- DL manuals

- ABB

- Power Supply

- ACS550-01

- User Manual

ABB ACS550-01 User Manual

Summary of ACS550-01

Page 1

Drive it low voltage ac drives user’s manual acs550-01 drives (0.75 … 90 kw) acs550-u1 drives (1 … 150 hp).

Page 2

2 acs550 user’s manual acs550 drive manuals general manuals acs550-01/u1 user's manual (0.75…90 kw) / (1…150 hp) • safety • installation • start-up • diagnostics • maintenance • technical data acs550-02/u2 user's manual (110…355 kw) / (150…550 hp) • safety • installation • start-up • diagnostics • m...

Page 3: Safety

Acs550 user’s manual 3 safety safety warning! The acs550 adjustable speed ac drive should only be installed by a qualified electrician. Warning! Even when the motor is stopped, dangerous voltage is present at the power circuit terminals u1, v1, w1 and u2, v2, w2 and, depending on the frame size, udc...

Page 4

4 acs550 user’s manual safety use of warnings and notes there are two types of safety instructions throughout this manual: • notes draw attention to a particular condition or fact, or give information on a subject. • warnings caution you about conditions which can result in serious injury or death a...

Page 5: Table Of Contents

Acs550 user’s manual 5 table of contents table of contents safety use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 table of contents installation installation flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6: Installation

6 acs550 user’s manual installation installation study these installation instructions carefully before proceeding. Failure to observe the warnings and instructions may cause a malfunction or personal hazard. Warning! Before you begin read "safety" on page 3. Installation flow chart the installation...

Page 7

Acs550 user’s manual 7 installation preparing for installation drive identification drive labels to determine the type of drive you are installing, refer to either: • serial number label attached on upper part of the chokeplate between the mounting holes. • type code label attached on the heat sink ...

Page 8

8 acs550 user’s manual installation motor compatibility the motor, drive, and supply power must be compatible: tools required to install the acs550 you need the following: • screwdrivers (as appropriate for the mounting hardware used) • wire stripper • tape measure • drill • mounting hardware: screw...

Page 9

Acs550 user’s manual 9 installation • the minimum space requirements for the drive are the outside dimensions (see "outside dimensions" on page 132), plus air flow space around the unit (see "cooling" on page 131). • the distance between the motor and the drive is limited by the maximum motor cable ...

Page 10

10 acs550 user’s manual installation second environment includes establishments other than those directly connected to a low voltage power supply network which supplies buildings used for domestic purposes. C-tick marking (pending as of publication date) a c-tick mark is attached to the acs550 ac dr...

Page 11

Acs550 user’s manual 11 installation constructed pe conductor is always recommended. The following figure shows the minimum requirement for the motor cable screen (for example, mcmk, nk cables). * input filters designed for acs550 cannot be used in an isolated, or high impedance earthed industrial d...

Page 12

12 acs550 user’s manual installation at the motor end the motor cable screen must be earthed 360 degrees with an emc cable gland or the screen wires must be twisted together into a bundle not longer than five times its width and connected to the pe terminal of the motor. En61800-3 and as/nzs 2064, 1...

Page 13

Acs550 user’s manual 13 installation control cables general recommendations use shielded cables, temperature rated at 60 °c (140 °f) or above: • control cables must be multi-core cables with a braided copper wire screen. • the screen must be twisted together into a bundle not longer than five times ...

Page 14

14 acs550 user’s manual installation installing the drive warning! Before installing the acs550, ensure the input power supply to the drive is off. Unpack the drive 1. Unpack the drive. 2. Check for any damage and notify the shipper immediately if damaged components are found. 3. Check the contents ...

Page 15

Acs550 user’s manual 15 installation mount the drive 1. Position the acs550 onto the mounting screws or bolts and securely tighten in all four corners. Note! Lift the acs550 by its metal chassis. 2. Non-english speaking locations: add a warning sticker in the appropriate language over the existing w...

Page 16

16 acs550 user’s manual installation connection diagrams the layout of connection terminals is similar for all frame sizes (r1 … r6). The only significant layout difference is in the power and ground terminals for frame sizes r5 and r6. The following diagrams show: • power and ground terminal layout...

Page 17

Acs550 user’s manual 17 installation warning! For floating networks remove screws at em1 and em3. Panel connector power led (green) fault led (red) optional module 1 (encoder or j2/j5 – dip switches x1 – communications optional module 2 gnd power output to motor power input em1 j1 – dip switches x1 ...

Page 18

18 acs550 user’s manual installation wiring with cables 1. Open the appropriate knockouts in the conduit/gland box. (see "conduit/gland kit" above.) 2. Install the cable clamps for the power/motor cables. 3. On the input power cable, strip the sheathing back far enough to route individual wires. 4. ...

Page 19

Acs550 user’s manual 19 installation wiring with conduit 1. Open the appropriate knockouts in the conduit/gland box. (see "conduit/gland kit" above.) 2. Install thin-wall conduit clamps (not supplied). 3. Install conduit/gland box. 4. Connect conduit runs to box. 5. Route input power and motor wirin...

