirements defined in "preparing for installation" on page 8 are met....

Page 12

12 acs550 user’s manual installation ip 54 / ul type 12 1. If hood is present: remove screws (2) holding hood in place. 2. If hood is present: slide hood up and off of the cover. 3. Loosen the captive screws around the edge of the cover. 4. Remove the cover. Mount the drive ip 21 / ul type 1 1. Posi...

Page 13

Acs550 user’s manual 13 installation wiring overview conduit/gland kit wiring drives with the ip 21 / ul type 1 enclosure requires a conduit/gland kit with the following items: • conduit/gland box • five (5) cable clamps (acs550-01 only) • screws • cover the kit is included with ip 21 / ul type 1 en...

Page 14

14 acs550 user’s manual installation • for frame size r6, see "power terminal considerations – r6 frame size" on page 223 to install the appropriate cable lugs. • for drives using braking (optional), refer to the following, as appropriate: • when installing control wiring, refer to the following, as...

Page 15

Acs550 user’s manual 15 installation power connection diagrams the following diagram shows the terminal layout for frame size r3, which, in general, applies to frame sizes r1 … r6, except for the r5/r6 power and ground terminals. Warning! For floating, impedance grounded, or unsymmetrically grounded...

Page 16

16 acs550 user’s manual installation the following diagram shows the power and ground terminal layout for frame sizes r5 and r6 warning! For floating, impedance grounded, or unsymmetrically grounded networks, disconnect the internal rfi filter by removing screws: f1 and f2. See "floating networks" o...

Page 17

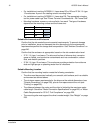

Acs550 user’s manual 17 installation control terminals table the following provides information for connecting control wiring at x1 on the drive. 1 digital input impedance 1.5 k Ω . Maximum voltage for digital inputs is 30 v. 2 default values depend on the macro used. Values specified are for the de...

Page 18

18 acs550 user’s manual installation note! Terminals 3, 6, and 9 are at the same potential. Note! For safety reasons the fault relay signals a “fault” when the acs550 is powered down. You can wire the digital input terminals in either a pnp or npn configuration. Install the wiring checking motor and...

Page 19

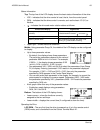

Acs550 user’s manual 19 installation wiring ip 21 / ul type 1 enclosure with cables 1. Open the appropriate knockouts in the conduit/gland box. (see "conduit/gland kit" above.) 2. Install the cable clamps for the power/motor cables. 3. On the input power cable, strip the sheathing back far enough to...

Page 20

20 acs550 user’s manual installation wiring ip 21 / ul type 1 enclosure with conduit 1. Open the appropriate knockouts in the conduit/gland box. (see "conduit/gland kit" above.) 2. Install thin-wall conduit clamps (not supplied). 3. Install conduit/gland box. 4. Connect conduit runs to box. 5. Route...

Page 21

Acs550 user’s manual 21 installation wiring ip 54 / ul type 12 enclosure with cables 1. Cut the cable seals as needed for the power, motor, and control cables. (the cable seals are cone-shaped, rubber seals on the bottom of the drive.) 2. On the input power cable, strip the sheathing back far enough...

Page 22

22 acs550 user’s manual installation wiring ip 54 / ul type 12 enclosure with conduit 1. Depends on frame size: • r1…r4: remove and discard the cable seals where conduit will be installed. (the cable seals are cone-shaped, rubber seals on the bottom of the drive.) • r5 and r6: use punch to create ho...

Page 23

Acs550 user’s manual 23 installation check installation before applying power, perform the following checks. Check installation environment conforms to the drive’s specifications for ambient conditions. The drive is mounted securely. Space around the drive meets the drive’s specifications for coolin...

Page 24

24 acs550 user’s manual installation re-install cover ip 21 / ul type 1 1. Align the cover and slide it on. 2. Tighten the captive screw. 3. Re-install the control panel. Ip 54 / ul type 12 1. Align the cover and slide it on. 2. Tighten the captive screws around the edge of the cover. 3. R1…r4: slid...

Page 25

Acs550 user’s manual 25 installation apply power always re-install the front cover before turning power on. Warning! The acs550 will start up automatically at power up, if the external run command is on. 1. Apply input power. When power is applied to the acs550, the green led comes on. Note! Before ...

Page 26

26 acs550 user’s manual installation 2. Edit parameter 9902 to select the appropriate macro. • assistant control panel – use either of the following: – use the start-up assistant, which displays the macro selection immediately after motor parameter setup. – refer to "parameters mode" on page 31, for...

Page 27: Start-Up

Acs550 user’s manual 27 start-up start-up start-up configures the drive. This process sets parameters that define how the drive operates and communicates. Depending on the control and communication requirements, the start-up process may require any or all of the following: • the start-up assistant (...

Page 28

28 acs550 user’s manual start-up controls/display overview the following table summarizes the button functions and displays on the assistant control panel. General display features soft key functions the soft key functions are defined by text displayed just above each key. Display contrast to adjust...

Page 29

Acs550 user’s manual 29 start-up status information top. The top line of the lcd display shows the basic status information of the drive. • loc – indicates that the drive control is local, that is, from the control panel. • rem – indicates that the drive control is remote, such as the basic i/o (x1)...

Page 30

30 acs550 user’s manual start-up to switch to local control (loc) and control the drive using the control panel, press and hold the button until first, local control, or later, local, keep run, is displayed: • release the button while local control is displayed to set the panel reference to the curr...

Page 31

Acs550 user’s manual 31 start-up parameters mode use the parameters mode to view and edit parameter values: 1. Select parameters in the main menu. 2. Press up/down to highlight the appropriate parameter group, then press sel. 3. Press up/down to highlight the appropriate parameter in a group. Note! ...

Page 32

32 acs550 user’s manual start-up the order of the tasks presented by the start-up assistant depends on your entries. The task list in the following table is typical. 1. Select assistants in the main menu. 2. Press up/down to select start-up assistant. Note! Rather than the start-up assistant, you ca...

Page 33

Acs550 user’s manual 33 start-up changed parameters mode use the changed parameters mode to view (and edit) a listing of all parameters that have been changed from macro default values. Procedure: 1. Select changed par in the main menu. The display lists all changed parameters. 2. Press enter. 3. Pr...

Page 34

34 acs550 user’s manual start-up par backup mode the assistant control panel can store a full set of drive parameters. The par backup mode has these functions: • upload to panel – copies all parameters from the drive to the control panel. This includes user sets of parameters (if defined) and intern...

Page 35

Acs550 user’s manual 35 start-up as a default, the control panel handles these situations by: • discarding parameters/values not available on the target drive. • using parameter default values when the download provides no values or invalid values. • providing a differences list – a listing of the t...

Page 36

36 acs550 user’s manual start-up • set not found – you are attempting to download a data set that was not defined in the backup. The remedy is to manually define the set, or upload the set from a drive that has the desired set definitions. • par lock – the remedy is to unlock the parameter set (para...

Page 37

Acs550 user’s manual 37 start-up basic control panel features the basic control panel features: • numeric control panel with a lcd display. • drive connection that can be made or detached at any time • copy function – parameters can be copied to the control panel memory for later transfer to other d...

Page 38

38 acs550 user’s manual start-up status information when the basic control panel is in the output mode, the display: • top-left shows the control location: – loc – indicates that the drive control is local, that is, from the control panel. – rem – indicates that the drive control is remote, such as ...

Page 39

Acs550 user’s manual 39 start-up shaft direction – to change the shaft direction press dir (parameter 1003 must be set to 3 ( request )). Reference – see "reference mode" below. Reference mode use the reference mode to set the speed or frequency reference. Normally this reference control is only pos...

Page 40

40 acs550 user’s manual start-up 4. Use up or down arrow key to step through to the desired group, for example “03”. 5. Press menu/enter. The display shows one of the parameters in the selected parameter group. For example, “0301”. 6. Use up or down arrow key to step through to the desired parameter...

Page 41

Acs550 user’s manual 41 start-up • dl p (download partial) – copies a partial parameter set from the control panel to a drive. The partial set does not include internal motor parameters, parameters 9905…9909, 1605, 1607, 5201, nor any group 51 and group 53 parameters. Use this option to transfer par...

Page 42

42 acs550 user’s manual start-up application macros macros change a group of parameters to new, predefined values. Use macros to minimize the need for manual editing of parameters. Selecting a macro sets all other parameters to their default values, except: • group 99: start-up data parameters (exce...

