- DL manuals

- Bunn

- Coffee Maker

- Single TF DBC

- Installation And Operating Manual

Bunn Single TF DBC Installation And Operating Manual

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. Contact Bunn-O-Matic

Corporation at 1-800-286-6070 to obtain a paper copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

35879.0001 01/08 ©2005 Bunn-O-Matic Corporation

www.bunn.com

INSTALLATION & OPERATING MANUAL

SINGLE TF DBC

W/SMART FUNNEL

®

S/N SNG0033000 & UP

Summary of Single TF DBC

Page 1

Bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit the bunn-o-matic website, at www.Bunn.Com. This is absolutely free, a...

Page 2

Page 2 35879.1 011108 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) co...

Page 3

Page 3 table of contents user notices ...............................................................................................................................4 electrical .............................................................................................................................

Page 4: Main On/off

Page 4 user notices the notices on this brewer should be kept in good condition. Replace unreadable or damaged labels. 35879.1 011108 00656.0000 00831.0000 00658.0000 20201.5600 37881.0000 03408.0004 03409.0004 27508.0000 this equipment must be installed to comply with the international plumbing cod...

Page 5

Page 5 35879.1 110507 electrical hook-up warning – if the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personel with a special cord available from the manufacturer or its authorized service personel in order to avoid a hazard. Improper electrical installa...

Page 6

Page 6 l1, l2, l3, are the 3 phases v1 = phase to phase voltage, between any 2 phases. V2 = phase to neutral voltage, l1 to neutral must be 120v. System voltage v1 v2 208 208 120 240 240 120 caution: do not connect l1 to a circuit operating at more than 150 volts to ground. 200 and 230 volt ac singl...

Page 7

Page 7 plumbing requirements this brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138 and 620 kpa) from a 1 ⁄ 2 " or larger supply line. A shut-off valve should be installed in the line before the brewer. Install a regulator in the line when pressure is...

Page 8

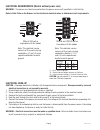

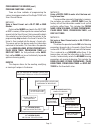

Page 8 (a) main on/off switch this switch, located under the brewer behind the front leg, turns power on and off to all components in the brewer. (b) batch selector switches pressing the switch corresponding to the small, medium, or large batch selects the amount of coffee to be brewed. Pressing a d...

Page 9

Page 9 initial setup caution – the brewer must be disconnected from the power source throughout the initial setup, except when specified in the instructions. 1. Insert an empty funnel into the funnel rails of the brew station. 2. Place an empty server under the funnel. 3. Connect the brewer to the p...

Page 10

Page 10 cleaning 1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all surfaces on bunn-o-matic equipment. Do not clean this equipment with a water jet device. 2. Check and clean each sprayhead. The sprayhead holes must always remain open. Note:...

Page 11

Page 11 glossary ad card: an assembly consisting of computer chips and an instruction label. Used for loading advertising messages into the brewer. Brew lockout: the inability to initiate a brew if the water temperature is less than the ready temperature programmed into the brewer. Bypass: the proce...

Page 12

Page 12 programming using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various brewing parameters such as brew temperatures, brew volumes, bypass percentages, etc. This allows for the precise brewing of various flavors of coffee. Programming of ...

Page 13

Page 13 main screen this screen will be shown when the brewer is ready for use. The screen displays the water temperature in the tank. When the water in the tank reaches the correct set temperature, the display will change from heating to ready to brew. Programming lockout switch (mounted on main co...

Page 14

Page 14 programming the brewer (cont.) program functions - level 2 there are three methods of programming the various brewing parameters of the single tf dbc with smart funnel brewer. Method 1: using a smart funnel and a g9-2t dbc or mhg grinder: certain coffee names are stored in the g9-2t dbc or m...

Page 15

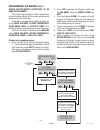

Page 15 programming the brewer (cont.) level i press upper right hidden switch for approximately 2 seconds, until the following screen appears. Level ii press upper right hidden switch for approximately 4 seconds, until “units” appears on screen. Returns to (a) review recipes? No yes no-name modify ...

Page 16

Page 16 continues to (e) (d) enable ads? No done yes set temp: 200°f (-) done (+) set ready 195°f (-) done (+) 0 refill 155 (-) done (+) spry oz/m xx.X (-) done (+) bypas oz/m xx.X (-) done (+) % bypass xx (-) done (+) 3 batches done? No yes set pulse brew full 1/2 1/4 3 batches done? No yes drip ti...

Page 17

Page 17 calibrate flow? No yes brew counters? No yes funnel detect no done yes service tools no yes sel brewer type? No yes (e) finished, returns to main screen count 0 next reset count 0 next test outputs? No yes test switches? No yes brew valve on next off funnel lock on next off refill valve on n...

Page 18

Page 18 units metric done eng changing units will!! Erase!! All previously stored recipes and all setup info wil be lost! Are you sure? Yes no selects metric as the unit of measure replace exit selects english as the unit of measure units (setting units of measure) this function allows the units of ...

Page 19

Page 19 procedure for setting the recipe: note: before beginning setup, place a server beneath the brew funnel. 1. Insert the funnel into the grinder and select a batch size to grind. It is not necessary to have coffee beans in the hopper(s) in order to program the brewer. The coffee name is pre-sel...