Page 20

20 acs550 user’s manual installation power connections warning! Ensure the motor is compatible for use with the acs550. The acs550 must be installed by a competent person in accordance with the considerations defined in "preparing for installation" on page 7. If in doubt, contact your local abb sale...

Page 21

Acs550 user’s manual 21 installation 1 digital input impedance 1.5 k Ω . Maximum voltage for digital inputs is 30 v. 2 default values depend on the macro used. Values specified are for the default macro. See "application macros" on page 31. X1 hardware description 1 scr terminal for signal cable scr...

Page 22

22 acs550 user’s manual installation note! Terminals 3, 6, and 9 are at the same potential. Note! For safety reasons the fault relay signals a “fault” when the acs550 is powered down. You can wire the digital input terminals in either a pnp or npn configuration. Communications terminals 28 … 32 are ...

Page 23

Acs550 user’s manual 23 installation check installation before applying power, perform the following checks. Re-install cover 1. Align the cover and slide it on. 2. Tighten the captive screw. 3. Re-install the control panel. Apply power always re-install the front cover before turning power on. Warn...

Page 24

24 acs550 user’s manual installation start-up 1. Use any, or all of the following options to configure the drive: • use the start-up assistant. With the assistant control panel, the start-up assistant runs automatically at the first power up. See "start-up assistant mode" on page 29 for an overview ...

Page 25: Start-Up

Acs550 user’s manual 25 start-up start-up start-up configures the drive. This process sets parameters that define how the drive operates and communicates. Depending on the control and communication requirements, the start-up process may require any or all of the following: • the start-up assistant (...

Page 26

26 acs550 user’s manual start-up controls/display overview the following table summarizes the button functions and displays on the assistant control panel control mode use the control mode to read information on the drive’s status and to operate the drive. To reach the control mode, press exit until...

Page 27

Acs550 user’s manual 27 start-up • – indicates the drive and motor rotation status as follows: • upper right – shows the active reference. Middle. Using parameter group 34, the middle of the lcd display can be configured to display: • 3 parameter values the default values depend on the parameter 990...

Page 28

28 acs550 user’s manual start-up the reference can be modified in the local control mode, and can be parameterized (using group 11: reference select) to also allow modification in the remote control mode. Other modes besides the control mode, the assistant control panel has: • other operating modes ...

Page 29

Acs550 user’s manual 29 start-up – download restores the parameters into the drive. – a partial restore option excludes the following parameters from the backup: 9905…9909, 1605, 1607, 5201, and all group 51 parameters. Parameters mode use the parameters mode to manually set parameters: • select par...

Page 30

30 acs550 user’s manual start-up task name description language select selects the language used in control panel displays motor set-up enters motor data and motor identification application selects an application macro option modules activates optional modules, if any, mounted on the drive. Speed c...

Page 31

Acs550 user’s manual 31 start-up application macros macros change a group of parameters to new, predefined values. Use macros to minimize the need for manual editing of parameters. Selecting a macro sets all other parameters to their default values, except: • group 99: start-up data parameters • the...

Page 32

32 acs550 user’s manual start-up application macro: abb standard (default) this macro provides a general purpose, 2-wire i/o configuration, with three (3) constant speeds. This is the default macro. Parameter values are the default values defined in the "complete parameter list for acs550" on page 4...

Page 33

Acs550 user’s manual 33 start-up application macro: 3-wire this macro is used when the drive is controlled using momentary push-buttons, and provides three (3) constant speeds. To enable, set the value of parameter 9902 to 2 (3- wire ). Note! When the stop input ( di 2) is deactivated (no input), th...

Page 34

34 acs550 user’s manual start-up application macro: alternate this macro provides an i/o configuration adopted to a sequence of di control signals used when alternating the rotation direction of the drive.To enable, set the value of parameter 9902 to 3 ( alternate ). Connection example: input signal...

Page 35

Acs550 user’s manual 35 start-up application macro: motor potentiometer this macro provides a cost-effective interface for plcs that vary the speed of the drive using only digital signals. To enable, set the value of parameter 9902 to 4 ( motor pot ). Connection example: input signals output signals...

Page 36

36 acs550 user’s manual start-up application macro: hand-auto this macro provides an i/o configuration that is typically used in hvac applications. To enable, set the value of parameter 9902 to 5 ( hand / auto ). Note! Parameter 2107 start inhibit must remain in the default setting, 0 ( off ). Conne...

Page 37

Acs550 user’s manual 37 start-up application macro: pid control this macro provides parameter settings for closed-loop control systems such as pressure control, flow control, etc. To enable, set the value of parameter 9902 to 6 ( pid ctrl ). Note! Parameter 2107 start inhibit must remain in the defa...

Page 38

38 acs550 user’s manual start-up application macro: pfc this macro provides parameter settings for pump and fan control (pfc) applications. To enable, set the value of parameter 9902 to 7 ( pfc control ). Note! Parameter 2107 start inhibit must remain in the default setting, 0 ( off ). Connection ex...

Page 39

Acs550 user’s manual 39 start-up application macro: torque control this macro provides parameter settings for applications that require torque control of the motor. Control can also be switched to speed control. To enable, set the value of parameter 9902 to 8 (t orque control ). Connection example: ...