Page 43

Acs550 user’s manual 43 start-up application macro: abb standard (default) this macro provides a general purpose, 2-wire i/o configuration, with three (3) constant speeds. This is the default macro. Parameter values are the default values defined in the "complete parameter list for acs550" on page 5...

Page 44

44 acs550 user’s manual start-up application macro: 3-wire this macro is used when the drive is controlled using momentary push-buttons, and provides three (3) constant speeds. To enable, set the value of parameter 9902 to 2 (3- wire ). Note! When the stop input ( di 2) is deactivated (no input), th...

Page 45

Acs550 user’s manual 45 start-up application macro: alternate this macro provides an i/o configuration adopted to a sequence of di control signals used when alternating the rotation direction of the drive. To enable, set the value of parameter 9902 to 3 ( alternate ). Connection example: input signa...

Page 46

46 acs550 user’s manual start-up application macro: motor potentiometer this macro provides a cost-effective interface for plcs that vary the speed of the drive using only digital signals. To enable, set the value of parameter 9902 to 4 ( motor pot ). Connection example: input signals output signals...

Page 47

Acs550 user’s manual 47 start-up application macro: hand-auto this macro provides an i/o configuration that is typically used in hvac applications. To enable, set the value of parameter 9902 to 5 ( hand / auto ). Note! Parameter 2108 start inhibit must remain in the default setting, 0 ( off ). Conne...

Page 48

48 acs550 user’s manual start-up application macro: pid control this macro provides parameter settings for closed-loop control systems such as pressure control, flow control, etc. To enable, set the value of parameter 9902 to 6 ( pid ctrl ). Note! Parameter 2108 start inhibit must remain in the defa...

Page 49

Acs550 user’s manual 49 start-up application macro: pfc this macro provides parameter settings for pump and fan control (pfc) applications. To enable, set the value of parameter 9902 to 7 ( pfc control ). Note! Parameter 2108 start inhibit must remain in the default setting, 0 ( off ). Connection ex...

Page 50

50 acs550 user’s manual start-up application macro: torque control this macro provides parameter settings for applications that require torque control of the motor. Control can also be switched to speed control. To enable, set the value of parameter 9902 to 8 ( torque control ). Connection example: ...

Page 51

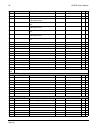

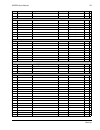

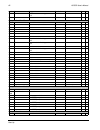

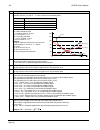

Acs550 user’s manual 51 start-up macro default values for parameters parameter default values are listed in "complete parameter list for acs550". Changing from the default macro (abb standard), that is, editing the value of parameter 9902, changes the parameter default values as defined in the follo...

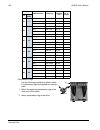

Page 52

52 acs550 user’s manual start-up acs550-u1 parameter abb st a n d a rd 3-wire alte rna te motor potentiometer hand-a uto pid control pfc control to rq u e control 9902 applic macro 1 2 3 4 5 6 7 8 9904 motor ctrl mode 3 1 1 1 1 1 3 2 1001 ext 1 commands 2 4 9 2 2 1 1 2 1002 ext 2 commands 0 0 0 0 7 ...

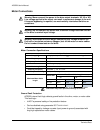

Page 53

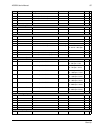

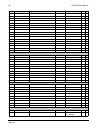

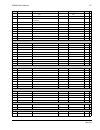

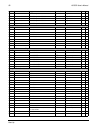

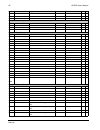

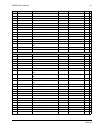

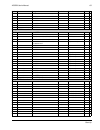

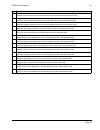

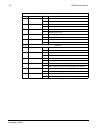

Acs550 user’s manual 53 start-up complete parameter list for acs550 the following table lists all parameters. Table header abbreviations are: • s = parameters can be modified only when the drive is stopped. • user = space to enter desired parameter values some values depend on the “construction” as ...

Page 54

54 acs550 user’s manual start-up 0126 pid 1 output -1000…1000% 0.1% - 0127 pid 2 output -100…100% 0.1% - 0128 pid 1 setpnt unit and scale defined by par. 4006/ 4106 and 4007/4107 - - 0129 pid 2 setpnt unit and scale defined by par. 4206 and 4207 0130 pid 1 fbk unit and scale defined by par. 4006/ 41...

Page 55

Acs550 user’s manual 55 start-up 0409 status at flt - 1 0 0410 di 1-3 at flt 000…111 (0…7 decimal) 1 0 0411 di 4-6 at flt 000…111 (0…7 decimal) 1 0 0412 previous fault 1 as par. 0401 1 0 0413 previous fault 2 as par. 0401 1 0 group 10: start/stop/dir 1001 ext 1 commands 0…14 1 2 9 1002 ext 2 command...

Page 56

56 acs550 user’s manual start-up 1402 relay output 2 0…45 1 2 1403 relay output 3 0…45 1 3 1404 ro 1 on delay 0…3600 s 0.1 s 0 s 1405 ro 1 off delay 0…3600 s 0.1 s 0 s 1406 ro 2 on delay 0…3600 s 0.1 s 0 s 1407 ro 2 off delay 0…3600 s 0.1 s 0 s 1408 ro 3 on delay 0…3600 s 0.1 s 0 s 1409 ro 3 off del...

Page 57

Acs550 user’s manual 57 start-up 2003 max current 0… 1.8 * i 2hd 0.1 a 1.8 * i 2hd 9 2005 overvolt ctrl 0 = disable , 1 = enable 1 1 2006 undervolt ctrl 0 = disable , 1 = enable ( time ), 2 = enable 1 1 2007 minimum freq -500…500 hz 0.1 hz 0 hz 9 2008 maximum freq 0…500 hz 0.1 hz 01: 50 hz / u1: 60 ...

Page 58

58 acs550 user’s manual start-up 2503 crit speed 1 hi 0…30000 rpm / 0…500 hz 1 rpm / 0.1 hz 0 rpm / 0 hz 2504 crit speed 2 lo 0…30000 rpm / 0…500 hz 1 rpm / 0.1 hz 0 rpm / 0 hz 2505 crit speed 2 hi 0…30000 rpm / 0…500 hz 1 rpm / 0.1 hz 0 rpm / 0 hz 2506 crit speed 3 lo 0…30000 rpm / 0…500 hz 1 rpm /...

Page 59

Acs550 user’s manual 59 start-up 3022 ai 2 fault limit 0…100% 0.1% 0% 3023 wiring fault 0 = disable , 1 = enable 1 1 group 31: automatic reset 3101 nr of trials 0…5 1 0 3102 trial time 1.0…600.0 s 0.1 s 30 s 3103 delay time 0.0…120.0 s 0.1 s 0 s 3104 ar overcurrent 0 = disable , 1 = enable 1 0 ( dis...

Page 60

60 acs550 user’s manual start-up 3419 output 3 unit -128…127 1 . 3420 output 3 min - 1 - 3421 output 3 max - 1 - group 35: motor temp meas 3501 sensor type 0…6 1 0 3502 input selection 1…8 1 1 3503 alarm limit -10...200 ° c / 0...5000 ohm / 0…1 1 110 ° c / 1500 ohm / 0 3504 fault limit -10...200 ° c...

Page 61

Acs550 user’s manual 61 start-up 4012 setpoint min -500.0%…500.0% 0.1% 0% 4013 setpoint max -500.0%…500.0% 0.1% 100% 4014 fbk sel 1…10 - 1 4015 fbk multiplier -32.768…32.767 (0 = not used) 0.001 0 4016 act 1 input 1…2 - 2 9 4017 act 2 input 1…2 - 2 9 4018 act 1 minimum -1000…1000% 1% 0% 4019 act 1 m...

Page 62

62 acs550 user’s manual start-up 4125 wake - up dev unit and scale defined by par. 4106 and 4107 - - 4126 wake - up delay 0…60 s 0.01 s 0.50 s group 42: ext / trim pid 4201 gain 0.1…100 0.1 1.0 4202 integration time 0.0s = not sel , 0.1…3600 s 0.1 s 60 s 4203 derivation time 0…10 s 0.1 s 0 s 4204 pi...

Page 63

Acs550 user’s manual 63 start-up 5202 baud rate 9.6, 19.2, 38.4, 57.6, 115.2 kbits/s - 9.6 kbits/s 5203 parity 0 = 8 n 1, 1 = 8 n 2, 2 = 8 e 1, 3 = 8 o 1 1 0 5204 ok messages 0…65535 1 - 5205 parity errors 0…65535 1 - 5206 frame errors 0…65535 1 - 5207 buffer overruns 0…65535 1 - 5208 crc errors 0…6...

