- DL manuals

- Baroness

- Lawn Mower

- LM2700

- Operator's Manual

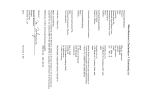

Baroness LM2700 Operator's Manual

Summary of LM2700

Page 1

Mower operator's manual ver.1.0 lm2700 (22/26) sn10348 and onwards front 5-reel fairway mower "required reading" read this manual and the owner’s manual for the engine before using the machine. Original instructions r r.

Page 2

−1− introduction ................................................................................................. 3 1. Training ................................................................................................... 4 2. Preparation .........................................................

Page 3

−2− 4. Measuring instrument .................................................................................... 26 4-1 instruments of operation panel ............................................................. 26 4-2 tachometer & hour meter ...........................................................

Page 4

−3− california proposition 65 the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Warning introduction thank you for purchasing the baroness lm2700, front 5-reel fairway mower. This operator’s manual desc...

Page 5

−4− training 1. Read the operator's manual and other training material carefully. Be familiar with the n controls and safety indications and learn how to stop the mower in an emergency. If the operator cannot understand the manual, it is the owner's responsibility to n thoroughly explain the content...

Page 6

−5− precautions during operation 3. Do not start the engine in a closed space since there is a danger of carbon monoxide n poisoning. Operate the mower during the day or in an area with sufficient lighting. N before starting the engine, disengage all equipment, place the gearshift into neutral, and ...

Page 7

−6− to use the baroness mower safely the following precautions should always be followed to operate the baroness mower safely. Warnings for safety warning symbols have been attached to this machine to ensure that you can operate it safely. The warning symbols indicate items which are particularly im...

Page 8

−7− be sure to observe for safe operation. The precautions that are described here are the important contents concerning safety. L be sure to follow these safety precautions. Failure to follow these precautions can cause injury or death, or accidents or damage to l the machine. The information descr...

Page 9

−8− performing the periodic checks and maintenance n perform the periodic checks and maintenance every year, and maintain each part. Be sure to change the power steering hose every two years and to check the electrical wires every year. Failure to follow this precaution can cause an accident or the ...

Page 10

−9− caution be sure to check the electrical parts and wires. N check if the electrical wires are touching other parts, if the covering is damaged, or if the connector is loose every day before operating the machine. Failure to follow this precaution can cause a short cut and a fire. * do not fill th...

Page 11

−10− when moving and taking the machine 5. On or off a field warning do not operate the machine on public roads. N this machine is not authorized as a special motorized vehicle. Do not operate it on public roads. Failure to follow this precaution is subject to punishment for violating the traffic la...

Page 12

−11− keep away from children. N keep away from children and do not operate the machine near them. Failure to follow this precaution can cause a personal injury. * inspect and perform maintenance immediately if unusual vibration n occurs. If unusual vibration occurs, stop the engine immediately, then...

Page 13

−12− take precaution with high pressure hydraulic oil. N always check if the fittings and hoses are loose or damaged. When disconnecting the joints and hoses, release the pressure in the hydraulic circuit. Failure to follow this precaution can cause the high-pressure hydraulic oil to break * through...

Page 14

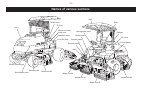

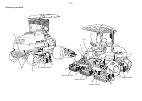

−13− names of various sections parking brake lever brake pedal reverse pedal mower unit #4 forward pedal hood operation panel mower unit raise/ lower lever throttle lever tilt lever mower unit #2 mower unit #1 mower unit #5 mower unit #3 fuel filler hole number plate muffler exhaust port specificati...

Page 15

−14− warning label and operation label attachment locations *2 *1 * attach on the left and right. K4205001580 k4205001530 k4205001540 k4209001000 * low sulfur or ultra low sulfur diesel fuel only. K4205001600 k4205001840 k4205001580 k4209000980 * attach two labels to each mower..

Page 16

−15− warning label and operation label description warning warning danger danger : read the operator's manual. : leave the machine after setting the parking brake, turning the engine off, and removing the engine key. : flying objects - excluding the operator, keep a safe distance away from the machi...

Page 17

−16− *1 number plate *2 specification plate features of lm2700 compared with the conventional machine, the work at a quick speed can also be cut l finely. Moreover, since the travelling speed is also quick and the turning radius is small, efficient work can be performed. Comfortable work can be perf...

Page 18

−17− handling instructions inspection before use 1. Caution please be sure to check the following matter before putting the l engine into operation. 1-1 cleaning of the radiator and oil cooler be sure to clean when the dust has adhered to the radiator, oil cooler, and dustproof net. When you operate...

Page 19

−18− 1-3 inspection and refilling of engine oil put the engine on the level surface, and check the level of the oil by the dipstick. It will be the proper quantity, if the oil level is between the upper and lower limit when the dipstick is fully inserted. If the oil level is low, add the engine oil,...

Page 20

−19− 1-6 inspection of the engine and its surroundings please refer to "operating and instruction manual" for engine for handling of the engine. The parts of the fuel system should check whether there is 1) neither the crack nor the leak, and replace it with new one if necessary. When the grass, the...

Page 21

−20− operation method of each part 3. Caution 3-1 about the mechanical operation check whether the operation state of each part is good, and the brake disc, tires, steering, and mower do not have abnormalities in particular before operating the engine. In any cases, operate the engine by the speed t...

Page 22

−21− danger 3-5 cautions on fuel handling it is highly flammable. Do not smoke when handling fuel. L never fill the fuel tank indoors, and while engine is running or l the engine is hot. In order to prevent the fire, always keep the engine clean and be l sure to remove deposition of grass, grease, a...