Page 20

Page 20 set new recipes (cont.) 8. Using (-) and (+), set the amount of brew water, in ounces, to be dispensed for that particular batch size. 9. When finished, press another batch size and re- peat step 8 for that size. Continue setting all batch sizes. 10. When finished setting all batch sizes, pr...

Page 21

Page 21 programming the brewer (cont.) position card under the left side sensor coil (coffee name) show quit save card contains recipe for ready to brew water temp: 200º (coffee name) setup complete (coffee name) not saved scrolls through all of the brew settings for the three batch sizes for that c...

Page 22

Page 22 set new recipe: if not using a smart funnel (with a sensor coil) and/or a g9-2t dbc or mhg grinder, the brewer will function as a standard bunn single tf dbc brewer: it is possible to operate the brewer without using a smart funnel and/or a g9-2t dbc or mhg grinder. If a standard funnel, or ...

Page 23

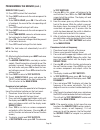

Page 23 review recipes/modify recipes/set up no name coffee names: this function has three parts. It allows the operator to view the brew settings for the various coffee names programmed into the brewer. It also allows the operator to modify (change) any of the brew volumes, bypass percentages, puls...

Page 24

Page 24 brew oz (setting or adjusting brew vol- umes) this function allows adjustment of the brew vol- umes for each batch. The indicator signifies volume in ounces per batch. Procedure for modifying recipes - brew ounces: range: 10.0 oz to 400 oz for all three batch sizes 1. Press and hold the uppe...

Page 25

Page 25 p2444 programming the brewer (cont.) % bypass this function allows adjustment of the amount of water that bypasses the grounds. The number signi- fies the percentage of the brew volume which does not flow over the coffee grounds. Modifying recipes - bypass percentages: range: 0% to 90% for a...

Page 26

Page 26 programming the brewer (cont.) set pulse brew: this function allows the operator to program the brewer to "pulse” the sprayhead flow on and off con- tinually during a brew cycle (start and stop the flow of water out of the sprayhead). This feature allows the ability to “fine-tune” the brewer...

Page 27

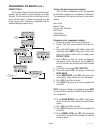

Page 27 set pulse brew (cont.) programming the brewer (cont.) exit to next function screen press done yes done yes screen displayed brew oz: xx.Xx 3 batches done? % bypass xx.X 3 batches done? Advances to all other coffee names programmed in the brewer's memory when the last coffee name in the brewe...

Page 28

Page 28 programming the brewer (cont.) p3507 5 sec. Delay set pulse brew? No yes 3 batches done? No yes 3 batches done? No yes coffee name setup complete brew time xx.X (-) done (+) drip time xx.X (-) done (+) 1st off last xx.X xx.X xx.X easy pulse setup no yes enter times ? No yes see set pulse bre...

Page 29

Page 29 programming the brewer (cont.) set pulse brew - enter times note: the procedure to enter the pulse brew function must be performed prior to following the steps listed below. 1. Press and release yes. The display should now read easy pulse setup. 2. Press and release no. The display will read...

Page 30

Page 30 programming the brewer (cont.) set pulse brew? No yes enter times? No yes easy pulse setup no yes 1st on time x:xx (-) done (+) off times: x:xx (-) done (+) last on: prei (-) done (+) 3 batches done? No yes exit to next function screen exit to next function screen 5 sec. Delay 1st off last x...

Page 31

Page 31 programming the brewer (cont.) drip time (now displayed on "non" funnel lock units as well) this function allows the setting or modification of the funnel locks to stay engaged after the end of a brew cycle. This ensures that the funnel cannot be removed until after the liquid has emptied ou...

Page 32

Page 32 programming the brewer (cont.) enable ads? This function allows the operator to choose whether or not to display the advertising message that was en- tered into the brewer with an ad card. This message will be displayed when the brewer is not in use. Procedure to enable/disable ads: 1. Press...

Page 33

Page 33 programming the brewer (cont.) procedure to set the sensitivity threshold of the refill circuit: note: make sure the water in the tank is touching the refill probe. 1. Press and hold the upper right hidden switch until the display reads units. Release the switch, then press and release switc...

Page 34

Page 34 programming the brewer (cont.) procedure to adjust the flow rate setting: 1. Press and hold the upper right hidden switch until the display reads units. Release the switch, then press and release switch until the display reads bypas oz/m. The number represents what the brewer thinks is the f...

Page 35

Page 35 programming the brewer (cont.) procedures to calibrate the bypass flow rate: 1. Place a container, accurately graduated in ounces, and with a minimum capacity of 60 ounces, below the funnel on the brewer. 2. Press and hold the upper right hidden switch until the display reads units.Release t...

Page 36

Page 36 programming the brewer (cont.) brew counters this function allows the operator to track the num- ber of brew cycles completed. There is one resettable counter, and one life counter that is not resettable. Exit to next function screen xxxx next reset xxxx next brew counters? No yes procedures...