Page 40

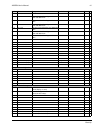

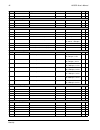

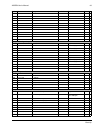

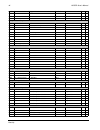

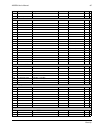

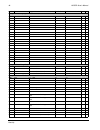

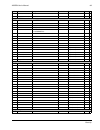

40 acs550 user’s manual start-up complete parameter list for acs550 the following table lists all parameters. Header abbreviations used in the table are: • s = parameters can be modified only when the drive is stopped. • i hd = heavy duty current • p hd = heavy duty power • v dn = drives nominal vol...

Page 41

Acs550 user’s manual 41 start-up 0127 pid 2 output -100…100% 0.1% - 0128 pid 1 setpnt unit and scale defined by par. 4006/ 4106 and 4007/4107 - - 0129 pid 2 setpnt unit and scale defined by par. 4206 and 4207 0130 pid 1 fbk unit and scale defined by par. 4006/ 4106 and 4007/4107 - - 0131 pid 2 fbk u...

Page 42

42 acs550 user’s manual start-up 0412 previous fault 1 as par. 0401 1 0 0413 previous fault 2 as par. 0401 1 0 group 10: start/stop/dir 1001 ext 1 commands 0…10 1 2 1002 ext 2 commands 0…10 1 0 1003 direction 1…3 1 3 group 11: reference select 1101 keypad ref sel 1…2 1 1 1102 ext 1/ ext 2 sel 0…8, -...

Page 43

Acs550 user’s manual 43 start-up 1407 ro 2 off delay 0…3600 s 0.1 s 0 s 1408 ro 3 on delay 0…3600 s 0.1 s 0 s 1409 ro 3 off delay 0…3600 s 0.1 s 0 s 1410 relay output 4 0…36 1 0 1411 relay output 5 0…36 1 0 1412 relay output 6 0…36 1 0 1413 ro 4 on delay 0…3600 s 0.1 s 0 s 1414 ro 4 off delay 0…3600...

Page 44

44 acs550 user’s manual start-up 2016 min torque 2 -600.0%…0% 0.1% -300.0% 2017 max torque 1 0%…600.0% 0.1% 300.0% 2018 max torque 2 0%…600.0% 0.1% 300.0% group 21: start/stop 2101 start function 1…5 1 1 2102 stop function 1 = coast, 2 = ramp 1 1 2103 dc magn time 0…10 s 0.01 s 0.3 s 2104 dc hold 0…...

Page 45

Acs550 user’s manual 45 start-up 2607 sw freq ctrl 0 = off , 1 = on - 1 2608 slip comp ratio 0…200% 1 0 group 30: fault functions 3001 ai min function 0…3 1 0 3002 panel comm err 1…3 1 1 3003 external fault 1 0…6, -1…-6 1 0 3004 external fault 2 0…6, -1…-6 1 0 3005 mot therm prot 0…2 1 1 3006 mot th...

Page 46

46 acs550 user’s manual start-up group 34: panel display / process variables 3401 signal 1 param 100...199 1 103 3402 signal 1 min - 1 - 3403 signal 1 max - 1 - 3404 output 1 dsp form 0…7 1 - 3405 output 1 unit -128...127 1 . 3406 output 1 min - 1 - 3407 output 1 max - 1 - 3408 signal 2 param 100......

Page 47

Acs550 user’s manual 47 start-up 4016 act 1 input 1…5 - 2 4017 act 2 input 1…5 - 2 4018 act 1 minimum -1000…1000% 1% 0% 4019 act 1 maximum -1000…1000% 1% 100% 4020 act 2 minimum -1000…1000% 1% 0% 4021 act 2 maximum -1000…1000% 1% 100% 4022 sleep selection 0…7, -1…-6 - 0 4023 pid sleep level 0…7200 r...

Page 48

48 acs550 user’s manual start-up 4202 integration time 0.0s = not sel , 0.1…600 s 0.1 s 60 s 4203 derivation time 0…10 s 0.1 s 0 s 4204 pid deriv filter 0…10 s 0.1 s 1 s 4205 error value inv 0 = no, 1 = yes - 0 4206 unit 0…31 - 4 4207 dsp format 0…4 1 1 4208 0% value unit and scale defined by par. 4...

Page 49

Acs550 user’s manual 49 start-up 5207 buffer overruns 0…65535 1 - 5208 crc errors 0…65535 1 - group 53: efb protocol 5301 efb protocol id 0...0xffff 1 0 5302 efb station id 0…65535 1 1 5303 efb baud rate 1.2, 2.4, 4.8, 9.6, 19.2, 38.4, 57.6 kbits/s - 9.6 kbits/s 5304 efb parity 0...3 0 5305 efb ctrl...

Page 50

50 acs550 user’s manual start-up complete parameter descriptions this section describes the actual signals and parameters for acs550. Group 99: start-up data this group defines special start-up data required to: • set up the drive. • enter motor information. Code description 9902 applic macro select...

Page 51

Acs550 user’s manual 51 start-up group 01: operating data this group contains drive operating data, including actual signals. The drive sets the values for actual signals, based on measurements or calculations. You cannot set these values. Code description 0102 speed the calculated speed of the moto...