Page 23

−22− 3-9 speed limiter lever it is a shift lever, which restricts the forward pedal step in amount. The step in amount decreases if it turns to the "slow" side. Speed limiter lever "fast" "slow" caution be sure to make set to "slow" position when travelling by two- l wheel-drive. If make set to "fas...

Page 24

−23− 3-13 travelling-mowing changeover switch when it is set to up, the position of mower unit #4 & #5 can be changed. Press switch to the "travelling" position, #4 & #5 mower units raise to top. Press switch to the "operating" position, #4 & #5 mower units raise up to middle. Mowing travelling-mowi...

Page 25

−24− 3-16 reel reverse rotation switch it is swing type switch that exchange the rotation direction of the reel. To rotate the reels inverse (backlapping), press the switch to the "on" position. Engine does not stop, even though the * operator leaves the seat. Reel forward-reverse rotation switch re...

Page 26

−25− 3-20 bypass valve it is located on the hydraulic motor of each mower unit. The hydraulic motor will become free if the shift lever is shifted to the stop position. Rotate position: ( ). Stop position: ( ). Bypass valve rotation stop 3-21 reel rotation adjusting valve it is the valve that adjust...

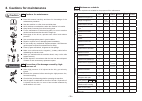

Page 27

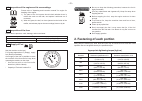

−26− measuring instrument 4. 4-1 instruments of operation panel tachometer & hour meter a. Water temperature gauge b. Fuel level gauge c. Pilot lamp d. Charge lamp • glow lamp • oil pressure lamp • (engine oil pressure lamp) a b c d 4-2 tachometer & hour meter i n d i c a t e t h e e n g i n e s p e...

Page 28

−27− 4-7 oil pressure lamp (engine oil pressure lamp) the lamp turns on when the ignition switch is in the "on" position. After the engine starts, the light will be turned off, if the oil begins to circulate and it becomes the normal pressure. W h e n t h e l a m p i s t u r n e d o n d u r i n g op...

Page 29

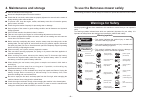

−28− maintenance of the main unit 6. 6-1 change of engine oil refer to the engine's instruction manual for handling of the engine. Change the oil after the first 50 hours 1) operation, and change it for every 100 hours operation from the next. Remove drain plug on the oil pan. If it 2) carries out w...

Page 30

−29− grease up positions 2 a b mower unit #2 1 c 78 34 5 mower unit #4 mower unit #1 > h mower unit #5 9 j mower unit #3 e f 6 d g i.

Page 31

−30− 6-6 inspection of battery refer to the battery's instruction manual. The machine exported from japan mounts the battery of refillable type. (fx105d31r) i n s p e c t a n d m a i n t e n a n c e t h e b a t t e r y periodically. C h e c k t h e e l e c t r o l y t e l e v e l b e t w e e n "uppe...

Page 32

−31− 6-7 opening and closing the engine hood disconnect the rubber catch in right and left, and pull up the engine hood upwards until the wire stretches to the limit. When you close the engine hood, lower it slowly. Rubber catch caution when you close the engine hood, be careful not to pinch your l ...

Page 33

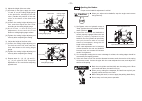

−32− maintenance of the mower 7. 7-1 greasing carry out the greasing up periodically to each part grease fitting. The parts greasing up every 10 hours is using the needle bearing. Be careful of the lubrication interval. Carry out about 1g (1 to 2 times with manual-type small grease gun) grease up fo...

Page 34

−33− adjust the height of the rear roller. 2) as shown in the figure, apply the screw (1) "a" and "b" on the cutting height gauge to the bed knife, and adjust the rear roller. (decide the position of the rear roller on the basis of the bed knife angle.) loosen the cutting height adjusting nut (2) fi...

Page 35

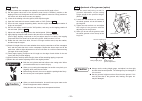

−34− 7-4 lapping inspect whether the newspaper can cleanly cut across the full length of reel. 1) set the bypass valve lever of the hydraulic motor into the "rotation" position on the 2) lapping mower unit. Set bypass valve lever of the hydraulic motor into "stop" position on the mower unit, which d...

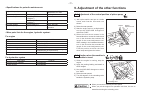

Page 36

−35− 7-6 adjustment of the reel cover loosen the fixing bolts on the right and l left sides of the reel cover, and adjust the angle of the reel cover. W h e n y o u u s e t h e o p t i o n a l g r a s s l catcher, set the reel cover housing in the most closed position. Fixing bolt reel cover 7-7 tur...

Page 37

−36− cautions for maintenance 8. Caution 8-1 cautions for maintenance read this manual carefully and have full knowledge of the l maintenance procedure. Stay the machine on a flat, clean and dried place. L never lubricate or maintenance when the machine is in motion. L keep hands, feet away from dri...

Page 38

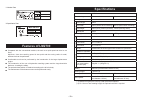

−37− engine oil capacity max: 9.7 l min: 7 l higher than the api service classification cd class coolant capacity total capacity 12 l including 1 l in reserve tank tire pressure (standard tire) front tire 150 kpa (1.5kgf/cm 2 ) rear tire 140 kpa (1.4kgf/cm 2 ) fuel tank capacity approximately 51 l d...

Page 39

−38− long-term storage 10. Please refer to the engine/battery operation manuals for details. L clean up dirt, grass and oil spot etc. 1. Inspect and replace the engine oil and air filter element. 2. Refill oil and apply lubricating/greasing to each lubrication part. 3. Empty the fuel tank and keep t...

Page 42

−41−.

Page 43

−42−.

Page 44

Aichi-pref. 442-8530 japan. Lm2700--um--gbz/10l-00-spec head office 1-26, miyuki-cho, t oyokawa, tu rf care machinery te l: (0533) 84-1390 fax: (0533) 89-3623.