Page 64

64 acs550 user’s manual start-up 8121 reg bypass ctrl 0…1 1 0 ( no ) 8122 pfc start delay 0…10 s 0.01 s 0.5 s 8123 pfc enable 0…1 - 0 ( not sel ) 9 8124 acc in aux stop 0.0...1800 s 0.1 s 0.0 s ( not sel ) 8125 dec in aux start 0.0...1800 s 0.1 s 0.0 s ( not sel ) 8126 tmed autochng 0…4 1 0 ( not se...

Page 65

Acs550 user’s manual 65 start-up complete parameter descriptions this section describes the actual signals and parameters for acs550. Group 99: start-up data this group defines special start-up data required to: • set up the drive. • enter motor information. Code description 9901 language selects th...

Page 66

66 acs550 user’s manual start-up 9908 motor nom speed defines the nominal motor speed. • must equal the value on the motor rating plate. 9909 motor nom power defines the nominal motor power. • must equal the value on the motor rating plate. 9910 motor id run this parameter controls a self-calibratio...

Page 67

Acs550 user’s manual 67 start-up group 01: operating data this group contains drive operating data, including actual signals. The drive sets the values for actual signals, based on measurements or calculations. You cannot set these values. Code description 0102 speed the calculated speed of the moto...

Page 68

68 acs550 user’s manual start-up 0121 ai2 the relative value of analog input 2 in %. 0122 ro1-3 status status of the three relay outputs. • 1 indicates that the relay is energized. • 0 indicates that the relay is de-energized. 0123 ro4-6 status status of the three relay outputs. See parameter 0122. ...

Page 69

Acs550 user’s manual 69 start-up 0139 process var 3 process variable 3 • defined by parameters in group 34: panel display / process variables. 0140 run time the drive’s accumulated running time in thousands of hours (kh). 0141 mwh counter the drive’s accumulated power consumption in megawatt hours. ...

Page 70

70 acs550 user’s manual start-up group 03: fb actual signals this group monitors fieldbus communications. Code description 0301 fb cmd word 1 read-only copy of the fieldbus command word 1. • the fieldbus command is the principal means for controlling the drive from a fieldbus controller. The command...

Page 71

Acs550 user’s manual 71 start-up 0305 fault word 1 read-only copy of the fault word 1. • when a fault is active, the corresponding bit for the active fault is set in the fault words. • each fault has a dedicated bit allocated within fault words. • see "fault listing" on page 201 for a description of...

Page 72

72 acs550 user’s manual start-up group 04: fault history this group stores a recent history of the faults reported by the drive. Code description 0401 last fault 0 = clear the fault history (on panel = no record). N = fault code of the last recorded fault. 0402 fault time 1 the day on which the last...

Page 73

Acs550 user’s manual 73 start-up group 10: start/stop/dir this group: • defines external sources ( ext 1, and ext 2) for commands that enable start, stop and direction changes. • locks direction or enables direction control. To select between the two external locations use the next group (parameter ...

Page 74

74 acs550 user’s manual start-up 11 = timer function 1. – assigns start/stop control to timer function 1 (timer function activated = start ; timer function de-activated = stop ). See group 36, timer functions. 12…14 = timer function 2… 4 – assigns start/stop control to timer function 2…4. See timer ...

Page 75

Acs550 user’s manual 75 start-up group 11: reference select this group defines: • how the drive selects between command sources. • characteristics and sources for ref 1 and ref 2. Code description 1101 keypad ref sel selects the reference controlled in local control mode. 1 = ref 1 (hz/rpm) – refere...

Page 76

76 acs550 user’s manual start-up 5 = di 3 u ,4 d ( r ) – defines digital inputs as the speed reference source (motor potentiometer control). • digital input di 3 increases the speed (the u stands for “up”). • digital input di 4 decreases the speed (the d stands for “down”). • a stop command resets t...

Page 77

Acs550 user’s manual 77 start-up 1104 ref1 min sets the minimum for external reference 1. • the minimum analog input signal (as a percent of the full signal in volts or amps) corresponds to ref 1 min in hz/rpm. • parameter 1301 minimum ai 1 or 1304 minimum ai 2 sets the minimum analog input signal. ...

Page 78

78 acs550 user’s manual start-up group 12: constant speeds this group defines a set of constant speeds. In general: • you can program up to 7 constant speeds, ranging from 0 … 500 hz or 0 … 30000 rpm. • values must be positive (no negative speed values for constant speeds). • constant speed selectio...

Page 79

Acs550 user’s manual 79 start-up 13 = di 3,4,5 – selects one of seven constant speeds (1…7) using di 3, di 4 and di 5. • see above ( di 1,2,3) for code. 14 = di 4,5,6 – selects one of seven constant speeds (1…7) using di 5, di 6 and di 7. • see above ( di 1,2,3) for code. 15…18 = timer function 1…4 ...

Page 80

80 acs550 user’s manual start-up 1209 timed mode sel defines timer activated, constant speed mode. Timer can be used to change between external reference and a maximum of three constant speeds, or to change between a maximum of 4 selectable speeds, i.E. Constant speeds 1, 2, 3 and 4. 1 = ext / cs 1/...

Page 81

Acs550 user’s manual 81 start-up group 13: analog inputs this group defines the limits and the filtering for analog inputs. Code description 1301 minimum ai1 defines the minimum value of the analog input. • define value as a percent of the full analog signal range. See example below. • the minimum a...

Page 82

82 acs550 user’s manual start-up group 14: relay outputs this group defines the condition that activates each of the relay outputs. Code description 1401 relay output 1 defines the event or condition that activates relay 1 – what relay output 1 means. 0 = not sel – relay is not used and is de-energi...

Page 83

Acs550 user’s manual 83 start-up 35 = comm – energize relay based on input from fieldbus communication. • fieldbus writes binary code in parameter 0134 that can energize relay 1…relay 6 according to the following: • 0 = de-energize relay, 1 = energize relay. 36 = comm (-1) – energize relay based on ...

Page 84

84 acs550 user’s manual start-up 1409 ro 3 off delay switch-off delay for relay 3. • see ro 1 off delay . 1410 … 1412 relay output 4…6 defines the event or condition that activates relay 4…6 – what relay output 4…6 means. • see 1401 relay output 1. 1413 ro 4 on delay defines the switch-on delay for ...

Page 85

Acs550 user’s manual 85 start-up group 15: analog outputs this group defines the drive’s analog (current signal) outputs. The drive’s analog outputs can be: • any parameter of the operating data group (group 01). • limited to programmable minimum and maximum values of output current. • scaled (and/o...

Page 86

86 acs550 user’s manual start-up group 16: system controls this group defines a variety of system level locks, resets and enables. Code description 1601 run enable selects the source of the run enable signal. 0 = not sel – allows the drive to start without an external run enable signal. 1 = di 1 – d...

Page 87

Acs550 user’s manual 87 start-up 1605 user par set chg defines control for changing the user parameter set. • see parameter 9902 ( applic macro ). • the drive must be stopped to change user parameter sets. • during a change, the drive will not start. Note: always save the user parameter set after ch...

Page 88

88 acs550 user’s manual start-up 1608 start enable 1 selects the source of the start enable 1 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di 1 – defines digital input di1 as t...

Page 89

Acs550 user’s manual 89 start-up 1609 start enable 2 selects the source of the start enable 2 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di 1 – defines digital input di1 as t...

Page 90

90 acs550 user’s manual start-up group 20: limits this group defines minimum and maximum limits to follow in driving the motor – speed, frequency, current, torque, etc. Code description 2001 minimum speed defines the minimum speed (rpm) allowed. • a positive (or zero) minimum speed value defines two...

Page 91

Acs550 user’s manual 91 start-up 2007 minimum freq defines the minimum limit for the drive output frequency. • a positive or zero minimum frequency value defines two ranges, one positive and one negative. • a negative minimum frequency value defines one speed range. See figure. Note! Keep minimum fr...

Page 92

92 acs550 user’s manual start-up 2017 max torque 1 sets the first maximum limit for torque (%). Value is a percent of the motor nominal torque. 2018 max torque 2 sets the second maximum limit for torque (%). Value is a percent of the motor nominal torque. Code description.

Page 93

Acs550 user’s manual 93 start-up group 21: start/stop this group defines how the motor starts and stops. The acs550 supports several start and stop modes. Code description 2101 start function selects the motor start method. 1 = auto – selects the automatic start mode. • vector control modes: optimal...