Page 52

52 acs550 user’s manual start-up 0121 ai2 the relative value of analog input 2 in %. 0122 ro1-3 status status of the three relay outputs. • 1 indicates that the relay is energized. • 0 indicates that the relay is de-energized. 0123 ro4-6 status status of the three relay outputs. See parameter 0122. ...

Page 53

Acs550 user’s manual 53 start-up 0139 process var 3 process variable 3 • defined by parameters in group 34: panel display / process variables. 0140 run time the drive’s accumulated running time in thousands of hours (kh). 0141 mwh counter the drive’s accumulated power consumption in megawatt hours. ...

Page 54

54 acs550 user’s manual start-up group 03: actual signals this group monitors fieldbus communications. Code description 0301 fb cmd word 1 read-only copy of the fieldbus command word 1. • the fieldbus command is the principal means for controlling the drive from a fieldbus controller. The command co...

Page 55

Acs550 user’s manual 55 start-up group 04: fault history this group stores a recent history of the faults reported by the drive. Code description 0401 last fault 0 = clear the fault history (on panel = no record). N = fault code of the last recorded fault. 0402 fault time 1 the day on which the last...

Page 56

56 acs550 user’s manual start-up group 10: start/stop/dir this group: • defines external sources ( ext 1, and ext 2) for commands that enable start, stop and direction changes. • locks direction or enables direction control. To select between the two external locations use the next group (parameter ...

Page 57

Acs550 user’s manual 57 start-up 1002 ext2 commands defines external control location 2 ( ext 2) – the configuration of start, stop and direction commands. • see parameter 1001 ext 1 commands above. 1003 direction defines the control of motor rotation direction. 1 = forward – rotation is fixed in th...

Page 58

58 acs550 user’s manual start-up group 11: reference select this group defines: • how the drive selects between command sources. • characteristics and sources for ref 1 and ref 2. Code description 1101 keypad ref sel selects the reference controlled in local control mode. 1 = ref 1 (hz/rpm) – refere...

Page 59

Acs550 user’s manual 59 start-up 4 = ai 2/ joyst – defines analog input 2 ( ai 2), configured for joystick operation, as the reference source. • see above ( ai 2/ joyst ) description. 5 = di 3 u ,4 d ( r ) – defines digital inputs as the speed reference source (motor potentiometer control). • digita...

Page 60

60 acs550 user’s manual start-up 1104 ref1 min sets the minimum for external reference 1. • the minimum analog input signal (as a percent of the full signal in volts or amps) corresponds to ref 1 min in hz/rpm. • parameter 1301 minimum ai 1 or 1304 minimum ai 2 sets the minimum analog input signal. ...

Page 61

Acs550 user’s manual 61 start-up group 12: constant speeds this group defines a set of constant speeds. In general: • you can program up to 7 constant speeds, ranging from 0 … 500 hz or 0 … 30000 rpm. • values must be positive (no negative speed values for constant speeds). • constant speed selectio...

Page 62

62 acs550 user’s manual start-up -7 = di 1,2( inv ) – selects one of three constant speeds (1…3) using di 1 and di 2. • inverse operation uses two digital inputs, as defined below (0 = di de-activated, 1 = di activated): -8 = di 2,3( inv ) – selects one of three constant speeds (1…3) using di 2 and ...

Page 63

Acs550 user’s manual 63 start-up group 13: analog inputs this group defines the limits and the filtering for analog inputs. Code description 1301 minimum ai1 defines the minimum value of the analog input. • define value as a percent of the full analog signal range. See example below. • the minimum a...

Page 64

64 acs550 user’s manual start-up group 14: relay outputs this group defines the condition that activates each of the relay outputs. Code description 1401 relay output 1 defines the event or condition that activates relay 1 – what relay output 1 means. 0 = not sel – relay is not used and is de-energi...

Page 65

Acs550 user’s manual 65 start-up 35 = comm – energize relay based on input from fieldbus communication. • fieldbus writes binary code in parameter 0134 that can energizes relay 1…relay 6 according to the following: • 0 = de-energize relay, 1 = energize relay. 36 = comm (-1) – energize relay based on...

Page 66

66 acs550 user’s manual start-up 1413 ro 4 on delay defines the switch-on delay for relay 4. • see ro 1 on delay . 1414 ro 4 off delay defines the switch-off delay for relay 4. • see ro 1 off delay . 1415 ro 5 on delay defines the switch-on delay for relay 5. • see ro 1 on delay . 1416 ro 5 off dela...

Page 67

Acs550 user’s manual 67 start-up group 15: analog outputs this group defines the drive’s analog (current signal) outputs. The drive’s analog outputs can be: • any parameter of the operating data group (group 01). • limited to programmable minimum and maximum values of output current. • scaled (and/o...

Page 68

68 acs550 user’s manual start-up group 16: system controls this group defines a variety of system level locks, resets and enables. Code description 1601 run enable selects the source of the run enable signal. 0 = not sel – allows the drive to start without an external run enable signal. 1 = di 1 – d...

Page 69

Acs550 user’s manual 69 start-up 1605 user par set chg defines control for changing the user parameter set. • see parameter 9902 ( applic macro ). • the drive must be stopped to change user parameter sets. • during a change, the drive will not start. Note: always save the user parameter set after ch...

