- DL manuals

- Biosystems

- Security Sensors

- MultiPro

- Reference Manual

Biosystems MultiPro Reference Manual

Summary of MultiPro

Page 1

1 reference manual multipro gas detector 651 south main street middletown, ct 06457 800 711-6776 860 344-1079 fax 860 344 –1068 11may2007 p/n 13-278 version 1.41 http://www.Biosystems.Com.

Page 2

1 multipro personal portable gas detectors have been designed for the detection and measurement of potentially hazardous atmospheric conditions in order to assure that the user is properly warned of potentially dangerous atmospheric conditions, it is essential that the instructions in this reference...

Page 3

2 table of contents c ertification i nformation 4 s ignal w ords 4 w arnings and c autions 4 1. D escription 6 1.1 methods of sampling 6 1.2 multi-sensor capability 6 1.3 calibration 6 1.4 alarm logic 7 1.4.1 atmospheric hazard alarms 7 1.4.2 low battery alarms 7 1.4.3 sensor over range alarms. 7 1....

Page 4

3 3.2.3 pump low flow alarm 16 3.3 sample draw probe 17 4. C alibration 17 4.1 functional (bump) testing 17 4.2 fresh air/zero calibration 18 4.2.1 fresh air/zero calibration failure 18 4.2.2 manual fresh air / zero calibration 19 4.3 span calibration 19 4.3.1 span calibration failure: toxic and lel...

Page 5: Certification Information

4 certification information the multipro carries the following certifications: ul class i division 1 groups a,b,c,d temp code t4 csa class i, division 1, groups a,b,c,d temp code t4 (per csa c22.2 no. 152, only the combustible gas detection portion of this instrument has been assessed for performanc...

Page 6

5 be charged with the ul/csa-approved charger, which is biosystems part number 54-49-103-1. European versions of the multipro must be charged with the atex- approved charger, which is biosystems part number 54-49-103-5. 7. The multipro must be located in a non-hazardous location during the charging ...

Page 7: 1. Description

6 1. Description the multipro is a multi-sensor gas detector that can be configured to meet a wide variety of user requirements. This chapter provides an overview of many of the features of the multipro. More detailed descriptions of the specific features of the multipro are contained in the subsequ...

Page 8

7 recommended calibration frequency is discussed in appendix b. 1.4 alarm logic multipro gas alarms can be adjusted with biosystems biotrak software through a pc with an irda port or directly with the mode button (see chapter 6 for direct programming instructions). Alarms may be set anywhere within ...

Page 9

8 that the instrument is powered up and running. Once enabled the multipro will emit a short audible beep and give a short flash on the led at a user-defined interval. The security beep/flash function may be enabled and the interval may be changed with biotrak software or directly with the mode butt...

Page 10

9 active and functioning properly, “pump” is displayed near the center of the lcd display. Low flow or other pump fault conditions activate audible and visible alarms and cause the display of the appropriate explanatory message. 1.7.1 special precautions when using the multipro pump the internal mat...

Page 11: 2. Basic

10 port is used for communications between the multipro and a pc. 6. On / off "mode" button: the large black push-button on the front of the instrument is called the "mode" button. The mode button is used to turn the multipro on and off as well as to control most other operations, including the auto...

Page 12: →

11 if the multipro is equipped with a fully enabled datalogger, the following screen will be shown. The time figure in the upper right corner indicates the sampling interval in minutes and seconds. Instruments without a fully enabled datalogger will show display “not a datalog” or the sampling inter...

Page 13: →

12 multipro will prompt you to leak test the pump. Note: the sample probe assembly must be attached when the pump is started. → block the sampling inlet by placing a finger over the end of the sample probe assembly. Once the multipro recognizes that the test is passed, it will instruct you to remove...

Page 14

13 2.4 alarms the multipro is configured with a series of alarms that are designed to warn the user of dangerous conditions. The multipro is designed to detect potentially life threatening atmospheric conditions. Any alarm condition should be taken seriously. The safest course of action is to immedi...

Page 15: →

14 2.4.6 sensor over range alarms the multipro will go into alarm if a sensor is exposed to a concentration of gas that exceeds its established range. In the case of an lel reading that exceeds 100% lel, the lel channel will be automatically disabled by the instrument and the alarm will latch (remai...

Page 16: 3. Sampling

15 bad invalid memory type 009 no sensors installed 010 bad temp sensor 012 bad vibrating alarm 014 if the multipro displays an error message, contact biosystems for further instructions. 3. Sampling the multipro may be used in either diffusion or sample-draw mode. In either mode, the gas sample mus...