Page 94

94 acs550 user’s manual start-up 2105 dc hold speed sets the speed for dc hold. Requires that parameter 2104 dc curr ctl = 1 ( dc hold ). 2106 dc curr ref defines the dc current control reference as a percentage of parameter 9906 ( motor nom curr ). 2107 dc brake time defines the dc brake time after...

Page 95

Acs550 user’s manual 95 start-up group 22: accel/decel this group defines ramps that control the rate of acceleration and deceleration. You define these ramps as a pair, one for acceleration and one for deceleration. You can define two pairs of ramps and use a digital input to select one or the othe...

Page 96

96 acs550 user’s manual start-up 2209 ramp input 0 defines control for forcing the ramp input to 0. 0 = not sel – 1 = di 1 – defines digital input di 1 as the control for forcing the ramp input to 0. • activating the digital input forces ramp input to 0. Ramp output will ramp to 0 according to the c...

Page 97

Acs550 user’s manual 97 start-up group 23: speed control this group defines variables used for speed control operation. Code description 2301 prop gain sets the relative gain for the speed controller. • larger values may cause speed oscillation. • the figure shows the speed controller output after a...

Page 98

98 acs550 user’s manual start-up 2304 acc compensation sets the derivation time for acceleration compensation. • adding a derivative of the reference to the output of the speed controller compensates for inertia during acceleration. • 2303 derivation time describes the principle of derivative action...

Page 99

Acs550 user’s manual 99 start-up group 24: torque control this group defines variables used for torque control operation. Code description 2401 torq ramp up defines the torque reference ramp up time – the minimum time for the reference to increase from zero to the nominal motor torque. 2402 torq ram...

Page 100

100 acs550 user’s manual start-up group 25: critical speeds this group defines up to three critical speeds or ranges of speeds that are to be avoided due, for example, to mechanical resonance problems at certain speeds. Code description 2501 crit speed sel sets the critical speeds function on or off...

Page 101

Acs550 user’s manual 101 start-up group 26: motor control code description 2601 flux optimization changes the magnitude of the flux depending on the actual load. Flux optimization can reduce the total energy consumption and noise, and should be enabled for drives that usually operate below nominal l...

Page 102

102 acs550 user’s manual start-up 2607 sw freq ctrl the switching frequency may be reduced if the acs550 internal temperature rises above a limit. See figure. This function allows the highest possible switching frequency to be used based on operating conditions. Higher switching frequency results in...

Page 103

Acs550 user’s manual 103 start-up group 29: maintenance trig this group contains usage levels and trigger points. When usage reaches the set trigger point, a notice displayed on the control panel signals that maintenance is due. Code description 2901 cooling fan trig sets the trigger point for the d...

Page 104

104 acs550 user’s manual start-up group 30: fault functions this group defines situations that the drive should recognize as potential faults and defines how the drive should respond if the fault is detected. Code description 3001 ai defines the drive response if the analog input ( ai ) signal drops...

Page 105

Acs550 user’s manual 105 start-up 3007 mot load curve sets the maximum allowable operating load of the motor. • when set to 100%, the maximum allowable load is equal to the value of start-up data parameter 9906 motor nom current . • adjust the load curve level if the ambient temperature differs from...

Page 106

106 acs550 user’s manual start-up 3013 underload function removal of motor load may indicate a process malfunction. The protection is activated if: • the motor torque drops below the load curve selected by parameter 3015 underload curve . • this condition has lasted longer than the time set by param...

Page 107

Acs550 user’s manual 107 start-up 3023 wiring fault defines the drive response to cross wiring faults and to ground faults detected when the drive is not running. When the drive is not running it monitors for: • improper connections of input power to the drive output (the drive can display fault 35,...

Page 108

108 acs550 user’s manual start-up group 31: automatic reset this group defines conditions for automatic resets. An automatic reset occurs after a particular fault is detected. The drive holds for a set delay time, then automatically restarts. You can limit the number of resets in a specified time pe...

Page 109

Acs550 user’s manual 109 start-up group 32: supervision this group defines supervision for up to three signals from group 01, operating data. Supervision monitors a specified parameter and energizes a relay output if the parameter passes a defined limit. Use group 14, relay outputs, to define the re...

Page 110

110 acs550 user’s manual start-up 3208 superv 3 lim lo sets the low limit for the third supervised parameter. See 3207 superv 3 param above. 3209 superv 3 lim hi sets the high limit for the third supervised parameter. See 3207 superv 3 param above. Code description.

Page 111

Acs550 user’s manual 111 start-up group 33: information this group provides access to information about the drive’s current programs: versions and test date. Code description 3301 fw version contains the version of the drive’s firmware. 3302 lp version contains the version of the loading package. 33...

Page 112

112 acs550 user’s manual start-up group 34: panel display process variables this group defines the content for control panel display (middle area), when the control panel is in the output mode. Code description 3401 signal1 param selects the first parameter (by number) displayed on the control panel...

Page 113

Acs550 user’s manual 113 start-up 3408 signal 2 param selects the second parameter (by number) displayed on the control panel. See parameter 3401. 3409 signal 2 min defines the minimum expected value for the second display parameter. See parameter 3402. 3410 signal 2 max defines the maximum expected...

Page 114

114 acs550 user’s manual start-up group 35: motor temp meas this group defines the detection and reporting for a particular potential fault – motor overheating, as detected by a temperature sensor. Typical connections are defined below. Warning! Iec 60664 requires double or reinforced insulation bet...

Page 115

Acs550 user’s manual 115 start-up for other faults, or for anticipating motor overheating using a model, see group 30: fault functions. Code description 3501 sensor type identifies the type of motor temperature sensor used, pt100 (°c) or ptc (ohms). See parameters 1501 and 1507. 0 = none 1 = 1 x pt1...

Page 116

116 acs550 user’s manual start-up group 36: timer functions this group defines the timer functions. The timer functions include: • four daily start and stop times. • four weekly start, stop and boost times. • four timers for collecting selected periods together. A timer can be connected to multiple ...

Page 117

Acs550 user’s manual 117 start-up code description 3601 timers enable selects the source for the timer enable signal. 0 = not sel – timed functions are disabled. 1 = di1– defines digital input di1 as the timed function enable signal. • the digital input must be activated to enable the timed function...

Page 118

118 acs550 user’s manual start-up 3611 stop time 3 defines timer 3 daily stop time. • see parameter 3603 3612 start day 3 defines timer 3 weekly start day. • see parameter 3604 3613 stop day 3 defines timer 3 weekly stop day. • see parameter 3605 3614 start time 4 defines timer 4 daily start time. •...

Page 119

Acs550 user’s manual 119 start-up 11 = p4 + p2 + p1 – time periods 4, 2 and 1 selected in the timer. 12 = p4 + p3 – time periods 4 and 3 selected in the timer. 13 = p4 + p3 + p1 – time periods 4, 3 and 1 selected in the timer. 14 = p4 + p3 + p2 – time periods 4, 3 and 2 selected in the timer. 15 = p...

Page 120

120 acs550 user’s manual start-up group 40: process pid set 1 this group defines a set of parameters used with the process pid (pid1) controller. Typically only parameters in this group are needed. Pid controller – basic set-up in pid control mode, the drive compares a reference signal (setpoint) to...

Page 121

Acs550 user’s manual 121 start-up pid controller – advanced acs550 has 2 separate pid controllers: • process pid (pid1) and • external pid (pid2) process pid (pid1) has 2 separate sets of parameters: • process pid (pid1) set1, defined in group 40 and • process pid (pid1) set2, defined in group 41 yo...

Page 122

122 acs550 user’s manual start-up 4002 integration time defines the pid controller’s integration time. Integration time is, by definition, is the time required to increase the output by the error value: • error value is constant and 100%. • gain = 1. • integration time of 1 second denotes that a 100...

Page 123

Acs550 user’s manual 123 start-up 4008 0 % value defines (together with the next parameter) the scaling applied to the pid controller’s actual values (pid1 parameters 0128, 0130, and 0132). • units and scale are defined by parameters 4006 and 4007. 4009 100 % value defines (together with the previou...

Page 124

124 acs550 user’s manual start-up analog input reference correction parameter values 9, 10, and 14…17 use the formula in the following table. Where: • c = main reference value ( = comm for values 9, 10 and = ai 1 for values 14…17). • b = correcting reference ( = ai 1 for values 9, 10 and = ai 2 for ...