Page 70

70 acs550 user’s manual start-up group 20: limits this group defines minimum and maximum limits to follow in driving the motor – speed, frequency, current, torque, etc. Code description 2001 minimum speed defines the minimum speed (rpm) allowed. • a positive minimum speed value defines two ranges, o...

Page 71

Acs550 user’s manual 71 start-up 2013 min torque sel defines control of the selection between two minimum torque limits (2015 min torque 1 and 2016 min torque 2). 0 = min torque 1 – selects 2015 min torque 1 as the minimum limit used. 1 = di 1 – defines digital input di 1 as the control for selectin...

Page 72

72 acs550 user’s manual start-up group 21: start/stop this group defines how the motor starts and stops. The acs550 supports several start and stop modes. Code description 2101 start function selects the motor start method. 1 = auto – selects the automatic start mode. • vector control mode: optimal ...

Page 73

Acs550 user’s manual 73 start-up 2108 start inhibit sets the start inhibit function on or off. The start inhibit function ignores a pending start command in any of the following situations (a new start command is required): • a fault is reset. • run enable activates while start command is active. • ...

Page 74

74 acs550 user’s manual start-up group 22: accel/decel this group defines ramps that control the rate of acceleration and deceleration. You define these ramps as a pair, one for acceleration and one for deceleration. You can define two pairs of ramps and use a digital input to select one or the othe...

Page 75

Acs550 user’s manual 75 start-up 2209 ramp input 0 defines control for forcing the ramp input to 0. 0 = not sel – 1 = di 1 – defines digital input di 1 as the control for forcing the ramp input to 0. • activating the digital input forces ramp input to 0. Ramp output will ramp to 0 according to the c...

Page 76

76 acs550 user’s manual start-up group 23: speed control this group defines variables used for speed control operation. Code description 2301 prop gain sets the relative gain for the speed controller. • larger values may cause speed oscillation. • the figure shows the speed controller output after a...

Page 77

Acs550 user’s manual 77 start-up 2304 acc compensation sets the derivation time for acceleration compensation. • adding a derivative of the reference to the output of the speed controller compensates for inertia during acceleration. • 2303 derivation time describes the principle of derivative action...

Page 78

78 acs550 user’s manual start-up group 24: torque control this group defines variables used for torque control operation. Code description 2401 torq ramp up defines the torque reference ramp up time – the minimum time for the reference to increase from zero to the nominal motor torque. 2402 torq ram...

Page 79

Acs550 user’s manual 79 start-up group 25: critical speeds this group defines up to three critical speeds or ranges of speeds that are to be avoided due, for example, to mechanical resonance problems at certain speeds. Code description 2501 crit speed sel sets the critical speeds function on or off....

Page 80

80 acs550 user’s manual start-up group 26: motor control code description 2603 ir comp volt sets the ir compensation voltage used for 0 hz. • requires parameter 9904 motor ctrl mode = 3 ( scalar control ). • keep ir compensation as low as possible to prevent overheating. • typical ir compensation va...

Page 81

Acs550 user’s manual 81 start-up group 30: fault functions this group defines situations that the drive should recognize as potential faults and defines how the drive should respond if the fault is detected. Code description 3001 ai defines the drive response if the analog input ( ai ) signal drops ...

Page 82

82 acs550 user’s manual start-up 3007 mot load curve sets the maximum allowable operating load of the motor. • when set to 100%, the maximum allowable load is equal to the value of start-up data parameter 9906 motor nom current . • adjust the load curve level if the ambient temperature differs from ...

Page 83

Acs550 user’s manual 83 start-up 3013 underload function removal of motor load may indicate a process malfunction. The protection is activated if: • the motor torque drops below the load curve selected by parameter 3015 underload curve . • this condition has lasted longer than the time set by parame...

Page 84

84 acs550 user’s manual start-up group 31: automatic reset this group defines conditions for automatic resets. An automatic reset occurs after a particular fault is detected. The drive holds for a set delay time, then automatically restarts. You can limit the number of resets in a specified time per...

Page 85

Acs550 user’s manual 85 start-up group 32: supervision this group defines supervision for up to three signals from group 01, operating data. Supervision monitors a specified parameter and energizes a relay output if the parameter passes a defined limit. Use group 14, relay outputs, to define the rel...

Page 86

86 acs550 user’s manual start-up 3208 superv 3 lim lo sets the low limit for the second supervised parameter. See 3207 superv 3 param above. 3209 superv 3 lim hi sets the high limit for the third supervised parameter. See 3207 superv 3 param above. Code description.

Page 87

Acs550 user’s manual 87 start-up group 33: information this group provides access to information about the drive’s current programs: versions and test date. Code description 3301 fw version contains the version of the drive’s firmware. 3302 lp version contains the version of the loading package. 330...

Page 88

88 acs550 user’s manual start-up group 34: panel display process variables this group defines the content for control panel display (middle area), when the control panel is in the control mode. Code description 3401 signal1 param selects the first parameter (by number) displayed on the control panel...