Page 17: →

16 continuous "hands free" remote monitoring. Use of the motorized sample draw pump allows the multipro to continuously monitor remote locations. The pump is powered by the multipro battery. When the pump is attached to the instrument, “pump” will be shown on the display in the current gas readings ...

Page 18: ↔

17 center of the lcd display. Low flow or other pump fault conditions activate audible and visible alarms and cause the display of the appropriate explanatory message. The pressure sensor in the sample draw pump is designed to detect pressure changes while the sample-draw probe is being held in a ve...

Page 19: →

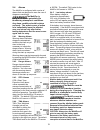

18 4.2 and perform the fresh air calibration adjustment then proceed to step 4. 4. Attach the calibration adapter and connect the calibration cylinder to the multipro as shown in figure 4.1. Flow gas to the sensors. 5. Wait for the readings to stabilize. (forty- five seconds to one minute is usually...

Page 20: ↔

19 possible causes and solutions 1. The atmosphere in which the instrument is located is contaminated (or was contaminated at the time the instrument was last fresh air calibrated. 2. A new sensor has just been installed. 3. Instrument has been dropped or banged since last turned on. 4. There has be...

Page 21: ↔

20 → once the calibration of all sensors is successfully completed, the multipro will briefly show the maximum adjustment values screen. The maximum adjustment values for the lel and toxic sensors give an indication of the remaining sensitivity of the sensors. As sensitivity decreases, the maximum p...

Page 22: 5. Maintenance

21 a sensor that cannot be calibrated or is found to be out of tolerance should be replaced immediately. An instrument that fails calibration may not be used until testing with known concentration test gas determines that accuracy has been restored, and the instrument is once again fit for use. Poss...

Page 23

22 5.3.1 storage guidelines for the li-ion battery never store li-ion -version multipro instruments at temperatures above 30 degrees celsius (86 degrees fahrenheit). Li- ion batteries may suffer deterioration resulting in damage to the internal components when stored at high temperatures. The batter...

Page 24

23 with the new sensor. For an overview of the duo-tox replacement procedure see section 5.4.2 below. The sensors in the multipro are located in a vented compartment at the bottom of the instrument. To install a sensor: 1. Turn the multipro off. 2. Remove the battery pack as described in section 5.1...

Page 25: ↔

24 7. Reassemble the multipro and allow the new sensor to stabilize as described in steps 6-8 in section 5.4.1. 8. When the instrument restarts for the first time, the cf screen will be shown. 9. Press the mode button to advance the cf value until the correct value is shown. 10. Once the correct cf ...

Page 26: 6. Direct

25 fitting and compression sleeve. The standard probe tube can be interchanged with other custom length sections of 1/4” od tubing, or probe tubes made of other materials (such as stainless steel). Probe tubes are exchanged by loosening the hex-nut compression fitting, removing the old tube, sliding...

Page 27: ↔

26 the mode button is used to make all selections in the advanced menu. 1. Click the mode button once to advance to the next menu screen 2. Click the mode button three times in rapid succession to enter the submenu for the menu item that is currently shown. 3. Hold the mode button for three full sec...

Page 28

27 counter to advance past the maximum possible alarm level for the specific channel, and continue back to the lowest possible setting. To restore the default alarms click the mode button three times in rapid succession with “default alarms” displayed. “def set” will be shown to indicate that the de...

Page 29: Appendices

28 appendices appendix a toxic gas measurement – warning, danger, stel and twa alarms many toxic substances are commonly encountered in industry. The presence of toxic substances may be due to materials being stored or used, the work being performed, or may be generated by natural processes. Exposur...

Page 30

29 appendix b calibration frequency recommendation appendix c: calibration frequency one of the most common questions that we are asked at biosystems is: “how often should i calibrate my gas detector?” sensor reliability and accuracy today’s sensors are designed to provide years of reliable service....

Page 31

Appendix c multipro sensor information part no. Description range resolution 54-49-80 lel combustible gas 0 – 100% lel 1% lel 54-49-90 o 2 oxygen 0 – 30% by volume 0.1% 54-49-01 co carbon monoxide 0 – 1000 ppm 1 ppm 54-49-02 h 2 s hydrogen sulfide 0 – 200 ppm 1 ppm 54-49-14 duo-tox dual channel co/h...

Page 32

31 appendix f biosystems standard warranty gas detection products general biosystems, llc (hereafter biosystems) warrants gas detectors, sensors and accessories manufactured and sold by biosystems, to be free from defects in materials and workmanship for the periods listed in the tables below. Damag...