Page 125

Acs550 user’s manual 125 start-up 4016 act1 input defines the source for actual value 1 ( act 1). 0 = ai 1 – uses analog input 1 for act 1. 1 = ai 2 – uses analog input 2 for act 1. 2 = current – uses current for act 1, scaled so: • min act 1 = 0 current • max act 1 = 2 x nominal current 3 = torque ...

Page 126

126 acs550 user’s manual start-up 4022 sleep selection defines the control for the pid sleep function. 0 = not sel – disables the pid sleep control function. 1 = di 1 – defines digital input di 1 as the control for the pid sleep function. • activating the digital input activates the sleep function. ...

Page 127

Acs550 user’s manual 127 start-up 4027 pid 1 param set defines how selections are made between pid set 1 and pid set 2. Pid parameter set selection. When set 1 is selected, parameters 4001…4026 are used. When set 2 is selected, parameters 4101…4126 are used. 0 = set 1 – pid set 1 (parameters 4001…40...

Page 128

128 acs550 user’s manual start-up group 41: process pid set 2 parameters of this group belong to pid parameter set 2. The operation of parameters 4101…4126 is analogous with set 1 parameters 4001…4026. Pid parameter set 2 can be selected by parameter 4027 pid 1 param set . Group 41: process pid set ...

Page 129

Acs550 user’s manual 129 start-up group 42: external / trimming pid this group defines the parameters used for the second pid controller (pid2), which is used for the external / trimming pid. The operation of parameters 4201 … 4221 is analogous with process pid set 1 (pid1) parameters 4001…4021. Cod...

Page 130

130 acs550 user’s manual start-up 4232 correction src defines the trimming reference for the correction source. 1 = pid 2 ref – uses appropriate ref max (s witch a or b): • 1105 ref 1 max when ref 1 is active (a). • 1108 ref 2 max when ref 2 is active (b). 2 = pid 2 output – uses the absolute maximu...

Page 131

Acs550 user’s manual 131 start-up group 51: ext comm module this group defines set-up variables for a fieldbus adapter (fba) communication module. For more information on these parameters, refer to the user’s manual supplied with the fba module. Code description 5101 fba type displays the type of th...

Page 132

132 acs550 user’s manual start-up group 52: panel communication this group defines the communication settings for the control panel port on the drive. Normally, when using the supplied control panel, there is no need to change settings in this group. In this group, parameter modifications take effec...

Page 133

Acs550 user’s manual 133 start-up group 53: efb protocol this group defines set-up variables used for an embedded fieldbus (efb) communication protocol. The standard efb protocol in the acs550 is modbus. See "embedded fieldbus" starting on page 148. Code description 5301 efb protocol id contains the...

Page 134

134 acs550 user’s manual start-up 5311 efb par 11 specifies the parameter mapped to modbus register 40006. 5312 efb par 12 specifies the parameter mapped to modbus register 40007. 5313 efb par 13 specifies the parameter mapped to modbus register 40008. 5314 efb par 14 specifies the parameter mapped ...

Page 135

Acs550 user’s manual 135 start-up group 81: pfc control this group defines a pump-fan control (pfc) mode of operation. The major features of pfc control are: • the acs550 controls the motor of pump no. 1, varying the motor speed to control the pump capacity. This motor is the speed regulated motor. ...

Page 136

136 acs550 user’s manual start-up 8104 reference step 2 sets a percentage value that is added to the process reference. • applies only when at least two auxiliary (constant speed) motors are running. • see parameter 8103 reference step 1. 8105 reference step 3 sets a percentage value that is added t...

Page 137

Acs550 user’s manual 137 start-up 8112 low freq 1 sets the frequency limit used to stop the first auxiliary motor. The first auxiliary motor stops if: • the first auxiliary motor is running alone. • acs550 output frequency drops below the limit: 8112 - 1. • output frequency stays below the relaxed l...

Page 138

138 acs550 user’s manual start-up 8117 nr of aux mot sets the number of auxiliary motors. • each auxiliary motor requires a relay output, which the drive uses to send start/stop signals. • the autochange function, if used, requires an additional relay output for the speed regulated motor. • the foll...

Page 139

Acs550 user’s manual 139 start-up • the table below shows the acs550 pfc motor assignments for some typical settings in the relay output parameters (1401…1403 and 1410…1412), where the settings are either =31 ( pfc ), or =x (anything but 31), and where the autochange function is disabled (8118 autoc...

Page 140

140 acs550 user’s manual start-up 8119 autochng level sets an upper limit, as a percent of output capacity, for the autochange logic. When the output from the pid/pfc control block exceeds this limit, autochange is prevented. For example, use this parameter to deny autochange when the pump-fan syste...

Page 141

Acs550 user’s manual 141 start-up 8120 interlocks defines operation of the interlock function. When the interlock function is enabled: • an interlock is active when its command signal is absent. • an interlock is inactive when its command signal is present. • the acs550 will not start if a start com...

Page 142

142 acs550 user’s manual start-up 2 = di 2 – enables the interlock function, and assigns a digital input (starting with di 2) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 and...

Page 143

Acs550 user’s manual 143 start-up 3 = di 3 – enables the interlocks function, and assigns a digital input (starting with di 3) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 an...

Page 144

144 acs550 user’s manual start-up 5 = di 5 – enables the interlock function, and assigns a digital input (starting with di 5) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 and...

Page 145

Acs550 user’s manual 145 start-up 8121 reg bypass ctrl selects regulator by-pass control. When enabled, regulator by-pass control provides a simple control mechanism without a pid regulator. • use regulator by-pass control only in special applications. 0 = no – disables regulator by-pass control. Th...

Page 146

146 acs550 user’s manual start-up 8124 acc in aux stop sets the pfc acceleration time for a zero-to-maximum frequency ramp. This pfc acceleration ramp: • applies to the speed regulated motor, when an auxiliary motor is switched off. • replaces the acceleration ramp defined in group 22: accel / decel...

Page 147

Acs550 user’s manual 147 start-up group 98: options this group configures for options, in particular, enabling serial communication with the drive. Code description 9802 comm prot sel selects the communication protocol. 0 = not sel – no communication protocol selected. 1 = std modbus – the drive com...

Page 148: Embedded Fieldbus

148 acs550 user’s manual embedded fieldbus embedded fieldbus overview the acs550 can be set up to accept control from an external system using standard serial communication protocols. When using serial communication, the acs550 can either: • receive all of its control information from the fieldbus, ...

Page 149

Acs550 user’s manual 149 embedded fieldbus – actual value 4 – actual value 5 – actual value 6 – actual value 7 – actual value 8 the content of these words is defined by profiles. For details on the profiles used, see "abb control profiles technical data" on page 168. Note! The words “output” and “in...

Page 150

150 acs550 user’s manual embedded fieldbus • to reduce noise on the network, terminate the rs485 network using 120 Ω resistors at both ends of the network. Use the dip switch to connect or disconnect the termination resistors. See following diagram and table. • connect the shield at each end of the ...

Page 151

Acs550 user’s manual 151 embedded fieldbus serial communication configuration setting 9802 automatically sets the appropriate default values in parameters that define the communication process. These parameters and descriptions are defined below. In particular, note that the station id may require a...

Page 152

152 acs550 user’s manual embedded fieldbus activate drive control functions – efb controlling the drive fieldbus control of various drive functions requires configuration to: • tell the drive to accept fieldbus control of the function. • define as a fieldbus input, any drive data required for contro...

Page 153

Acs550 user’s manual 153 embedded fieldbus input reference select using the fieldbus to provide input references to the drive requires: • drive parameter values set as defined below. • fieldbus controller supplied reference word(s) in the appropriate location. (the location is defined by the protoco...

Page 154

154 acs550 user’s manual embedded fieldbus relay output control using the fieldbus for relay output control requires: • drive parameter values set as defined below. • fieldbus controller supplied, binary coded, relay command(s) in the appropriate location. (the location is defined by the protocol re...

Page 155

Acs550 user’s manual 155 embedded fieldbus pid control setpoint source using the following settings to select the fieldbus as the setpoint source for pid loops: communication fault when using fieldbus control, specify the drive’s action if serial communication is lost. Drive parameter value descript...

Page 156

156 acs550 user’s manual embedded fieldbus feedback from the drive – efb pre-defined feedback inputs to the controller (drive outputs) have pre-defined meanings established by the protocol. This feedback does not require drive configuration. The following table lists a sample of feedback data. For a...