Page 89

Acs550 user’s manual 89 start-up 3411 output 2 dsp form defines the decimal point location for the second display parameter. See parameter 3404. 3412 output 2 dsp unit selects the units used with the second display parameter. See parameter 3405. 3413 output 2 min sets the minimum value displayed for...

Page 90

90 acs550 user’s manual start-up group 35: motor temp meas this group defines the detection and reporting for a particular potential fault – motor overheating, as detected by a temperature sensor. Typical connections are defined below. Warning! Iec 60664 requires double or reinforced insulation betw...

Page 91

Acs550 user’s manual 91 start-up code description 3501 sensor type identifies the type of motor temperature sensor used, pt100 (°c) or ptc (ohms). See parameters 1501 and 1507. 0 = none 1 = 1 x pt100 – sensor configuration uses one pt 100 sensor. • analog output ao 1 or ao 2 feeds constant current t...

Page 92

92 acs550 user’s manual start-up group 40: process pid set 1 this group defines a process pid control operation mode for the drive. In pid control mode, the drive compares a reference signal (setpoint) to an actual signal (feedback), and automatically adjusts the speed of the drive to match the two ...

Page 93

Acs550 user’s manual 93 start-up 4004 pid deriv filter defines the filter time constant for the error-derivative part of the pid controller output. • before being added to the pid controller output, the error-derivative is filtered with a 1-pole filter. • increasing the filter time smooths the error...

Page 94

94 acs550 user’s manual start-up 4010 set point sel defines the reference signal source for the pid controller. • parameter has no significance when the pid regulator is by-passed (see 8121 reg bypass ctrl ). 0 = keypad – control panel provides reference. 1 = ai 1 – analog input 1 provides reference...

Page 95

Acs550 user’s manual 95 start-up 4012 setpoint min sets the minimum value for the reference signal source. See parameter 4010. 4013 setpoint max sets the maximum value for the reference signal source. See parameter 4010. 4014 fbk sel defines the pid controller feedback (actual signal). • you can def...

Page 96

96 acs550 user’s manual start-up 4018 act1 minimum sets the minimum value for act 1. • used with analog input min/max settings (e.G. 1301 minimum ai 1, 1302 maximum ai 1). • scales analog inputs used as actual values. • see figure: a= normal; b = inversion ( act 1 minimum > act 1 maximum ) 4019 act1...

Page 97

Acs550 user’s manual 97 start-up 4023 pid sleep level sets the motor speed / frequency that enables the pid sleep function – a motor speed / frequency below this level, for at least the time period 4024 pid sleep delay enables the pid sleep function (stopping the drive). • requires 4022 = 7 internal...

Page 98

98 acs550 user’s manual start-up group 41: process pid set 2 parameters of this group belong to pid parameter set 2. The operation of parameters 4101…4126 is analogous with set 1 parameters 4001…4026. Pid parameter set 2 can be selected by parameter 4027 pid 1 param set ..

Page 99

Acs550 user’s manual 99 start-up group 42: external / trimming pid this group defines the parameters used for the external / trimming pid. The operation of parameters 4201 … 4221 is analogous with set 1 (and set 2) parameters 4001 … 4021 (4011 … 4021). The parameter groups 40 and 41 define the param...

Page 100

100 acs550 user’s manual start-up 4232 correction src defines the trimming reference for the correction source. 1 = trimming pid 2 ref – uses appropriate ref max (s witch a or b): • 1105 ref 1 max when ref 1 is active (a). • 1108 ref 2 max when ref 2 is active (b). 2 = trimming pid 2 output – uses t...

Page 101

Acs550 user’s manual 101 start-up group 51: ext comm module this group defines set-up variables for an external fieldbus communication module. Refer to communication module documentation for more information on these parameters. Code description 5101 fba type displays the type of the connected field...

Page 102

102 acs550 user’s manual start-up 5133 fba appl fw rev contains the revision of the module’s application program format is xyz where: • x = major revision number • y = minor revision number • z = correction number example: 107 = revision 1.07 code description.

Page 103

Acs550 user’s manual 103 start-up group 52: rs-232 / panel this group defines the settings required to connect the acs550 to a modbus fieldbus system. For example: station number, communication speed, and parity. In this group, parameter modifications take effect on the next power-up. Code descripti...

Page 104

104 acs550 user’s manual start-up group 53: efb protocol this group defines set-up variables used for an embedded fieldbus (efb) communication protocol. Refer to communication protocol documentation for more information on these parameters. Code description 5301 efb protocol id contains the identifi...

Page 105

Acs550 user’s manual 105 start-up 5312 efb par 12 specifies the parameter mapped to modbus register 40007. 5313 efb par 13 specifies the parameter mapped to modbus register 40008. 5314 efb par 14 specifies the parameter mapped to modbus register 40009. 5315 efb par 15 specifies the parameter mapped ...

Page 106

106 acs550 user’s manual start-up group 81: pfc control this group defines a pump-fan control (pfc) mode of operation. The major features of pfc control are: • the acs550 controls the motor of pump no. 1, varying the motor speed to control the pump capacity. This motor is the speed regulated motor. ...

Page 107

Acs550 user’s manual 107 start-up 8104 reference step 2 sets a percentage value that is added to the process reference. • applies only when at least two auxiliary (constant speed) motors are running. • see parameter 8103 reference step 1. 8105 reference step 3 sets a percentage value that is added t...