Page 37

Page 37 programming the brewer (cont.) service tools this function allows the testing of individual com- ponents and the ability to check switches for proper function. This function also tests the soft heat server's status on the brewer (in place or removed), and the funnel sensor coil's frequency (...

Page 38

Page 38 to test switches. 7. Pressing no in this screen will advance to the next function. Press yes in the test switches screen to test the switches. The display will read nothing pressed. 8. From this screen, press any of the switches on the front of the brewer. While the switch is pressed, the di...

Page 39

Page 39 programming the brewer (cont.) factory defaults this function allows the operator to erase all of the previously entered recipes and ad messages. Factory- set default values will replace all previous settings. Exit exit replace will replace all brew settings are you sure? No yes factory defa...

Page 40

Page 40 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of...

Page 41

Page 41 troubleshooting (cont.) screen displayed possible cause troubleshooting procedures 1. Water temperature in the tank does not meet the set ready temperature. 1. Brew funnel was not removed after the previous brew cycle was finished. 1. Brew funnel was moved out of position after the brew cycl...

Page 42

Page 42 troubleshooting (cont.) troubleshooting procedures possible cause screen displayed 1. On/off switch was pressed after the brew cycle was started. 1. Tank heater failure 2. Triac failure 3. Control board/thermistor failure to resume brewing, press brew again. The brew cycle resumes form the p...

Page 43

Page 43 troubleshooting (cont.) troubleshooting procedures possible cause screen displayed 1. Water shut off to brewer 2. Inlet solenoid valve failure 3. Control board failure 1. Temperature sensor probe wire(s) broken or not making connection. 1. Temperature sensor probe wire(s) shorted to housing,...

Page 44

Page 44 equipment will not operate. Brew cycle will not start. Automatic refill will not operate or display shows fill time too long 1. No power or incorrect voltage. 1. No water 2. On/off switch 3. Brew switch 4. Brew valve 5. Electronic control board 1. No water 2. Water strainer measure the volta...

Page 45

Page 45 troubleshooting procedure troubleshooting (cont.) problem possible cause check the sensitivity setting. Refer to the refill function. If the left three digit number is less than the right number, the machine “thinks” it is full and the refill valve should be off. If the left number is larger...

Page 46

Page 46 troubleshooting (cont.) problem possible cause troubleshooting procedures check the sensitivity setting. Refer to the refill function. If the left three digit number is less than the right number, the machine “thinks” it is full and the refill valve should be off. If the left number is large...

Page 47

Page 47 troubleshooting (cont.) problem possible cause troubleshooting procedures remove power from the brewer. Connect a voltmeter across one of the tank heaters. Reapply power to the brewer and refer to testing individual components. If the full supply voltage is measured when the tank heater is t...

Page 48

Page 48 troubleshooting (cont.) problem possible cause troubleshooting procedures perform the previous procedure for testing triacs. If the voltage measured is very low or zero, then substitute a control board known to be in good working order. (a) direction of flow arrow must be pointing towards th...

Page 49

Page 49 troubleshooting (cont.) problem possible cause troubleshooting procedures adjust the brew volume as required to achieve the recommended volume for each brew cycle. Repair or replace leaky valve. Bunn paper filters should be used for proper extraction. Check sprayhead the brew cycle should be...

Page 50

Page 50 troubleshooting (cont.) problem possible cause troubleshooting procedures consider adjusting bypass percent- age, preinfusion, or pulse brew. Contact bunn-o-matic for sugges- tions. The nut on back of the solenoid must be tight or it will vibrate during operation plumbing lines should not be...

Page 51

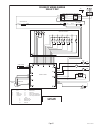

Page 51 35726.0000b 02/07 © 2003 bunn-o-matic corporation 120/208 or 120/240 volt a.C. 3 wire + gnd single phase schematic wiring diagram single tf dbc funnel lock sol brew bypass refill whi whi whi vio gry whi/grn brn/whi brn/blk tan yel blk whi tank heater triac mt 1 blu-14 blk-14 blk-14 mt2 limit...

Page 52

Page 52 36883.0000a 05/04 © 2004 bunn-o-matic corporation 230 or 200 volt a.C. Single phase schematic wiring diagram single tf dbc funnel lock sol sol sol sol brew bypass refill red red red vio gry whi/grn brn/whi brn/blk tan yel blk red l2 tank heater triac mt 1 blu-14 red-14 blk-14 blk-14 red-14 b...

Page 53

Page 53 36883.0002a 11/04 © 2004 bunn-o-matic corporation 120 volt a.C. 2 wire single phase 60hz schematic wiring diagram single tf dbc funnel lock sol sol sol sol brew bypass refill whi whi whi vio gry whi/grn brn/whi brn/blk tan yel blk whi n tank heater triac mt 1 blu-14 whi-14 blk-14 blk-14 mt2 ...

Page 54

Page 54 36883.0001b 02/07 © 2004 bunn-o-matic corporation 200,208 or 240 volt a.C. 2 wire + gnd single phase 50/60hz schematic wiring diagram single tf dbc funnel lock sol brew bypass refill red red red vio gry whi/grn brn/whi brn/blk tan yel blk red tank heater triac mt 1 blu-14 red-14 blk-14 blk-1...