Page 157

Acs550 user’s manual 157 embedded fieldbus for example: 1. Assuming, for the sake of this example, that the actual value uses parameter 9908 mot nom speed as the 100% reference, and that 9908 = 1500 rpm. 2. Assuming, for the sake of this example, that the actual value uses parameter 9907 mot nom fre...

Page 158

158 acs550 user’s manual embedded fieldbus diagnostic situations the sub-sections below describe various diagnostic situations – the problem symptoms and corrective actions. Normal operation during normal network operation, 5306…5309 parameter values act as follows at each drive: • 5306 efb ok messa...

Page 159

Acs550 user’s manual 159 embedded fieldbus fault 28 – serial 1 err if the drive’s control panel shows fault code 28 “ serial 1 err ”, check for either of the following: • the master system is down. To correct, resolve problem with master system. • the communication connection is bad. To correct, che...

Page 160

160 acs550 user’s manual embedded fieldbus modbus protocol technical data overview the modbus® protocol was introduced by modicon, inc. For use in control environments featuring modicon programmable controllers. Due to its ease of use and implementation, this common plc language was quickly adopted ...

Page 161

Acs550 user’s manual 161 embedded fieldbus mapping summary the following table summarizes the mapping between the acs550 (parameters and i/0) and modbus reference space. For details, see "modbus addressing" below. Communication profiles when communicating by modbus, the acs550 supports multiple prof...

Page 162

162 acs550 user’s manual embedded fieldbus • relay output states, numbered sequentially beginning with coil 00033. The following table summarizes the 0xxxx reference set: * = active low for the 0xxxx registers: • status is always readable. • forcing is allowed by user configuration of the drive for ...

Page 163

Acs550 user’s manual 163 embedded fieldbus the acs550 supports the following modbus function codes for coils: 1xxxx mapping – modbus discrete inputs. The drive maps the following information to the 1xxxx modbus set called modbus discrete inputs: • bit-wise map of the status word (selected using para...

Page 164

164 acs550 user’s manual embedded fieldbus * = active low for the 1xxxx registers: • additional discrete inputs are added sequentially. The acs550 supports the following modbus function codes for discrete inputs: 3xxxx mapping – modbus inputs. The drive maps the following information to the 3xxxx mo...

Page 165

Acs550 user’s manual 165 embedded fieldbus the following table summarizes the 4xxxx drive control registers 40001…40099 (for 4xxxx registers above 40099, see the drive parameter list, e.G. 40102 is parameter 0102): modbus register access remarks 4 0001 control word r/w maps directly to the profile‘ ...

Page 166

166 acs550 user’s manual embedded fieldbus for the modbus protocol, drive parameters in group 53 report the parameter mapping to 4xxxx registers. Except where restricted by the drive, all parameters are available for both reading and writing. The parameter writes are verified for the correct value, ...

Page 167

Acs550 user’s manual 167 embedded fieldbus actual values the contents of the register addresses 40005…40012 are actual values and are: • specified using parameters 5310…5317. • read-only values containing information on the operation of the drive. • 16-bit words containing a sign bit and a 15-bit in...

Page 168

168 acs550 user’s manual embedded fieldbus abb control profiles technical data overview abb drives profile the abb drives profile provides a standard profile that can be used on multiple protocols, including modbus and the protocols available on the fba module. Two implementations of the abb drives ...

Page 169

Acs550 user’s manual 169 embedded fieldbus abb drives profile the following table and the state diagram later in this sub-section describe the control word content for the abb drives profile. Abb drives profile control word (see parameter 5319) bit name value commanded state comments 0 off1 control ...

Page 170

170 acs550 user’s manual embedded fieldbus dcu profile the following tables describe the control word content for the dcu profile. 7 reset 0=>1 reset fault reset if an active fault exists (enter switch - on inhibited ). Effective if 1604 = comm . 0 operating continue normal operation 8…9 unused 10 u...

Page 171

Acs550 user’s manual 171 embedded fieldbus status word the contents of the status word is status information, sent by the drive to the master station. 8 stpmode_em 1 emergency ramp stop mode 0 (no op) 9 stpmode_c 1 coast stop mode 0 (no op) 10 ramp_2 1 ramp pair 2 0 ramp pair 1 11 ramp_out_0 1 ramp ...

Page 172

172 acs550 user’s manual embedded fieldbus abb drives profile the following table and the state diagram later in this sub-section describe the status word content for the abb drives profile. Abb drives profile (efb) status word (see parameter 5320) bit name value description (correspond to states/bo...

Page 173

Acs550 user’s manual 173 embedded fieldbus dcu profile the following tables describe the status word content for the dcu profile. Dcu profile status word (see parameter 0303) bit name value status 0 ready 1 drive is ready to receive start command. 0 drive is not ready. 1 enabled 1 external run enabl...

Page 174

174 acs550 user’s manual embedded fieldbus dcu profile status word (see parameter 0304) bit name value status 16 alarm 1 an alarm is on. 0 no alarms are on. 17 req_maint 1 a maintenance request is pending. 0 no maintenance request is pending. 18 dirlock 1 direction lock is on. (direction change is l...

Page 175

Acs550 user’s manual 175 embedded fieldbus state diagram abb drives profile to illustrate the operation of the state diagram, the following example ( abb drv lim implementation of the abb drives profile) uses the control word to start the drive: • first, the requirements for using the control word m...

Page 176

176 acs550 user’s manual embedded fieldbus the state diagram below describes the start-stop function of control word (cw) and status word (sw) bits for the abb drives profile. (cw xxxx x1xx xxxx x110) mains off power on (cw bit0=0) (sw bit6=1) (sw bit0=0) from any state n(f)=0 / i=0 off1 (cw bit0=0)...

Page 177

Acs550 user’s manual 177 embedded fieldbus reference scaling abb drives and dcu profiles the following table describes reference scaling for the abb drives and dcu profiles. Note! The setting of parameter 1104 ref 1 min and 1107 ref 2 min has no effect on the scaling of references. When parameter 11...

Page 178

178 acs550 user’s manual embedded fieldbus ref1 comm * ai 1 comm (%) * ( ai (%) / 0.5* ref 1 max (%)) ref2 comm + ai 1 comm (%) + ( ai (%) - 0.5* ref 2 max (%)) ref2 comm * ai 1 comm (%) * ( ai (%) / 0.5* ref 2 max (%)) abb drives and dcu profiles reference value setting ai reference scaling 0% 50% ...

Page 179

Acs550 user’s manual 179 embedded fieldbus reference handling use group 10 parameters to configure for control of rotation direction for each control location ( ext 1 and ext 2). The following diagrams illustrate how group 10 parameters and the sign of the fieldbus reference interact to produce refe...

Page 180: Fieldbus Adapter

180 acs550 user’s manual fieldbus adapter fieldbus adapter overview the acs550 can be set up to accept control from an external system using standard serial communication protocols. When using serial communication, the acs550 can either: • receive all of its control information from the fieldbus, or...

Page 181

Acs550 user’s manual 181 fieldbus adapter control interface in general, the basic control interface between the fieldbus system and the drive consists of: • output words: – control word – reference (speed or frequency) – others: the drive supports a maximum of 15 output words. Protocols limits may f...

Page 182

182 acs550 user’s manual fieldbus adapter – parameter 9802 comm prot sel = 4 (ext fba). – the external plug-in fieldbus adapter is configured to use the drive profile mode or drive profile objects. The content of the control word depends on the protocol/profile used. See the user’s manual provided w...

Page 183

Acs550 user’s manual 183 fieldbus adapter mechanical and electrical installation – fba warning! Connections should be made only while the drive is disconnected from the power source. Overview the fba (fieldbus adapter) is a plug-in module that fits in the drive’s expansion slot 2. The module is held...

Page 184

184 acs550 user’s manual fieldbus adapter communication set-up – fba serial communication selection to activate the serial communication, use parameter 9802 comm protocol sel . Set 9802 = 4 ( ext fba ). Serial communication configuration setting 9802, together with mounting a particular fba module, ...

Page 185

Acs550 user’s manual 185 fieldbus adapter input reference select using the fieldbus to provide input reference to the drive requires: • drive parameter value set as defined below. • fieldbus controller supplied reference word(s) in the appropriate location. (the location is defined by the protocol r...

Page 186

186 acs550 user’s manual fieldbus adapter relay output control using the fieldbus for relay output control requires: • drive parameter values set as defined below. • fieldbus controller supplied, binary coded, relay command(s) in the appropriate location. (the location is defined by the protocol ref...

Page 187

Acs550 user’s manual 187 fieldbus adapter pid control setpoint source using the following settings to select the fieldbus as the setpoint source for pid loops: communication fault when using fieldbus control, specify the drive’s action if serial communication is lost. Feedback from the drive – fba i...