Page 108

108 acs550 user’s manual start-up 8112 low freq 1 sets the frequency limit used to stop the first auxiliary motor. The first auxiliary motor stops if: • the first auxiliary motor is running alone. • acs550 output frequency drops below the limit: 8112 - 1. • output frequency stays below the relaxed l...

Page 109

Acs550 user’s manual 109 start-up 8117 nr of aux mot sets the number of auxiliary motors. • each auxiliary motor requires a relay output, which the drive uses to send start/stop signals. • the autochange function, if used, requires an additional relay output for the speed regulated motor. • the foll...

Page 110

110 acs550 user’s manual start-up • the table below shows the acs550 pfc motor assignments for some typical settings in the relay output parameters (1401…1403 and 1410…1412), where the settings are either =31 ( pfc ), or =x (anything but 31), and where the autochange function is disabled (8118 autoc...

Page 111

Acs550 user’s manual 111 start-up 8119 autochng level sets an upper limit, as a percent of output capacity, for the autochange logic. When the output from the pid/pfc control block exceeds this limit, autochange is prevented. For example, use this parameter to deny autochange when the pump-fan syste...

Page 112

112 acs550 user’s manual start-up 8120 interlocks defines operation of the interlock function. When the interlock function is enabled: • an interlock is active when its command signal is absent. • an interlock is inactive when its command signal is present. • the acs550 will not start if a start com...

Page 113

Acs550 user’s manual 113 start-up 2 = di 2 – enables the interlock function, and assigns a digital input (starting with di 2) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 and...

Page 114

114 acs550 user’s manual start-up 3 = di 3 – enables the interlocks function, and assigns a digital input (starting with di 3) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 an...

Page 115

Acs550 user’s manual 115 start-up 5 = di 5 – enables the interlock function, and assigns a digital input (starting with di 5) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays (number of parameters 1401…1403 and...

Page 116

116 acs550 user’s manual start-up 8121 reg bypass ctrl selects regulator by-pass control. When enabled, regulator by-pass control provides a simple control mechanism without a pid regulator. • use regulator by-pass control only in special applications. 0 = no – disables regulator by-pass control. Th...

Page 117

Acs550 user’s manual 117 start-up 8124 acc in aux stop sets the pfc acceleration time for a zero-to-maximum frequency ramp. This pfc acceleration ramp: • applies to the speed regulated motor, when an auxiliary motor is switched off. • replaces the acceleration ramp defined in group 22: accel / decel...

Page 118

118 acs550 user’s manual start-up group 98: options this group configures for options, in particular, enabling serial communication with the drive. Code description 9802 comm prot sel selects the communication protocol. 0 = not sel – no communication protocol selected. 1 = std modbus – the drive com...

Page 119: Diagnostics

Acs550 user’s manual 119 diagnostics diagnostics warning! Do not attempt any measurement, parts replacement or other service procedure not described in this manual. Such action will void the warranty, may endanger correct operation, and increase downtime and expense. Warning! All electrical installa...

Page 120

120 acs550 user’s manual diagnostics fault listing fault code fault name in panel description and recommended corrective action 1 overcurrent output current is excessive. Check for and correct: • excessive motor load. • insufficient acceleration time (parameters 2202 acceler time 1 and 2205 acceler ...

Page 121

Acs550 user’s manual 121 diagnostics 11 id run fail the motor id run was not completed successfully. Check for and correct: • motor connections 12 motor stall motor or process stall. Motor is operating in the stall region. Check for and correct: • excessive load. • insufficient motor power. • parame...

Page 122

122 acs550 user’s manual diagnostics 29 efb con file 30 force trip 31 efb 1 fault code reserved for the efb protocol application. The meaning is protocol dependent. 32 efb 2 fault code reserved for the efb protocol application. The meaning is protocol dependent. 33 efb 3 fault code reserved for the ...

Page 123

Acs550 user’s manual 123 diagnostics fault resetting the acs550 can be configured to automatically reset certain faults. Refer to parameter group 31: automatic reset. Warning! If an external source for start command is selected and it is active, the acs550 may start immediately after fault reset. Fl...

Page 124: Maintenance

124 acs550 user’s manual maintenance maintenance warning! Read "safety" on page 3 before performing any maintenance on the equipment. Ignoring the safety instructions can cause injury or death. Maintenance intervals if installed in an appropriate environment, the drive requires very little maintenan...

Page 125

Acs550 user’s manual 125 maintenance fan failure can be predicted by the increasing noise from fan bearings and the gradual rise in the heatsink temperature in spite of heatsink cleaning. If the drive is operated in a critical part of a process, fan replacement is recommended once these symptoms sta...

Page 126

126 acs550 user’s manual maintenance control panel cleaning use a soft damp cloth to clean the control panel. Avoid harsh cleaners which could scratch the display window. Battery a battery is only used in control panels that have the clock function available and enabled. The battery keeps the clock ...