Page 188

188 acs550 user’s manual fieldbus adapter diagnostics – fba fault handling the acs550 provides fault information as follows: • the control panel display shows a fault code and text. See "diagnostics" starting on page 200 for a complete description. • parameters 0401 last fault , 0402 previous fault ...

Page 189

Acs550 user’s manual 189 fieldbus adapter serial communication diagnostics besides the drive fault codes, the fba module has diagnostic tools. Refer to the user’s manual supplied with the fba module. 28 serial 1 err 7510h 29 efb config file 6306h 30 force trip ff90h 31 efb 1 ff92h 32 efb 2 ff93h 33 ...

Page 190

190 acs550 user’s manual fieldbus adapter abb drives profile technical data overview the abb drives profile provides a standard profile that can be used on multiple protocols, including protocols available on the fba module. This section describes the abb drives profile implemented for fba modules. ...

Page 191

Acs550 user’s manual 191 fieldbus adapter status word as described earlier in "control interface", the contents of the status word is status information, sent by the drive to the master station. The following table and the state diagram later in this sub-section describe the status word content. 5 r...

Page 192

192 acs550 user’s manual fieldbus adapter 4 off_2_sta 1 off 2 inactive 0 of f 2 active 5 off_3_sta 1 off 3 inactive 0 of f 3 active 6 swc_on_inhib 1 switch - on inhibit active 0 switch - on inhibit not active 7 alarm 1 warning/alarm (see "alarm listing" in the "diagnostics" section for details on al...

Page 193

Acs550 user’s manual 193 fieldbus adapter the state diagram below describes the start-stop function of control word (cw) and status word (sw) bits. (cw xxxx x1xx xxxx x110) mains off power on (cw bit0=0) (sw bit6=1) (sw bit0=0) from any state n(f)=0 / i=0 off1 (cw bit0=0) a c d (cw bit3=0) (sw bit2=...

Page 194

194 acs550 user’s manual fieldbus adapter reference as described earlier in "control interface", the reference word is a speed or frequency reference. Reference scaling the following table describes reference scaling for the abb drives profile. Note! The setting of parameter 1104 ref 1 min and 1107 ...

Page 195

Acs550 user’s manual 195 fieldbus adapter ref1 comm * ai 1 comm (%) * ( ai (%) / 0.5* ref 1 max (%)) ref2 comm + ai 1 comm (%) + ( ai (%) - 0.5* ref 2 max (%)) ref2 comm * ai 1 comm (%) * ( ai (%) / 0.5* ref 2 max (%)) abb drives profile (fba) reference value setting ai reference scaling 0% 50% 200%...

Page 196

196 acs550 user’s manual fieldbus adapter reference handling use group 10 parameters to configure for control of rotation direction for each control location ( ext 1 and ext 2). The following diagrams illustrate how group 10 parameters and the sign of the fieldbus reference interact to produce refer...

Page 197

Acs550 user’s manual 197 fieldbus adapter actual value as described earlier in "control interface", actual values are words containing drive values. Actual value scaling the scaling of the integers sent to the fieldbus as actual values depends on the resolution of the selected drive parameter. Excep...

Page 198

198 acs550 user’s manual fieldbus adapter generic profile technical data overview the generic profile aims to fulfill the industry-standard drive profile for each protocol (e.G. Profidrive for profibus, ac/dc drive for devicenet). Control word as described earlier in "control interface" the control ...

Page 199

Acs550 user’s manual 199 fieldbus adapter actual value scaling for actual values, scale the feedback integer using the parameter’s resolution. (see "complete parameter list for acs550" section for parameter resolutions.) for example: where parameters are in percent, the "complete parameter list for ...

Page 200: Diagnostics

200 acs550 user’s manual diagnostics diagnostics warning! Do not attempt any measurement, parts replacement or other service procedure not described in this manual. Such action will void the warranty, may endanger correct operation, and increase downtime and expense. Warning! All electrical installa...

Page 201

Acs550 user’s manual 201 diagnostics flashing green – alarms for less severe errors, called alarms, the diagnostic display is advisory. For these situations, the drive is simply reporting that it had detected something “unusual.” in these situations, the drive: • flashes the green led on the drive (...

Page 202

202 acs550 user’s manual diagnostics 4 short circ fault current. Check for and correct: • a short-circuit in the motor cable(s) or motor. • supply disturbances. 5 reserved not used. 6 dc undervolt intermediate circuit dc voltage is not sufficient. Check for and correct: • missing phase in the input ...

Page 203

Acs550 user’s manual 203 diagnostics 16 earth fault possible ground fault detected in the motor or motor cables. The drive monitors for ground faults while the drive is running and while the drive is not running. Detection is more sensitive when the drive is not running and can produce false positiv...

Page 204

204 acs550 user’s manual diagnostics 31 efb 1 fault code reserved for the embedded fieldbus (efb) protocol application. The meaning is protocol dependent. 32 efb 2 33 efb 3 34 motor phase fault in the motor circuit. One of the motor phases is lost. Check for and correct: • motor fault. • motor cable...

Page 205

Acs550 user’s manual 205 diagnostics faults that indicate conflicts in the parameter settings are listed below. Fault code fault name in panel description and recommended corrective action 1000 par hzrpm parameter values are inconsistent. Check for any of the following: • 2001 minimum speed > 2002 m...

Page 206

206 acs550 user’s manual diagnostics fault resetting the acs550 can be configured to automatically reset certain faults. Refer to parameter group 31: automatic reset. Warning! If an external source for start command is selected and it is active, the acs550 may start immediately after fault reset. Fl...

Page 207

Acs550 user’s manual 207 diagnostics alarm listing the following table lists the alarms by code number and describes each. Alarm code display description 2001 overcurrent current limiting controller is active. Check for and correct: • excessive motor load. • insufficient acceleration time (parameter...

Page 208

208 acs550 user’s manual diagnostics 2009 device overtemp drive heatsink is hot. This alarm warns that a device overtemp fault may be near. R1…r4 & r7/r8: 100 °c (212 °f) r5/r6: 110 °c (230 °f) check for and correct: • fan failure. • obstructions in the air flow. • dirt or dust coating on the heat s...

Page 209

Acs550 user’s manual 209 diagnostics note 1. Even when the relay output is configured to indicate alarm conditions (e.G. Parameter 1401 relay output 1 = 5 ( alarm ) or 16 ( flt / alarm )), this alarm is not indicated by a relay output. Alarm codes (basic control panel) the basic control panel indica...

Page 210

210 acs550 user’s manual diagnostics 5032 parameter error was detected. 5040 selected parameter set can’t be found in the current parameter backup. 5041 parameter backup doesn't fit into memory. 5042 selected parameter set can’t be found in the current parameter backup. 5043 no start inhibit was gra...

Page 211: Maintenance

Acs550 user’s manual 211 maintenance maintenance warning! Read "safety" on page 3 before performing any maintenance on the equipment. Ignoring the safety instructions can cause injury or death. Maintenance intervals if installed in an appropriate environment, the drive requires very little maintenan...

Page 212

212 acs550 user’s manual maintenance main fan replacement the drive’s main cooling fan has a life span of about 60,000 operating hours at maximum rated operating temperature and drive load. The expected life span doubles for each 10 °c (18 °f) drop in the fan temperature (fan temperature is a functi...

Page 213

Acs550 user’s manual 213 maintenance internal enclosure fan replacement ip 54 / ul type 12 enclosures have an additional internal fan to circulate air inside the enclosure. Frame sizes r1…r4 to replace the internal enclosure fan in frame sizes r1 to r4: 1. Remove power from drive. 2. Remove the fron...

Page 214

214 acs550 user’s manual maintenance control panel cleaning use a soft damp cloth to clean the control panel. Avoid harsh cleaners which could scratch the display window. Battery a battery is only used in assistant control panels that have the clock function available and enabled. The battery keeps ...

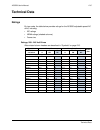

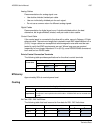

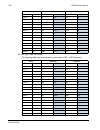

Page 215: Technical Data

Acs550 user’s manual 215 technical data technical data ratings by type code, the table below provides ratings for the acs550 adjustable speed ac drive, including: • iec ratings • nema ratings (shaded columns) • frame size ratings, 208…240 volt drives abbreviated column headers are described in “symb...

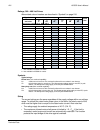

Page 216

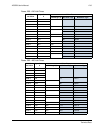

216 acs550 user’s manual technical data ratings, 380…480 volt drives abbreviated column headers are described in “symbols” on page 216. 1. Not available in acs550-u1 series. 2. Not available in acs550-01 series. Symbols sizing the current ratings are the same regardless of the supply voltage within ...

Page 217

Acs550 user’s manual 217 technical data derating the load capacity (current and power) decreases for certain situations, as defined below. In such situations, where full motor power is required, oversize the drive so that the derated value provides sufficient capacity. For example, if your applicati...

Page 218

218 acs550 user’s manual technical data input power connections warning! Do not operate the drive outside the nominal input line voltage range. Over-voltage can result in permanent damage to the drive. Input power specifications disconnect device the acs550 does not include a disconnect device. A me...

Page 219

Acs550 user’s manual 219 technical data fuses, 208…240 volt drives fuses, 380…480 volt drives acs550-x1- see below input current a mains fuses iec269 gg (a) ul class t (a) bussmann type -04a6-2 4.6 10 10 jjs-10 -06a6-2 6.6 -07a5-2 7.5 -012a-2 11.8 16 15 jjs-15 -017a-2 16.7 25 25 jjs-25 -024a-2 24.2 ...

Page 220

220 acs550 user’s manual technical data emergency stop devices the overall design of the installation must include emergency stop devices and any other safety equipment that may be needed. Pressing stop on the drive’s control panel does not: • generate an emergency stop of the motor. • separate the ...

Page 221

Acs550 user’s manual 221 technical data ground connections for personnel safety, proper operation and to reduce electromagnetic emission/pick- up, the drive and the motor must be grounded at the installation site. • conductors must be adequately sized as required by safety regulations. • power cable...

Page 222

222 acs550 user’s manual technical data • acs550-u1 drives are shipped with the screw removed (but included in the conduit box). Em3 (an m4x16 screw) makes an internal ground connection that reduces electro-magnetic emission. Where emc (electro- magnetic compatibility) is a concern, and the network ...

Page 223

Acs550 user’s manual 223 technical data drive’s power connection terminals the following table provides specifications for the drive’s power connection terminals. 1. Do not use aluminum cable with frame sizes r1…r4. Power terminal considerations – r6 frame size warning! For r6 power terminals, if co...

Page 224

224 acs550 user’s manual technical data compression lugs use the following procedure to attach cables if compression lugs are supplied and can be used. 1. Attach the supplied compression lugs to the drive end of the cables. 2. Attach compression lug to the drive. 35 2 burndy ya2c-l4box my29-3 2 ilsc...

Page 225

Acs550 user’s manual 225 technical data motor connections warning! Never connect line power to the drive output terminals: u2, v2 or w2. Line voltage applied to the output can result in permanent damage to the unit. If frequent bypassing is required, use mechanically interlocked switches or contacto...

Page 226

226 acs550 user’s manual technical data grounding and routing motor cable shielding motor cables require shielding using conduit, armored cable or shielded cable. • conduit – when using conduit: – bridge joints with a ground conductor bonded to the conduit on each side of the joint. – bond conduit r...

Page 227

Acs550 user’s manual 227 technical data recommendation for conductor layout the following figure compares conductor layout features in motor cables. Effective motor cable screens the general rule for cable screen effectiveness is: the better and tighter the cable’s screen, the lower the radiated emi...

Page 228

228 acs550 user’s manual technical data installation must conform to the instructions in the filter package for all cable screen connections. 1. For any motor cable length (up to the100 m maximum length limit) compliance does not require an additional filter. 2. Data not available at time of publica...

Page 229

Acs550 user’s manual 229 technical data note! The filter does not assure compliance with radiated emissions limits. Warning! Do not use rfi/emc filters in a floating, or impedance grounded network. Maximum cable length for en 61800-3 ce first environment, unrestricted distribution (cispr11 class b) ...

Page 230

230 acs550 user’s manual technical data brake components availability braking availability for acs550 drives, by frame size is: • r1 and r2 – a built-in brake chopper is standard equipment. Add appropriate resistor, as determined using the following section. Resistors are available from abb. • r3…r6...

Page 231

Acs550 user’s manual 231 technical data the many variables in the last requirement above are most easily dealt with using the following tables. • first, determine your maximum braking time on (on max ), minimum braking time off (off min ) and load type (deceleration or overhauling load). • calculate...

Page 232

232 acs550 user’s manual technical data 380…480 volt drives 1. Resistor time constant specification must be > 85 seconds. Warning! Never use a brake resistor with a resistance below the minimum value specified for the particular drive. The drive and the internal chopper are not able to handle the ov...

Page 233

Acs550 user’s manual 233 technical data mandatory circuit protection the following setup is essential for safety – it interrupts the main supply in fault situations involving chopper shorts: • equip the drive with a main contactor. • wire the contactor so that it opens if the resistor thermal switch...

Page 234

234 acs550 user’s manual technical data control connections control connection specifications control cables general recommendations use multi-core cables with a braided copper wire screen, temperature rated at 60 °c (140 °f) or above: at the drive end, twist the screen together into a bundle not lo...

Page 235

Acs550 user’s manual 235 technical data analog cables recommendations for analog signal runs: • use double shielded, twisted pair cable. • use one individually shielded pair for each signal. • do not use a common return for different analog signals. Digital cables recommendation for digital signal r...

Page 236

236 acs550 user’s manual technical data air flow, 380…480 volt drives the following table lists heat loss and air flow data for 380…480 volt drives. -07a5-2 r1 81 276 44 26 -012a-2 r1 116 404 44 26 -017a-2 r1 161 551 44 26 -024a-2 r2 227 776 88 52 -031a-2 r2 285 373 88 52 -046a-2 r3 420 1434 134 79 ...

Page 237

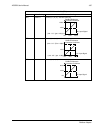

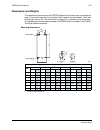

Acs550 user’s manual 237 technical data dimensions and weights the dimensions and mass for the acs550 depend on the frame size and enclosure type. If unsure of frame size, first, find the “type” code on the drive labels. Then look up that type code in the "technical data" on page 215, to determine t...

Page 238

238 acs550 user’s manual technical data outside dimensions units with ip 21 / ul type 1 enclosures units with ip 54 / ul type 12 enclosures ip 21 / ul type 1 – dimensions for each frame size ref. R1 r2 r3 r4 r5 r6 mm in mm in mm in mm in mm in mm in w 125 4.9 125 4.9 203 8.0 203 8.0 265 10.4 300 11....

Page 239

Acs550 user’s manual 239 technical data weight the following table lists typical maximum weights for each frame size. Variations within each frame size (due to components associated with voltage/current ratings, and options) are minor. Degrees of protection available enclosures: • ip 21 / ul type 1 ...

Page 240

240 acs550 user’s manual technical data ambient conditions the following table lists the acs550 environmental requirements. The following table lists the standard stress testing that the acs550 passes. Ambient environment requirements installation site storage and transportation in the protective pa...

Page 241

Acs550 user’s manual 241 technical data materials applicable standards drive compliance with the following standards is identified by the standards “marks” on the type code label. Compliance is valid with the following provisions: • the motor and control cables are chosen as specified in this manual...

Page 242

242 acs550 user’s manual technical data ul markings when a ul mark is attached to the acs550 ac drive, it verifies that the drive follows the provisions of ul 508c. The acs550 is ul listed to 100 kaic without use of input fuses or circuit breaker. For end-users convenience, the section "fuses" provi...

Page 243

Acs550 user’s manual 243 technical data electromagnetic environments product standard en 61800-3 (adjustable speed electrical power drive systems - part 3: emc product standard including specific test methods) defines first environment as environment that includes domestic premises. It also includes...

Page 244: Index

244 acs550 user’s manual index index numerics 0xxxx register efb function codes. . . . . . . . . . . . . . . . . . . 163 efb mapping . . . . . . . . . . . . . . . . . . . . . . . 161 1xxxx register efb function codes. . . . . . . . . . . . . . . . . . . 164 efb mapping . . . . . . . . . . . . . . . ...

Page 245

Acs550 user’s manual 245 index ce marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242 changed parameters (assistant panel) . . . . . . . . 33 chopper see braking cispr11 class a radiation limits . . . . . . . . . . . . . . . . . . . . . . . 227 cispr11 class b radiation limits . . . ...

Page 246

246 acs550 user’s manual index control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cable requirements . . . . . . . . . . . . . . . . . . . 235 comm error, fault parameter . . . . . . . . . . . . 104 contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 display b...

Page 247