Page 127: Technical Data

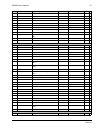

Acs550 user’s manual 127 technical data technical data ratings by type code, the table below provides ratings for the acs550 adjustable speed ac drive, including: • iec ratings • nema ratings (shaded columns) • frame size • drive cabinet heat dissipation and air flow abbreviated column headers are d...

Page 128

128 acs550 user’s manual technical data symbols sizing the current ratings are the same regardless of the supply voltage within one voltage range. To achieve the rated motor power given in the table, the rated current of the drive must be higher than or equal to the rated motor current. Note 1:the m...

Page 129

Acs550 user’s manual 129 technical data input power (mains) cables and fuses branch circuit protection must be provided by the end-user, sized per national and local electric codes. Recommendations for fuses for short-circuit protection on the mains cable are below. Note 1: mains cable sizing is bas...

Page 130

130 acs550 user’s manual technical data input power (mains) connection motor connection input power (mains) connection specifications voltage (u 1 ) 208/220/230/240 vac 3-phase (or 1-phase)+10% -15% for 230 vac units 400/415/440/460/480 vac 3-phase+10% -15% for 400 vac units prospective short- circu...

Page 131

Acs550 user’s manual 131 technical data control connection efficiency approximately 98% at nominal power level. Cooling dimensions, weights and noise the dimensions and mass for the acs550 depend on the frame size and enclosure type. If unsure of frame size, first, find the “type” code on the drive ...

Page 132

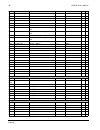

132 acs550 user’s manual technical data units with ip 21 / ul type 1 enclosures outside dimensions ip 21 / ul type 1 – dimensions for each frame size ref. R1 r2 r3 r4 r5 r6 mm in mm in mm in mm in mm in mm in w 125 4.9 125 4.9 203 8.0 203 8.0 265 10.4 300 11.8 h 330 13.0 430 16.9 490 19.3 596 23.4 6...

Page 133

Acs550 user’s manual 133 technical data mounting dimensions * center to center dimension. Weight degrees of protection available enclosures: • ip 21 / ul type 1 enclosure. The site must be free of airborne dust, corrosive gases or liquids, and conductive contaminants such as condensation, carbon dus...

Page 134

134 acs550 user’s manual technical data ambient conditions the following table lists the acs550 environmental requirements. Ambient environment requirements installation site storage and transportation in the protective package altitude • 0…1000 m (0…3,300 ft) • 1000…2000 m (3,300…6,600 ft) if p n a...

Page 135

Acs550 user’s manual 135 technical data materials applicable standards the drive complies with the following standards. The compliance with the european low voltage directive is verified according to standards en 50178 and en 60204-1. Ul markings ul markings status: ul the acs550 is suitable for use...

Page 136

136 acs550 user’s manual technical data motor protection feature that complies with the requirements of ul 508c. When this feature is selected and properly adjusted, additional overload protection is not required unless more than one motor is connected to the drive or unless additional protection is...

Page 137: Index

Acs550 user’s manual 137 index index numerics 3-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 a abb standard (default) macro . . . . . . . . . . . . . . . 32 acceleration /deceleration, parameter group . . . . . . . . . . . 74 at aux. Stop (pfc), parameter. . . . . . . . . . ...

Page 138

138 acs550 user’s manual index control location, data parameter . . . . . . . . . . . . . . . . 51 reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 shaft direction . . . . . . . . . . . . . . . . . . . . . . . . 27 start/stop . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 139

Acs550 user’s manual 139 index emergency deceleration time, parameter . . . . . . . . . . . . 74 stop select, parameter. . . . . . . . . . . . . . . . . . 73 enclosure protection class code . . . . . . . . . . . . . . 7 encoder error, fault code . . . . . . . . . . . . . . . . . . 121 error value in...

Page 140

140 acs550 user’s manual index l label serial number . . . . . . . . . . . . . . . . . . . . . . . . . 7 type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 limits, parameter group . . . . . . . . . . . . . . . . . . . . 70 load package version, parameter . . . . . . . . . . . . 87 l...

Page 141

Acs550 user’s manual 141 index p panel display variables, parameter group . . . . . . 88 panel loss, fault code . . . . . . . . . . . . . . . . . . . . . 120 parameter analog input scale, fault code . . . . . . . . . . . 122 analog output scale, fault code . . . . . . . . . . 122 change lock . . . ....

Page 142

142 acs550 user’s manual index reference analog input corrections . . . . . . . . . . . . . . . . 59 corrections for parameter values . . . . . . . . . 59 keypad control, parameter . . . . . . . . . . . . . . 58 maximum, parameters . . . . . . . . . . . . . . . . . 60 minimum, parameters . . . . . ....

Page 143

Acs550 user’s manual 143 index start-up data, parameter group . . . . . . . . . . . . . . 50 station id (rs-232), parameter . . . . . . . . . . . . . 103 status at fault, history parameter . . . . . . . . . . . . . 55 status led . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 stop aux...

Page 144

Abb oy ac drives p.O. Box 184 fin-00381 helsinki finland telephone +358 10 22 11 telefax +358 10 22 22681 internet http://www.Abb.Com abb inc. Automation technologies drives & machines 16250 west glendale drive new berlin, wi 53151 usa telephone 262 785-3200 800 help-365 telefax 262 780-5135 a c s5 ...